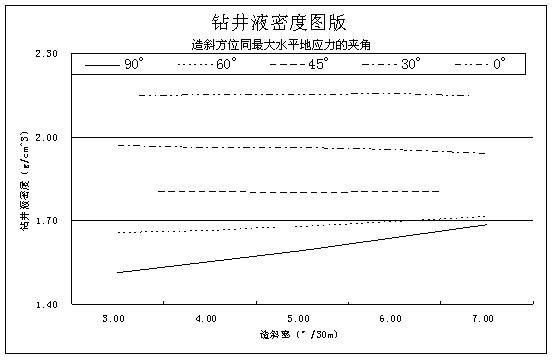

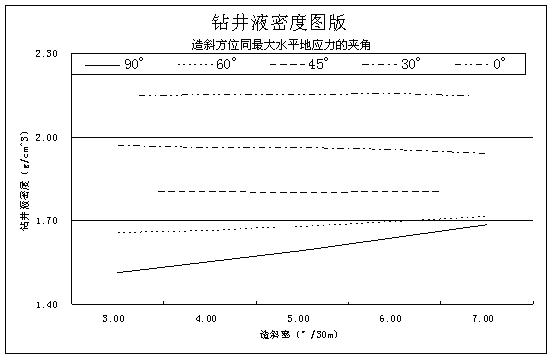

Method for determining drilling fluid density in salt-gypsum layer deflection

A technology of drilling fluid density and determination method, applied in chemical instruments and methods, earthwork drilling, flushing wellbore, etc., can solve problems such as limited formation pressure bearing capacity, easy leakage of lost circulation, restricting downhole directional instruments, etc., to prevent The effect of wellbore shrinkage and prevention of downhole complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] The embodiment of the present invention provides a method for determining the density of a deflection drilling fluid in a salt-gypsum layer, which is applied to a salt layer in a well in a certain block, with a depth of 3350 meters, and specifically includes the following steps:

[0023] (1) For the composite salt-gypsum layer of a certain structure, the wax-sealed salt rock core obtained by drilling and coring was processed as an experimental sample, and the standard core (diameter 25.5mm, length 50mm cylinder, or diameter 38mm, length 50mm) was obtained respectively. 72mm cylinder) 4 groups with a total of 16 pieces (if conditions permit, more groups can be used), that is, one piece with an angle of 0°, 45°, and 90° with the X-axis; one piece with an angle with the Z-axis of 0°, a total of 4 blocks are 1 group;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com