A sub-unit installation and construction method of a large-span double-layer PTFE membrane structure roof

A PTFE and construction method technology, applied in special structures, building components, building structures, etc., can solve problems such as economic losses and safety accidents, and achieve the effect of saving construction time, avoiding investment, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

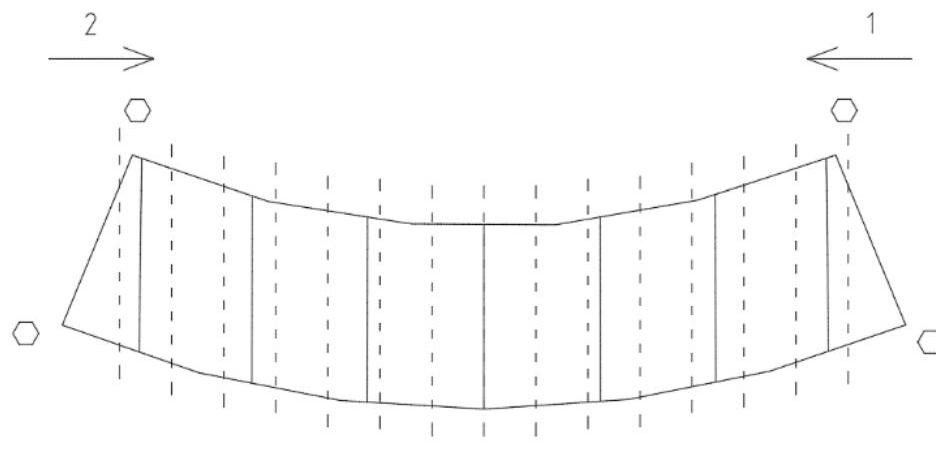

[0029] Embodiment: a kind of large-span double-layer PTFE membrane structure roof sub-unit installation and construction method, such as Figure 1-6 shown, including the following steps:

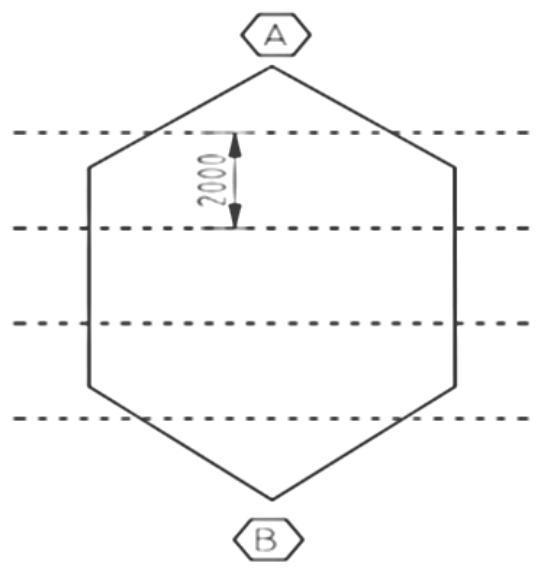

[0030] S1, model the roof structure and divide the roof into several units, the top central area is the first unit, and then divided into the second unit, the third unit, the fourth unit according to the latitude from top to bottom... the first unit N units; then divide each unit except the first unit into several equally divided blocks according to longitude;

[0031] The first unit is a polygonal structure, and the number of blocks in each unit is the same as the number of sides of the first unit.

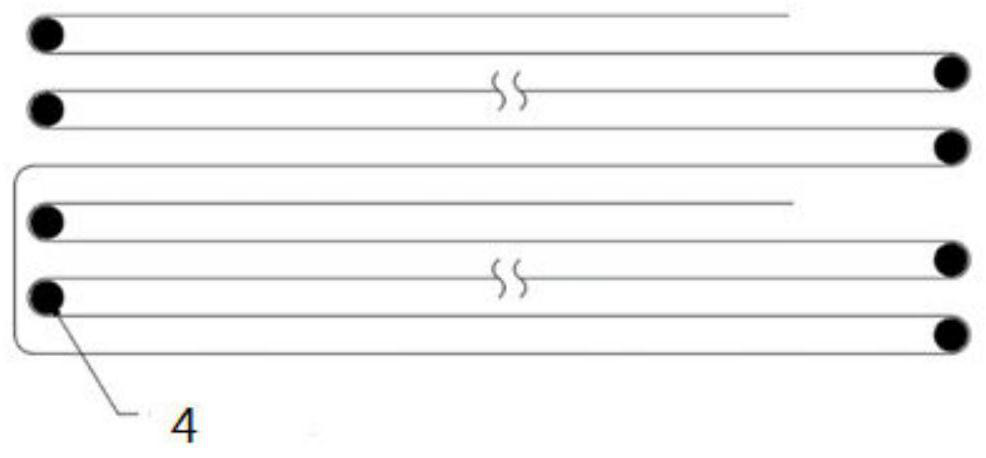

[0032] S2, pack the unit film, pack each piece of unit film produced according to the unit shape from the center to both sides, and add a paper tube at the bend. In this embodiment, the paper tube adopts pearl cotton stick 4;

[0033] In S2, the width of the membrane body of the packaged unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com