Ball seat suitable for acidification of ultra-deep carbonate rock gas reservoir and use method of ball seat

A technology of carbonate rock and ball seat, which is applied in earthwork drilling, wellbore/well components, construction, etc. It can solve problems such as difficult secondary setting, unsealing, and rising annular pressure, so as to speed up the progress of production , Improve work stability, reduce engineering costs and cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

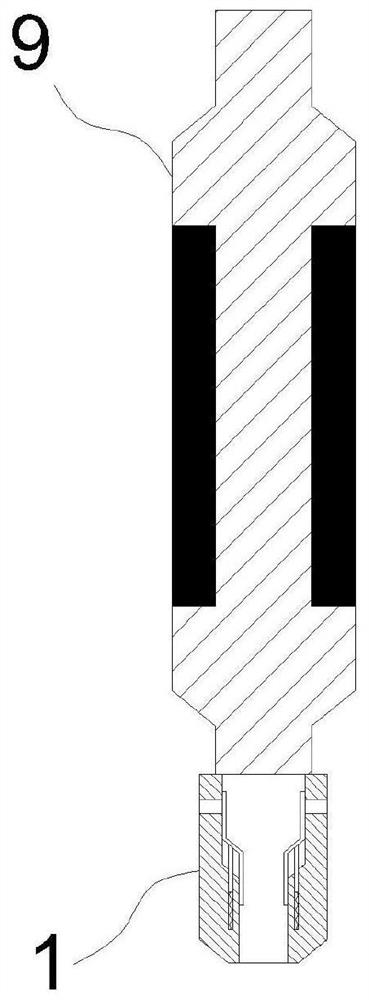

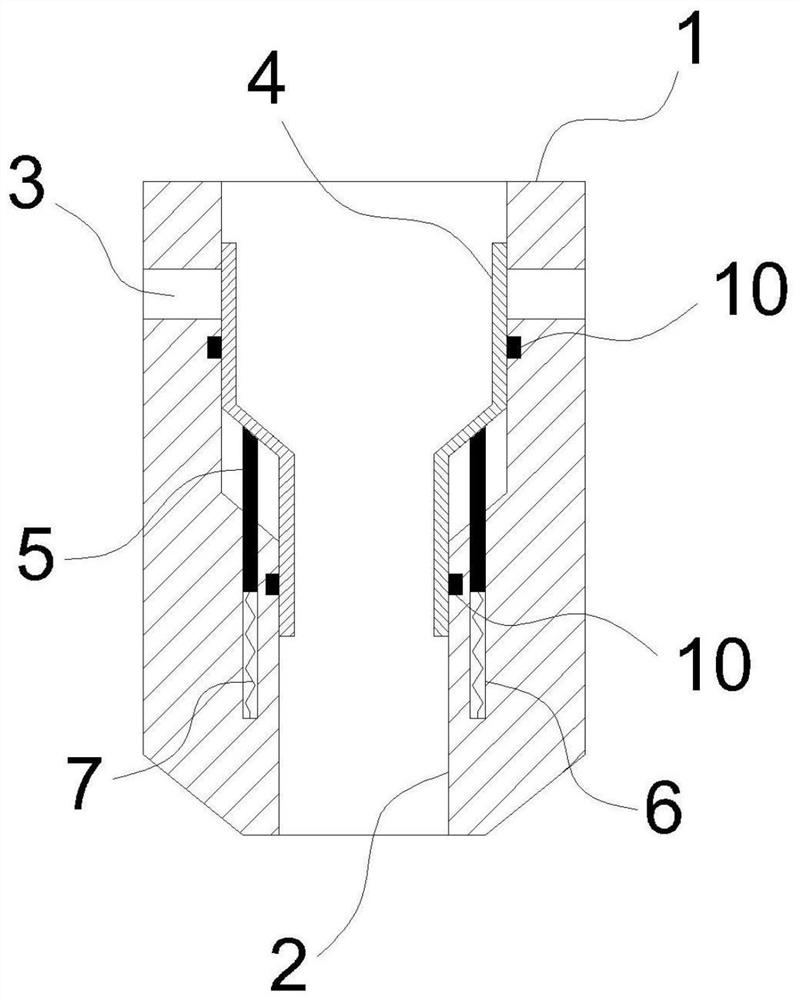

[0028] A ball seat suitable for acidizing ultra-deep carbonate gas reservoirs, the ball seat body 1 is arranged at the bottom of the K344 packer 9, and a main channel 2 that communicates with the center pipe of the packer is arranged inside, and at least part of the main channel 2 is vertical. The diameter of the straight inner wall section is smaller than the diameter of the vertical inner wall section above it, so that a reduced diameter structure is formed in the main channel 2 .

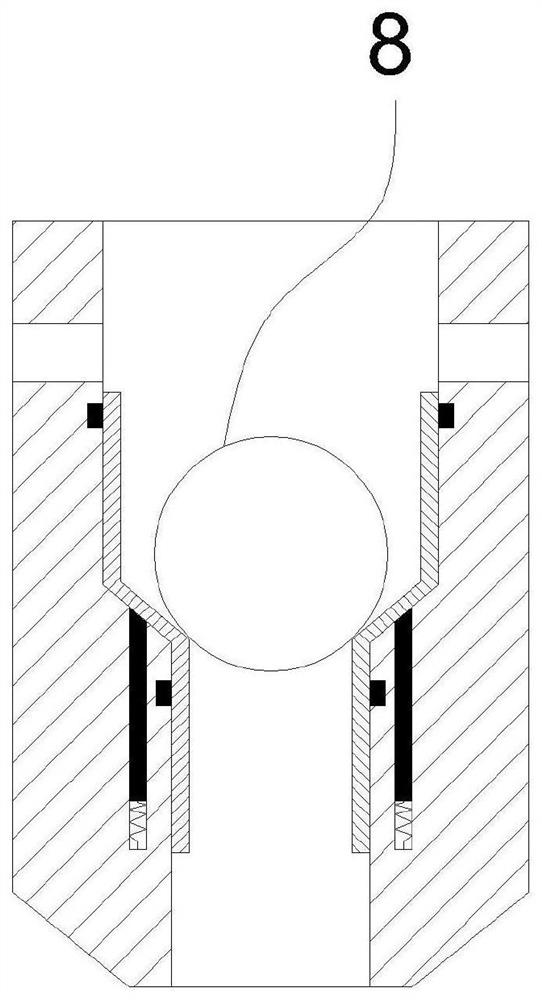

[0029] The ball receiving shaft 4 is funnel-shaped, and is movably arranged in the ball seat body 1, and can move up and down coaxially along the main channel 2 in the ball seat body 1. The largest part of the ball receiving shaft core 4 is close to the larger diameter of the main channel. The inner wall section of the main channel with the smallest diameter is close to the inner wall section with the smaller diameter in the main channel. When the setting ball is put into the setting ball, the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com