Patents

Literature

56results about How to "Has bactericidal ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fresh-keeping packaging material and products thereof

InactiveCN101701082AHigh strengthHigh air permeabilityFlexible coversWrappersDispersitySodium Bentonite

The invention relates to a fresh-keeping packaging material and products thereof, belonging to the technical field of packaging. The invention has the technical scheme that a certain proportion of mineral micropowder of kieselguhr or sepiolite or medical stone or bentonite or tephros or perlite and the like is doped into plastics of PE, PP, PVC and the like and paper pulp, and then the mixture is made into thin films, packaging paper or packaging bags or packaging boxes or packaging cases, trays and the like; the characteristics of dispersity, air permeability, adsorbability, far infrared ray and positive and negative ion function and the like of the mineral micropowder are utilized to enable the packaging material to generate micropores, and therefore, the packaging material has a certain air permeability and adsorbability or generates positive and negative ions or far infrared rays; gas and a small quantity of moisture which are generated from packaged articles are discharged from the micropores, and harmful gas is absorbed and transferred, and thereby, the heat value of the packaged articles can be effectively lowered; microbes are killed or restrained, thereby meeting the demands of keeping fresh of live and fresh food and prolonging storage life.

Owner:钟爱民

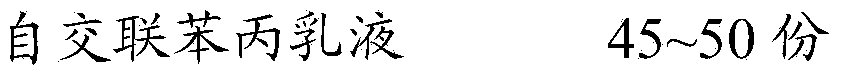

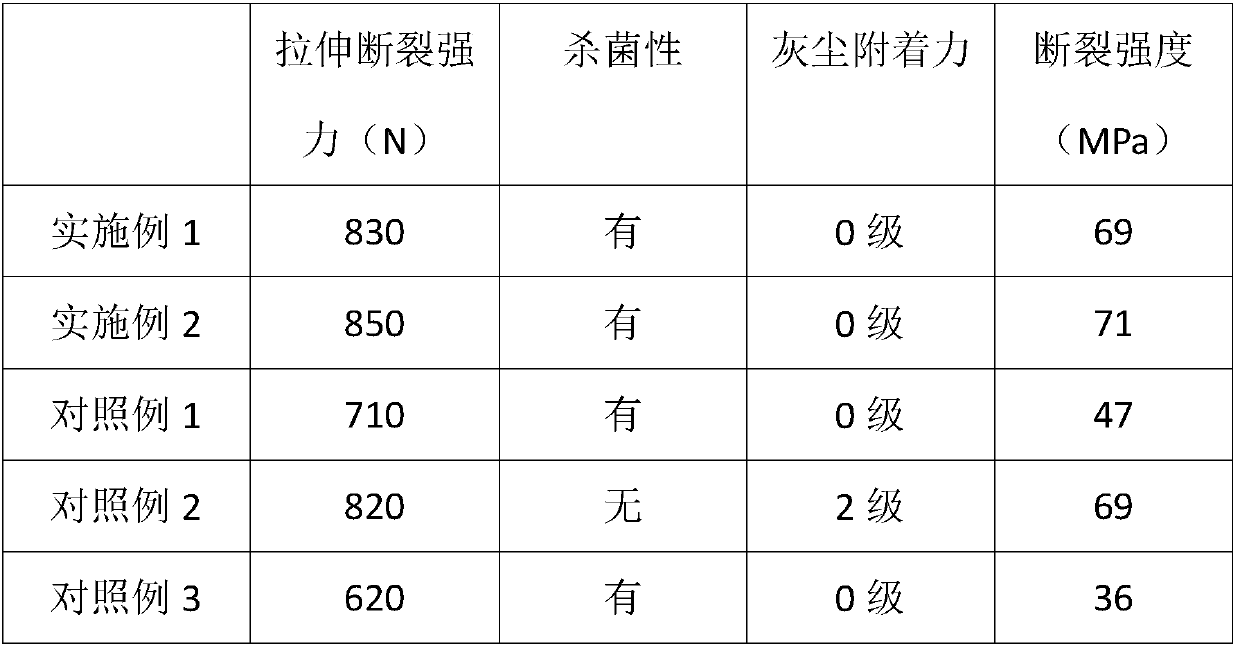

Waterborne ink and preparation method thereof as well as application of waterborne ink in PP (Polypropylene) decorative film

ActiveCN104371420ADry completelyGood reproducibilitySpecial ornamental structuresInksPolymer scienceSolvent based

The invention discloses a waterborne ink and a preparation method thereof, application of the waterborne ink in a PP (Polypropylene) decorative film and a preparation method of the PP decorative film. The preparation method of the waterborne ink comprises the following process steps: a, preparing mill base; b, grinding; and c, blending ink. The PP decorative film sequentially comprises a PP substrate layer, a waterborne ink printing layer and a varnish coating layer from bottom to top. The preparation method of the PP decorative film comprises the following process steps: 1) carrying out polarity treatment on the surface of the PP film; 2) preparing the waterborne ink; 3) printing the waterborne ink; 4) glazing and coating; and 5) embossing. By integrating the selection of materials and optimization of the process, the PP decorative film reaches the printing effect of a solvent-based ink, the printed product has no water mark, the texture is shallow and clear, natural and realistic and the PP decorative film is non-toxic and odorless and has excellent performances such as light resistance, scratch resistance, wear resistance, disinfection and sterilization; the preparation method is convenient and feasible in production processes, simple to operate and low in production cost, and is prone to industrial production.

