Novel energy-saving anti-floating pile

A new type of technology for anti-floating piles, applied in sheet pile walls, protection devices, buildings, etc., can solve the problems of unreliable durability protection of anti-pull ribs, difficult promotion of anti-floating piles, and imperfect construction technology, etc., to achieve long-term Durability, shortened construction period, and high buoyancy resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

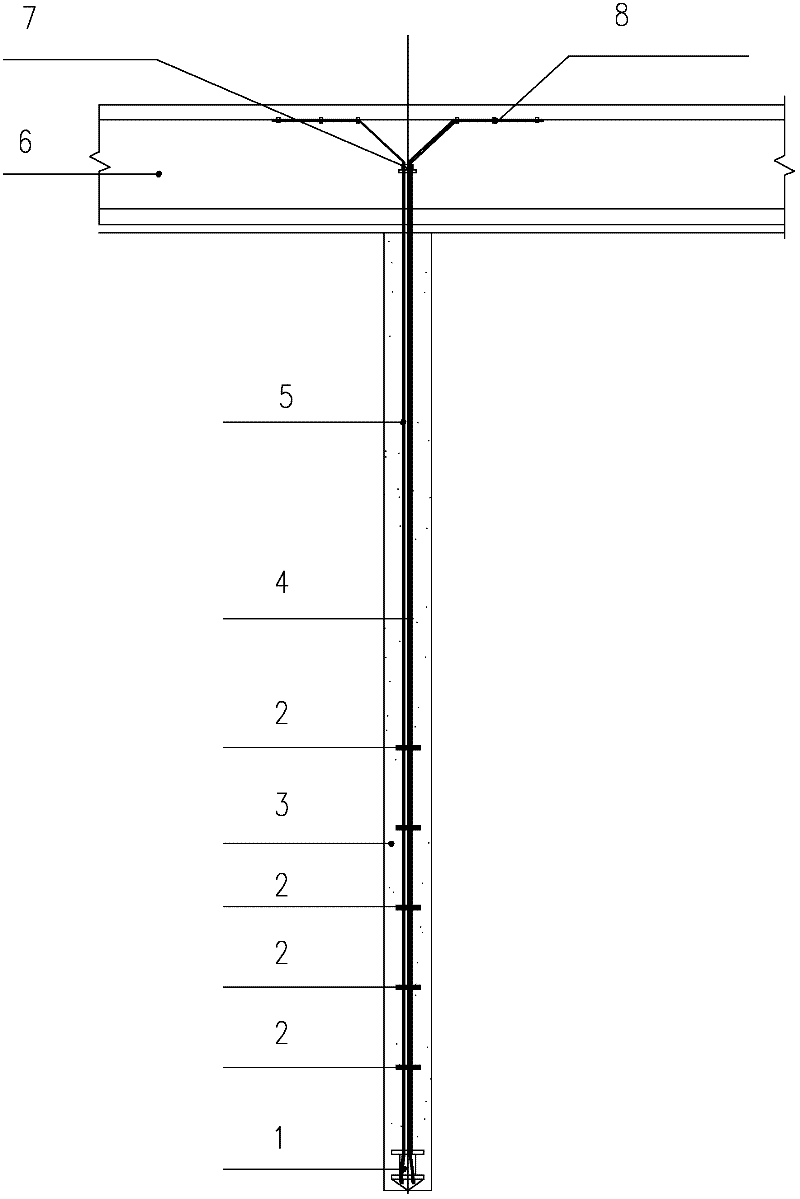

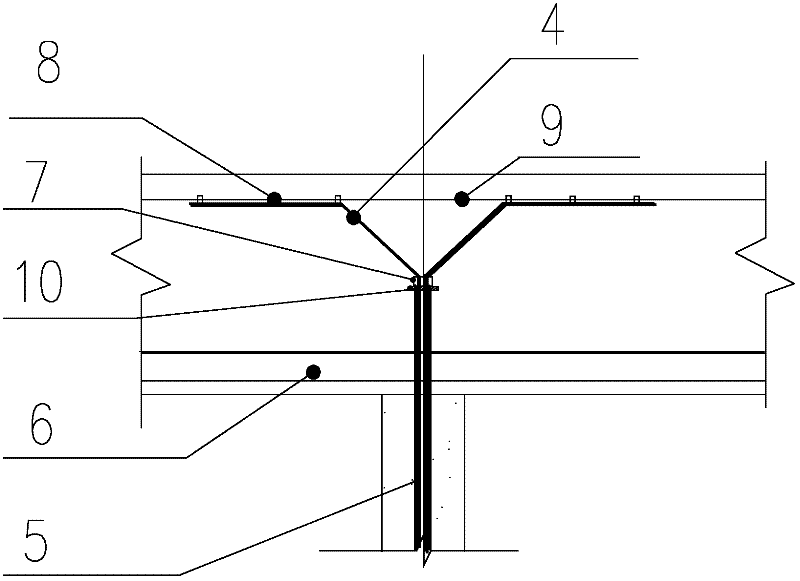

[0064] see figure 1 , the pile body structure of this novel anti-floating pile is, comprising a cement-soil pile body 3, the anti-pull reinforcement 