A ring-arranged pre-embedded bolt fixing structure and installation method for CDQ coke oven body

A technology of circular arrangement and pre-embedded bolts, which is applied in the direction of building construction, construction, etc., can solve the problems of overall deviation of bolt installation, and achieve the effect of saving measures and temporary support materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

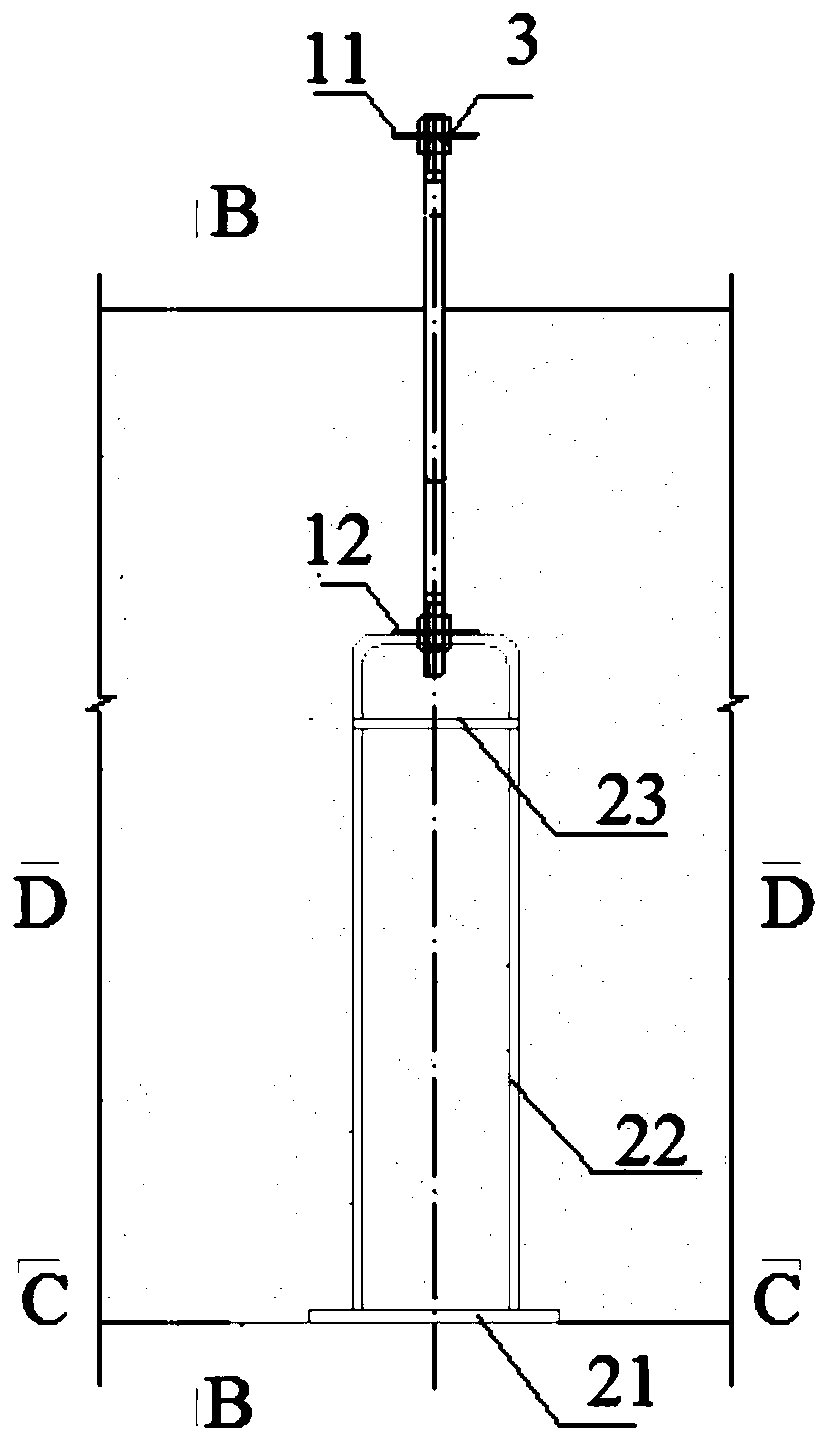

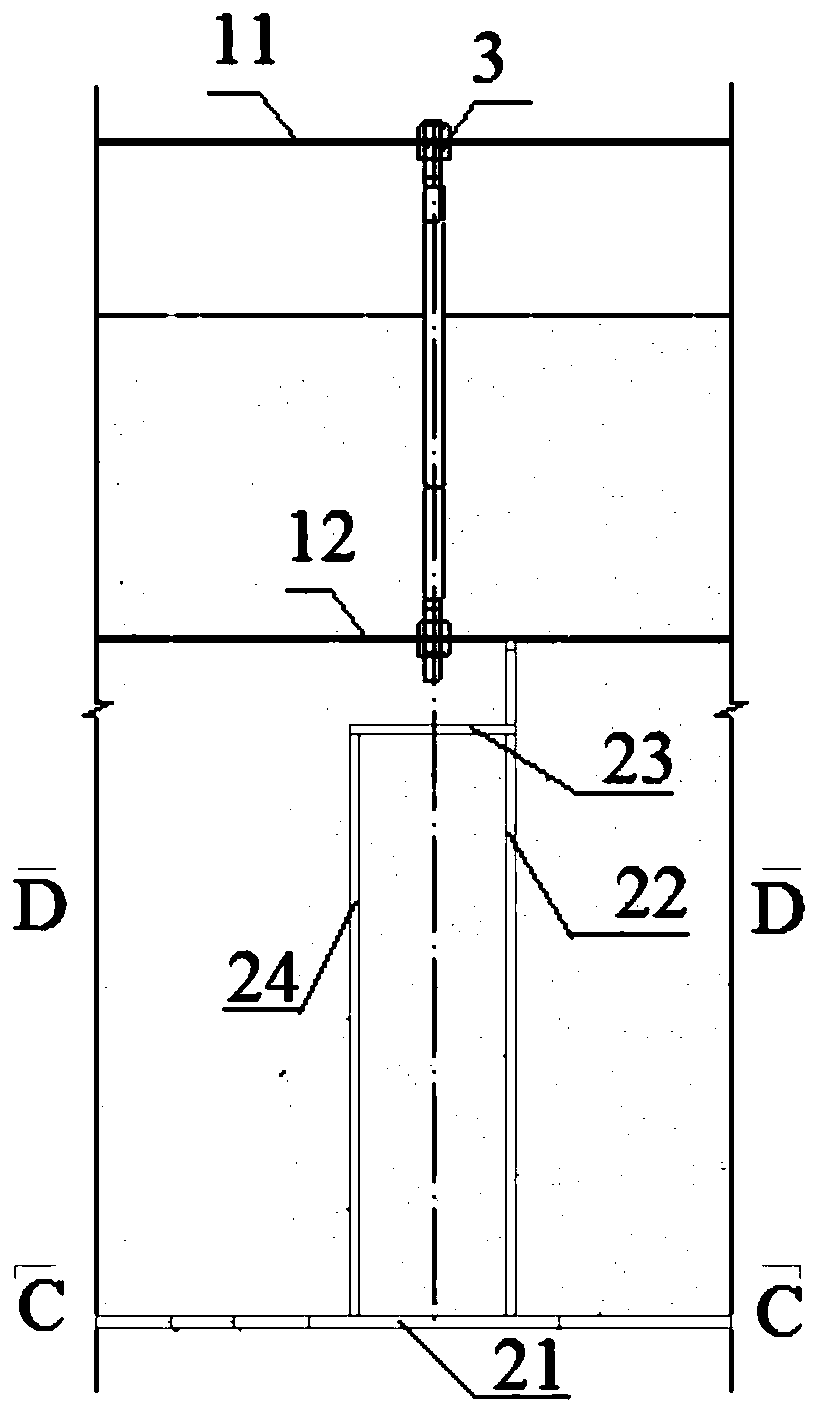

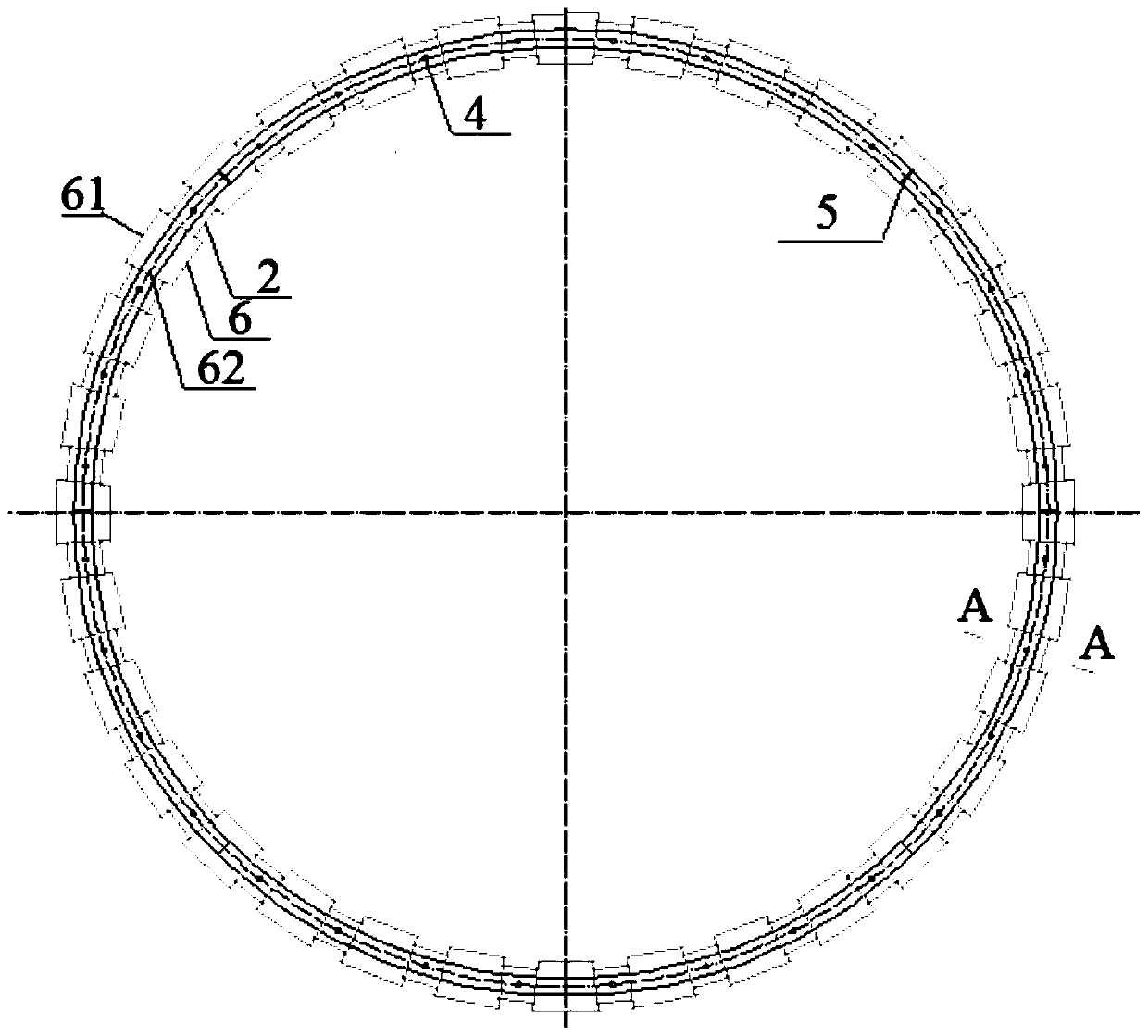

[0043] A pre-embedded bolt fixing structure arranged in a ring in a CDQ coke oven body, including a connecting plate 1, a support frame 2 and a connecting piece 6, a connecting plate 1 is provided on the top of the supporting frame 2, and a bolt hole 4 is provided on the connecting plate 1, The connecting piece 6 is provided at the bottom of the support frames 2, and connects two adjacent support frames 2 together.

[0044] Described support frame 2 comprises bottom beam 21, column one 22, beam 23 and column two 24, and the bottom of support frame 2 is bottom beam 21, and a pair of column one 22 and a pair of column one 22 and a pair of column