System and method for on-line detection and analysis of multi-channel vibration signals of rotating machinery

A technology of rotating machinery and vibration signals, which is used in the testing of machines/structural components, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., to achieve high data transmission rates and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

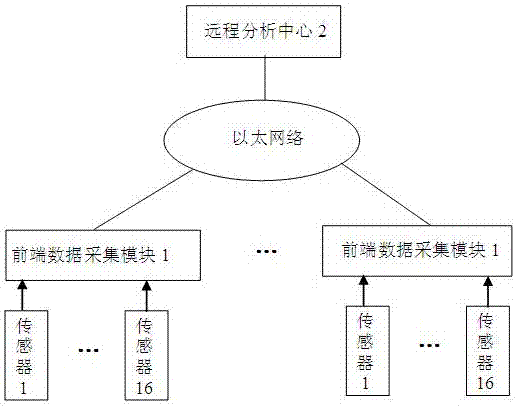

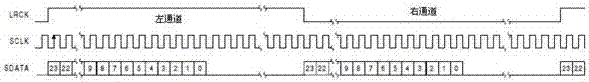

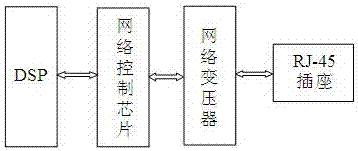

[0042] Such as Figure 1~11 As shown, the online detection and analysis system of multi-channel vibration signals of rotating machinery according to an embodiment of the present invention includes a front-end data acquisition module 1 and a remote analysis center 2, and the front-end data acquisition module 1 is connected to the remote analysis center 2 through an Ethernet network The front-end data acquisition module 1 includes an acceleration sensor module, a channel switching module, a constant current power supply circuit module, a signal conditioning circuit module, an A / D conversion module 3, an interface logic circuit module 4, a microprocessor module 5, and a network interface module 6. Speed signal detection module and relay module; the acceleration sensor module is connected to the input end of the microprocessor module 5 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com