High-frequency-vibration servo hydraulic cylinder

A servo hydraulic cylinder and high-frequency vibration technology, applied in the field of hydraulic cylinders, can solve the problems of low precision, large vibration amplitude and low vibration frequency of hydraulic cylinders, and achieve the effects of good dynamic characteristics, space saving and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

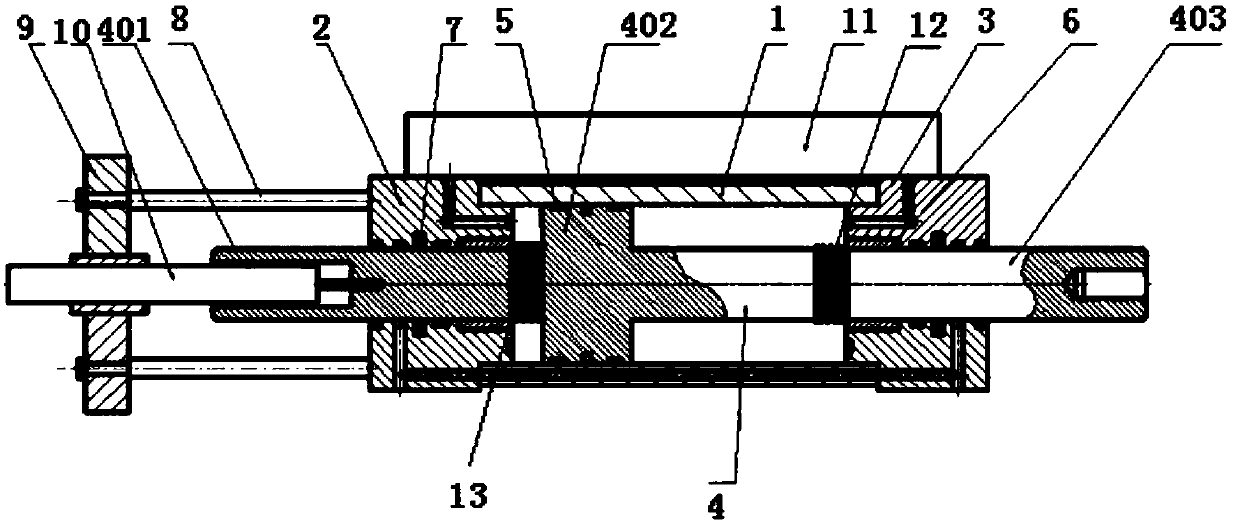

[0020] A high-frequency vibration servo hydraulic cylinder, such as figure 1 As shown, including the cylinder 1, the left and right end faces of the cylinder 1 are sealed and fixed with two identical left cylinder heads 2 and right cylinder heads 3, the cylinder 1 is sleeved with a piston rod 4, and the two ends of the piston rod 4 pass through the left and right cylinders. The cylinder head 2 and the right cylinder head 3 are sealed and fixed in the left cylinder head 2 and the right cylinder head 3;

[0021] The left cylinder head 2 and the right cylinder head 3 include a cylinder head and a sealing ring fixed on the end face of the cylinder head. The radius of the sealing ring is 3-5 cm smaller than that of the cylinder head. The outer surface of the side wall of the fixed ring, and the two end faces of the cylinder barrel 1 and the end face of the cylinder head are compressed and sealed and fixed simultaneously, and the surfaces of the left cylinder head 2 and the right cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com