Garbage classification and recovery system

A recycling system and garbage classification technology, applied in garbage collection, trash cans, household appliances, etc., can solve the problems of low garbage disposal and recycling efficiency, inability to classify solid garbage by size, etc., and achieve the effect of improving recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

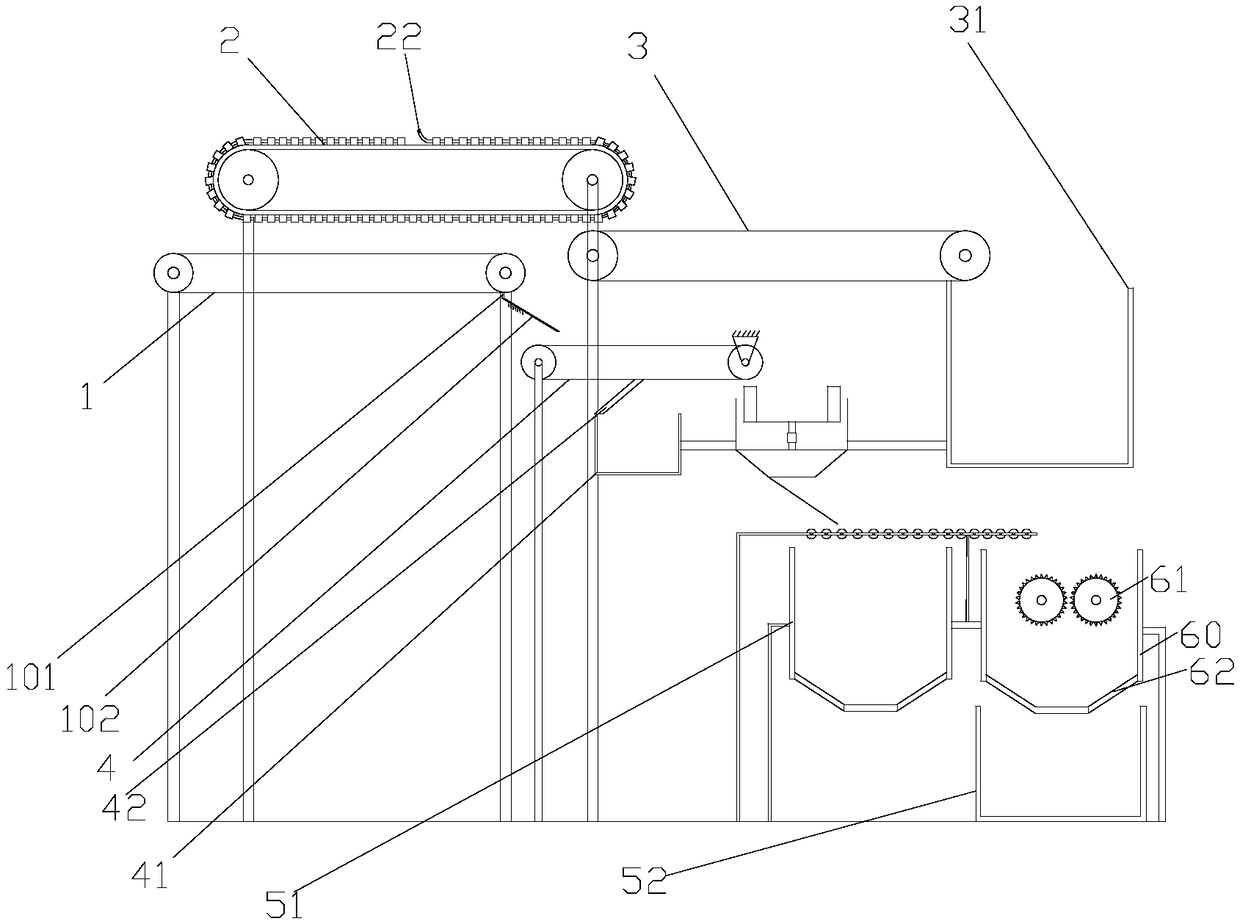

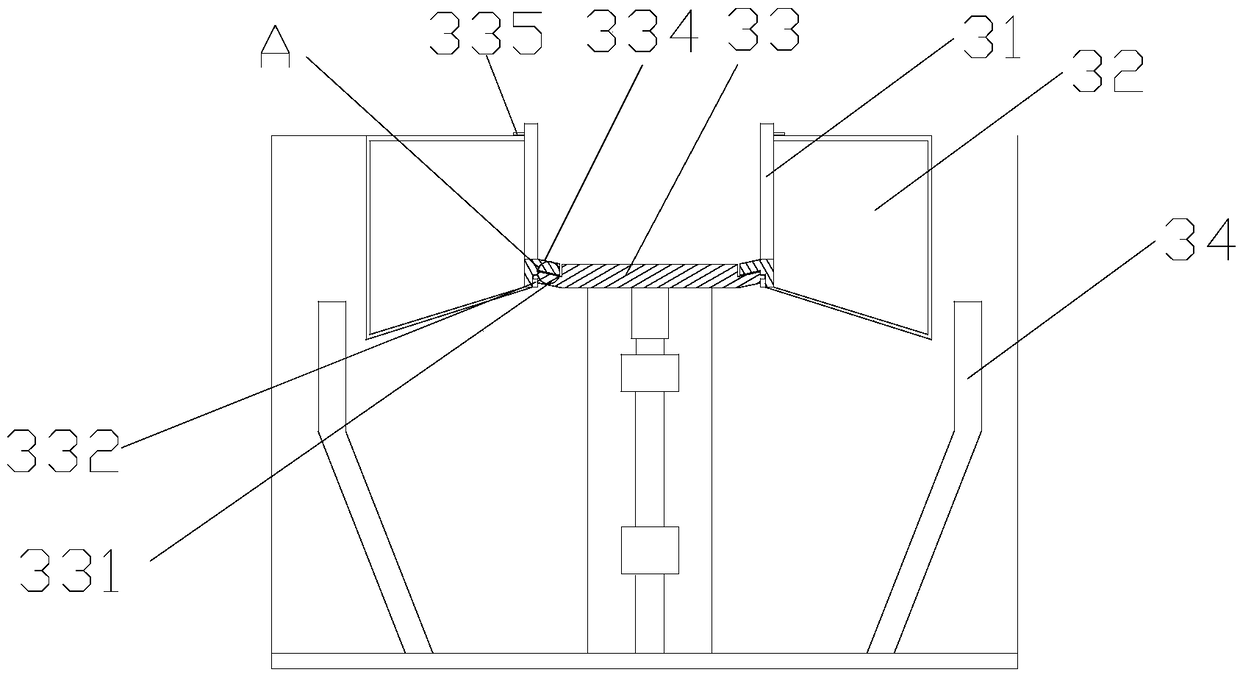

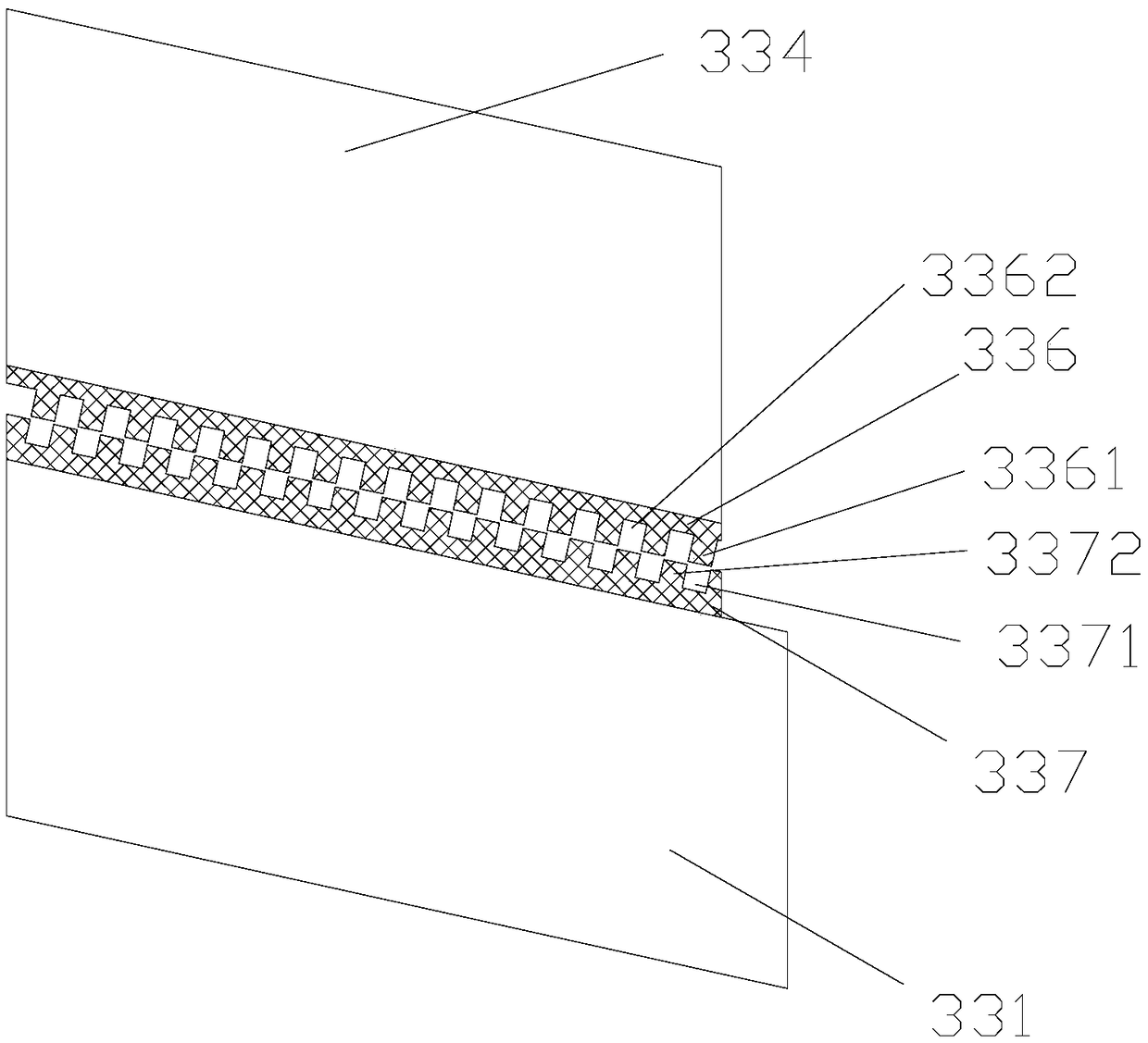

[0026] Such as Figure 1-6 As shown, a garbage sorting and recycling system includes a first separation device, a second separation device for separating metals, a third separation device for separating liquids, and a crushing device for processing garbage. The first separation device It is used to separate the plastics in the garbage, including the first conveyor belt 1 for transporting the initial garbage, the second conveyor belt 2 above the first conveyor belt, the third conveyor belt 3 and the separation cylinder 31 at the bottom right of the second conveyor belt, so The first conveyor belt is a conventional conveyor belt, and the second conveyor belt is provided