Wheel set shaft for an electric drive unit mounted on the axle and drive unit

A wheel-to-axle and motor technology, applied in the field of wheel-to-axle, can solve the problems of increasing manufacturing cost, high cost, etc., and achieve the effect of reducing types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

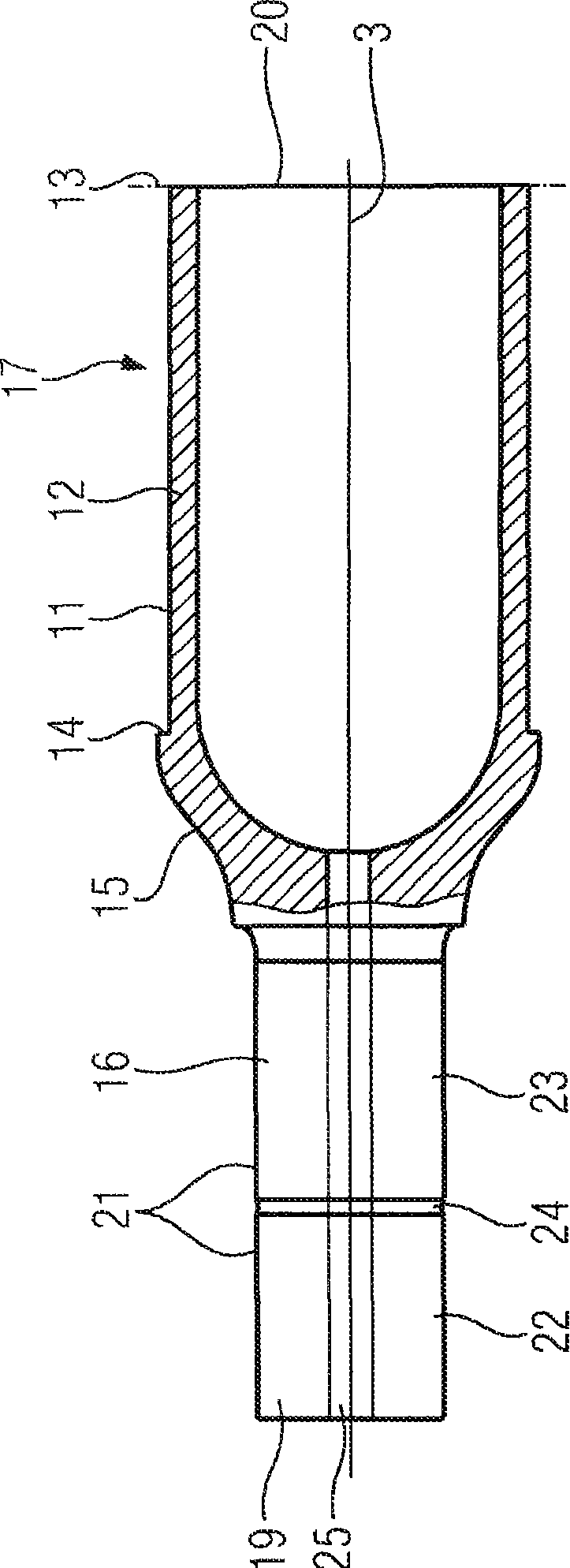

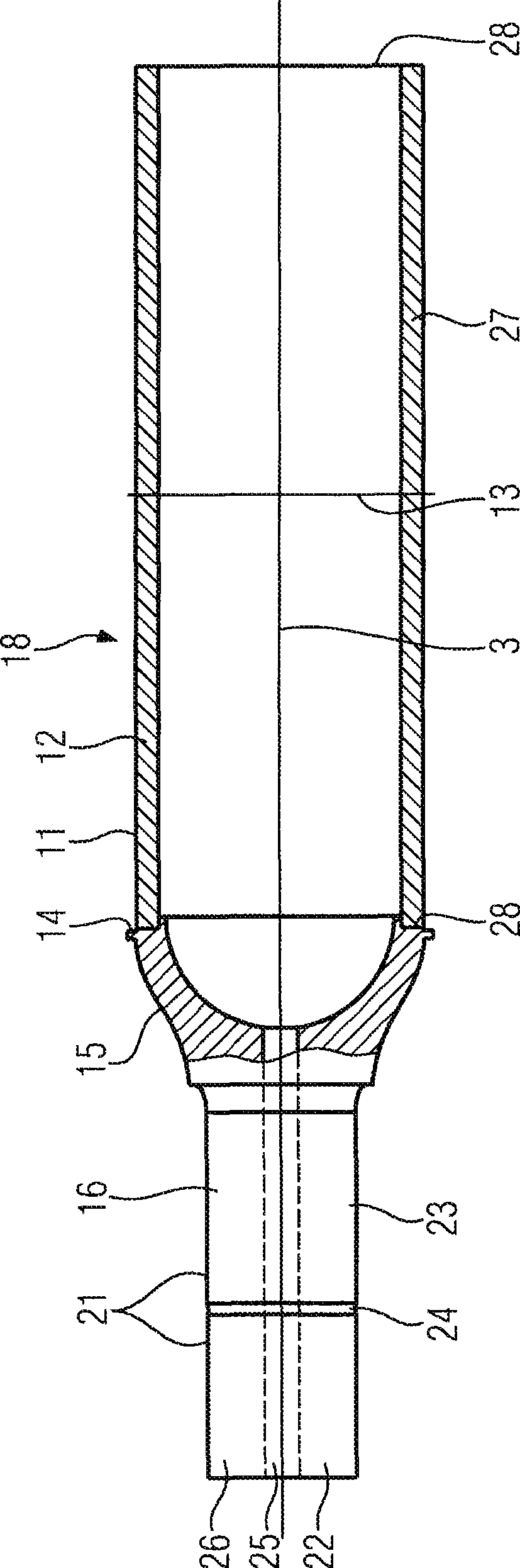

[0022] same parts in Figure 1 to Figure 3 are indicated by the same reference symbols.

