Screening device for efficient separation and slagging of mass-flow slurry

A kind of screening equipment and high flow technology, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of high-efficiency screening treatment of slurry that cannot be large flow, hinder the uniform transmission of vibration force, and increase production costs, etc., to achieve Simple structure, improved vibration effect, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

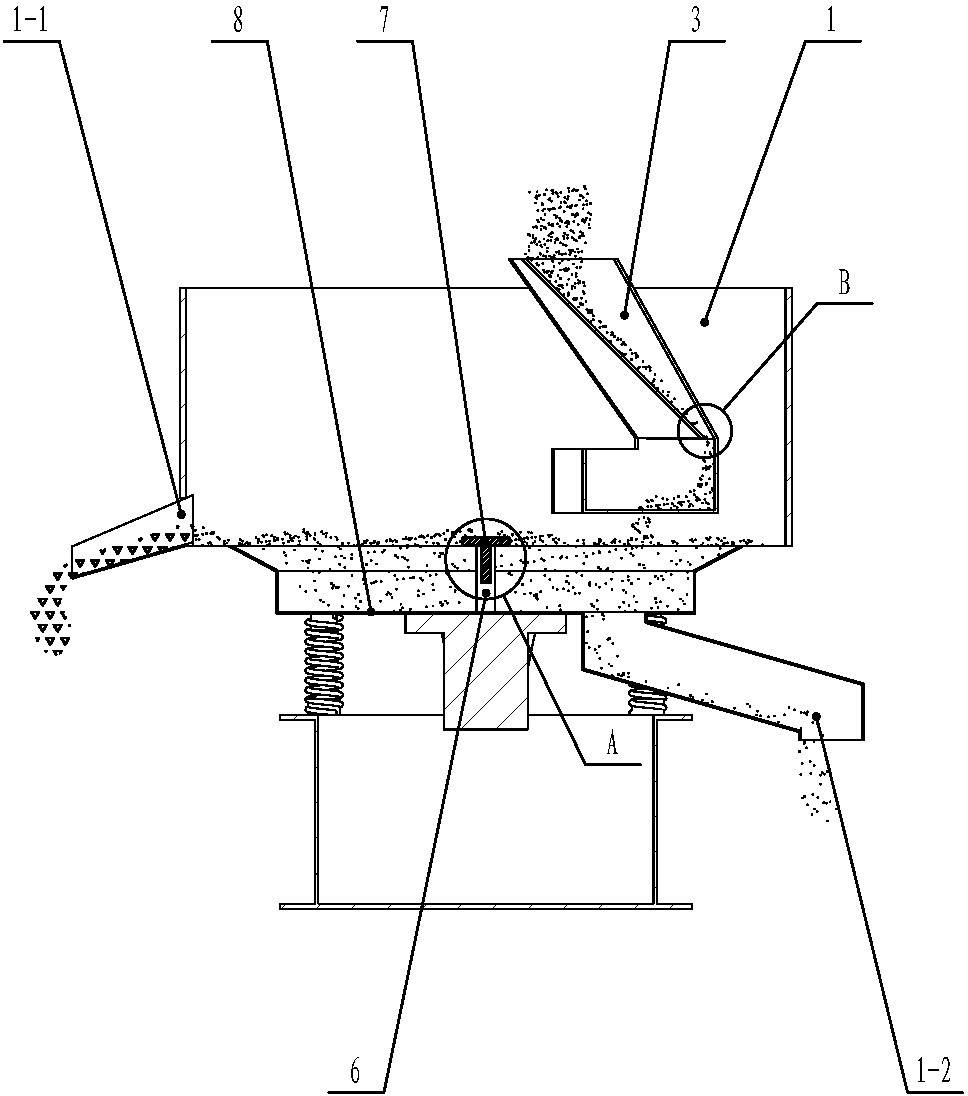

[0034] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0035] A screening device for efficiently separating and discharging slag from large-flow slurry is based on a conventional vibrating screen with additional supports, baffles and distributors.

