Special perforating gun for fracturing, special FracGun composite perforating device and method for fracturing

A composite perforating and perforating gun technology, which is applied in earthwork drilling, wellbore/well components, and production fluids, etc., can solve the problems of high-pressure operation costs and potential safety hazards, and achieve safety assurance, high cost, and Difficult to manage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

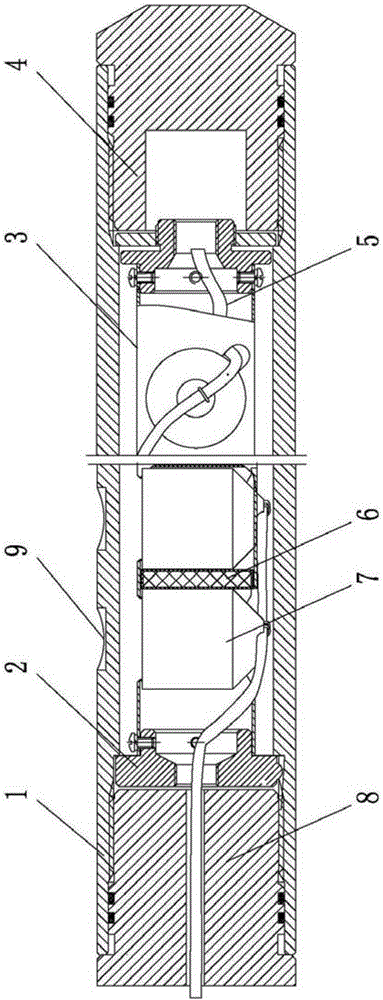

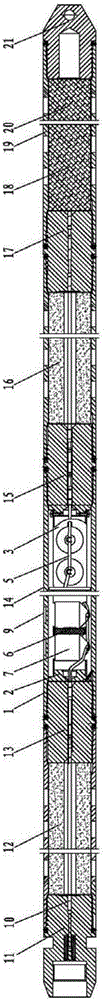

[0031] Such as figure 1 As shown, the present invention provides a special perforating gun for fracturing. The perforating gun includes a gun body 1, a positioning ring 2, a bullet holder tube 3, a gun tail 4, a detonating cord 5, a fracturing powder 6, and a perforating gun. Ammo 7 and gun head 8;

[0032] The improvements of this perforating gun are:

[0033] At least two perforating charges 7 are installed on each phase of the bullet holder tube 3; each phase of the gun body 1 is provided with blind holes corresponding to the perforating charges 7 one by one.

[0034] Wherein at least 2 perforating charges on each phase are arranged side by side along the axial direction of the carrier tube or along the radial direction of the carrier tube, and when working downhole, a 1m-long formation in the same direction is required, The number of holes in the perforating charge does not exceed 16. If it is larger than this number, the perforating gun will be deformed after perforatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com