Owner:佛山市南海天元茂新新材料有限公司

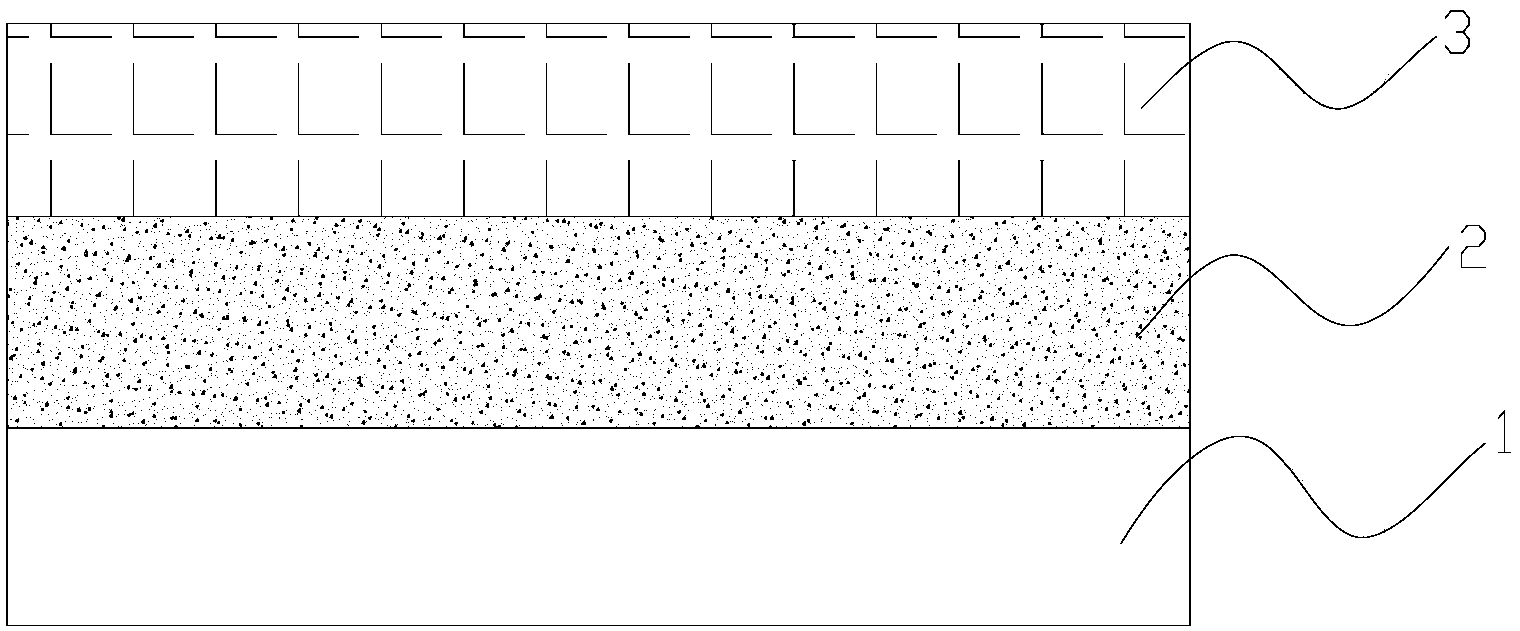

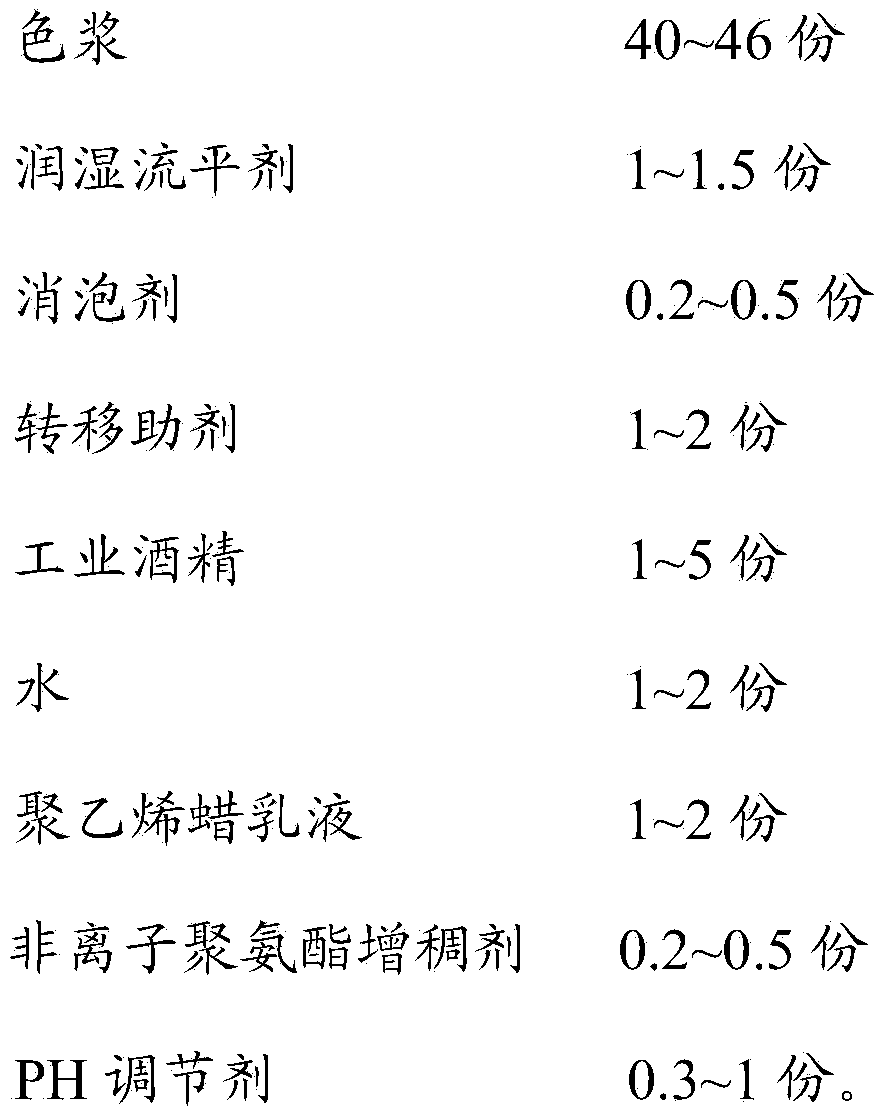

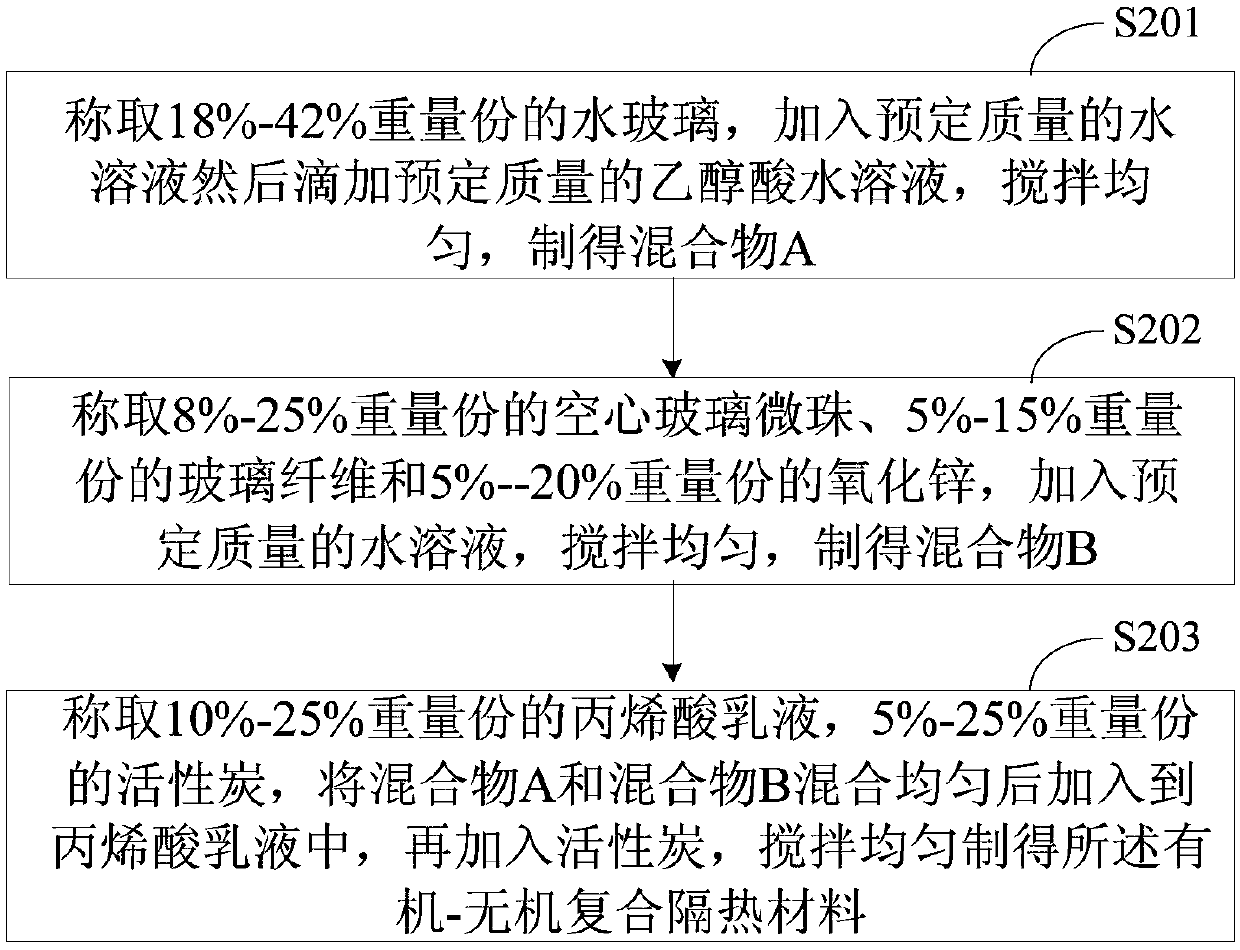

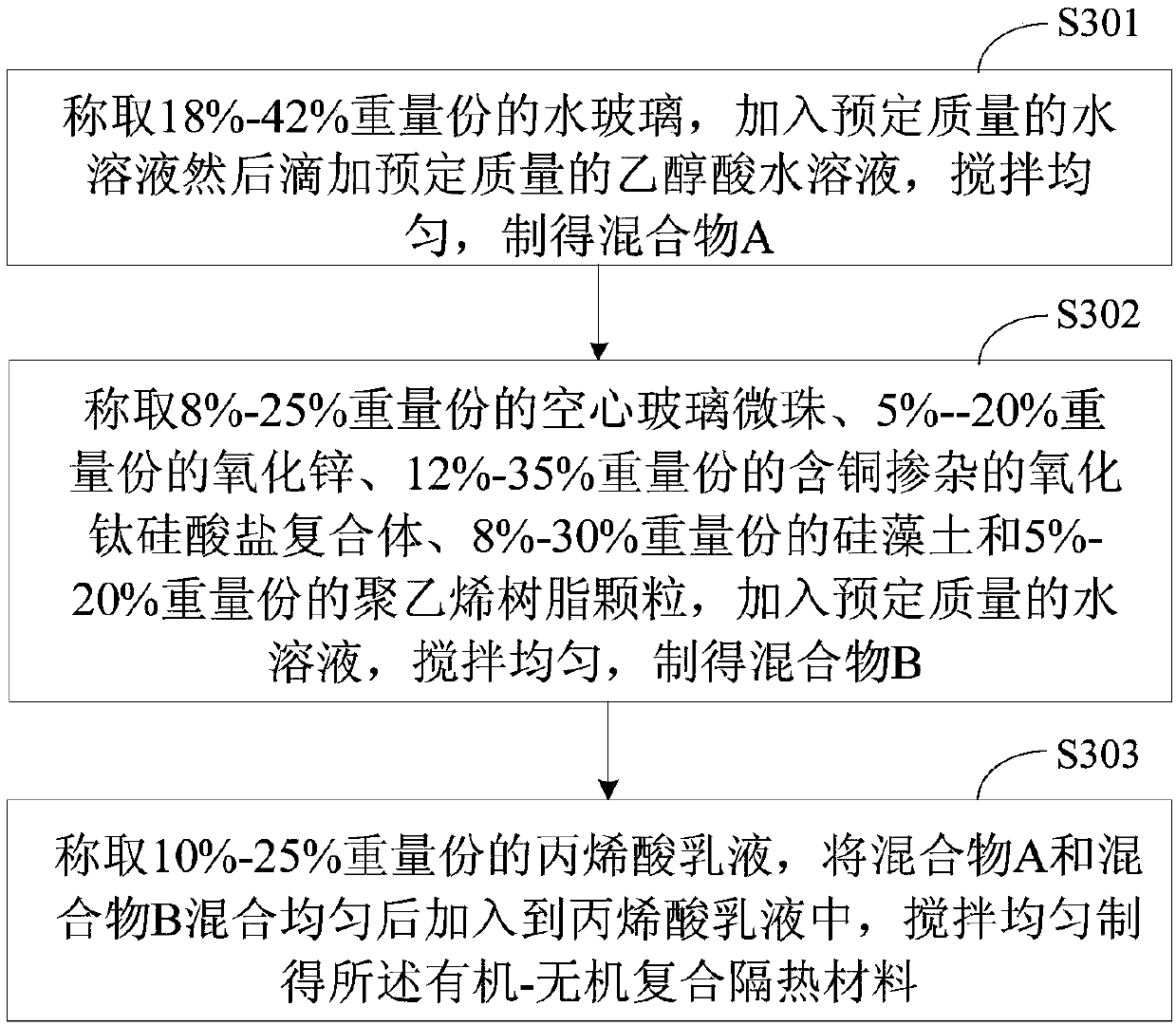

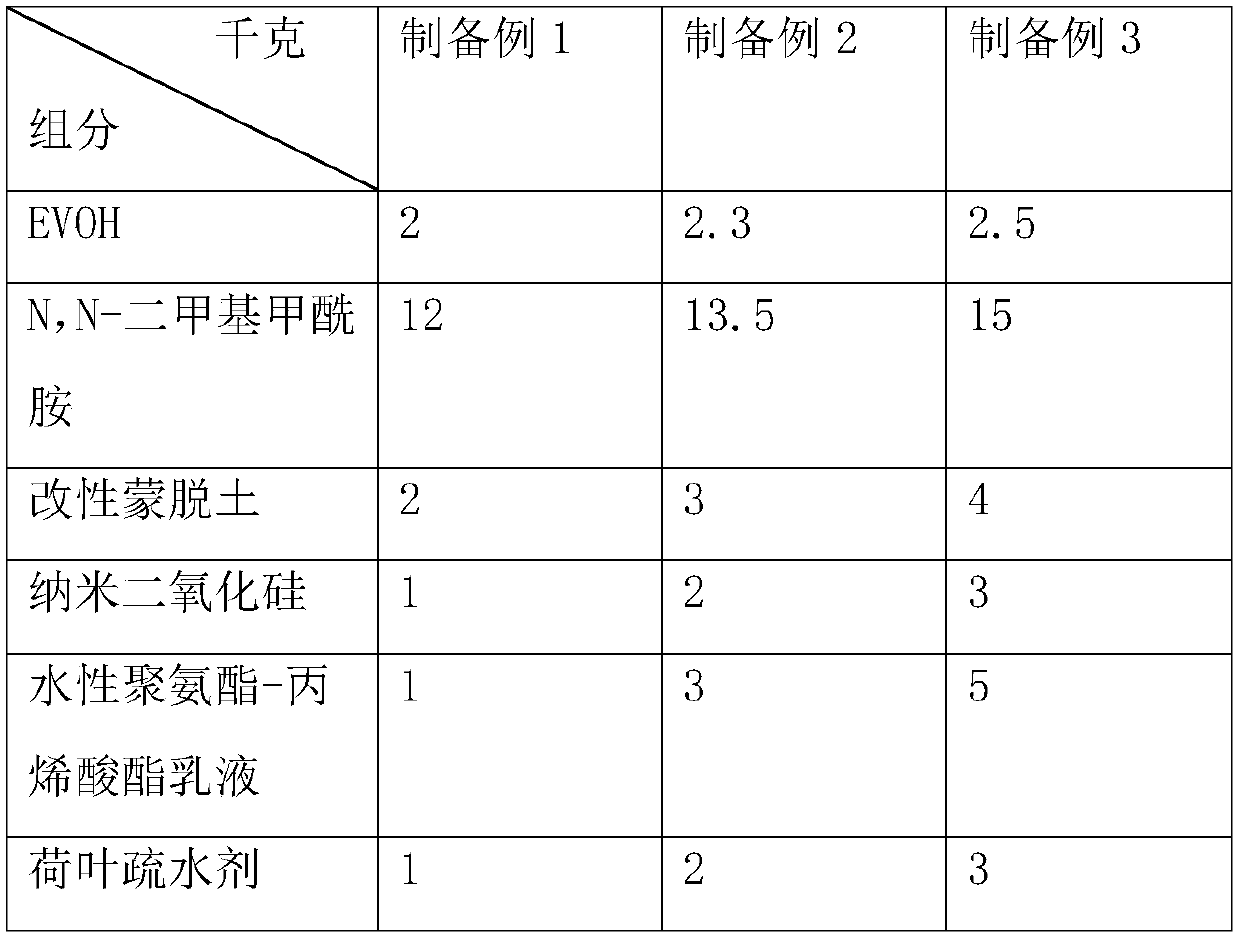

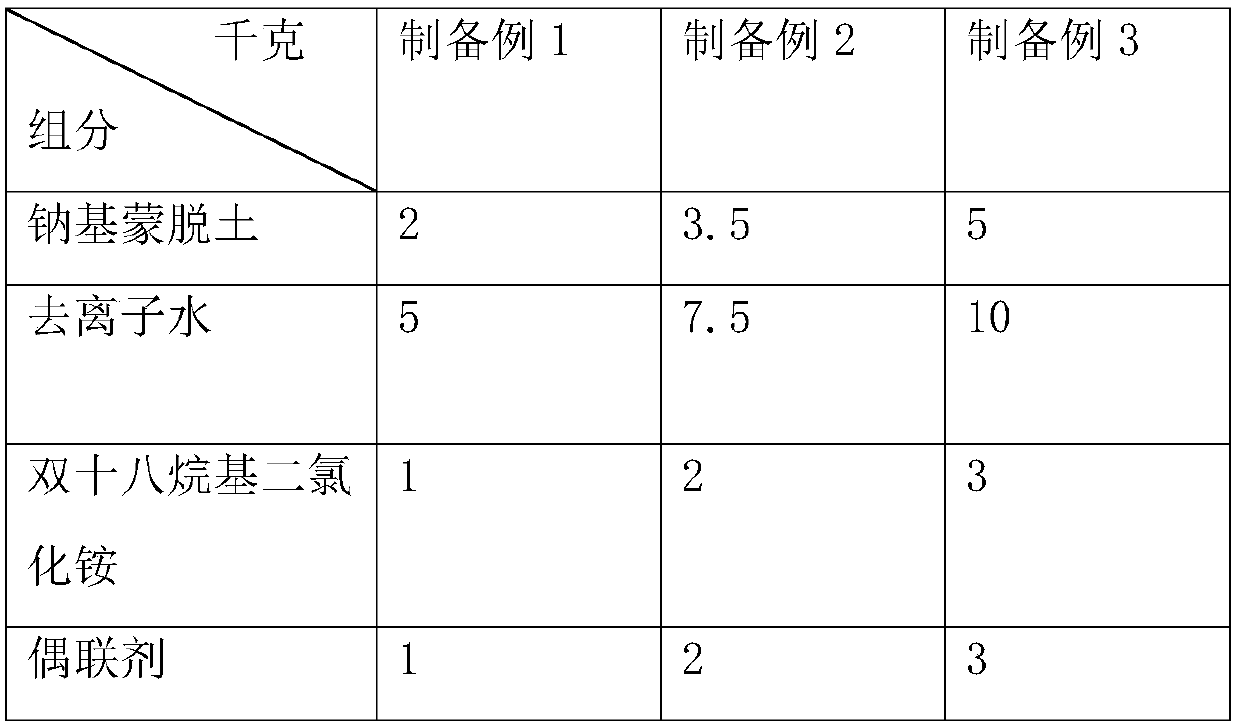

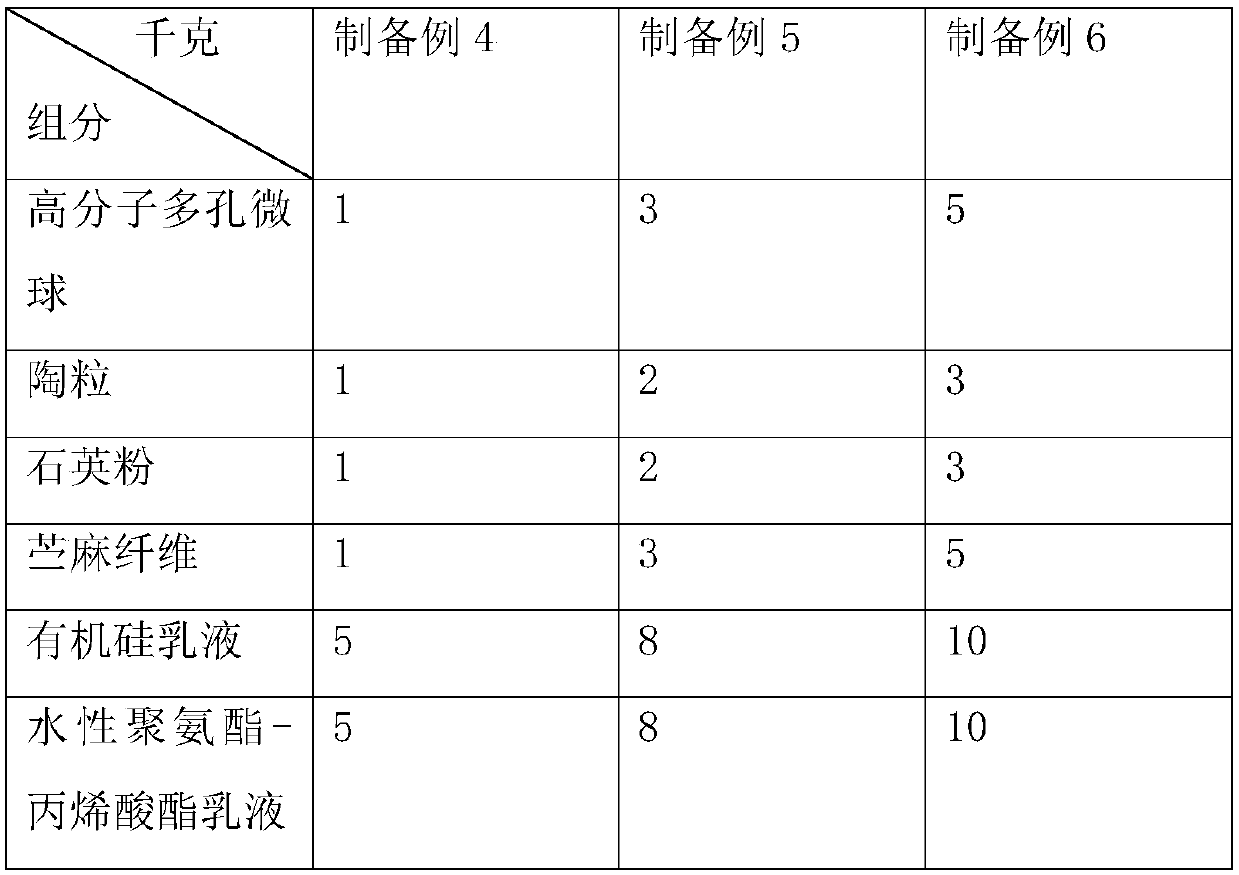

Organic/inorganic composite heat insulation coating and preparation method thereof

InactiveCN107746590AImprove adhesionImprove water resistanceFireproof paintsAntifouling/underwater paintsEmulsionSodium silicate

The invention discloses an organic / inorganic composite heat insulation coating and a preparation method thereof and belongs to the technical field of chemical coatings. The coating includes, by weight, 18-42% of sodium silicate, 10-25% of an acrylic emulsion, 8-25% of hollow glass microbeads, and 5-20% of zinc oxide. The coating is improved in adhesion force, alkaline resistance, pollution resistance and flame-retarding property, and also improves the water resistance, elasticity and glossiness of a coating film. The sodium silicate is low in cost and has abundant sources, so that cost of thecoating is effectively reduced.

