Battery pole plate, method for producing the pole plate, and Li-ion battery

A manufacturing method and battery electrode technology, applied in the field of lithium-ion batteries, can solve the problems of low battery capacity, distance can not meet tolerance requirements, etc., and achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the preparation method of the positive electrode sheet, except that the punching process is provided by the present invention, the others are conventional preparation methods. For example, the positive electrode slurry is prepared by mixing the positive electrode active material, conductive agent and binder with a solvent, coating and / or filling the positive electrode slurry on the current collector, drying, and punching to obtain the positive electrode slurry. Said positive plate. Wherein, the solvent can be selected from N-methylpyrrolidone (NMP), dimethylformamide (DMF), diethylformamide (DEF), dimethylsulfoxide (DMSO), tetrahydrofuran (THF) and One or more of water and alcohols. The amount of the solvent can make the positive electrode slurry have viscosity and fluidity, and it only needs to be able to be coated on the current collector. Generally, based on the weight of the positive electrode active material, the content of the solvent is 5-70% by weight, pref...

Embodiment 1

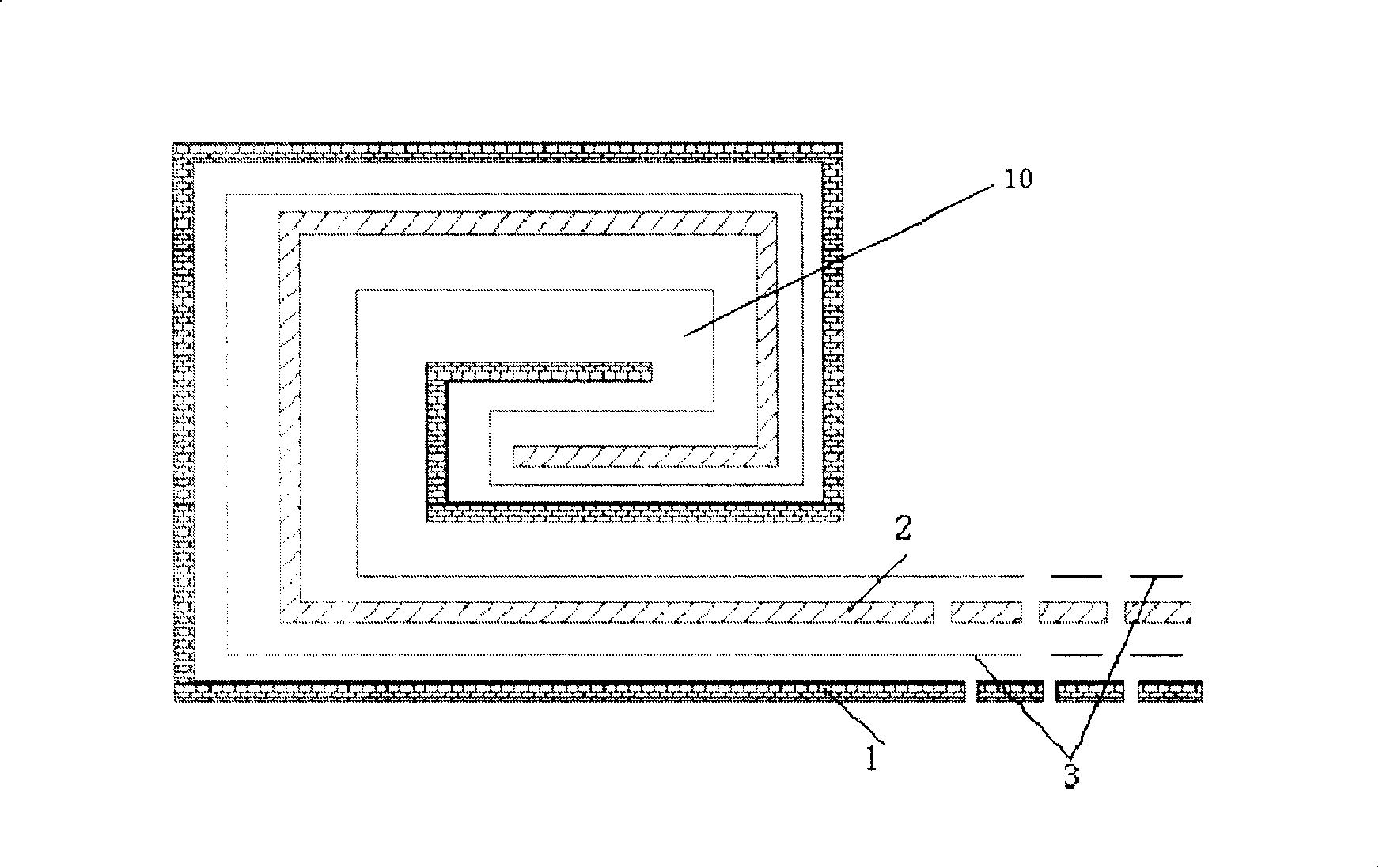

[0055] This embodiment illustrates the battery pole core and lithium ion battery provided by the present invention.