4 is embedded in the pile body and connected together with the pile tip 1, the anchor plate 2 and the protective pipe 5, and the pull-out reinforcement 4 It is connected with the structural bottom plate 6 and transmits the anti-buoyancy force provided by the anti-floating piles to the structural bottom plate to realize the anti-floating of underground structures.

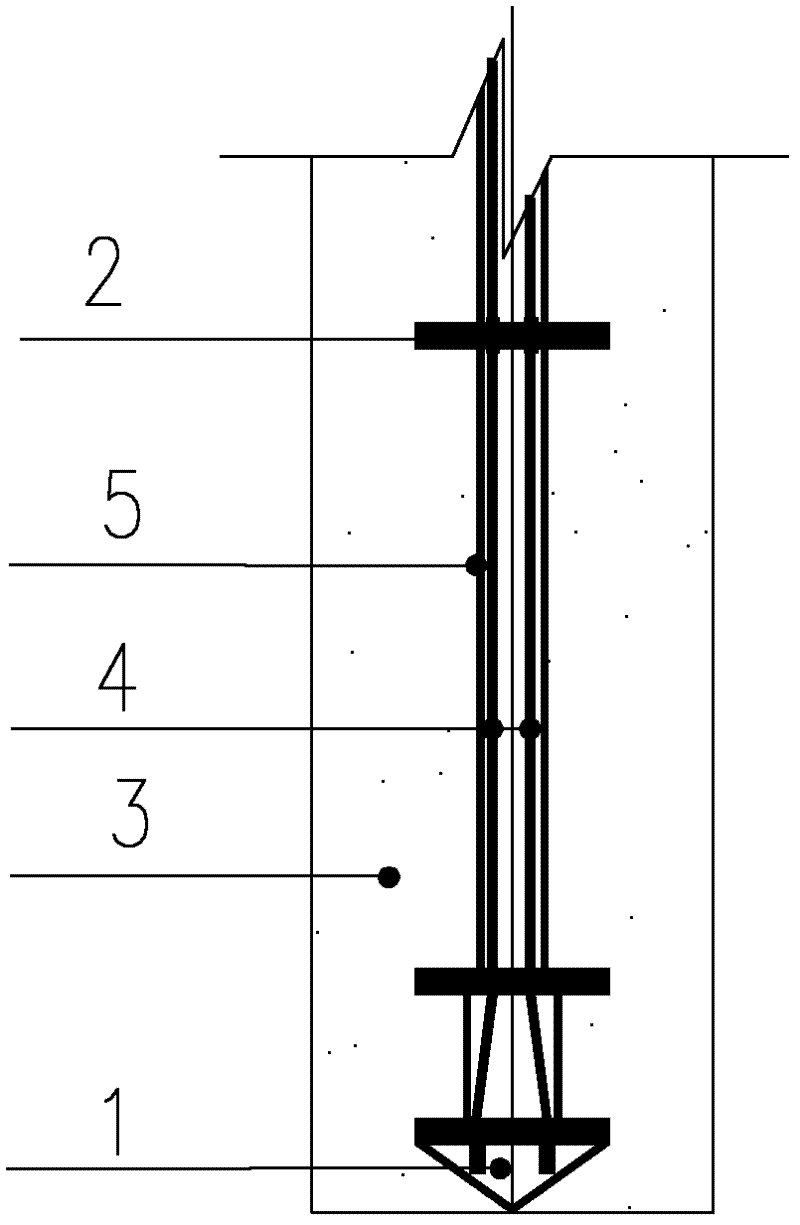

[0065] see figure 2 , the novel anti-floating pile structure is, comprising a jet-jet mixing pile body or a pile body 3 formed by cement grouting, the pile body 3 is embedded with pullout ribs 4, and the pullout ribs 4 are connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com