Owner:南京洞见环境科技有限公司

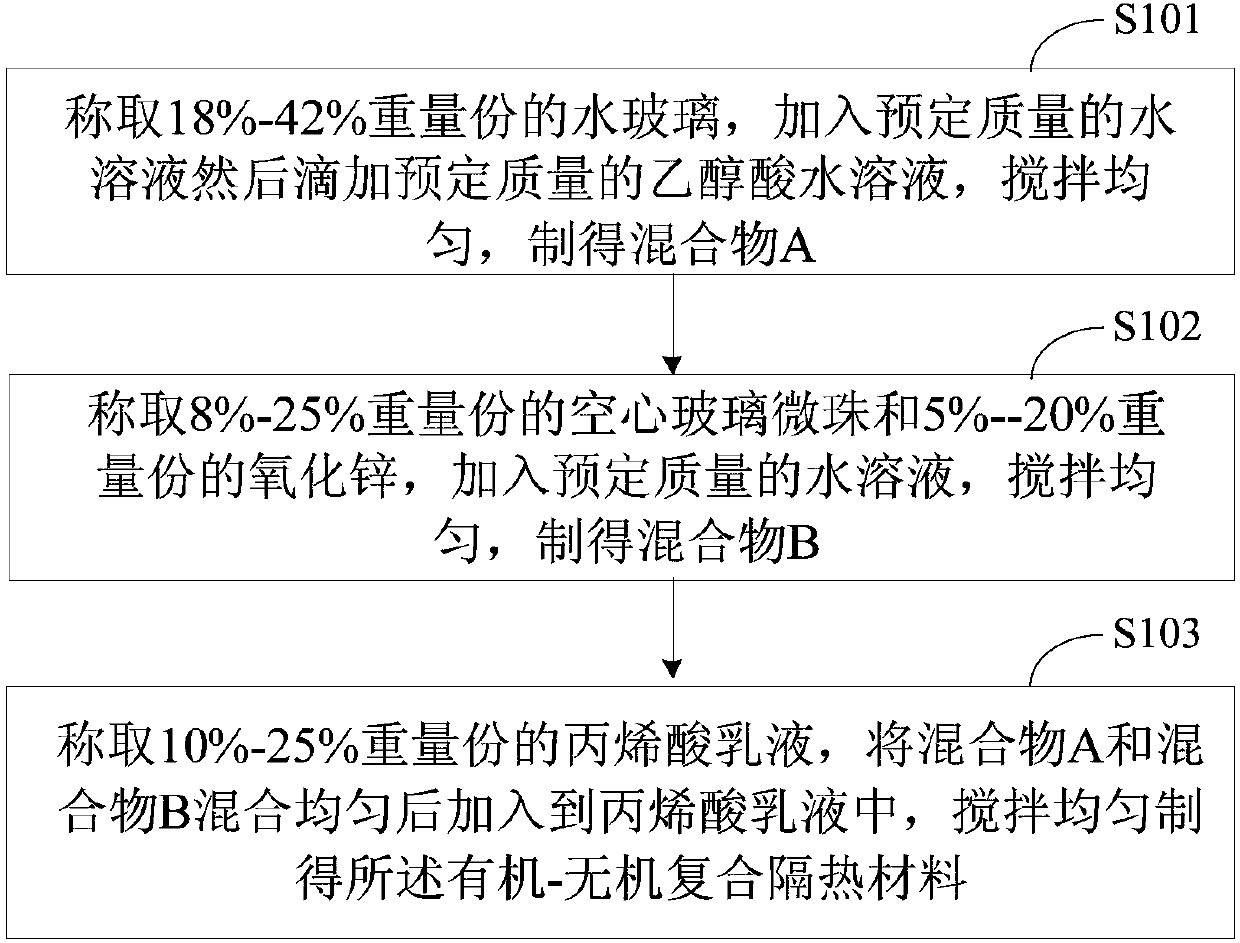

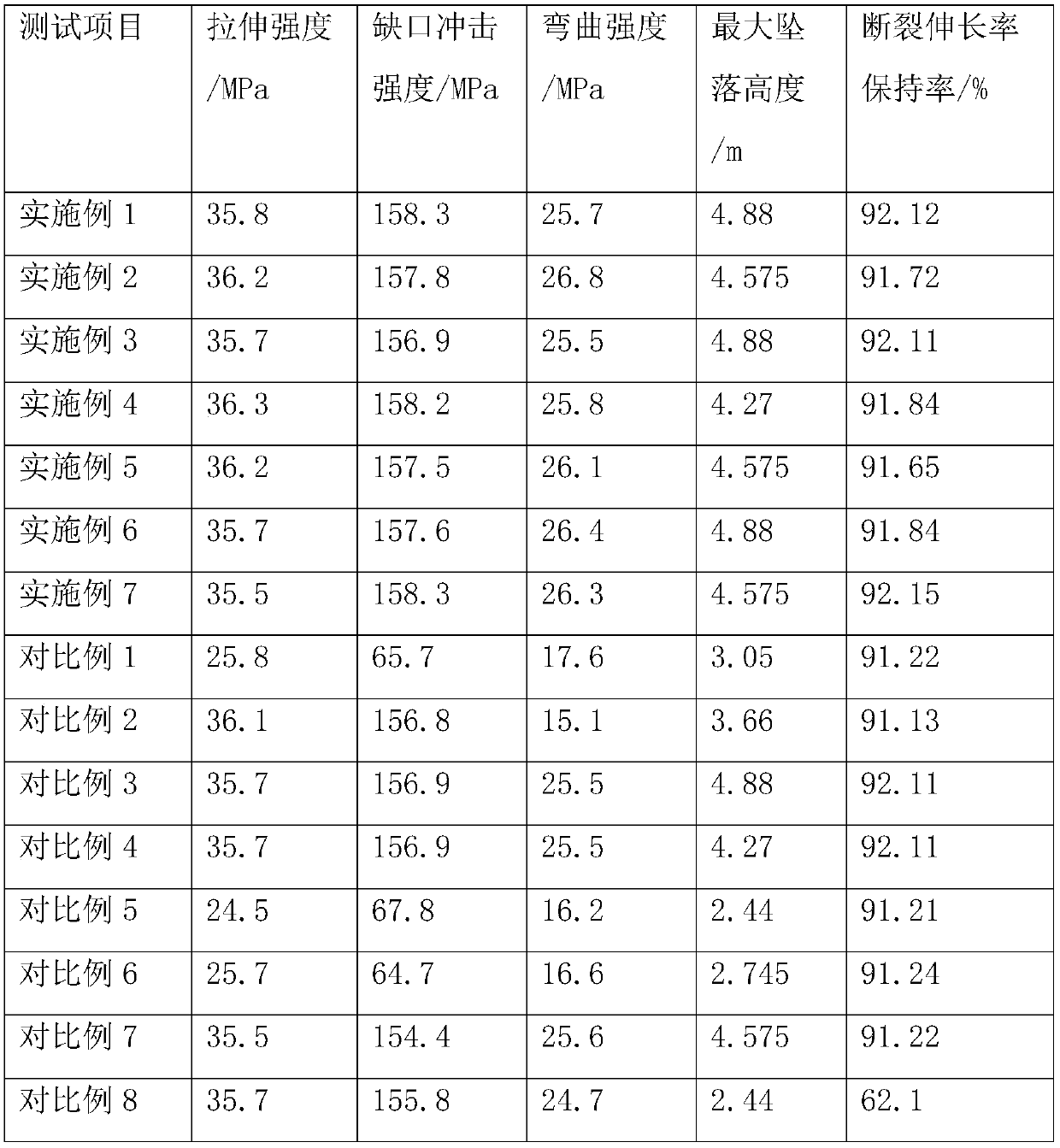

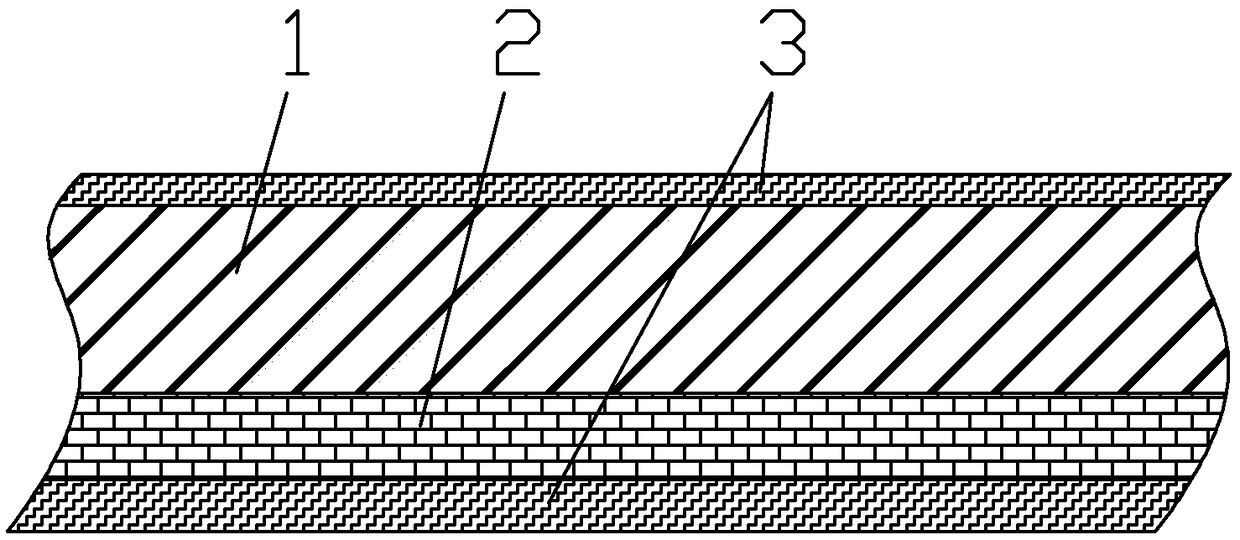

High-barrier-property pesticide packing bottle and preparation method thereof

ActiveCN109575410AImprove permeabilityImprove mechanical propertiesAdhesivesBlow moldingOrganic chemistry

The invention discloses a high-barrier-property pesticide packing bottle and preparation thereof. The high-barrier-property pesticide packing bottle comprises a barrier layer, an adhesion layer and abase layer which adhere to one another successively from inside to outside, the barrier layer and the base layer are separately attached to the two sides of the adhesion layer, and the thickness ratioof the barrier layer, the adhesion layer and the base layer is 1: 0.5-0.8: 2-2.5. The preparation method comprises the following steps: S1, raw material fusing; S2, double-screw extrusion forming; S3, blow molding; and S4, blow molding of the barrier layer. The high-barrier-property pesticide packing bottle has excellent mechanical property and pesticide permeation resistance, and has the advantage of good barrier property. In addition, a pesticide packing bottle prepared by the preparation method is formed integrally, the mechanical property and the pesticide permeation resistance are excellent, and the barrier property is good.