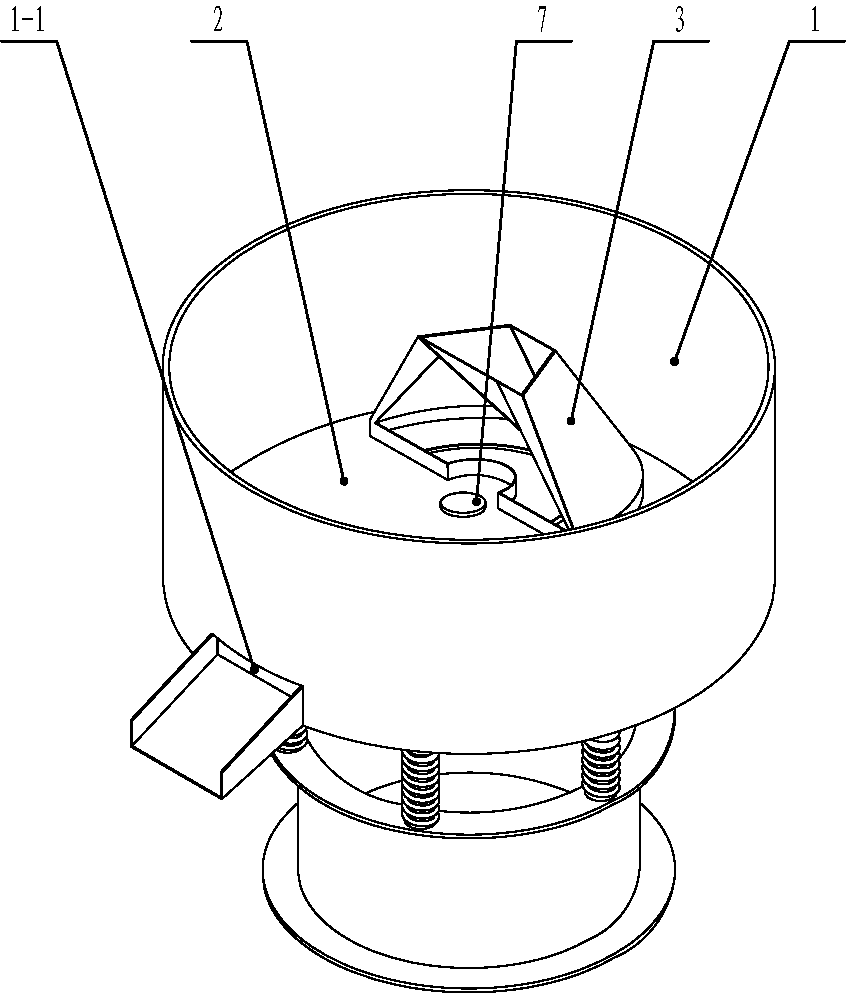

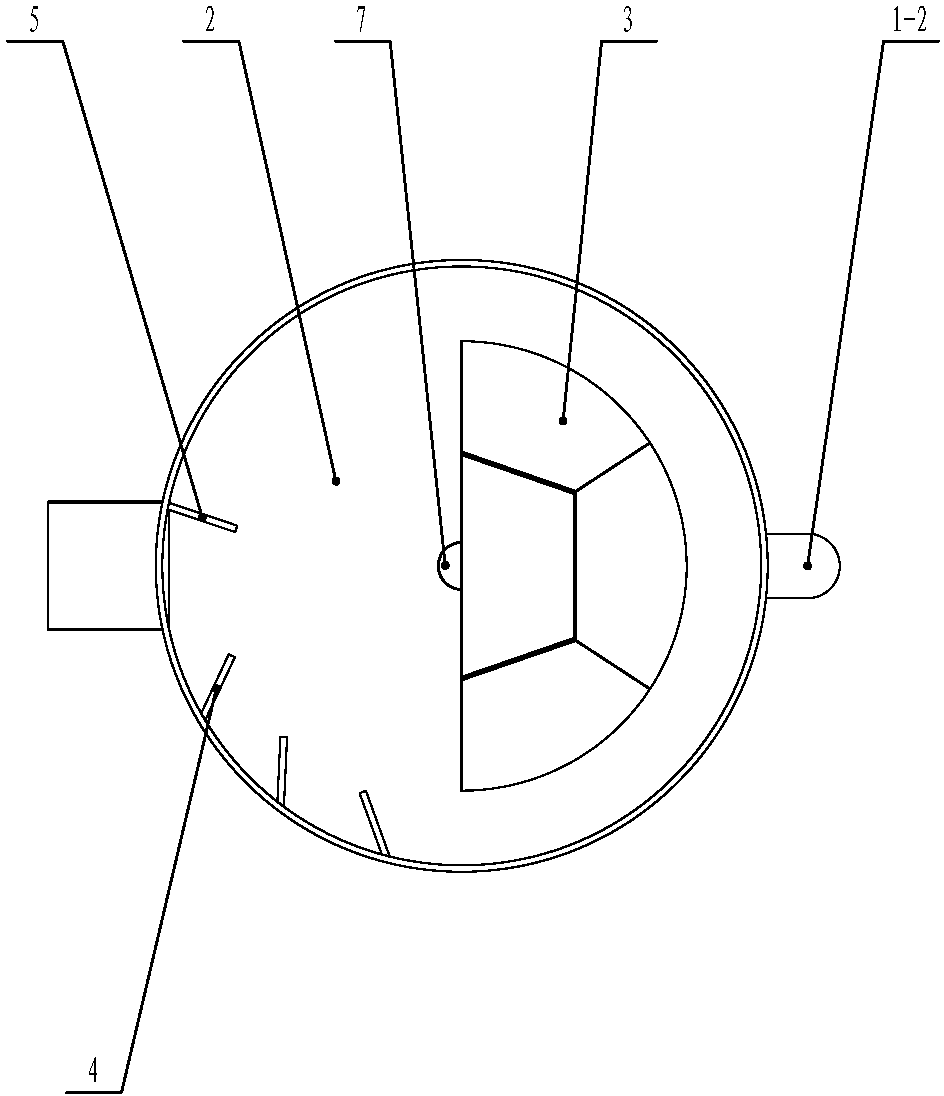

[0036] The specific implementation is as follows: figure 1 and 2 As shown, the equipment includes a vibrating screen frame 8, a screen frame 1 surrounding the screen frame 8, and a screen 2 fixed on the screen frame 1, and the screen frame 1 is also provided with a slag discharge port 1-1. One end of the baffle plate 4 is fixed on the inner wall of the screen frame 1 on both sides of the slag discharge port 1-1 and is located above the screen 2, and the other end faces the slag discharge port 1-1. The bottom edge of the baffle plate 4 contacts or is close to the upper surface of the screen cloth 2 . In order to better improve the screening effect, the length occup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com