Equipment and method for controlling industrial and mining limestone roof of well through acid fracturing

A technology for industrial and mining limestone and acid fracturing, which is applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of unsatisfactory limestone caving effect and high hydraulic fracturing construction pressure, and improve the caving of suspended ceiling. effect, reducing construction pressure, reducing the effect of limestone strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

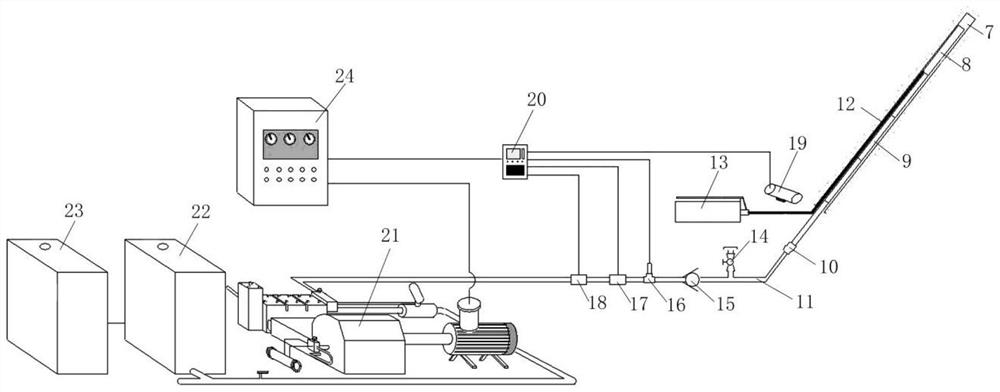

[0047] Acid fracturing to control limestone suspended roof in goaf:

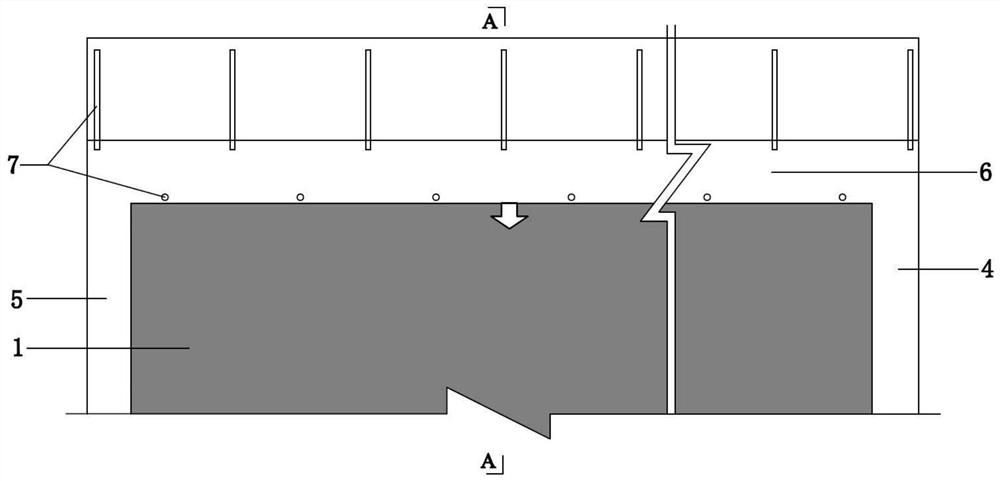

[0048] The average thickness of coal seam 1 in the construction coal mine is 3m, the inclination angle of coal seam 1 is 3-8°, the roof of coal seam 1 is limestone, with an average thickness of 8m, and the bottom plate 3 is mudstone, aluminous mudstone and sandy mudstone, with an average thickness of 4.69m. The design length of 6 cutting holes in the coal mining face is 150m, and it is a rectangular section with a net width of 7.0m, a net height of 3.0m, and an azimuth angle of 1°.

[0049] Acid fracturing specifically includes the following steps:

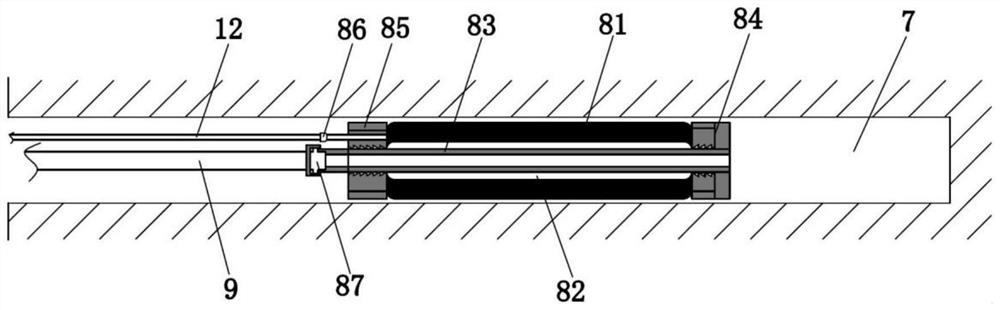

[0050] Step 1: If image 3 , 4 As shown, a group of parallel boreholes 7 are constructed on the vertical roof near the coal wall side between the 6 frames of the coal mining face, which are used for acid fracturing to cut off the coal wall support and reduce the caving step distance of the limestone suspended roof. A group of parallel boreholes 7 is construct...

Embodiment 2

[0061] Acidify the limestone roof 2 above the pre-splitting coal seam to weaken its strength, prompting it to collapse in time with the mining of the coal seam 1, avoiding the formation of a large-scale overhang in the goaf after the erection, and fundamentally eliminating the overhang of the goaf Disaster hazard.

[0062] The average thickness of coal seam 1 in the construction coal mine is 5m, and the roof of coal seam 1 is limestone with an average thickness of 12m. The design length of 6 cutting holes in the coal mining face is 200m, the net width is 7.6m, and the net height is 3.2m. Combined support method.

[0063] Acid fracturing specifically includes the following steps:

[0064] Step 1: If Figure 5 , 6 As shown, a group of parallel boreholes 7 are constructed on the vertical roof near the gob side between the 6 racks of the coal mining face, which are used for acid fracturing to cut off the coal wall support and reduce the caving step distance of the limestone su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com