Double axial warp knitting machine

A warp knitting machine, biaxial technology, applied in the field of warp knitting machines, can solve the problems that the fabric performance cannot meet the higher use requirements and the application range is narrow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The accompanying drawings disclose the specific structures of the embodiments of the present invention, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

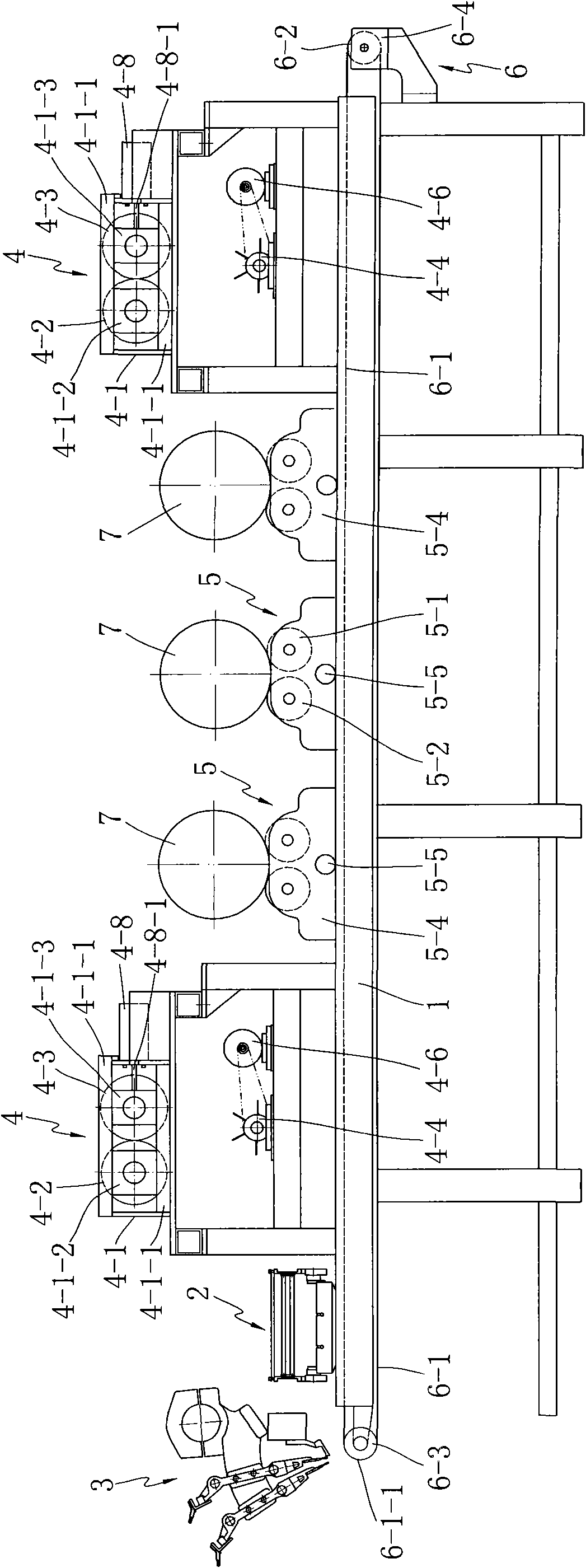

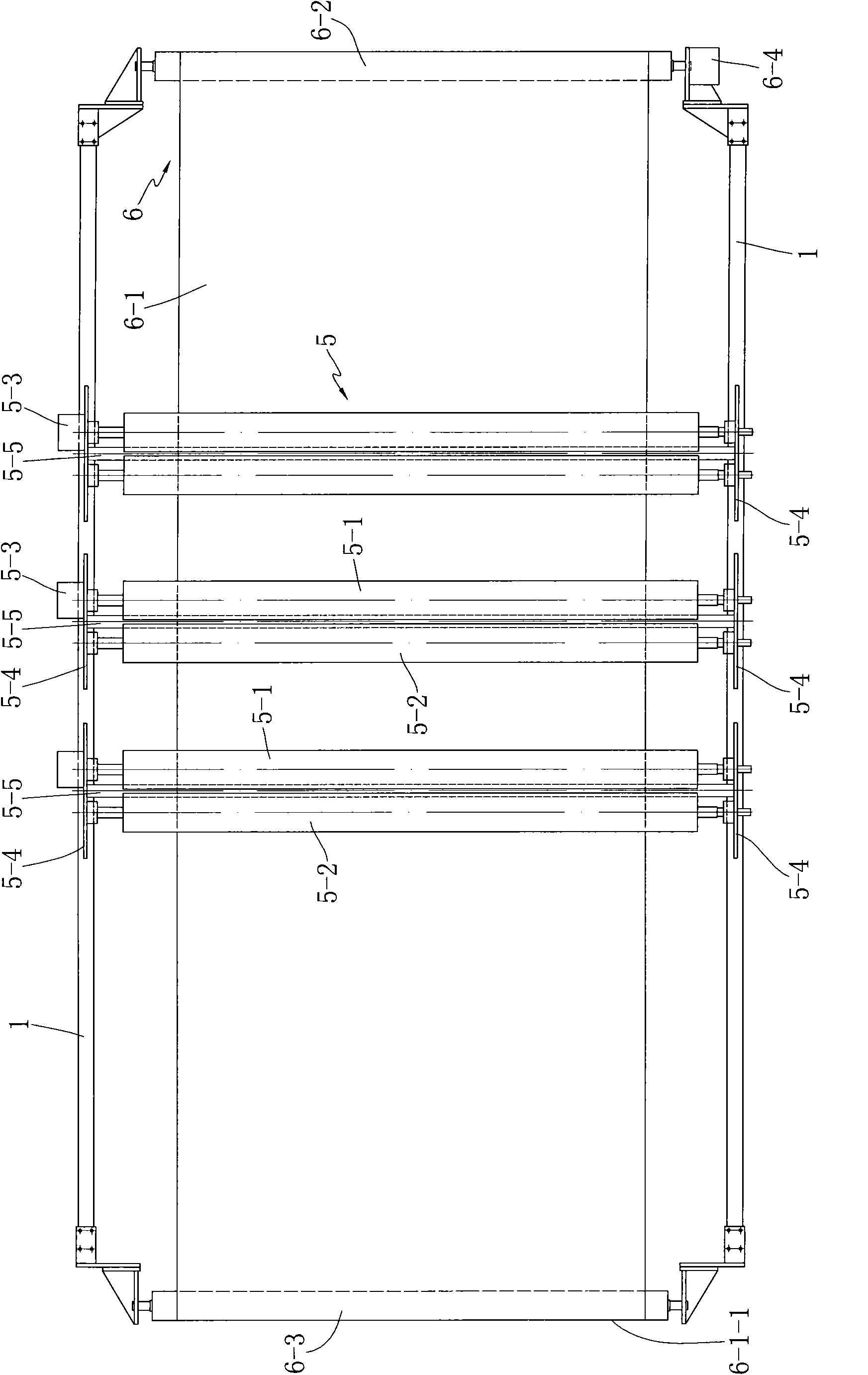

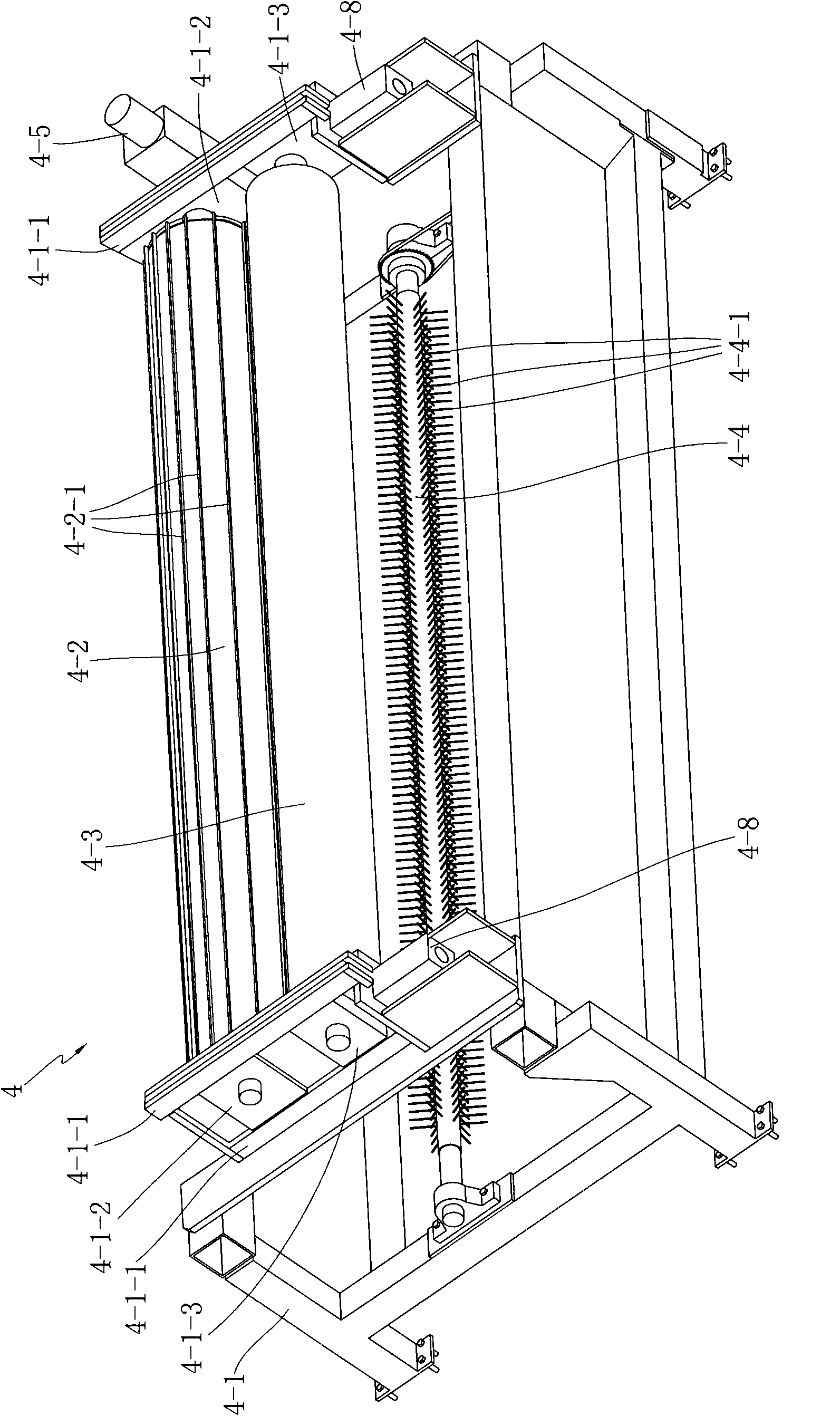

[0024] see figure 1 with Figure 4 The shown biaxial warp knitting machine includes: the warp yarn on the creel is unwound and sent to the warp lining mechanism in the knitting area; The unwound weft yarn is laid between the beams 1 on both sides of the warp knitting machine and sent into the weft insertion mechanism 2 in the knitting area by the chain; The fabric formed after binding is pulled out from the knitting area and wound into a pulling and winding mechanism for cloth rolls; the warp knitting machine also includes at least two fiber chopping machines 4 that can cut the fibers into specified lengths and are arranged in adjacent At least one cloth feeding mechanism 5 between the fiber chopping machine 4 and the conveying mechanism 6 arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com