Steel structure-concrete combined bridge tower structure

A reinforced concrete and concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as increasing the difficulty of design and construction, high cost, stress and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

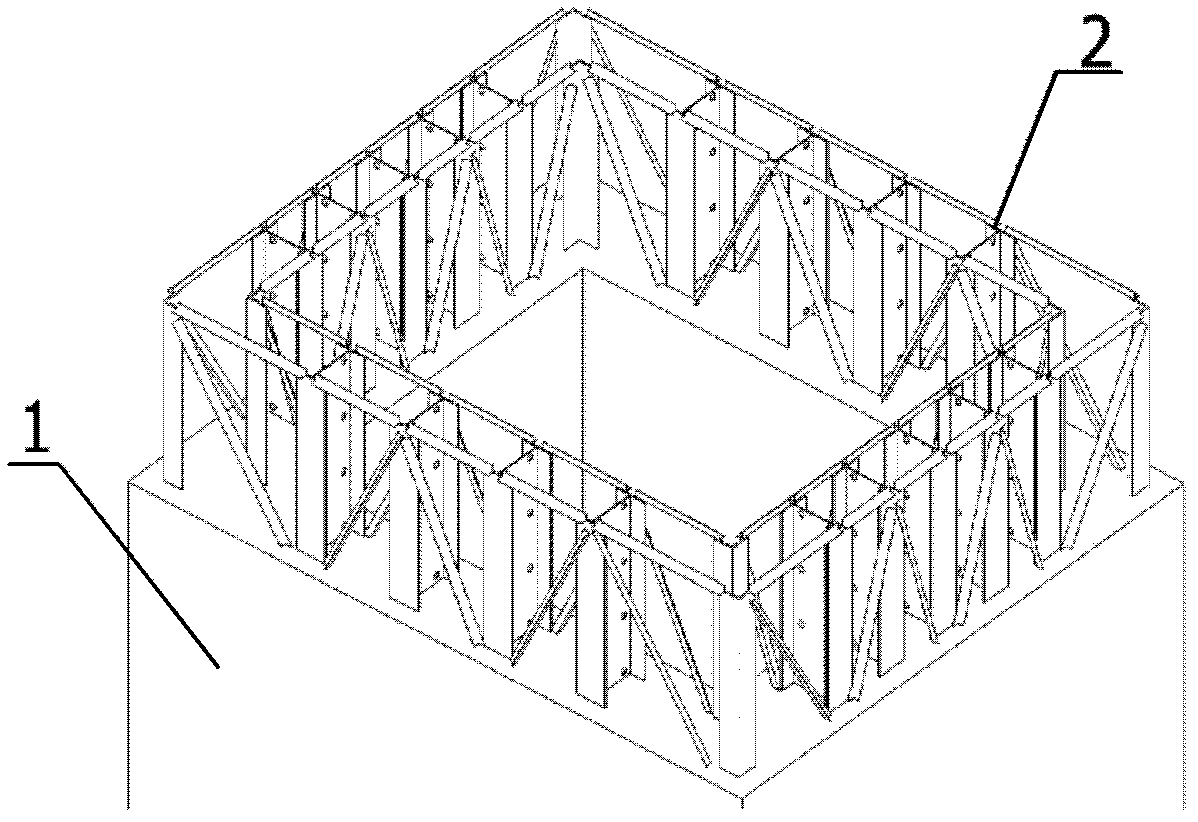

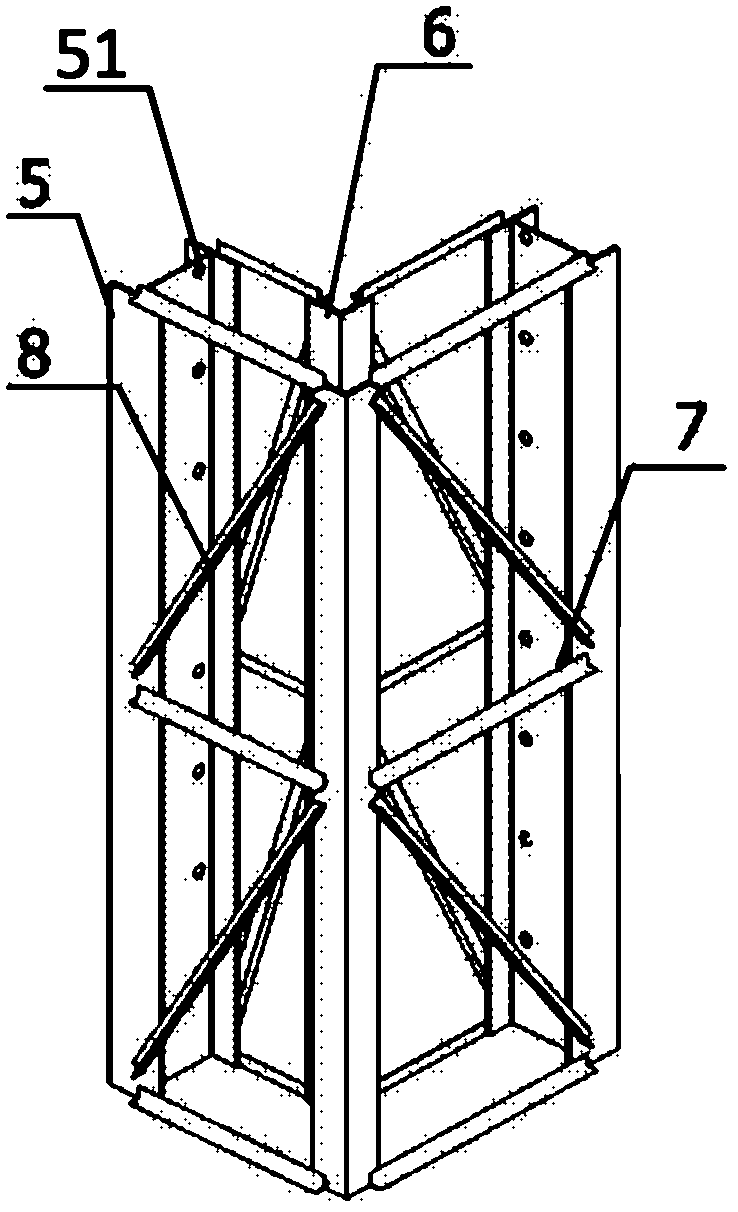

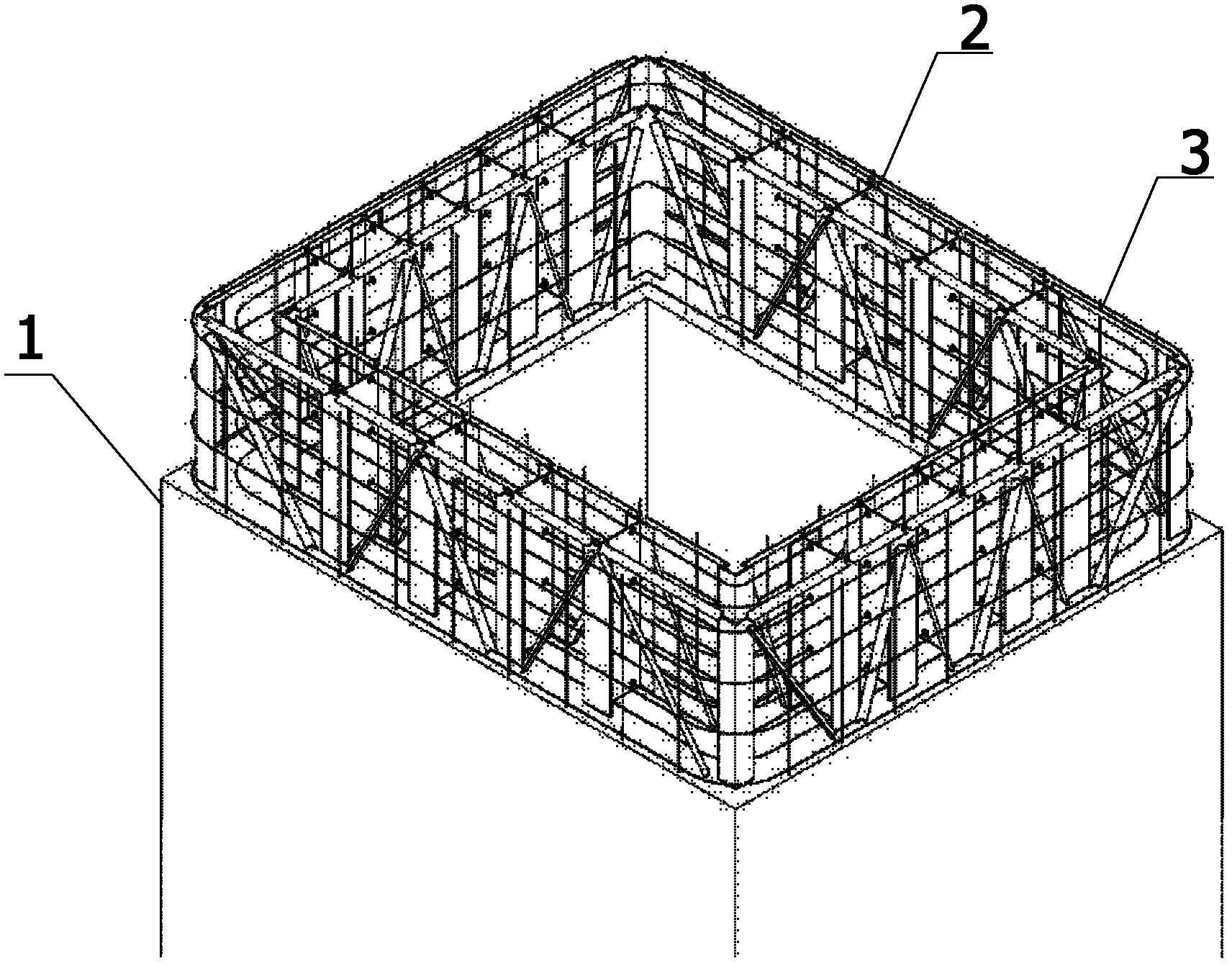

[0029] A steel structure-concrete composite bridge tower structure comprises a steel structure, a reinforced concrete tower column and a connecting piece between them.

[0030] The steel structure is modified with reference to the construction temporary rigid skeleton, and can be used as a construction temporary structure, and can also participate in the force bearing of the bridge structure. The steel structure includes vertical chords and connecting rods, the vertical chords are arranged along the entire length of the bridge tower, and can be H-shaped steel, round steel pipes, angle steels, etc.; the connecting rods include horizontal connecting rods and diagonal braces, which can be angle steel, Bar steel etc. The vertical chord and the connecting rod are welded to form a full-length lattice steel structure.

[0031] The reinforced concrete tower column is still equipped with longitudinal bars and stirrups, but the reinforcement ratio of the longitudinal bars for stress is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com