Three axes agitating pile construction method capable of assisting in grooving of reinforced underground diaphragm wall

A technology of underground diaphragm wall and construction method, which is applied in the direction of excavation, sheet pile wall, foundation structure engineering, etc., and can solve the problems of inconvenient construction method, hazard, and horizontal displacement of important pipelines in the groove of underground diaphragm wall, so as to achieve safe and reliable project quality , The effect of mature construction technology and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

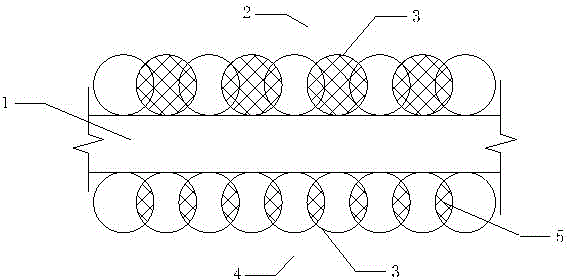

[0029] figure 1 It is the structure of three-axis mixing piles for auxiliary reinforcement of underground diaphragm walls formed into grooves according to the embodiment of the present invention. It is a schematic diagram of the reinforcement of the position within 8 meters of the house and the pipeline, wherein the pile-forming radius of the three-axis mixing piles is 600 mm, The pile overlap part is 250mm.

[0030] The construction method of the three-axis mixing pile for auxiliary reinforcement of the underground diaphragm wall into grooves of the present invention adopts mature three-axis stirring pile construction technology on both sides of the underground diaphragm wall, and is characterized in that it includes the following technical measures:

[0031] a. The reinforcement range of the triaxial mixing pile shall be reinforced on both sides of the ground connection wall within the distance H / 2 meters (H is the depth of the foundation pit) of buildings (structures), resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com