Method for overcomming creep of salt-rock layer by using ralation of drilling fluid density and chloride concentration

A technology of drilling fluid density and concentration, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling and production, and can solve the problems of difficult-to-control salt layer creep, limited formation pressure bearing capacity, and easy lost circulation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

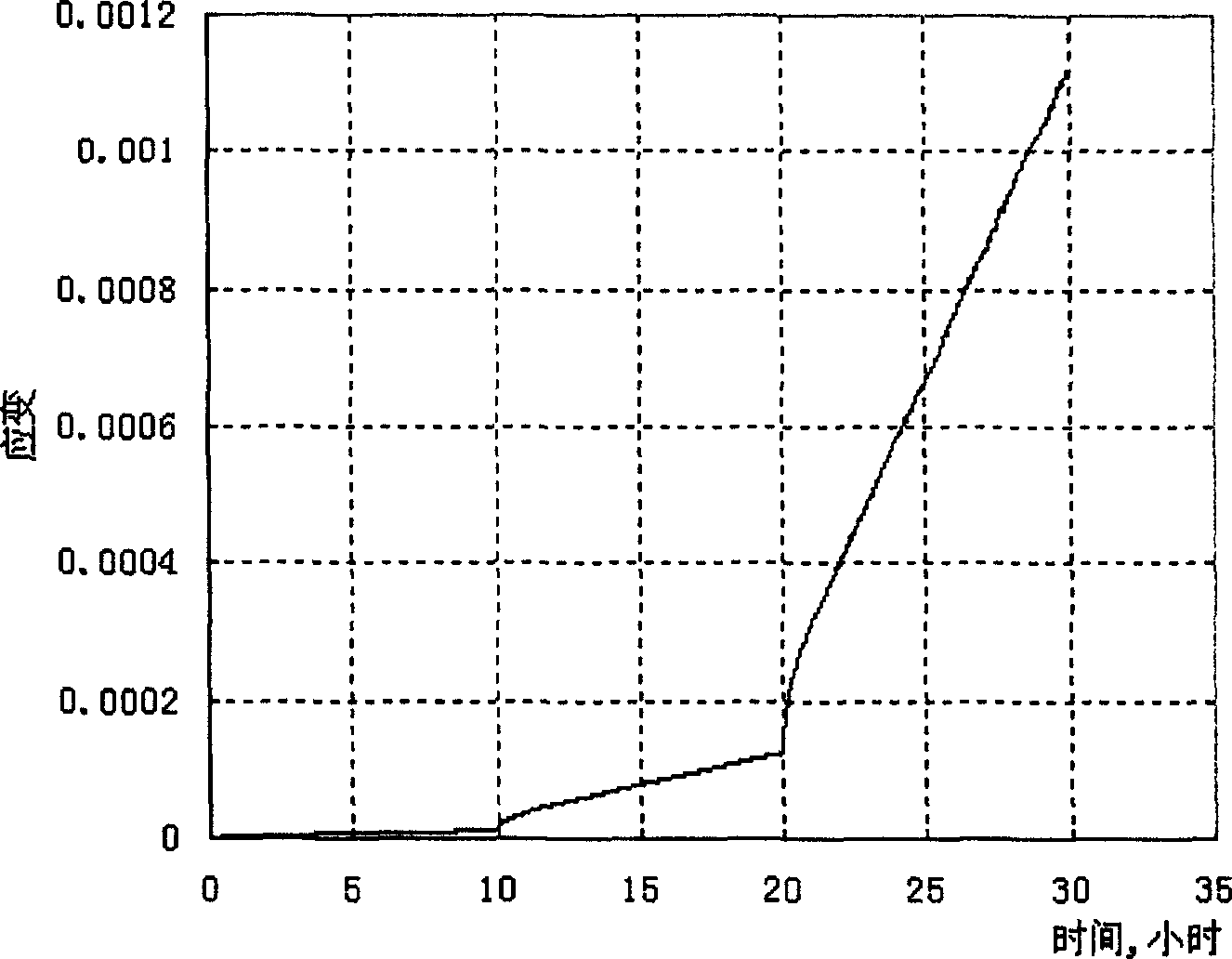