Owner:杭州普信塑料包装有限公司

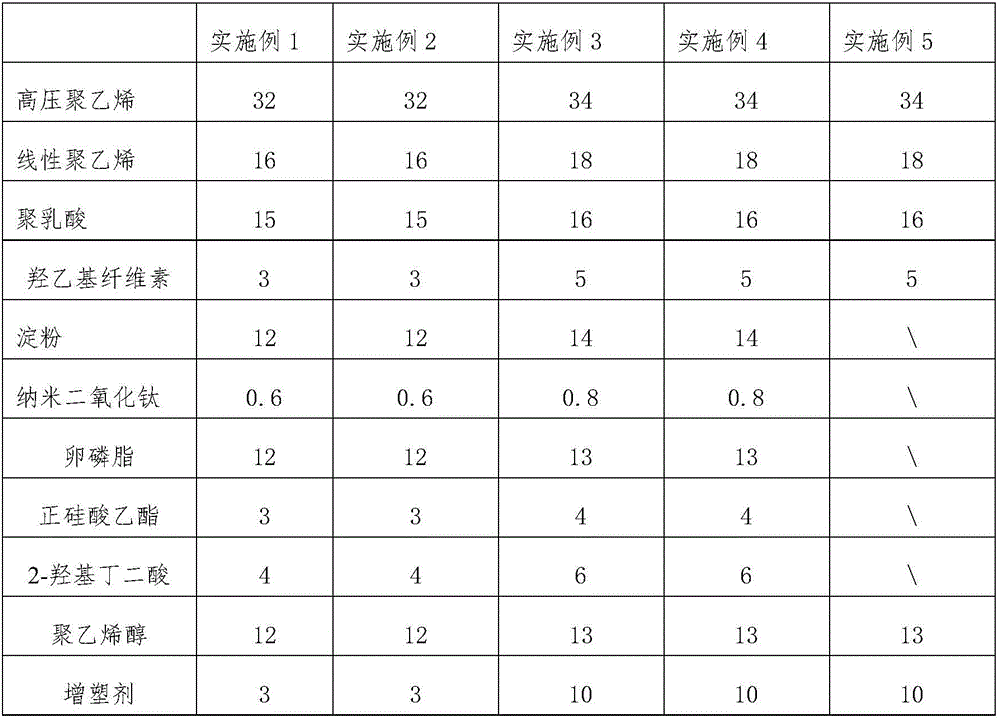

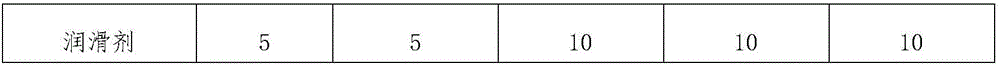

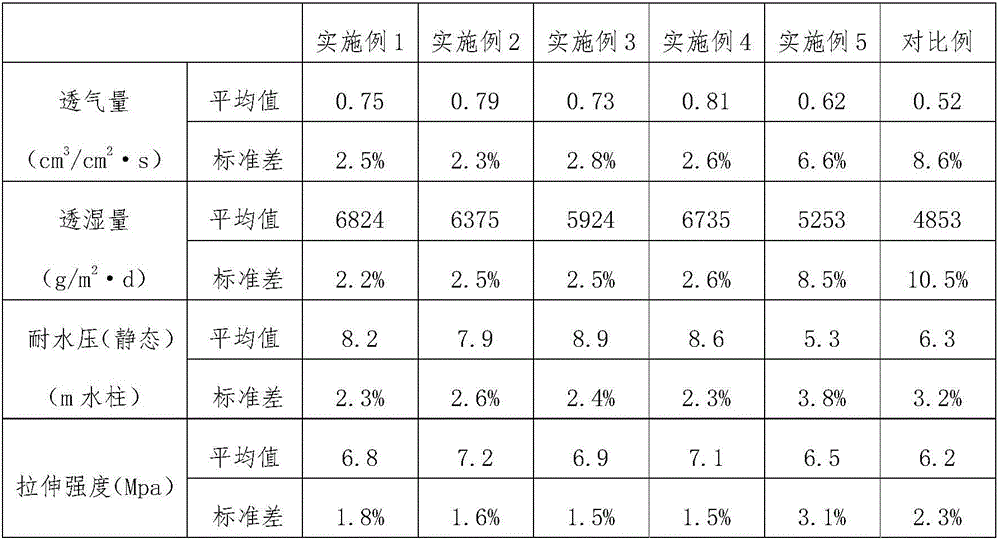

Nano waterproof breathable film and preparation method thereof

The invention provides a nano waterproof breathable film, made from the following materials in percent by weight: 30-35% of low-density polyethylene, 15-20% of linear polyethylene, 12-18% of polylactic acid, 2-6% of hydroxyethyl cellulose, 11-16% of starch, 0.6-0.8 part of nano titanium dioxide, 10-15% of lecithin, 2-5% of tetraethyl orthosilicate, 3-8% of 2-hydroxysuccinic acid, 10-15% of polyvinyl alcohol, 2-10% of a plasticizer, and 2-10% of a lubricant. In connection with the preparation method provided herein, the waterproof breathable nano film can be produced; the film is imparted good water resistance and breathability; the produced nano film is light and thin, soft to touch, high in tensile strength and suitable for use as a surface material for sanitary products.

