UV curing machine

A technology of curing machine and shell, which is applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of uneven heating of products, shortened UV life, etc., to improve production efficiency and product quality, Extend life and enhance the effect of irradiation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

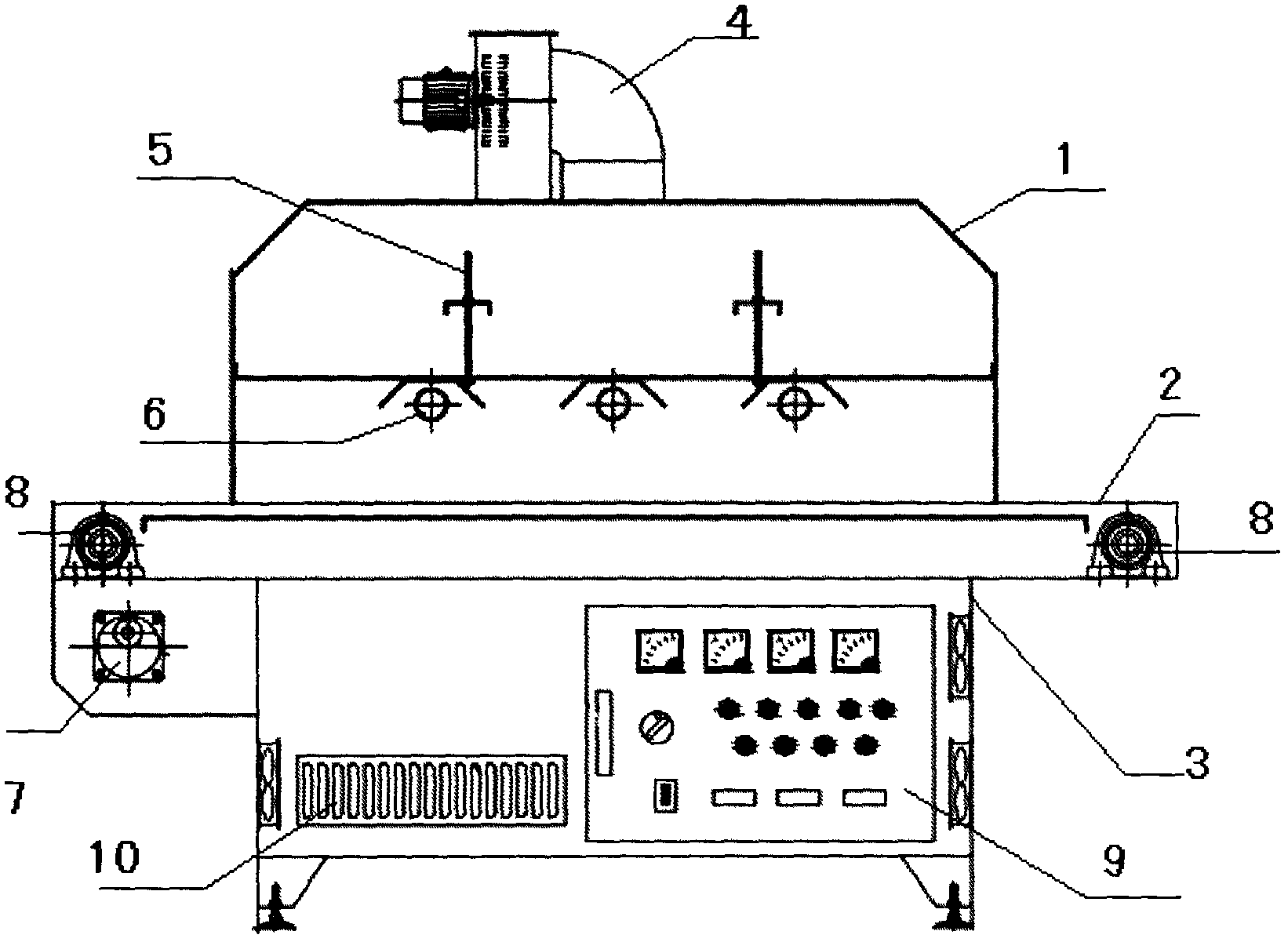

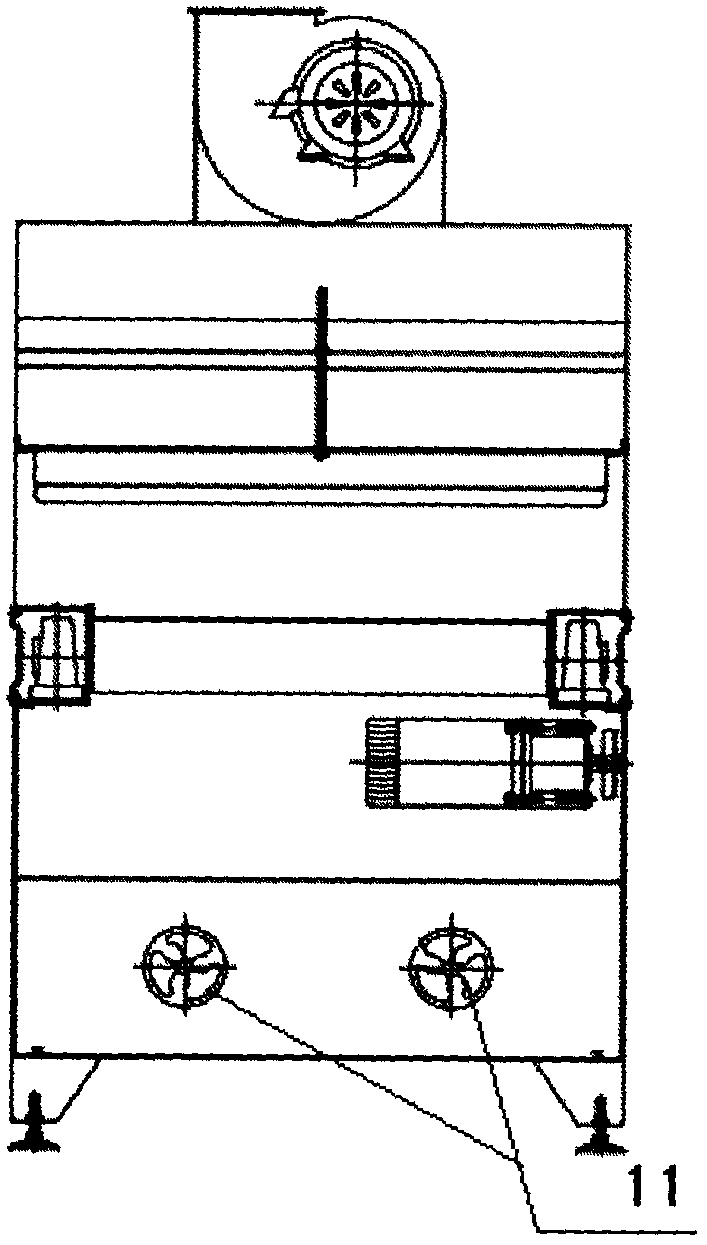

[0018] combined with figure 1 and attached figure 2 As shown, the present embodiment provides a UV curing machine, including a housing 1, which is a hollow box structure, and the bottom of both ends of the housing are respectively provided with a feed port and a discharge port, and the top of the housing is provided with The exhaust fan 4 is suspended with a UV lamp 6 fixed on the lamp stand in the middle of the housing, and the lamp stand is fixed on the bracket above the lamp stand through an adjusting screw 5; the transmission table 2 is located at the Below the UV lamp, one end of the conveyor belt is connected to the feed port, and one end is connected to the discharge port, and a roller 8 is respectively arranged on the conveyor table at the feed port and the discharge port; the console 3. Located below the transmission platform, the console 3 is a hollow steel structure without a top, and the surrounding steel plates are welded to the transmission platform 2. The cont...

Embodiment 2

[0020] combined with figure 1 and attached figure 2 As shown, the present embodiment provides a UV curing machine, including a housing 1, which is a hollow box structure, and the bottom of both ends of the housing are respectively provided with a feed port and a discharge port, and the top of the housing is provided with The exhaust fan 4 is suspended with a UV lamp 6 fixed on the lamp stand in the middle of the housing, and the lamp stand is fixed on the bracket above the lamp stand through an adjusting screw 5; the transmission table 2 is located at the Below the UV lamp, one end of the conveyor belt is connected to the feed port, and one end is connected to the discharge port, and a roller 8 is respectively arranged on the conveyor table at the feed port and the discharge port; the console 3. Located below the transmission platform, the console 3 is a hollow steel structure without a top, and the surrounding steel plates are welded to the transmission platform 2. The cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com