Pipe curtain construction method based on pipe banks

A construction method and pipe row technology, which are applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult control of the jacking trajectory of steel pipes, increased torque of drilling rigs, and easy deviation, so as to shorten the construction period and improve the Accuracy, avoid the effect of repeated installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

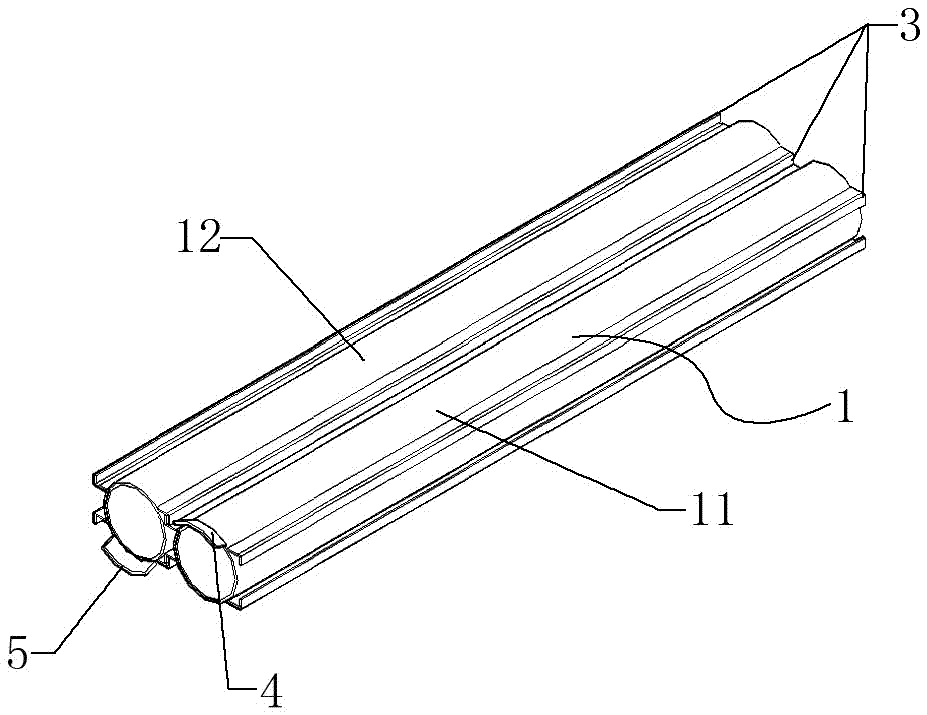

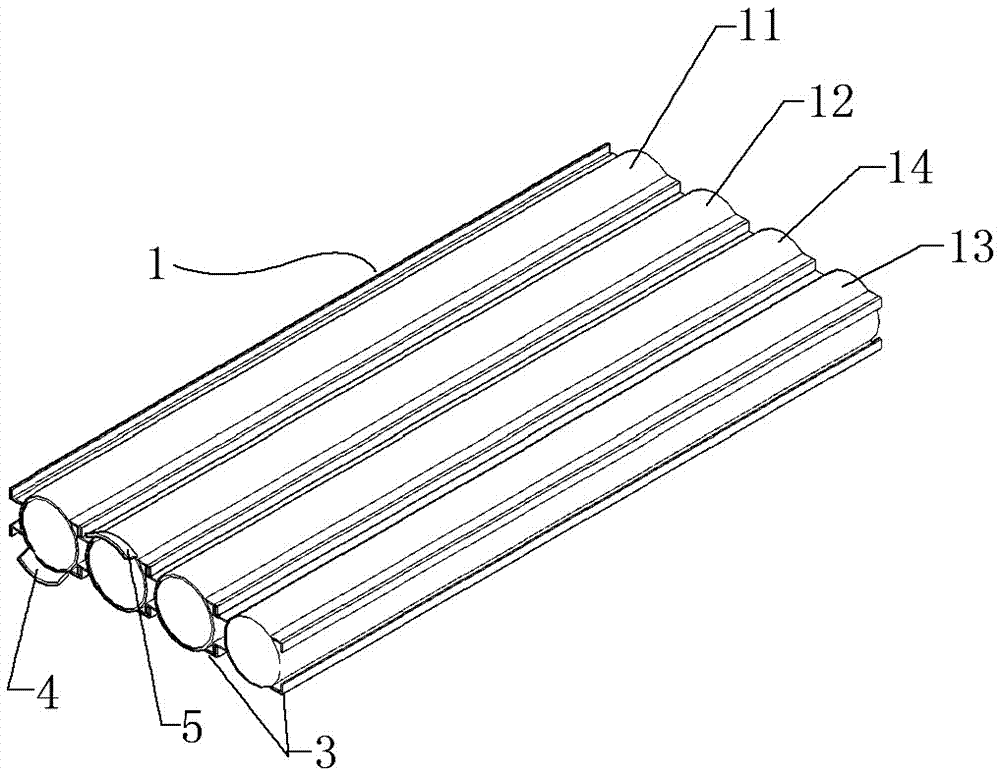

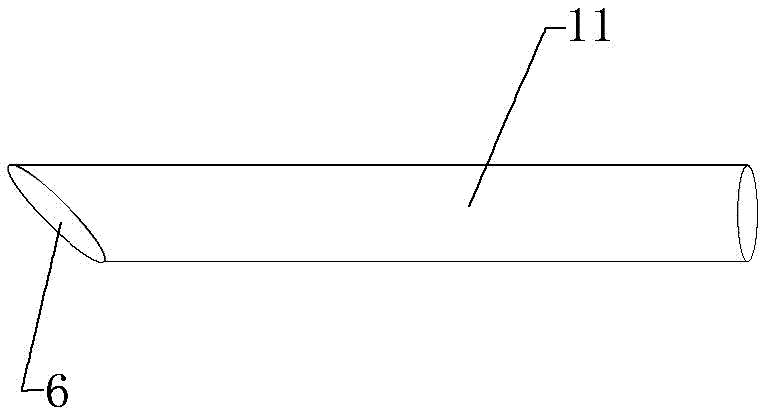

[0060] Such as figure 1 and figure 2 As shown, the construction method of the pipe row and pipe curtain of the present invention takes the pipe row 1 as the construction unit, and simultaneously jacks up to carry out the construction of the pipe curtain structure, wherein the pipe row 1 is composed of a group of steel pipes arranged side by side, and the adjacent steel pipes are connected by The components are connected by 3, and the number of steel pipes in each group is not less than 2.

[0061] The connecting member 3 connected between adjacent steel pipes is selected from the existing male lock and female lock connecting members used in conjunction with each other. The male connecting member includes two back-facing and parallel angle steels, which are respectively welded and fixed on the outer wall of the steel pipe. , parallel and non-overlapping settings; the female lock includes two buckle-oriented and parallel angle steels, which are respectively welded and fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com