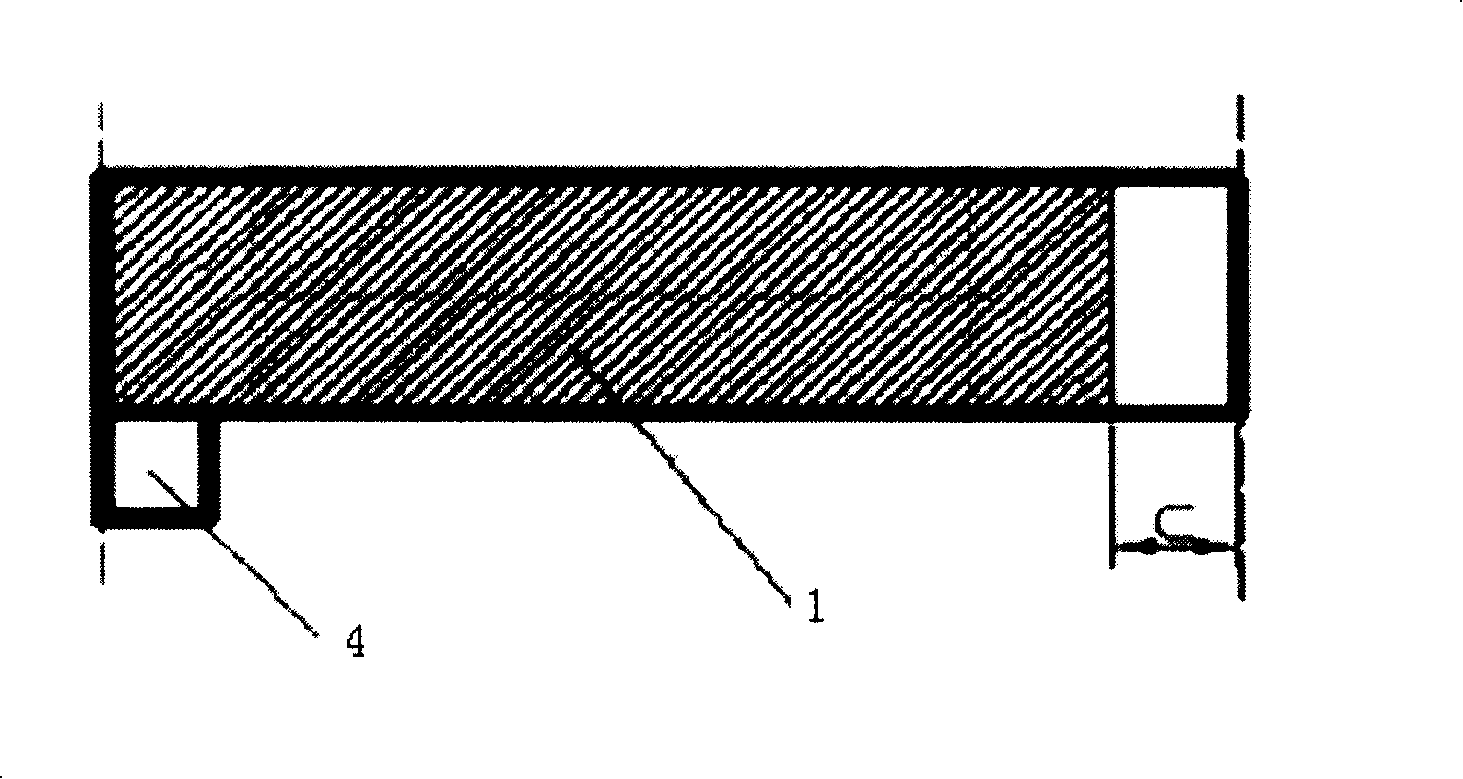

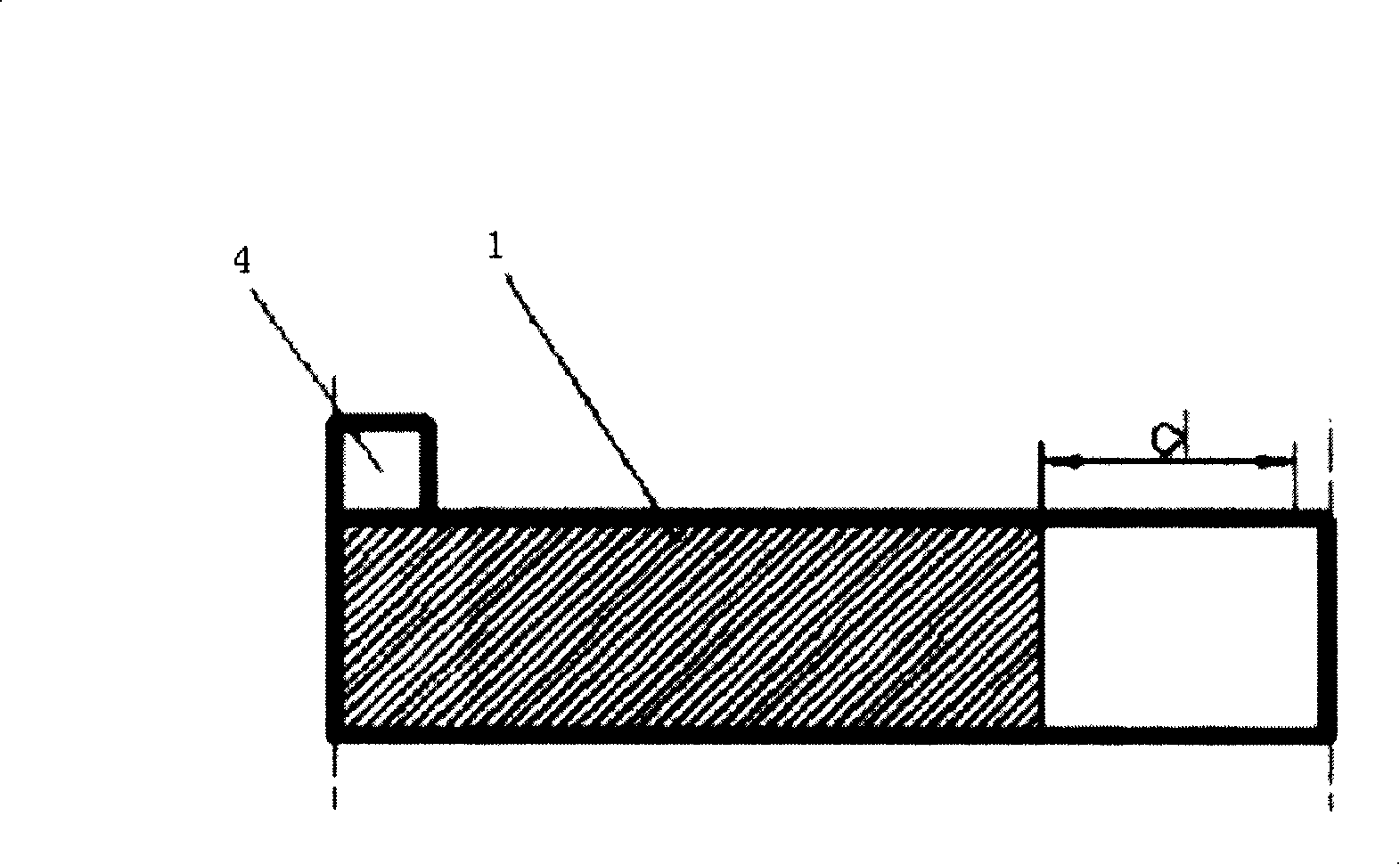

[0056] (1) Preparation of positive pole piece

[0057] The positive electrode material coating slurry is prepared by the following method: 15 parts by weight of polyvinylidene fluoride (Atofina Company, 761#PVDF) is dissolved in 225 parts by weight of N-methyl-2-pyrrolidone (NMP) solvent. Obtain binder solution, disperse 15 parts by weight of carbon black (the commodity of TIMICAL company, super-p by trade name) in the above-mentioned binder solution, then add 500 parts by weight of lithium manganese oxide in the gained solution, fully mix and prepare Obtain positive electrode material coating slurry.

[0058] On the aluminum foil, apply the positive electrode material coating slurry in the way of pulling slurry, the thickness of the positive electrode material coating is controlled at 0.10 mm, bake at 120 ° C for 5 hours, and then roll under a pressure of 1.6...

Embodiment 2

[0079] This example illustrates the capacity and tab spacing of the lithium ion battery provided by the present invention.

[0080] Take 100 lithium-ion batteries A1 produced according to the method of Example 1, use a vernier caliper to measure their external dimensions and the distance between tabs, and use a BS-9300 battery performance tester to measure the battery capacity. The obtained values are shown in Table 1:

[0081] Table 1

[0082]

[0083] 2

[0084] 30

[0085] 58

[0086] 86

[0087] The capacity of the 100 batteries in Example 1 has been increased by more than 50mAh on average, which is about 4%; the inter-lug spacing of the 100 batteries in Example 1 is between 12.69-13.43mm, all of which meet the requirements of 13±0.5mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com