Metal silicide nano-wire and its making method

A technology of metal silicide and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of disordered metal silicide nanowires, difficult to control size and shape, uncontrollable growth position, etc. Achieve the effect of improving characteristics and reliability, small line width and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

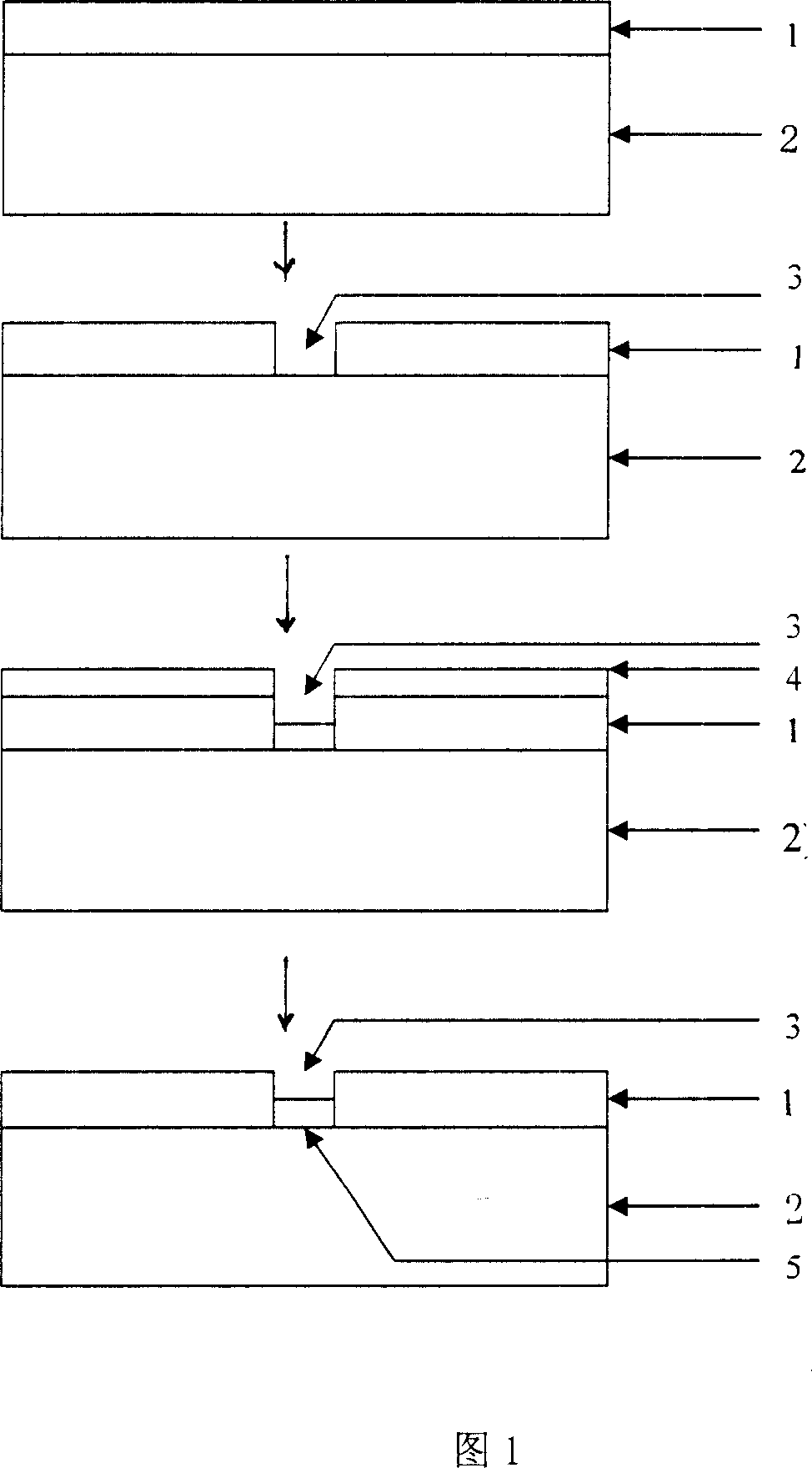

[0037] With reference to Fig. 1, prepare titanium disilicide nanowire of the present embodiment according to the flow process of the present invention:

[0038] 1) On the surface of the monocrystalline silicon substrate 2, a silicon dioxide insulating layer 1 with a thickness of 50 nanometers is grown by a conventional thermal oxidation method, and the thickness of the insulating film 1 is 50 nanometers;

[0039] 2), put the single crystal silicon substrate 2 on which the silicon dioxide insulating layer 1 has been grown in step 1) into the cavity of the focused ion beam system, and use the ion beam to etch the insulating layer with a length of 10 microns and a width of The trench 3 is 14 nanometers; the etching conditions adopted are: ion source voltage 30KV, ion beam current 1pA, beam scanning with beam spot overlapping 50%, and beam dwell time of 1 microsecond; When the groove 3 is etched on the top, and at the same time, a bias voltage is applied on the single crystal sili...

