Steel floral tube soil nailing wall hole forming process and level gauge

A technology of steel flower tube and soil nail wall, which is applied in sheet pile wall, soil protection, infrastructure engineering and other directions, can solve the problems of re-cleaning the ground, trouble, etc., and achieves the effects of stable installation, less environmental interference and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

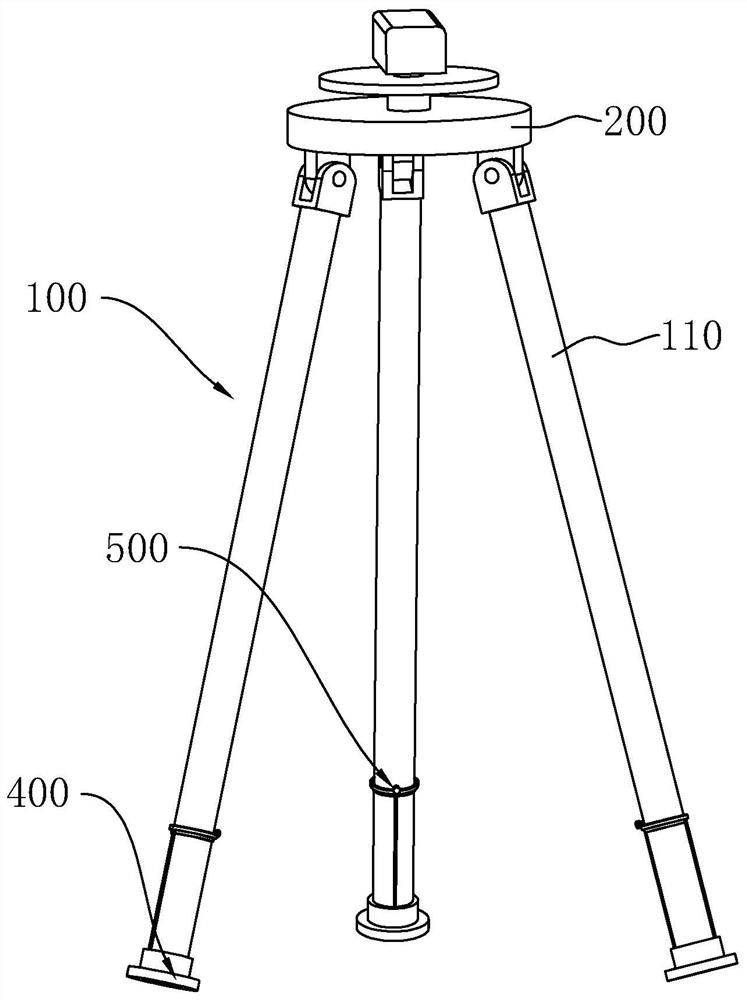

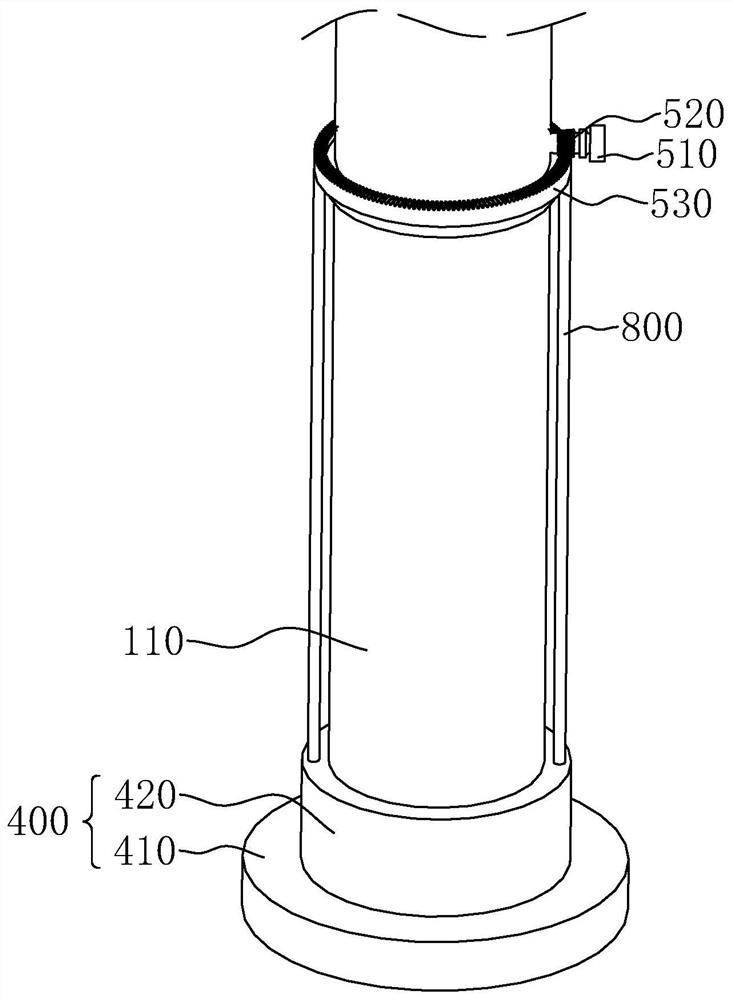

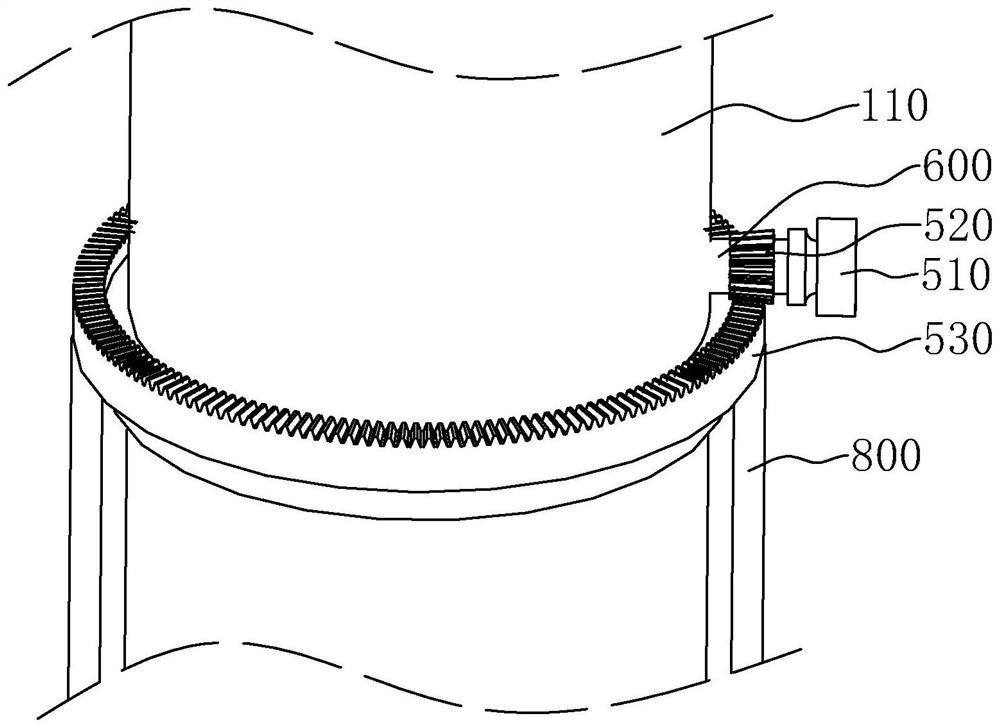

[0042] Attached to the following Figure 1-5 This application will be described in further detail.

[0043] The embodiment of the present application discloses a steel flower tube soil nailing wall hole level, refer to figure 1, including a tripod 100 and a base 200, the tripod 100 includes three poles 110, one end of the three poles 110 is rotatably mounted on one side of the base 200, and the three poles 110 are all located on the same side of the base 200, each The end of the pole 110 away from the base 200 is equipped with a driving assembly 500, a leveling assembly 400 and a stabilizing assembly 300, the leveling assembly 400 is in contact with the ground, the driving assembly 500 is connected with the stabilizing assembly 300, and the leveling assembly 400, and the driving assembly 500 drives the leveling assembly While the 400 rotates, the driving and stabilizing component 300 slides.

[0044] The leveling component 400 is in contact with the ground and rotates to smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com