Bobbin assembly capable of realizing peripheral unwinding

A bobbin and component technology, applied in the field of bobbin components, can solve the problems of yarn entanglement, great variation of warp tension, difficulty in maintaining uniform yarn tension, etc., so as to reduce the occupied space, reduce production costs, and avoid Mutual interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

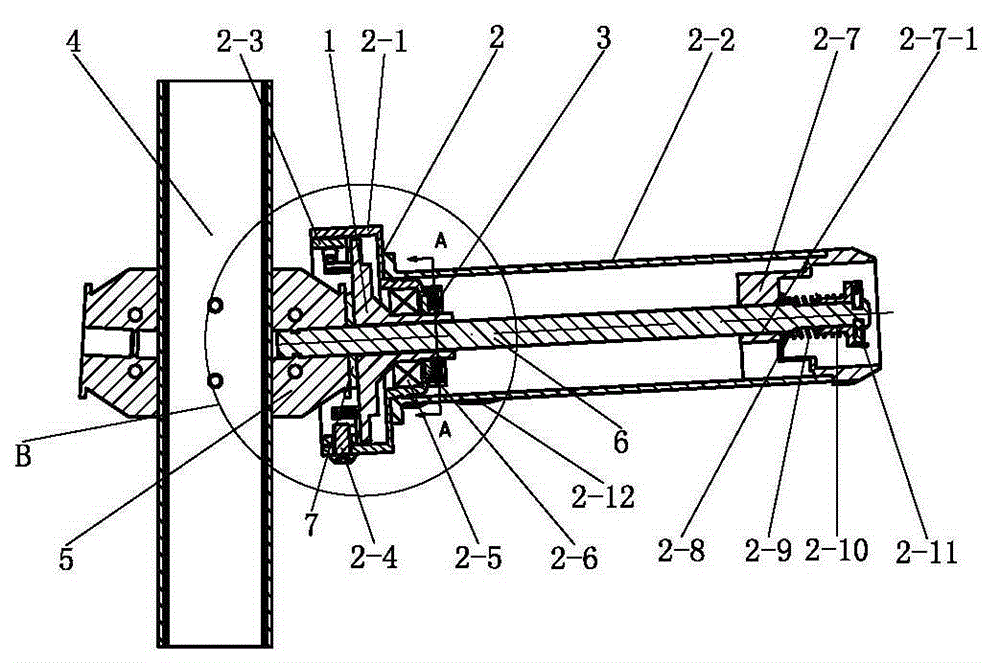

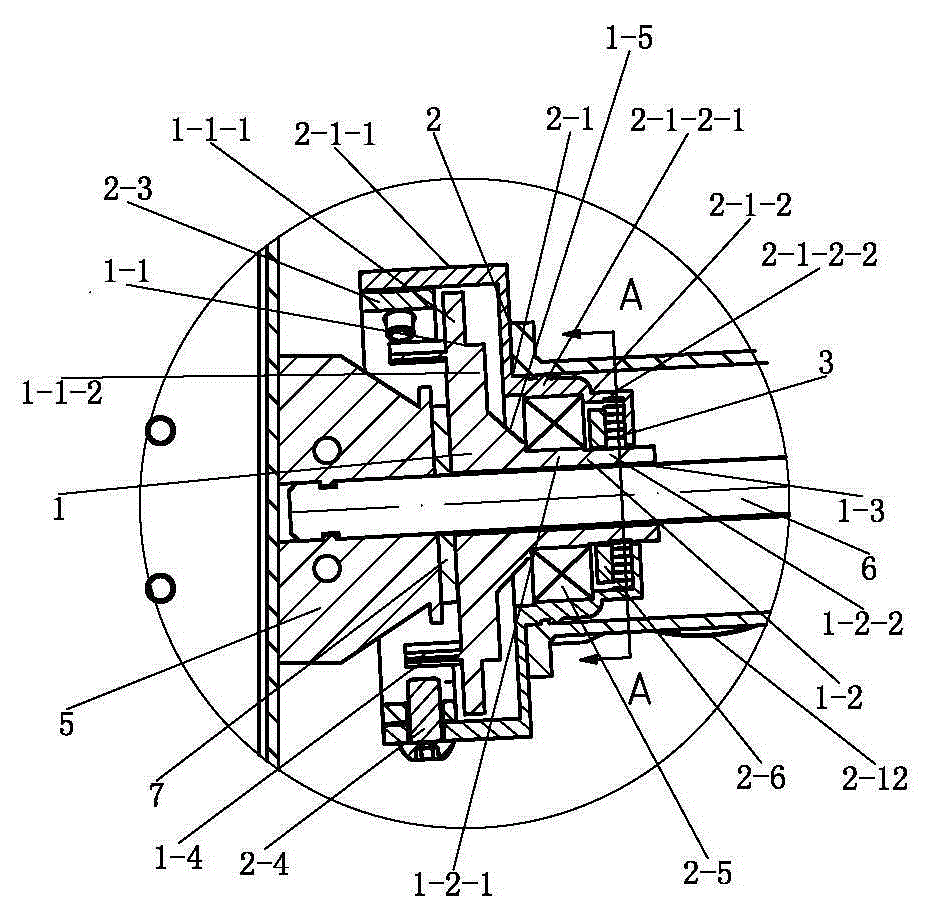

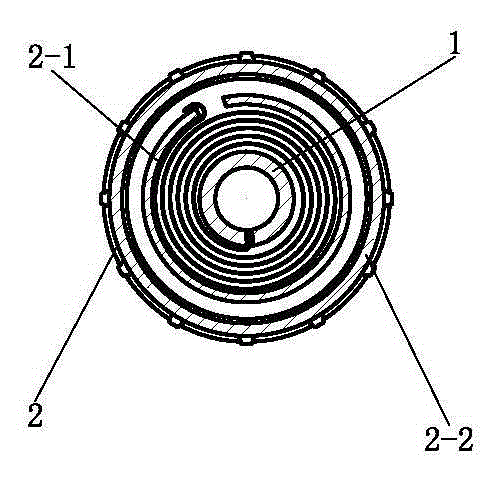

[0065] Such as Figure 1 to Figure 3 with Figure 5 As shown, this embodiment provides a bobbin assembly, including a bobbin 2, a rotating shaft 1 is arranged inside the bobbin 2, and a rotary elastic member 3 is arranged between the rotating shaft 1 and the bobbin 2, One end of the rotary elastic part 3 is connected to the rotating shaft 1, and the other end of the rotary elastic part 3 is connected to the bobbin 2. When unwinding: the bobbin 2 first tightens the rotary elastic part 3, and then rotates The elastic component 3 drives the rotating shaft 1 to rotate.

[0066] In this embodiment, a rotating shaft is arranged inside the bobbin, and a rotating elastic member is arranged between the rotating shaft and the bobbin. One end of the rotating elastic member is connected to the rotating shaft, and the rotating elastic The technical means by which the other end of the component is connected to said bobbin, so that the bobbins of the bobbin assembly are fixedly fitted over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com