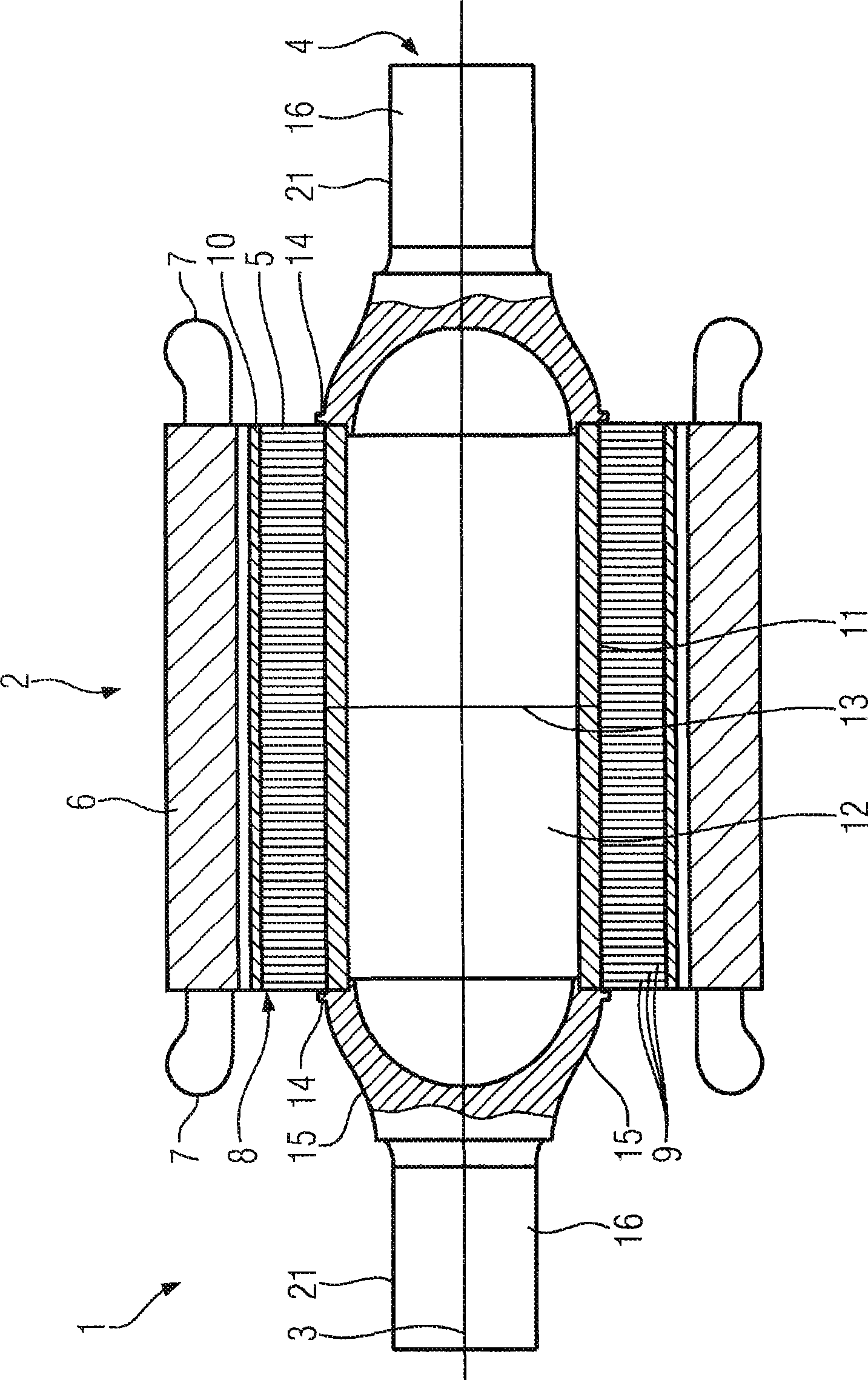

[0023] figure 1 Shown is an exemplary embodiment of a gearless drive unit 1 with an electric motor 2 and a wheel shaft 4 driven to rotate about a rotational axis 3 . In this embodiment, the motor 2 is a permanent magnet synchronous motor, the rotor 5 of which is directly mounted on the wheel set shaft 4 . That is to say, the drive unit 1 is a gearless shaft-mounted non-flexible wheel set direct drive. This type of drive is mainly used in figure 1 on rail vehicles not shown in detail.

[0024] The motor 2 basically adopts a common structure. In addition to the rotor 5, the electric motor 2 also includes a stator 6 with a winding system, figure 1 Only the two axial end windings 7 of this winding system are shown schematically. The rotor 5 includes a stack of laminations 8 which has a plurality of punched laminations 9 stacked one after the other along the axial direction. A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com