Fabricated construction platform of horizontal superimposed structure

A construction platform and prefabricated technology, which is applied to the scaffolding supported by the building structure, the building structure support, the building structure support, etc., can solve the problems of the high cost of the construction platform and affect the convenience of the synchronous construction of the lower layer, and achieve convenient assembly and disassembly and synchronization. The effect of hoisting and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

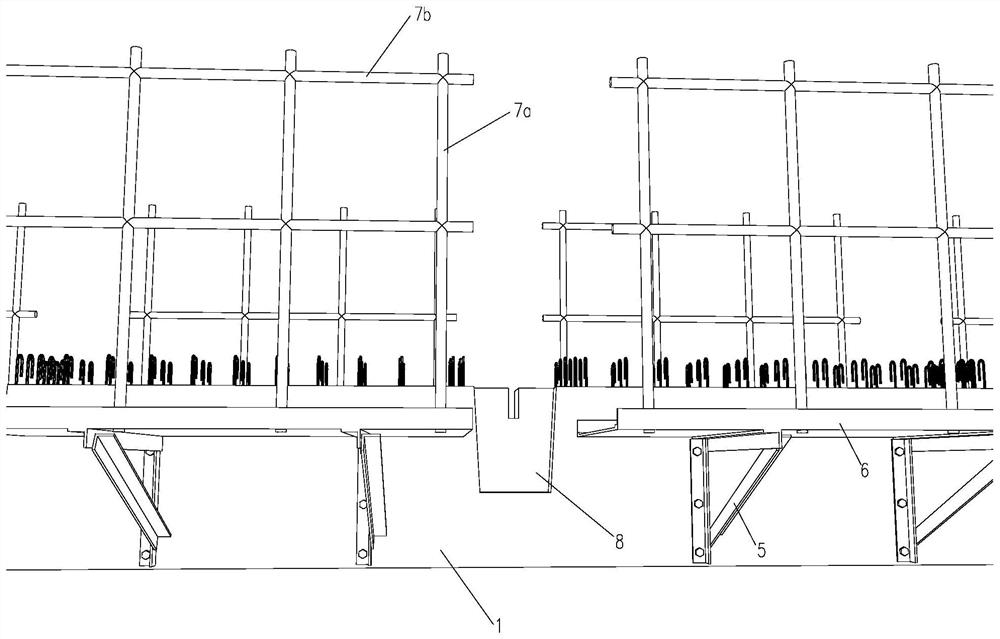

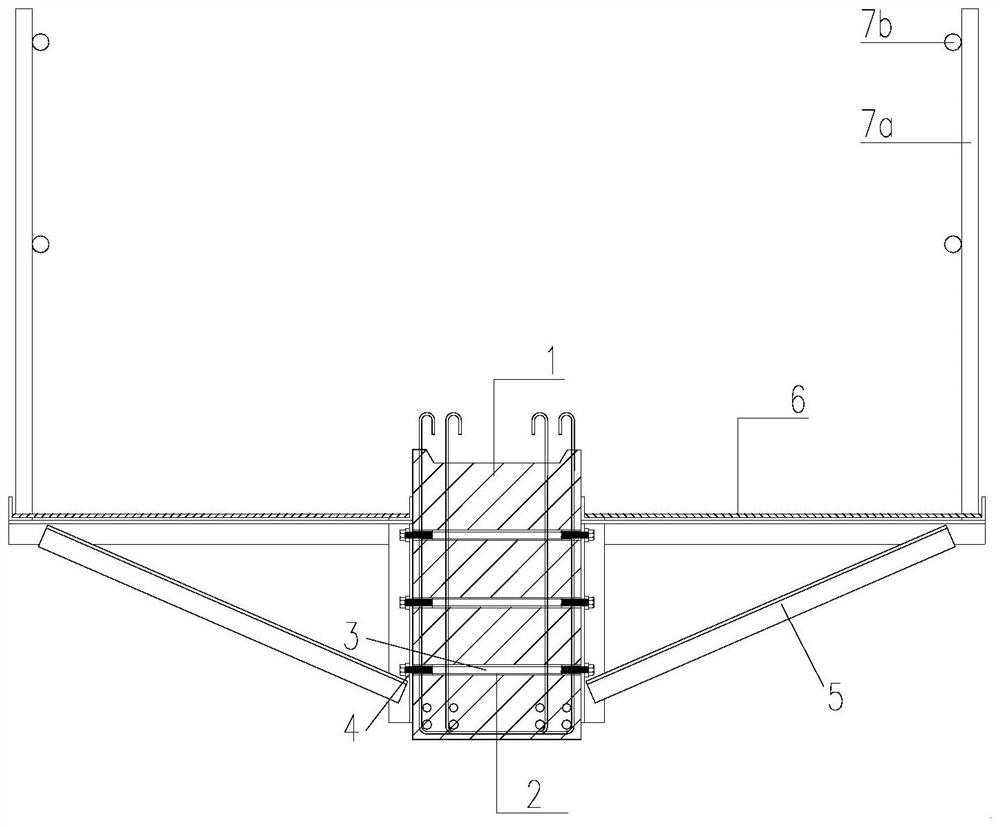

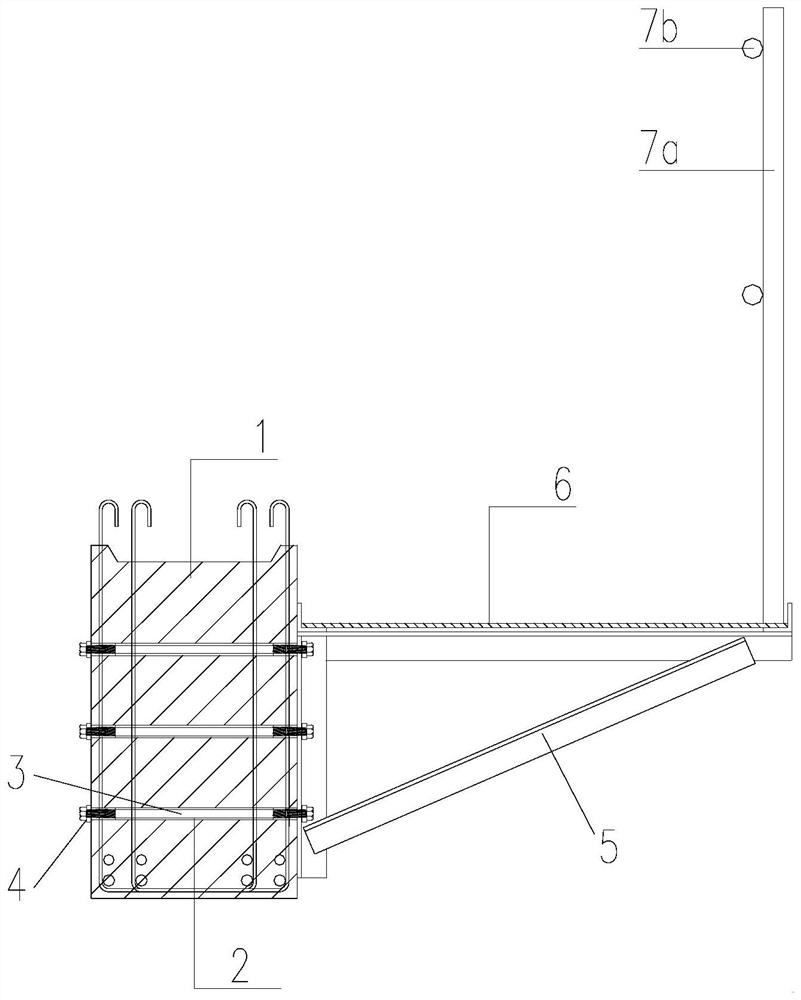

[0033] When the prefabricated beam is a beam with a rectangular cross-section, the prefabricated beam is provided with a through hole 2 that extends left and right and runs through the prefabricated beam; the connecting piece is a screw 3 passing through the through hole 2, and the two ends of the screw 3 are provided with The spacer and the nut 4 that match the through hole 2 and the screw rod 3 .

[0034] When installing the support truss, it can be installed on one side (such as image 3 shown), can also be installed on both sides (such as figure 1 , 2 shown); where the double-sided installation is to place the supporting truss at the screw rod 3, and then place the spacer and lock the nut 4. In one-sided installation, on the side where the support truss is not installed, place the spacer directly and lock the nut 4.

Embodiment 2

[0036] When the prefabricated beam is a special-shaped cross-section beam, part of the connecting parts can be replaced with bolt embedded parts 3a embedded in the prefabricated beam.

[0037] In terms of the installation method, there is not much difference from Embodiment 1. If necessary, the structure of the supporting truss can be adjusted adaptively.

[0038] The guard includes a protective net and a safety wire rope, the protective net is connected between adjacent platform boards 6 ; the safety wire rope is connected between adjacent railings.

[0039] The rib structure of the platform plate 6 is an angle steel provided on the inner and outer sides of the platform plate 6 . The bending resistance of the platform plate 6 can be improved.

[0040] The installation method of the present invention is as follows:

[0041] 1. During production, a through hole 2 is provided at the web position of the prefabricated beam 1; for prefabricated composite beams with special-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com