Owner:崔建中

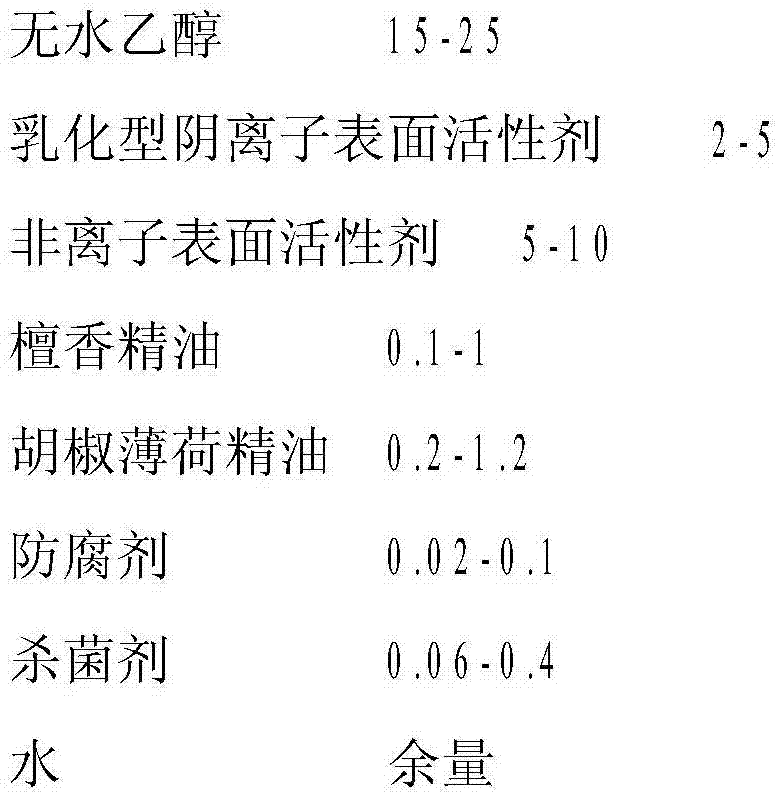

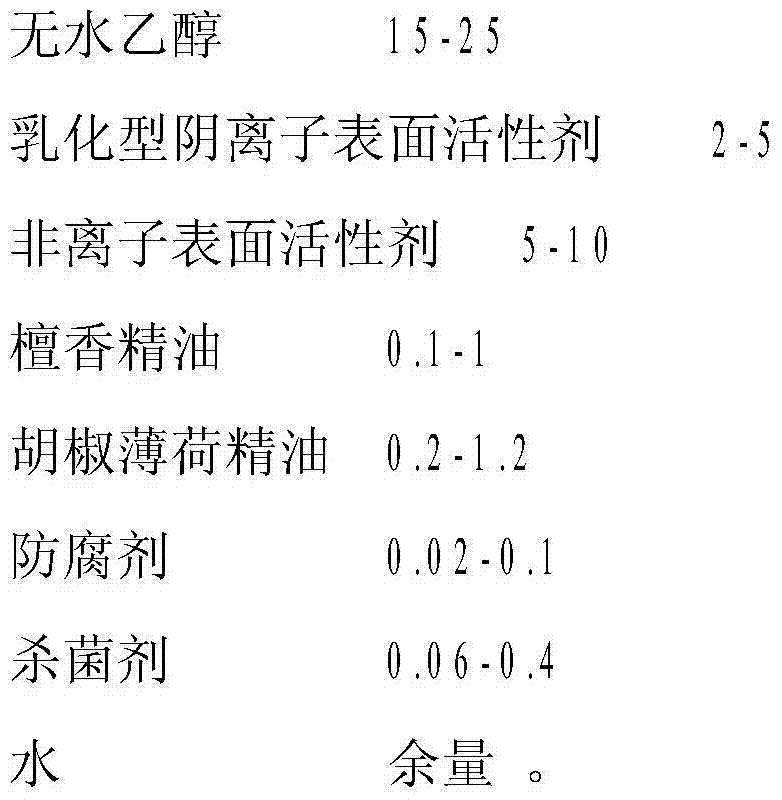

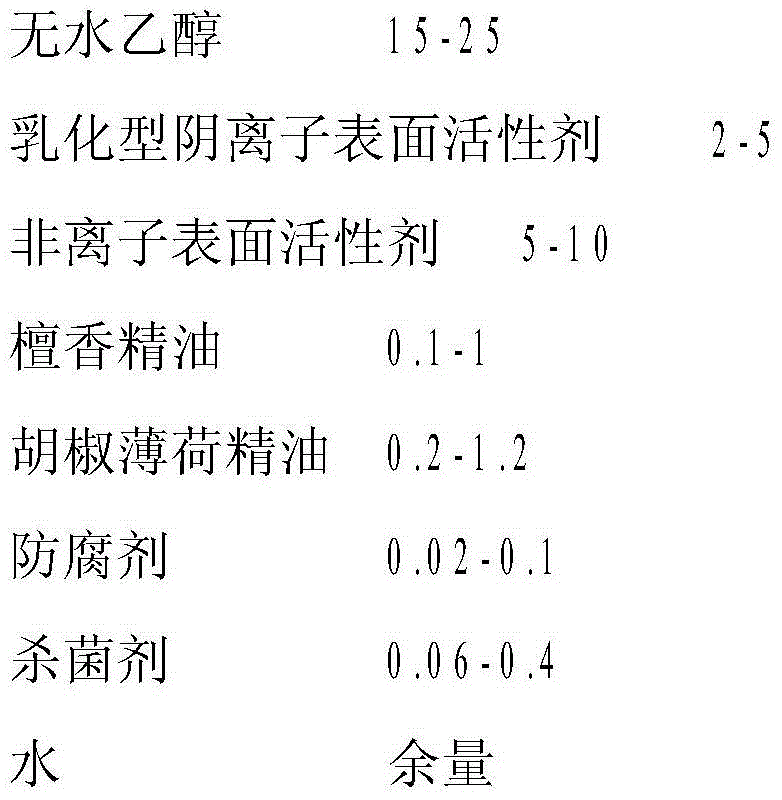

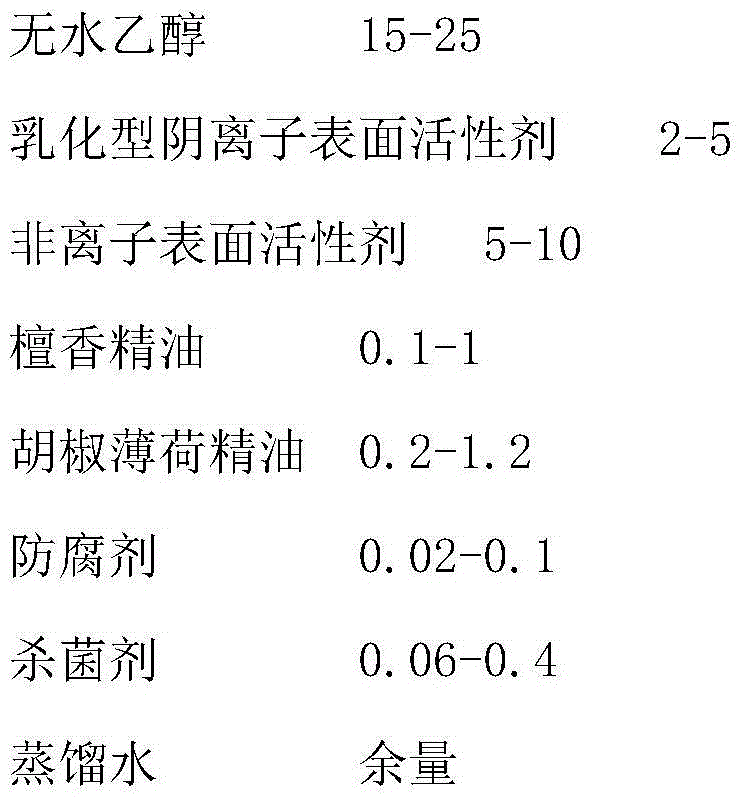

Teaching whiteboard nursing agent

InactiveCN103571666AHas bactericidal abilityGrowth inhibitionOther chemical processesSurface-active non-soap compounds and soap mixture detergentsWhiteboardAlcohol

The invention discloses a teaching whiteboard nursing agent, mainly comprising absolute ethyl alcohol, a surfactant, volatile flavors, a corrosion remover, a bactericide and water. By adopting the nursing agent disclosed by the invention, left ink marks, blots, moulages and the like of kinds of teaching whiteboards caused by long-term use can be quickly removed; the nursing agent can play good cleaning and maintaining roles in the teaching whiteboard and a matt board in long-term use. The nursing agent disclosed by the invention has a certain bactericidal ability, and can inhibit growth of bacteria. Meanwhile, the nursing agent disclosed by the invention has a fragrant smell, brings about a pleasant mood to people, and is especially applicable to cleaning of various writing boards of teaching sites, meeting places, training places, amusement parks for children and the like. The nursing agent disclosed by the invention also can be used for cleaning automotive windscreens and the like, and can play the roles of preventing a fog and cleaning the air inside the car when being applied to cleaning automotive glass. The teaching whiteboard nursing agent is simple in formula, available in raw materials, and low in cost, and is a multi-purpose cleaning care agent.

Owner:SHANXI UNIV

Infantile hand-mouth wet wipe and production method thereof

InactiveCN106176482AHigh acceptancePH reliefInorganic/elemental detergent compounding agentsCosmetic preparationsPreservativeWet wipe

The invention discloses infantile hand-mouth wet wipe, made with a detergent and nonwoven bearing the detergent; the detergent comprises the following components, by weight: 0.1-8 parts of a sweetener, 0.2-5 parts of a deterging agent, 0.2-8 parts of a plant extract, 1-5 parts of a moisturizer, 0.3-1.0 part of a preservative, 0.1-3 parts of a pH regulator and 90-99 parts of deionized water. The Infantile hand-mouth wet wipe is nontoxic, non-irritating, highly safe to use, soft and comfortable, suitable for wiping sensitive parts of a baby such as hand and mouth, also suitable for cleaning baby supplies such as nipples and feeding bottles. The invention also discloses a production method of the infantile hand-mouth wet wipe. The preparation method is simple, high in operational safety and high in efficiency.

Owner:HANGZHOU GUOGUANG TOURING COMMODITY

Preparation method for anti-flaming type medical non-woven fabric

