Intermediate high-voltage wire stripping device based on dual driving of electric driving and hand-operated driving

A high-voltage wire, double-drive technology, which is applied in the direction of cable installation, cable installation device, equipment for removing/armoring cables, etc., can solve the problem of short distance between the operator and the high-voltage cable, complex mechanical movement of the stripper, and efficiency of stripper removal Low-level problems, to achieve the effect of facilitating single-person operation, compact structure, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

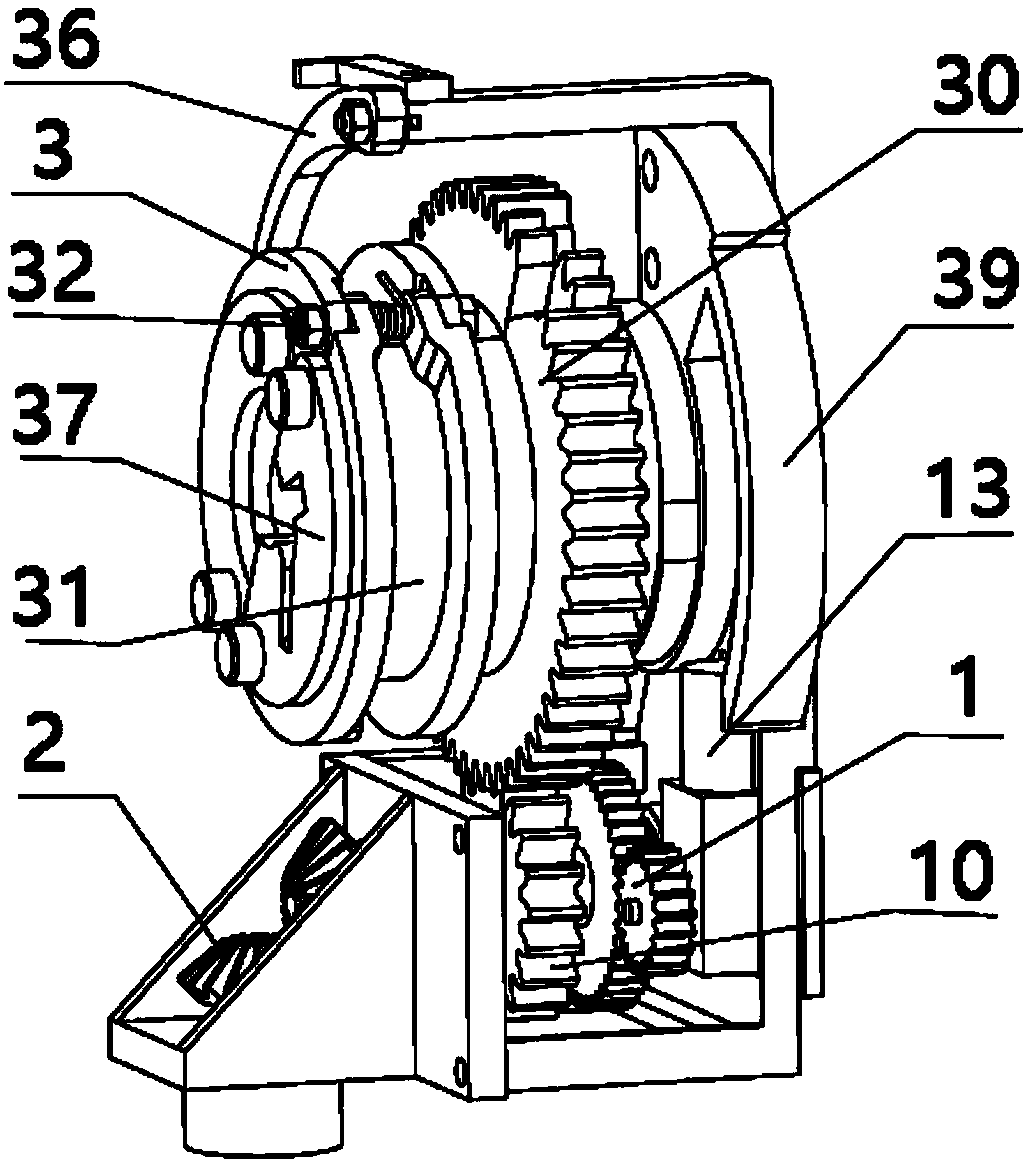

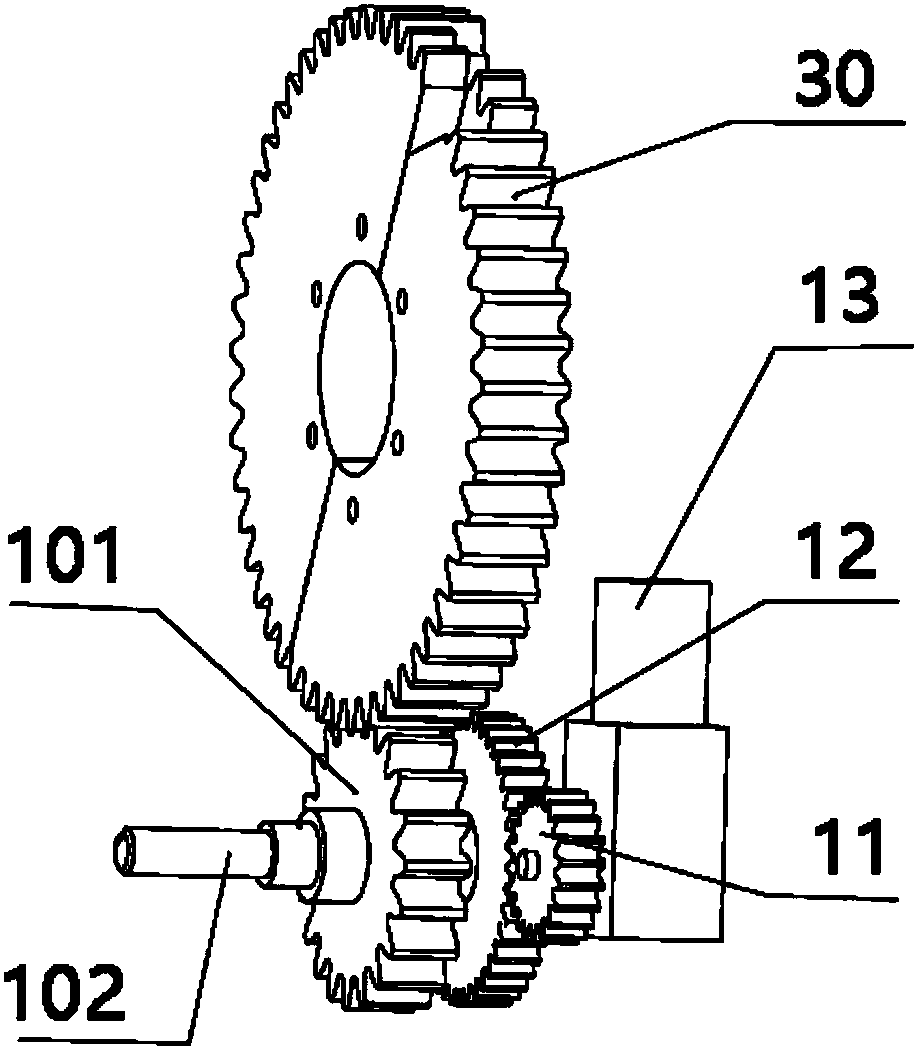

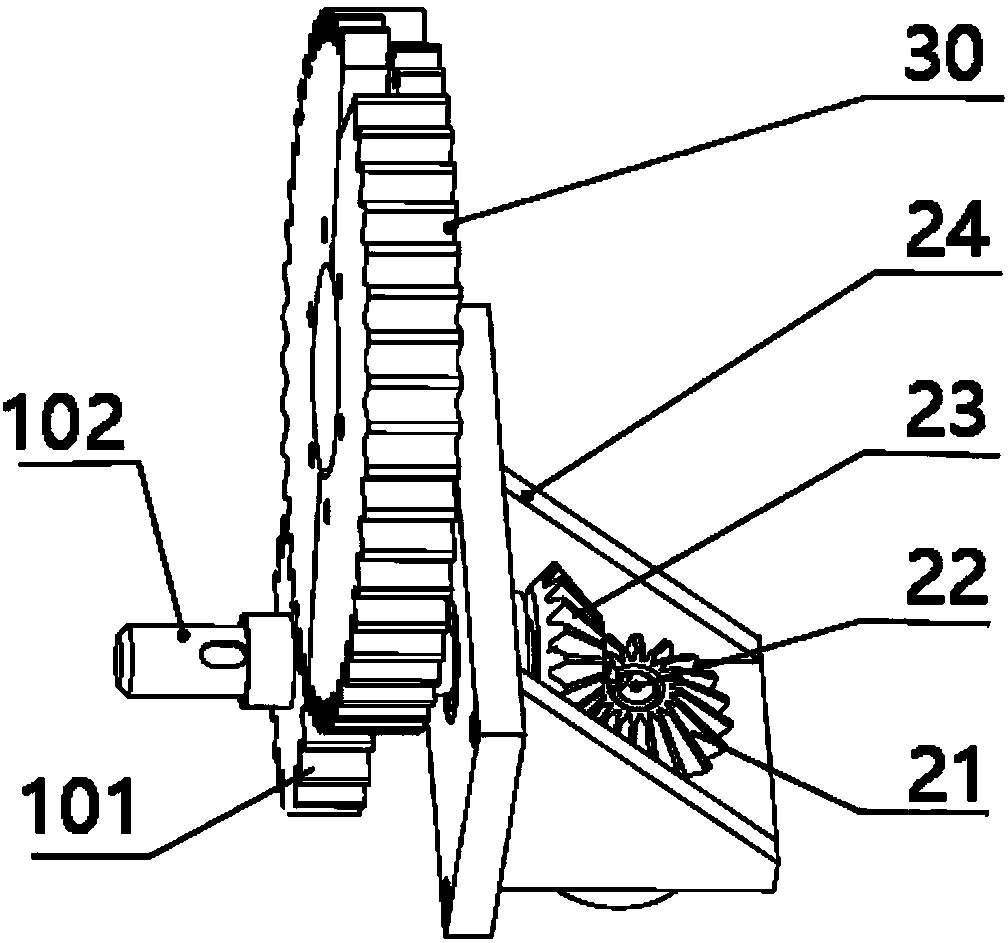

[0030] see figure 1 , figure 2 , image 3 , an electric and manual double-driven intermediate stripping device for high-voltage wires, including an electric transmission mechanism 1, a manual transmission mechanism 2, an opening and stripping mechanism 3, and a coupling mechanism 10.

[0031] The electric transmission mechanism 1 is composed of a motor transmission pinion gear 11 , a motor transmission bull gear 12 and a motor 13 . Described motor 13 is fixedly installed on the inner side wall of frame 39, and motor transmission pinion 11 is installed on the output shaft of motor 13, and when described motor 13 works, output shaft rotates and drives motor transmission pinion 11 to rotate, and described motor The transmission pinion 11 meshes with the motor transmission bull gear 12 , and the motor transmission bull gear 12 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com