Pure natural botanical insecticide and preparation method thereof

A natural plant and insecticide technology, applied in the field of pesticides, can solve the problems of uneven laying of materials, affecting the grinding quality of grinding balls, reducing grinding efficiency, etc., to save grinding time, improve grinding quality, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of pure natural plant insecticide, described preparation method is suitable for preparing above-mentioned pure natural plant insecticide, and the method steps are as follows:

[0055] S1: Take Cnidium Fructus Cnidii, camphor, tobacco leaf, chamae chamaejasma, flavescens, licorice and nuxychia by weight and put them into the grinder successively to grind into powder;

[0056] S2: Add the mixed powder obtained in step S1 into the leaching kettle, add water, emulsifier and dispersant according to the proportion, heat and stir fully;

[0057] S3: After cooling the mixture obtained in step S2, put it into a centrifuge for high-speed centrifugation, collect the finished product and put it in a medicine tank, and close the medicine tank.

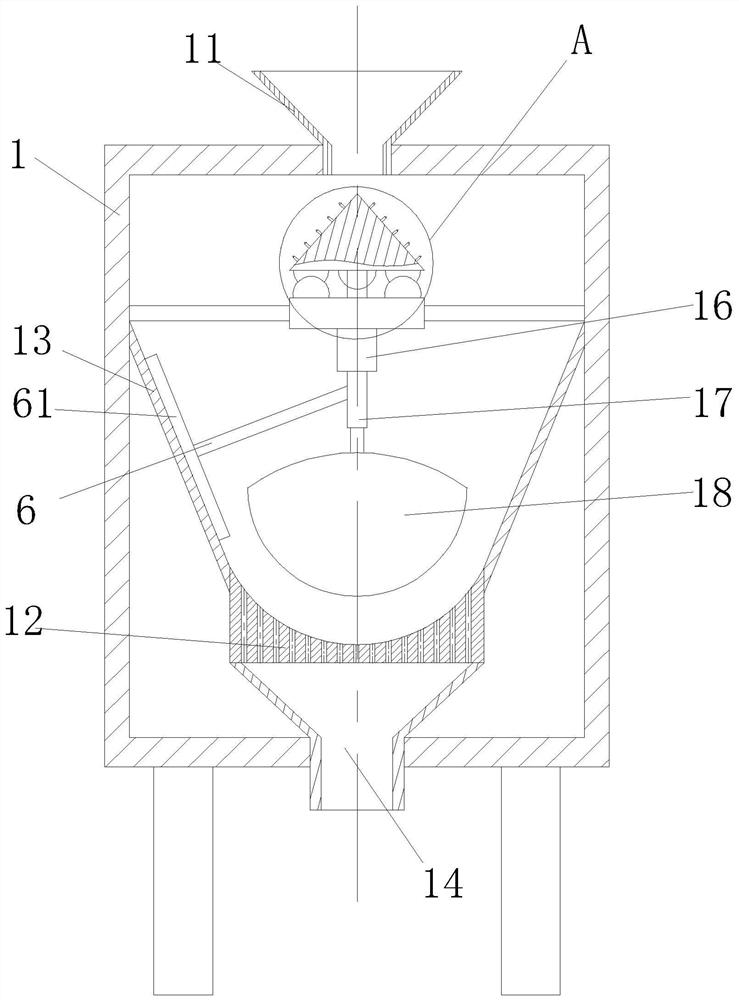

[0058] The grinding machine described in S1 includes a grinding box 1; a feed hopper 11 is arranged at the center of the top of the grinding box 1; a grinding seat 12 is fixedly connected to the grinding box 1 through ...

Embodiment approach

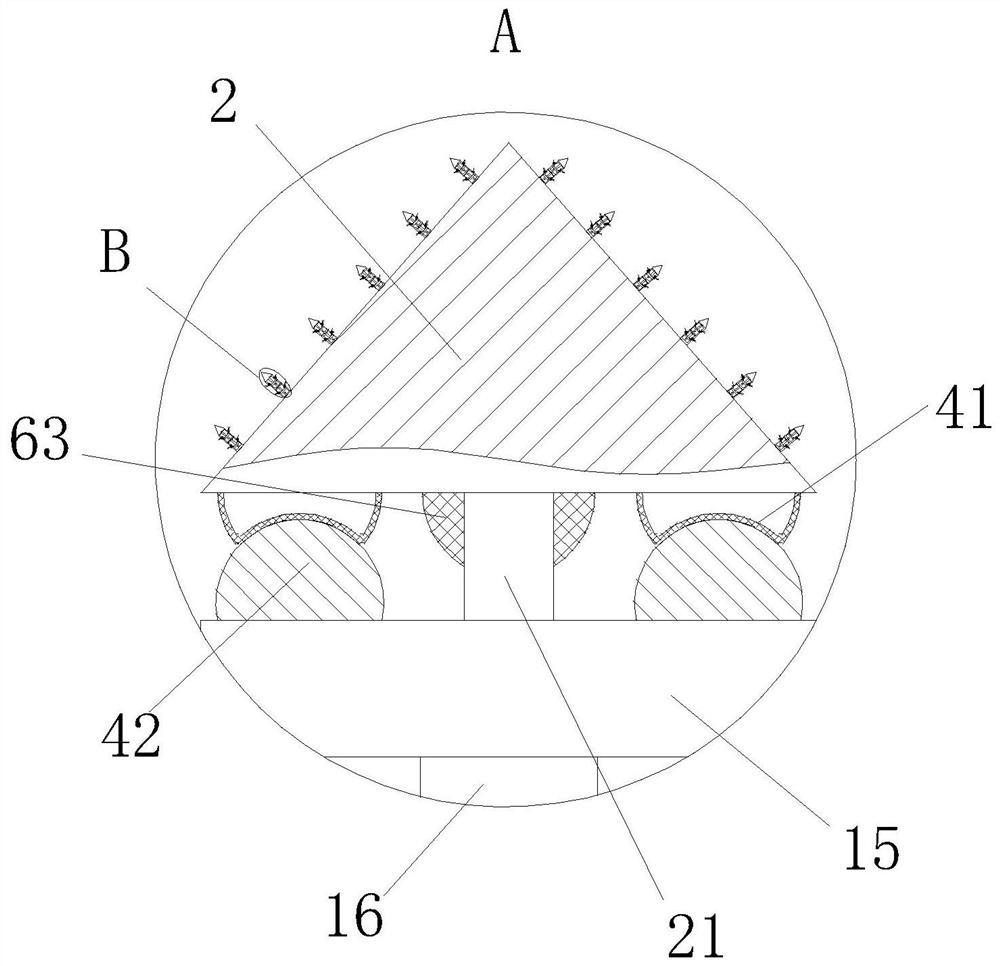

[0059] As an embodiment of the present invention, a set of push rods 3 are fixedly connected to the outer wall of the conical block 2; the push rods 3 include a conical end block 31, a first connecting rod 32 and a second connecting rod 33 ; The first connecting rod 32 and the second connecting rod 6 are provided with a first cavity 34; the inner wall of the first cavity 34 is slidably connected with a first push plate 35, and the first push plate 35 is connected by a spring Fixed on the top side wall of the first cavity 34; the bottom end of the first connecting rod 32 is fixed on the side wall of the tapered block 2; the bottom end of the second connecting rod 33 and the bottom end of the tapered end block 31 Both are fixedly connected with a first connecting rod 36; the first connecting rod 36 at the bottom end of the second connecting rod 33 extends into the first cavity 34 of the first connecting rod 32, and the end is fixedly connected to the first push plate 35 On; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com