Hibiscus cannabinus straw light anti-crack insulating mortar and preparation method thereof

A technology of thermal insulation mortar and kenaf, which is applied in the field of new materials, can solve the problems affecting the safety of highways and civil aviation traffic, the difficulty of comprehensive utilization, waste of straw, etc., and achieve broad market space and application prospects, good economic and social benefits, and increased Effect of large wall thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

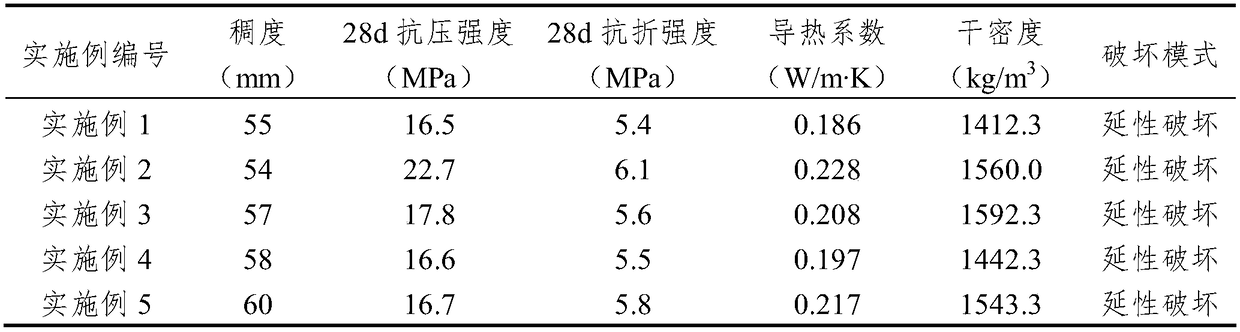

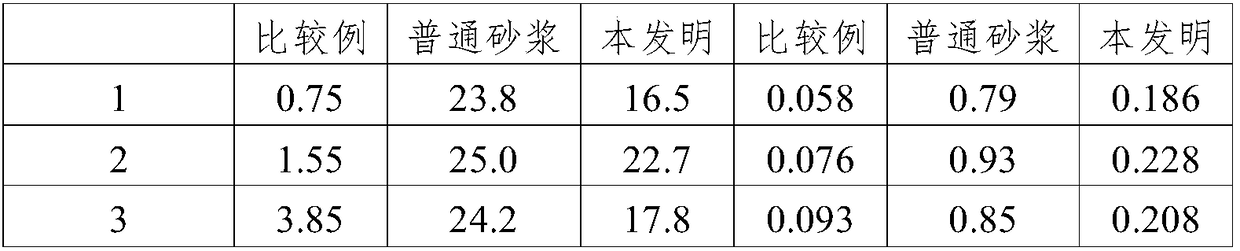

Examples

Embodiment 1

[0031] Kenaf stalk anti-crack thermal insulation mortar, said kenaf straw anti-crack thermal insulation mortar comprises the following components: Portland cement and microsilica fume form a cementitious material, wherein microsilica fume is 4%, cement is 96%, and both The sum of the weight component percentages is 100%;

[0032] In terms of cementitious material, kenaf straw fiber is 0.5%, fly ash floating beads are 2.4%, kenaf straw core is 24%; water is 89%; the mass ratio of cementitious material to sand is 1:2.

[0033] Wherein said cement is 42.5 grade ordinary Portland cement; said sand is medium sand with good particle size distribution; said microsilica fume SiO 2The content is 92%, and the fineness is 0.1-5 μm, wherein the part with a fineness less than 1 μm accounts for more than 80%; the particle size of the fly ash floating beads is 80-120 mesh; firstly, the obtained kenaf straw is crushed with a crusher Crushing, the crushed kenaf stalks are initially screened f...

Embodiment 2

[0038] Kenaf stalk anti-crack thermal insulation mortar, said kenaf straw anti-crack thermal insulation mortar comprises the following components: Portland cement and microsilica fume form a cementitious material, wherein microsilica fume is 12%, cement is 88%, and both The sum of the weight component percentages is 100%;

[0039] In terms of cementitious material, 1.5% of kenaf straw fiber, 2.4% of fly ash floating beads, 12% of kenaf straw core; 84% of water; the mass ratio of cementitious material to sand is 1:2.

[0040] Wherein said cement is 42.5 grade ordinary Portland cement; said sand is medium sand with good particle size distribution; said microsilica fume SiO 2 The content is 92%, and the fineness is 0.1-5 μm, wherein the part with a fineness less than 1 μm accounts for more than 80%; the particle size of the fly ash floating beads is 80-120 mesh; firstly, the obtained kenaf straw is crushed with a crusher Crushing, the crushed kenaf stalks are initially screened ...

Embodiment 3

[0045] Kenaf straw anti-crack thermal insulation mortar, said kenaf straw anti-crack thermal insulation mortar comprises the following components by weight: Portland cement and silica fume form a cementitious material, wherein microsilica fume is 8% and cement is 92% , the sum of the percentages by weight of the two components is 100%;

[0046] In terms of cementitious material, 1.5% of kenaf straw fiber, 1.2% of fly ash floating beads, 12% of kenaf straw core; 65% of water; the mass ratio of cementitious material to sand is 1:2.

[0047] Wherein said cement is 42.5 grade ordinary Portland cement; said sand is medium sand with good particle size distribution; said microsilica fume SiO 2 The content is 92%, and the fineness is 0.1-5 μm, wherein the part with a fineness less than 1 μm accounts for more than 80%; the particle size of the fly ash floating beads is 80-120 mesh; firstly, the obtained kenaf straw is crushed with a crusher Crushing, the crushed kenaf stalks are initi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com