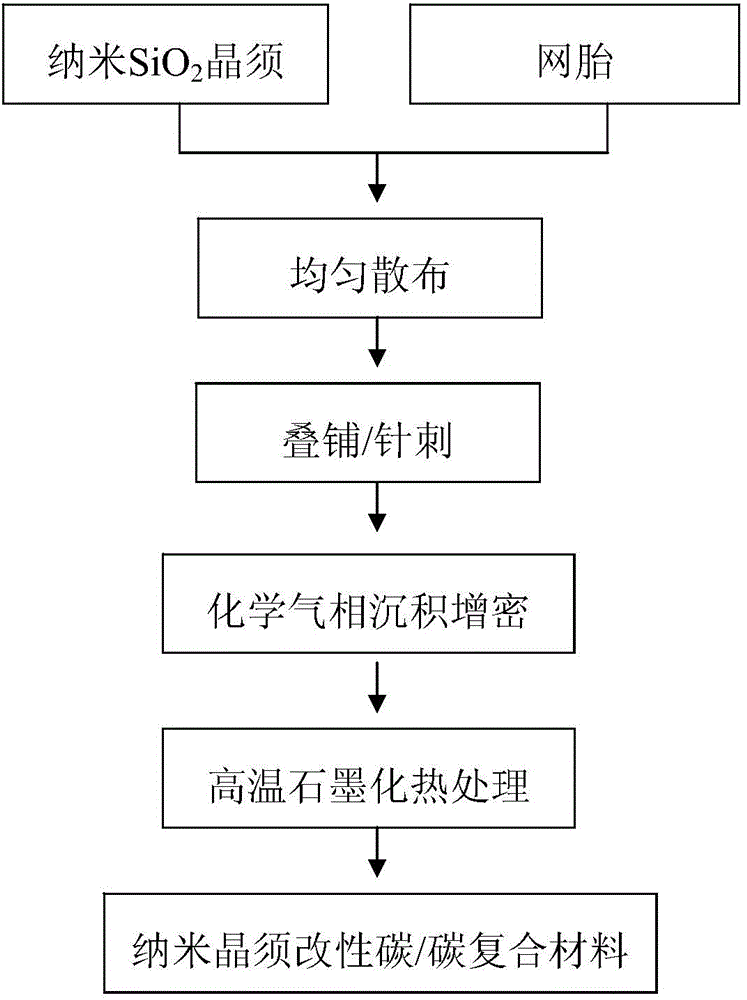

Preparation method of whisker modified carbon/carbon composite material

A technology of carbon composite materials and modified carbon, which is applied in the field of carbon/carbon composite material preparation to achieve the effect of changing pyrolytic carbon nucleation, improving uniformity and dispersion, and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) SiO with a diameter of about 100 nm and a length of about 1 μm 2 Whiskers are evenly spread on the upper and lower surfaces of each layer of carbon fiber mesh with a fine-mesh sieve, and 15 layers of mesh are stacked layer by layer, and the layers of mesh are connected by acupuncture to prepare an initial density of 0.21g / cm 3 Full net tire carbon fiber prefabricated body, control SiO in the prefabricated body 2 The mass fraction of whiskers is 6%;

[0033] (2) Implement densification in a CVI furnace for 62 hours with propylene as the carbon source gas and nitrogen as the diluent gas;

[0034] (3) Carry out high-temperature graphitization heat treatment in a vacuum induction graphitization furnace for 1 hour, and control the temperature at 2300°C. The process is as follows: in a protective atmosphere, first raise the temperature from room temperature to 1800°C at a rate of 750°C / h, and then Raise the temperature at 19°C / h to 2000°C, then raise the temperature at ...

Embodiment 2

[0037] (1) SiO with a diameter of about 100 nm and a length of about 1 μm 2 Whiskers are evenly spread on the upper and lower surfaces of each layer of carbon fiber mesh with a fine-mesh sieve, and the 18 layers of mesh are stacked layer by layer, and the layers of mesh are connected by acupuncture to prepare an initial density of 0.23g / cm 3 Full net tire carbon fiber prefabricated body, control SiO in the prefabricated body 2 The mass fraction of whiskers is 7%;

[0038] (2) Implement densification in a CVI furnace for 65 hours with propylene as the carbon source gas and nitrogen as the diluent gas;

[0039](3) Perform high-temperature graphitization heat treatment in a vacuum induction graphitization furnace for 1.5 hours, and control the temperature at 2400°C. The process is as follows: in a protective atmosphere, first raise the temperature from room temperature to 1800°C at a rate of 800°C / h, and then Raise the temperature at 200°C / h to 2000°C, then raise the temperatur...

Embodiment 3

[0042] (1) SiO with a diameter of about 100 nm and a length of about 1 μm 2 Whiskers are evenly spread on the upper and lower surfaces of each layer of carbon fiber mesh with a fine-mesh sieve, and the 20 layers of mesh are stacked layer by layer, and the layers of mesh are connected by acupuncture to prepare an initial density of 0.3g / cm 3 Full net tire carbon fiber prefabricated body, control SiO in the prefabricated body 2 The mass fraction of whiskers is 8%;

[0043] (2) Using propylene as the carbon source gas and nitrogen as the diluent gas to implement densification in a CVI furnace for 70 hours;

[0044] (3) Carry out high-temperature graphitization heat treatment in a vacuum induction graphitization furnace for 1.5 hours, and control the temperature at 2400°C. The process is as follows: in a protective atmosphere, first raise the temperature from room temperature to 1800°C at a rate of 1000°C / h, and then Raise the temperature at 210°C / h to 2000°C, then raise the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com