Carbon dioxide acid fracturing method for ultra-deep well carbonate reservoir transformation

A carbonate rock reservoir, carbon dioxide technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of reservoir damage to water resources, excessive consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

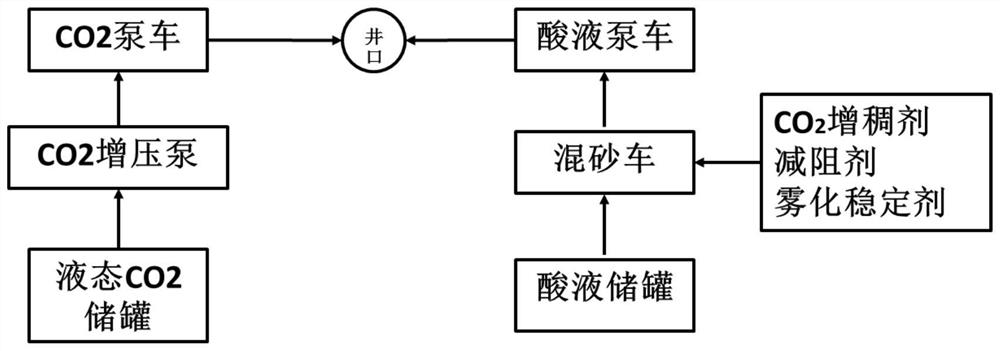

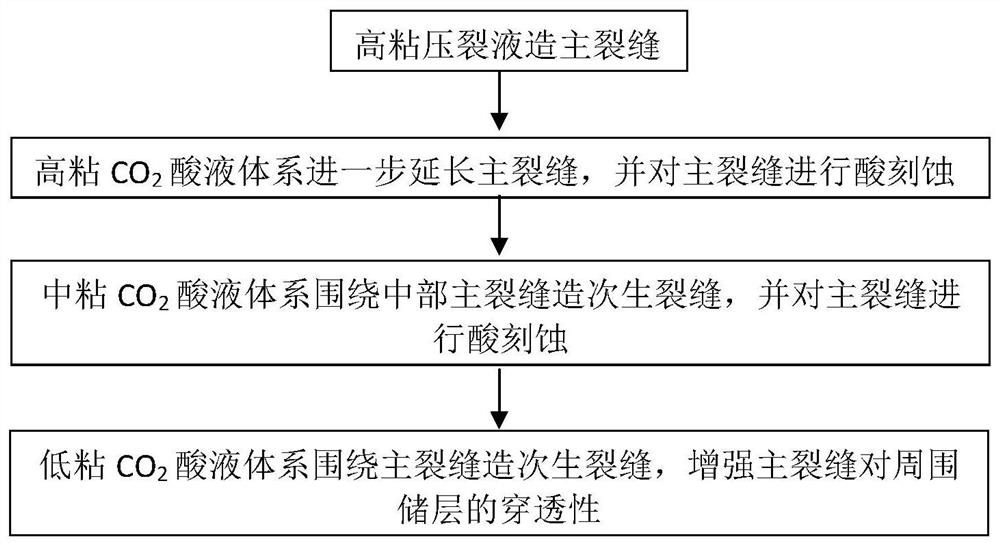

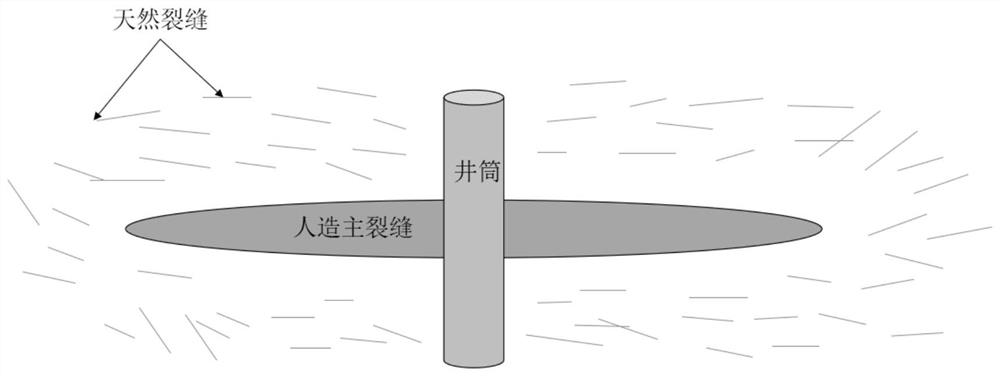

Method used

Image

Examples

Embodiment 1

[0073] The above method was applied to the acid fracturing operation of a carbonate reservoir in a well in an oilfield in western China. The target reservoir depth was 6009.5m, the original formation pressure was 64.99MPa, and the latest static pressure test was 58.73MPa; the reservoir temperature was 143°C, and the average porosity The density is 16.6%; the average permeability is 0.33md; among them, the actual construction parameters of carbon dioxide acid fracturing in ultra-deep wells are as follows:

[0074] High viscosity fracturing fluid: liquid CO 2 +20% hydrochloric acid +2.5% CO 2 Thickening drag reducer + 1% atomization stabilizer;

[0075] Medium viscosity fracturing fluid: liquid CO 2 +20% hydrochloric acid +1.5% CO 2 Thickening drag reducer + 1% atomization stabilizer;

[0076] Low viscosity fracturing fluid: liquid CO 2 +20% hydrochloric acid +1% CO 2 Thickened drag reducer + 1% fogging stabilizer.

[0077] Actual construction parameters of carbon dioxide...

Embodiment 2

[0084] The above method was used to carry out acid fracturing operation on a sandstone condensate gas reservoir reservoir in a well in an oilfield in western China. The target reservoir depth was 4320.8m. Due to the pollution of some reservoirs caused by previous operations, and considering the characteristics of the condensate gas reservoir, the The technology of the present invention performs acid fracturing and plugging removal operations on target reservoirs to dredge seepage channels, remove near-well pollution caused by well workover operations, and simultaneously remove near-well reverse condensate oil plugging, thereby restoring production. Among them, the actual construction parameters of carbon dioxide acid fracturing in ultra-deep wells are as follows:

[0085] Medium viscosity fracturing fluid: liquid CO 2 +20% hydrochloric acid +1% CO 2 Thickening drag reducer + 1% atomization stabilizer;

[0086] Low viscosity fracturing fluid: liquid CO 2 +20% hydrochloric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com