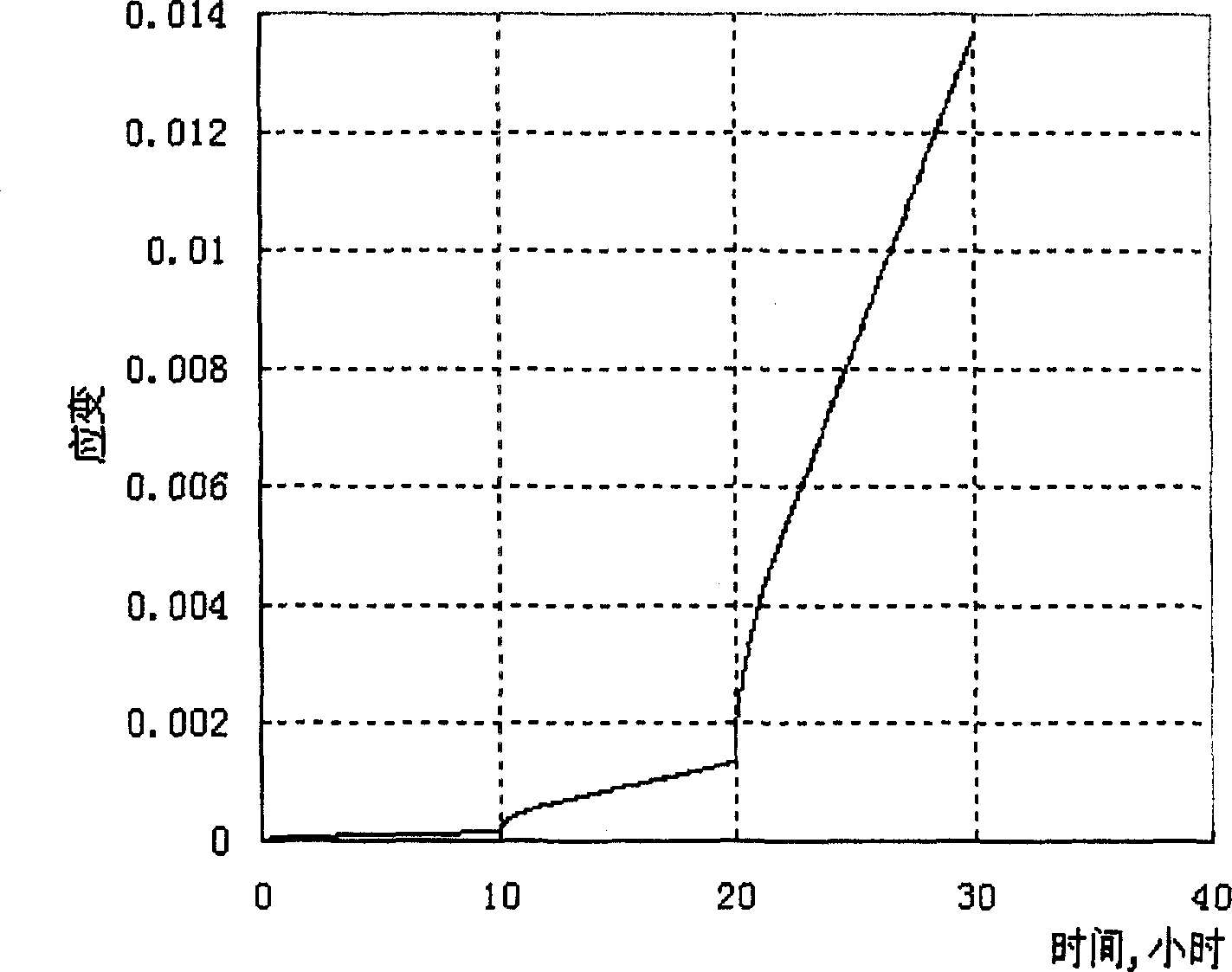

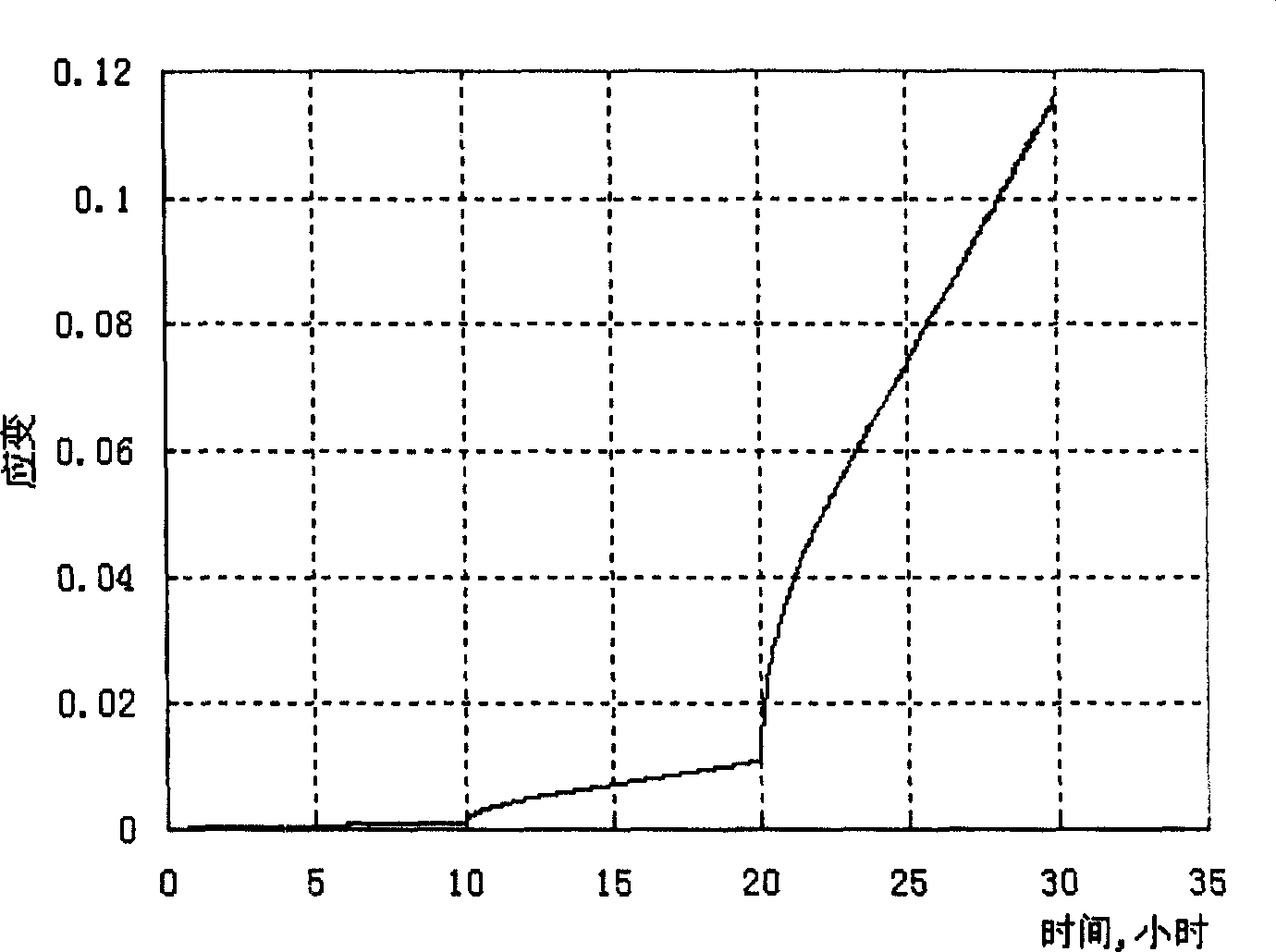

[0036] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] In the present invention, the method for overcoming the creep of the salt formation by utilizing the relationship between the drilling fluid density and the concentration of chloride radicals mainly includes the following steps:

[0038] 1. For a certain structural depth of salt rock layer that is H meters, the wax-sealed salt rock core obtained by drilling and coring is carried out for experimental sample processing. The size specification of the sample is that the length is 50mm, and the diameter is a cylinder of 25mm. The quantity is 8 (other quantities are also possible), and they are respectively numbered 1, 2, ..., 7, 8;

[0039] 2. Take 4 samples (numbered 1, 2, 3, 4), and carry out a creep test on a rock creep testing machine for each sample, adopt the experimental method of multi-stage temperature and multi-stage lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com