Two-way periodical shifting fork safety pipe welding device

A welding device and safety tube technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing the production cost of the enterprise, unstable production quality, and a large amount of labor costs, so as to save labor costs and improve product quality. The effect of stable quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

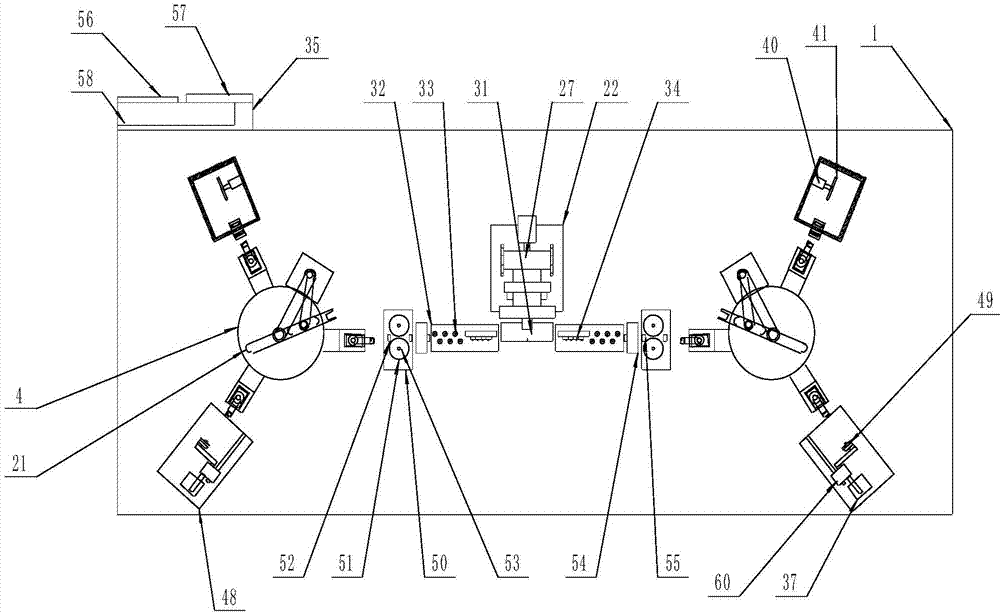

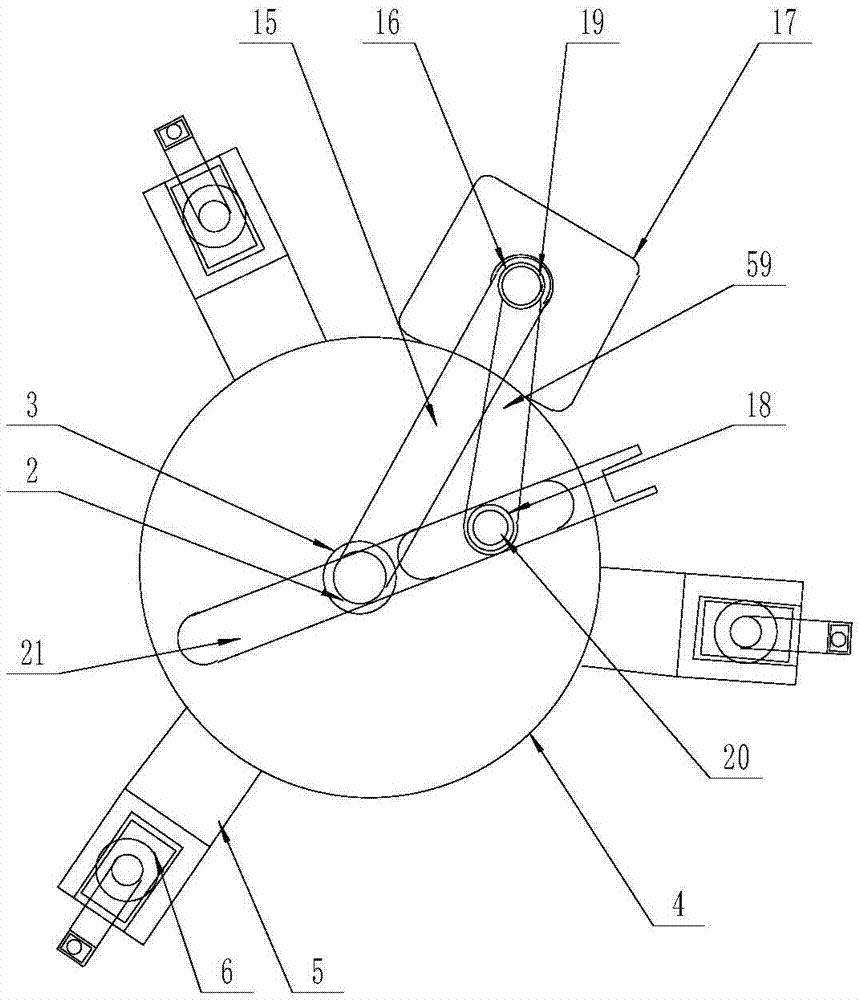

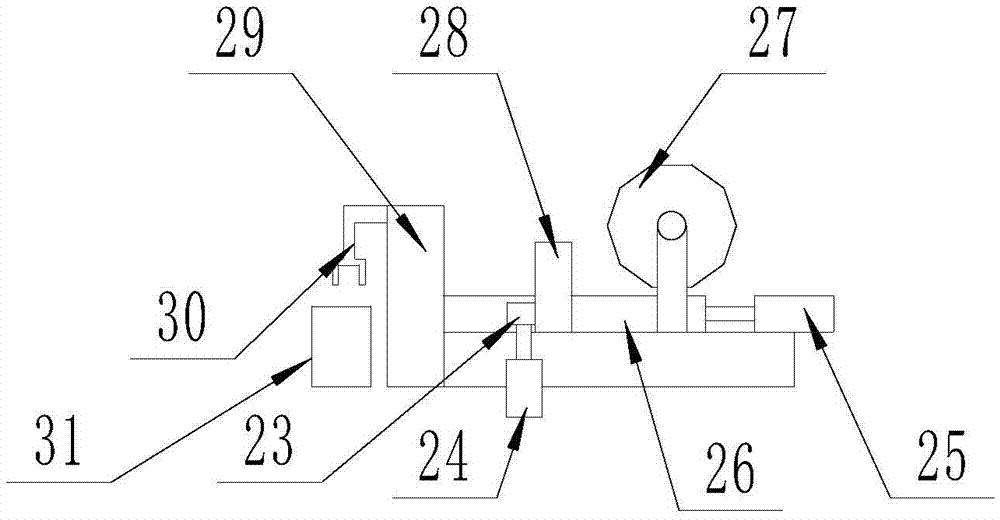

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a two-way periodic fork safety tube welding device includes a cuboid mobile base (1), the four corners of the outer lower surface of the mobile base (1) are provided with a mobile mechanism, and the mobile base (1) ) is equipped with two groups of wire terminal devices and welding mechanism, the welding mechanism is located between the two groups of wire terminal devices, the wire terminal device includes a feeding mechanism, a twisting mechanism, a terminal mechanism and a periodic pulling Fork rotation grabbing mechanism, the feeding mechanism, twisting wire mechanism, punching terminal mechanism and other angles are distributed on the surface of the mobile base (1), and the periodic fork rotating grabbing mechanism is located on the feeding mechanism, twisting wire mechanism, punching terminal At the center of the terminal mechanism, the periodic fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com