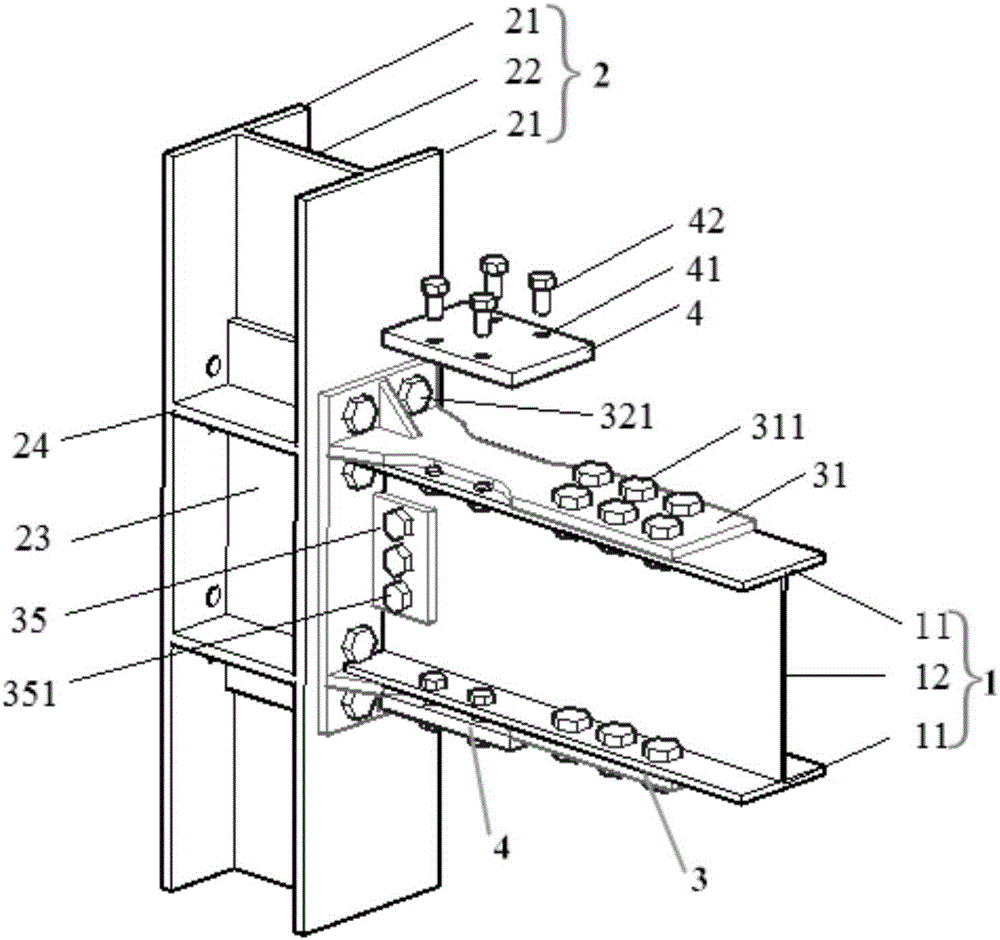

Buckling constraint type steel-beam-and-column end-plate connection joint and steel structure building

A technology of buckling constraints and connecting nodes, which is applied in the direction of protective buildings/shelters, buildings, building types, etc., can solve the problem that connecting bolts are susceptible to tensile damage, reduce the number of connecting bolts, improve ductility and energy dissipation capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