with a negative pressure suction mechanism for sucking plastic out of the garbage; the negative pressure suction mechanism includes an air suction pump 21, a suction nozzle 22 and a connecting pipe 23, Described suction pump 21 is fixedly connected on the second conveyer belt, and suction pump selects the convent...

Embodiment 2

[0032] Such as Figure 7-8 As shown, the difference between this implementation and Embodiment 1 is that the pulverizing device includes a first pulverizing box 70, a first pulverizing roller 71, a driving structure for driving the first pulverizing roller to rotate, and a separation mechanism located below the first pulverizing box 70. The conveyor belt 72 and the collection box 73 located below the separation conveyor belt, the first pulverizing roller 71 is located in the first pulverizing box, and is used to pulverize the larger solid waste for subsequent processing and recycling; the driving structure includes the first A driving part 741, a driving shaft 742, a driven shaft 743 and a fixed part, the first driving part is a conventional motor that can be purchased on the market, and one end of the driving shaft 742 is fixedly connected to the output end of the first driving part 741, so One end of the drive shaft 742 is locked in rotation through a keyway, one end of the ...

Embodiment 3

[0036] Such as Figure 9-11 As shown, the difference between this embodiment and Embodiment 1 is that the crushing device includes a screening structure, a first recovery box 51, a crushing box located at the bottom right of the screening assembly and a second recovery box 52 located below the crushing box, The first recovery box 51 is used to collect small solid waste that does not need to be crushed, and the second recovery box 52 is used to collect crushed garbage; the screening structure includes a first support frame 80, a plurality of roller bars 81, Be fixed on the transmission gear on the two ends of the roller bar 81, the dredging parts, the transmission chain 83 and the driving part that drives the transmission chain to rotate. Rotate, and then drive the garbage on the rod to move, the smaller garbage that does not need to be crushed will fall into the first recovery box 51 through the gap between the two rollers 81, and the larger garbage will be transported to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com