Coating composition for repairing rubber floor cloth and its application

A technology of rubber floor and composition, applied in the field of rubber floor cloth, can solve the problems of floor cloth material waste, floor cloth color difference, overhaul content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

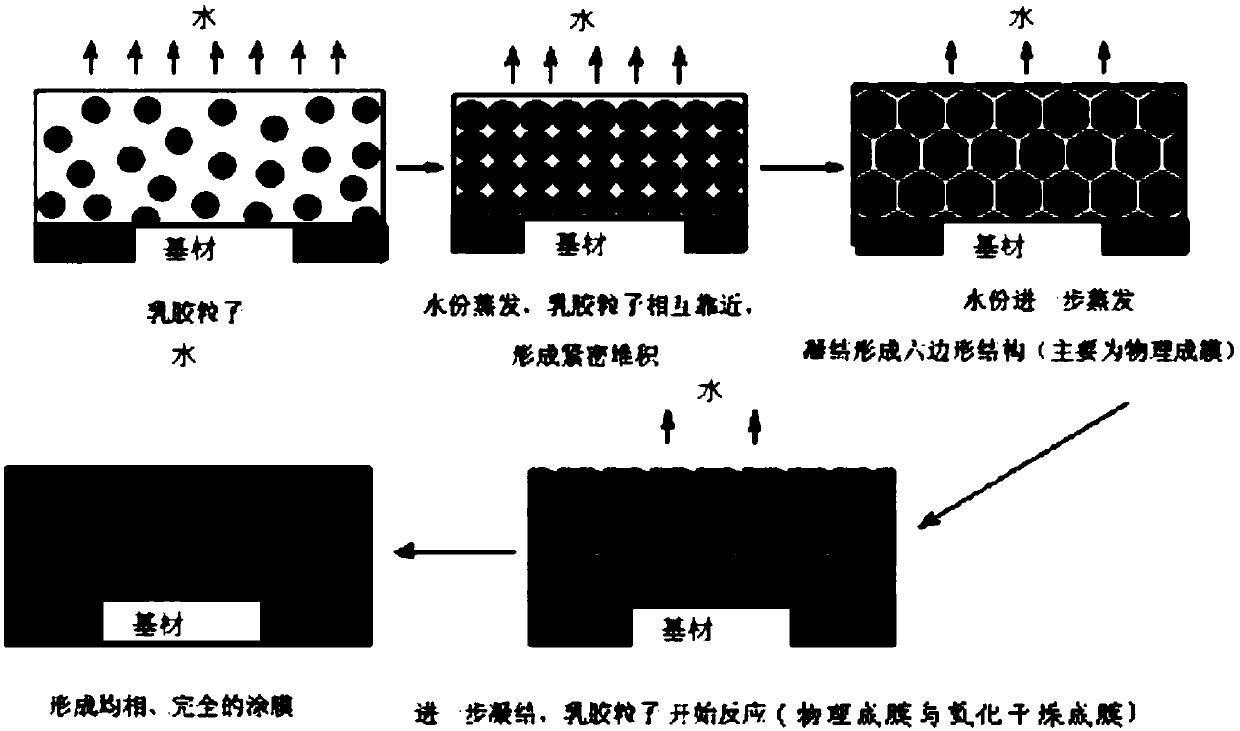

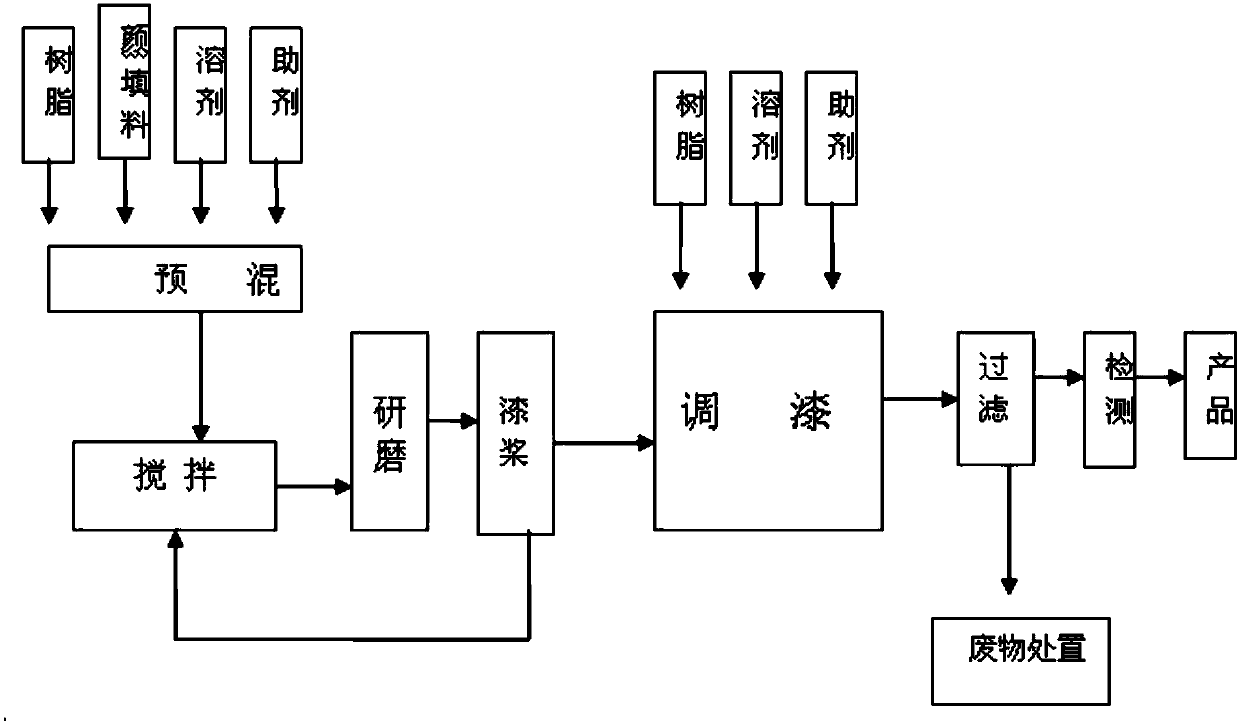

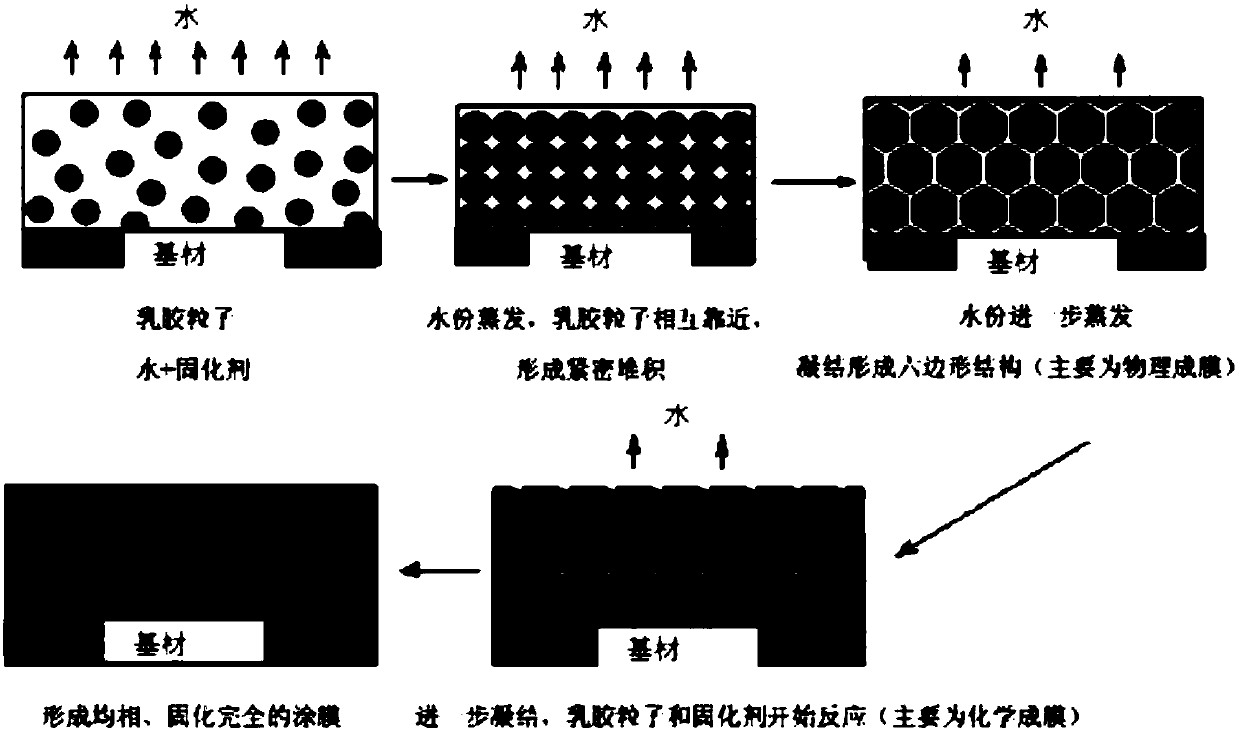

Method used

Image

Examples

Embodiment

[0094] The composition of the one-component polyurethane primer used in this embodiment is as shown in table 1:

[0095] The basic composition of base paint in the embodiment of table 1

[0096]

[0097]

[0098] Each component of the present invention is a general-purpose product; wherein, silicon-aluminum-based hollow microspheres are lightweight hollow microspheres formed by high-temperature melting and strong airflow gasification spraying with silicon-aluminum as the main component. The interior is a tiny porous hollow structure, and the surface is made of a fiber hollow network structure to form a hard shell. It is a standard physical spherical silica-alumina ceramic powder material with a particle size of 1 μm.

[0099] Mixed solvent: xylene: butyl acetate: propylene glycol methyl ether acetate = 3:2:2 (volume ratio). T-12 is polyurethane paint drier, dibutyltin dilaurate C 32 h 64 o 4 Sn.

[0100] The performance index of described polyurethane primer product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crimp elongation | aaaaa | aaaaa |

| crimp elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com