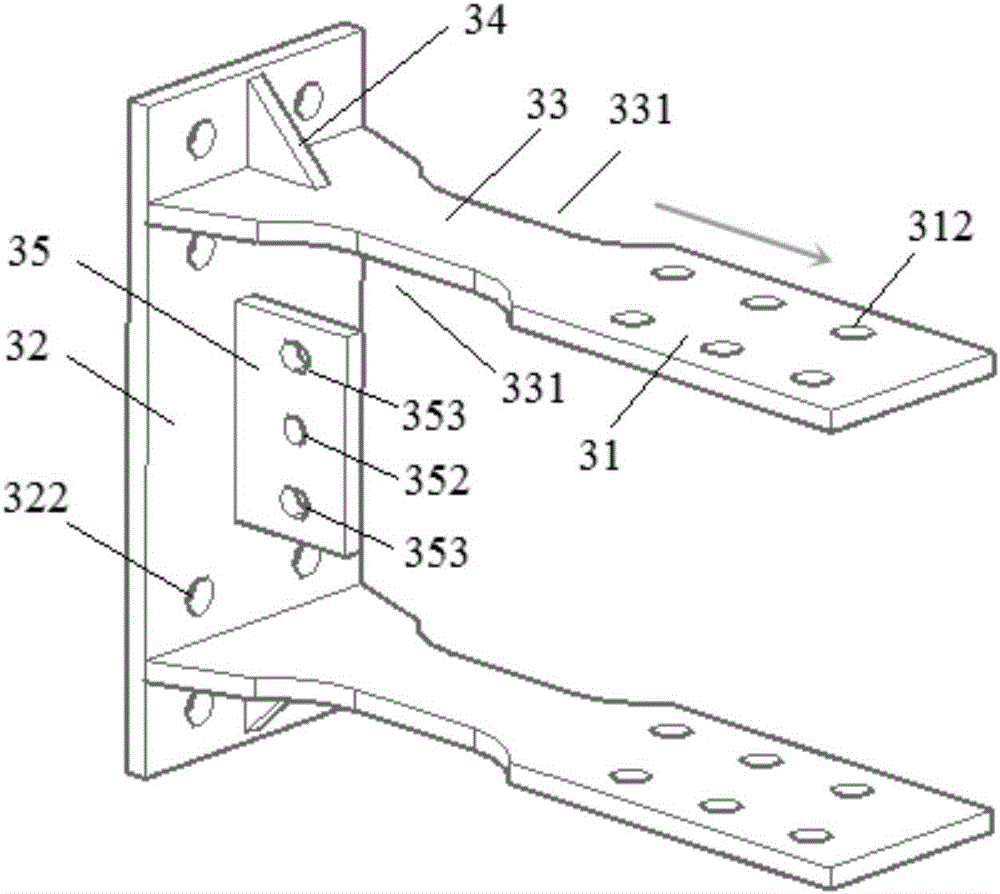

example 1

[0044] Example 1: if figure 2 As shown, the end of the flange connecting plate 31 adopts an enlarged cross-section, the weakened area 33 in the middle of the flange connecting plate 31 adopts a mixed cutting method of circular arc and straight line, and the first group of bolt holes 312 are staggered.

example 2

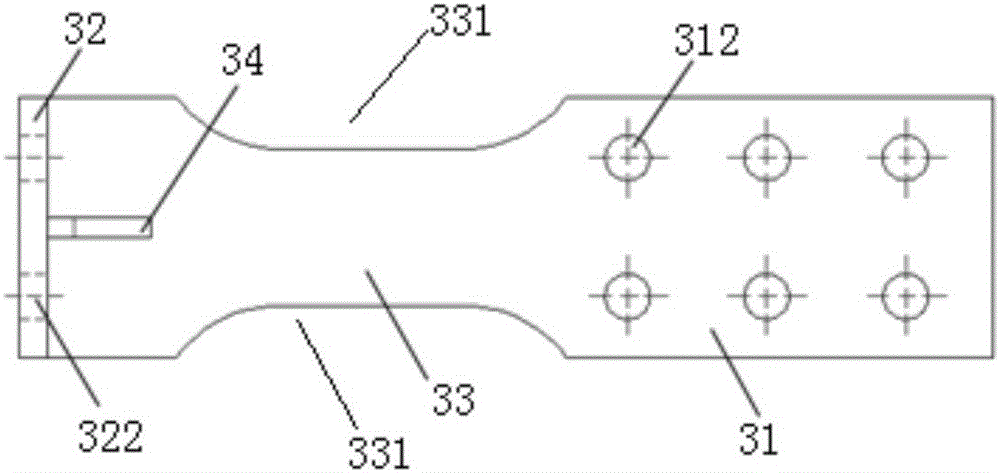

[0045] Example 2: if image 3 As shown, the end of the flange connecting plate 31 adopts a non-expanded section form, the weakened area 33 in the middle of the flange connecting plate 31 adopts a mixed arc and straight line cutting, and the first group of bolt holes 312 are arranged side by side.

example 3

[0046] Example 3: if Figure 4 As shown, the end of the flange connecting plate 31 adopts a non-expanded section form, the weakened area 33 in the middle of the flange connecting plate 31 adopts a straight line cutting method, and the first group of bolt holes 312 are arranged side by side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com