are set respectively on the relative position of bottom beam 21. Column two 24, the top of column one 22 and column two 24 are connected together successively by crossbeam 23, and the top of column two 24 is provided with lower connecting plate 12, and between two adjacent lower connecting plates 12 is connecting plate divider. In segmen...

Embodiment 2

[0065] This embodiment provides an installation method in which the pre-embedded bolt fixing structure arranged in a ring around the CDQ coke oven body is fixed by means of the upper and lower ring connecting plates of the bolts, and is not connected to the steel bars of the platform beam.

[0066] The main principle is to divide the upper and lower connecting plates of the bolts into 8 sections and make them in the steel structure processing base. Reserve 1mm at both ends of each section for pre-assembly. After meeting the requirements, drill a reserved hole with a diameter of 48mm according to the position on the drawing, and design a steel support The lower connecting plate of the frame fixing bolts is provided with a support frame 2 according to each bolt position. The support frame 2 is composed of four columns and beams 23, and a beam 23 with a height of 200mm is arranged on the top, and the plane size is 400mm*400mm. The columns and beams 23 are both The threaded steel b...

Embodiment 3

[0070] A method for installing pre-embedded bolts in a ring arrangement of CDQ coke oven bodies in this embodiment, pay attention to the following during installation:

[0071] 1. The plate thickness of this ▽5.95m platform is 2.45m (that is, the upper connecting plate 11). Displacement, it is recommended that the formwork be steel formwork, and the flatness of the formwork meets the requirements of the specification and is controlled within 0-5mm.

[0072] 2. The bolt 3 is mainly fixed by the upper and lower connecting plates, so the manufacturing precision of the upper and lower connecting plates is very high, and it must be set out and manufactured in a professional steel structure processing factory, and it needs to be pre-assembled. After the assembly is correct, the positioning and drilling are performed. Numbered transportation, the finished product must be protected for transportation and hoisting, and distortion, collision, etc. are strictly prohibited, causing deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com