Embodiment 2

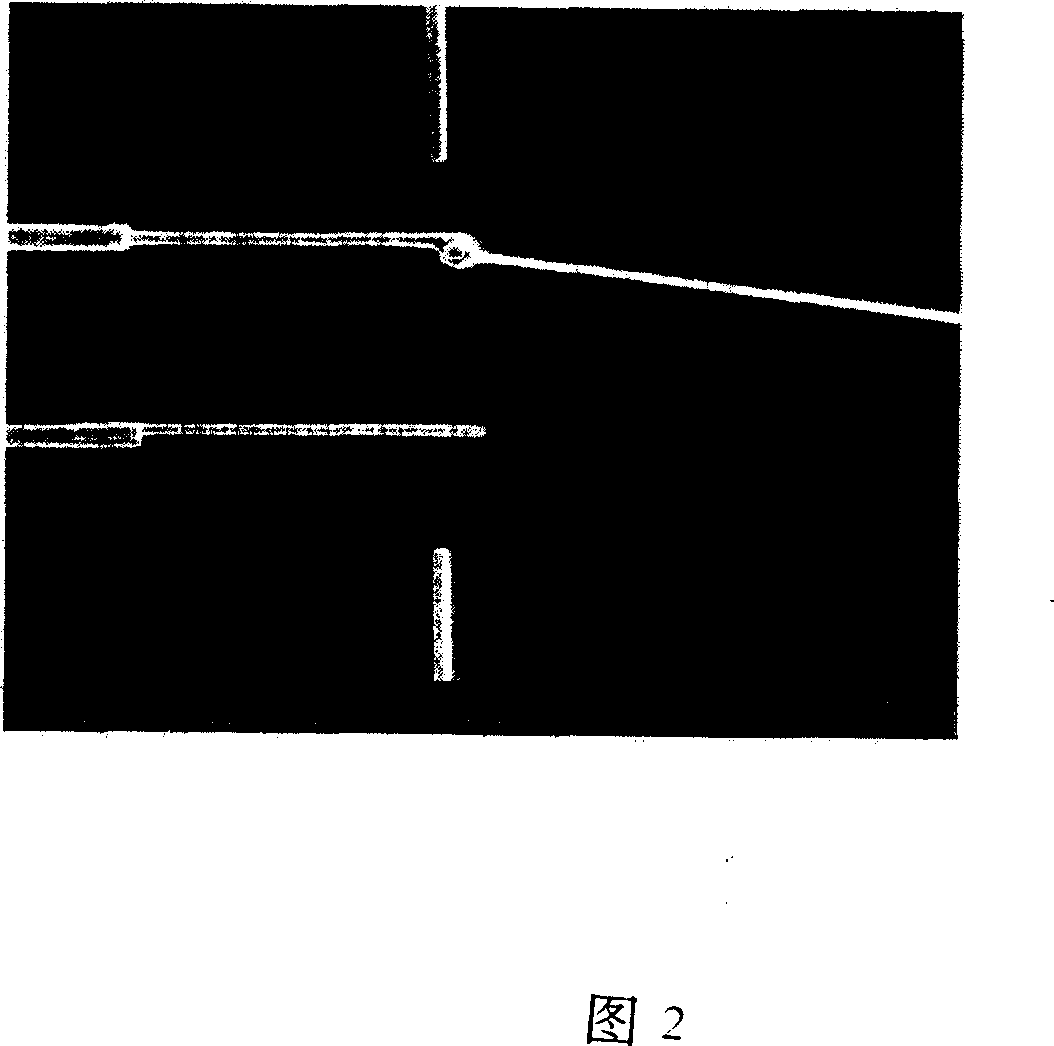

[0044] The specific structure of titanium disilicide nanowires prepared in this embodiment is shown in Figure 2; the nanowires have a line width of 100 nanometers and a length of 30 microns.

[0045] With reference to Fig. 1, the preparation method of the present embodiment is carried out according to the technological process of Fig. 1, and concrete technology is as follows:

[0046] 1. On the surface of the single crystal silicon substrate 2, a 100 nanometer thick aluminum nitride insulating layer 1 is grown by magnetron sputtering, and the thickness of the insulating film i is 100 nanometers;

[0047] 2. Put the silicon substrate 2 already with the aluminum nitride insulating layer 1 into the cavity of the focused ion beam system, and use the ion beam to etch the insulating layer with a length of 30 microns, a width of 100 nanometers, and a depth of 100 nanometer trench 3; the etching conditions adopted are: ion source voltage 30KV, ion beam current 20pA, beam spot overlapp...

Embodiment 3

[0052] The specific structure of titanium disilicide nanowires prepared in this embodiment is shown in Figure 2; the nanowires have a line width of 50 nanometers and a length of 10 microns.

[0053] With reference to Fig. 1, the preparation method of the present embodiment is carried out according to the technological process of Fig. 1, and concrete technology is as follows:

[0054] 1. On the surface of the single crystal silicon substrate 2, a polyimide insulating layer 1 with a thickness of 50 nanometers is coated by a spin coating process, and the thickness of the insulating film 1 is 50 nanometers;

[0055] 2. Put the silicon substrate 2 already covered with the polyimide insulating layer 1 into a conventional electron beam lithography and reactive ion etching system to fabricate nano-grooves. Using traditional electron beam exposure technology, a nanowire pattern with a width of 50 nanometers and a length of 10 nanometers is fabricated on P polyimide. The bias voltage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com