Method for constructing self-assembly environment-friendly long-lasting easy-to-clean anticorrosion coating

An anti-corrosion coating, easy-to-clean technology, applied in coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as peeling and peeling, and achieve a short cycle, flexible construction methods, and uniform adsorption process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

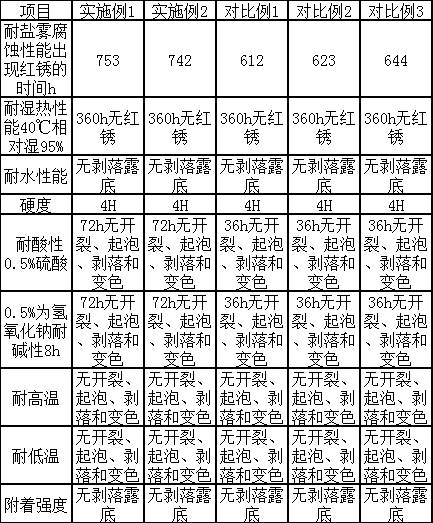

Examples

Embodiment 1

[0017] Self-assembly of galvanized iron sheet, environmental protection, long-term and easy-to-clean anti-corrosion coating construction: take 29# galvanized iron sheet thickness 0.437mm, zinc layer thickness 0.02mm, use sandpaper to polish the aluminum alloy sample, remove impurities and oxide film, and then use acetone to clean it ultrasonically , Blow dry, soak the dried metal test piece in 3g / L polyacylamine hydrochloride solution for 15 minutes, put it in distilled water for 8 minutes after soaking, and then put it in polyacylamine hydrochloride solution with a concentration of 8g / L Sodium styrene sulfonate solution for 10 minutes, then take it out and put it in distilled water for 8 minutes, the above is a cycle; repeat this cycle many times to realize the alternate deposition of sodium polystyrene sulfonate-polypropyleneamine hydrochloride layer film; the metal test piece of the alternate deposition film of the sodium polystyrene sulfonate-polypropylene amine hydrochlori...

Embodiment 2

[0019] Self-assembly of galvanized aluminum iron sheet for self-assembly, environmental protection, long-term and easy-to-clean anti-corrosion coating construction: take a galvanized aluminum iron sheet with a thickness of 0.437mm and a zinc layer thickness of 0.1mm with an aluminum content of 35%, and use sandpaper to polish the aluminum alloy sample to remove impurities and Oxide film, then ultrasonically cleaned with acetone and dried, soaked the dried metal test piece in 2g / L polyallylamine hydrochloride solution for 5 minutes, placed in distilled water for 6 minutes after soaking, and then placed in Sodium polystyrene sulfonate solution with a concentration of 4g / L for 10 minutes, then take it out and place it in distilled water for 2 minutes, the above is a cycle; repeat this cycle many times to achieve sodium polystyrene sulfonate-polypropylene The alternate deposition film of amine hydrochloride layer; the metal test piece of the alternate deposition film of the sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com