InactiveCN109403056AImprove toughnessImprove flame retardant performanceMedical preparationsNon-woven fabricsYarnMolten state

The invention discloses a preparation method for an anti-flaming type medical non-woven fabric. The preparation method comprises the following steps: S1) adopting a material absorbing machine for absorbing and guiding a mixture of fine fiber polymer to a heater for heating under heating temperature at 260-280 DEG C, thereby acquiring a polymer A under molten state; S2) adopting an extruding machine for pressurizing and spinning the polymer A under 4.8-5.3MPa, stretching spun yarns by a stretching machine, forming drawing fibers B, guiding the drawing fibers B into a soaking solution, soaking for 6-8h, and then guiding to a netting machine; S3) guiding overlapped fibers into a hot mill for hot milling when three or four layers of drawing fibers B are overlapped on the netting machine, uniformly spraying resin powder and aluminum hydroxide anti-flaming grain powder onto the drawing fiber surfaces while hot milling under the conditions of 160-180 DEG C and 4MPa, acquiring the non-woven fabric, winding and forming. On the basis of guaranteed toughness, the anti-flaming type medical non-woven fabric has an anti-flaming capacity and is especially suitable for hospitals.

Owner:桐城市鸿江包装有限公司

Teaching whiteboard nursing agent

InactiveCN103571666BHas bactericidal abilityGrowth inhibitionOther chemical processesSurface-active non-soap compounds and soap mixture detergentsWhiteboardAlcohol

The invention discloses a teaching whiteboard nursing agent, mainly comprising absolute ethyl alcohol, a surfactant, volatile flavors, a corrosion remover, a bactericide and water. By adopting the nursing agent disclosed by the invention, left ink marks, blots, moulages and the like of kinds of teaching whiteboards caused by long-term use can be quickly removed; the nursing agent can play good cleaning and maintaining roles in the teaching whiteboard and a matt board in long-term use. The nursing agent disclosed by the invention has a certain bactericidal ability, and can inhibit growth of bacteria. Meanwhile, the nursing agent disclosed by the invention has a fragrant smell, brings about a pleasant mood to people, and is especially applicable to cleaning of various writing boards of teaching sites, meeting places, training places, amusement parks for children and the like. The nursing agent disclosed by the invention also can be used for cleaning automotive windscreens and the like, and can play the roles of preventing a fog and cleaning the air inside the car when being applied to cleaning automotive glass. The teaching whiteboard nursing agent is simple in formula, available in raw materials, and low in cost, and is a multi-purpose cleaning care agent.

Owner:SHANXI UNIV

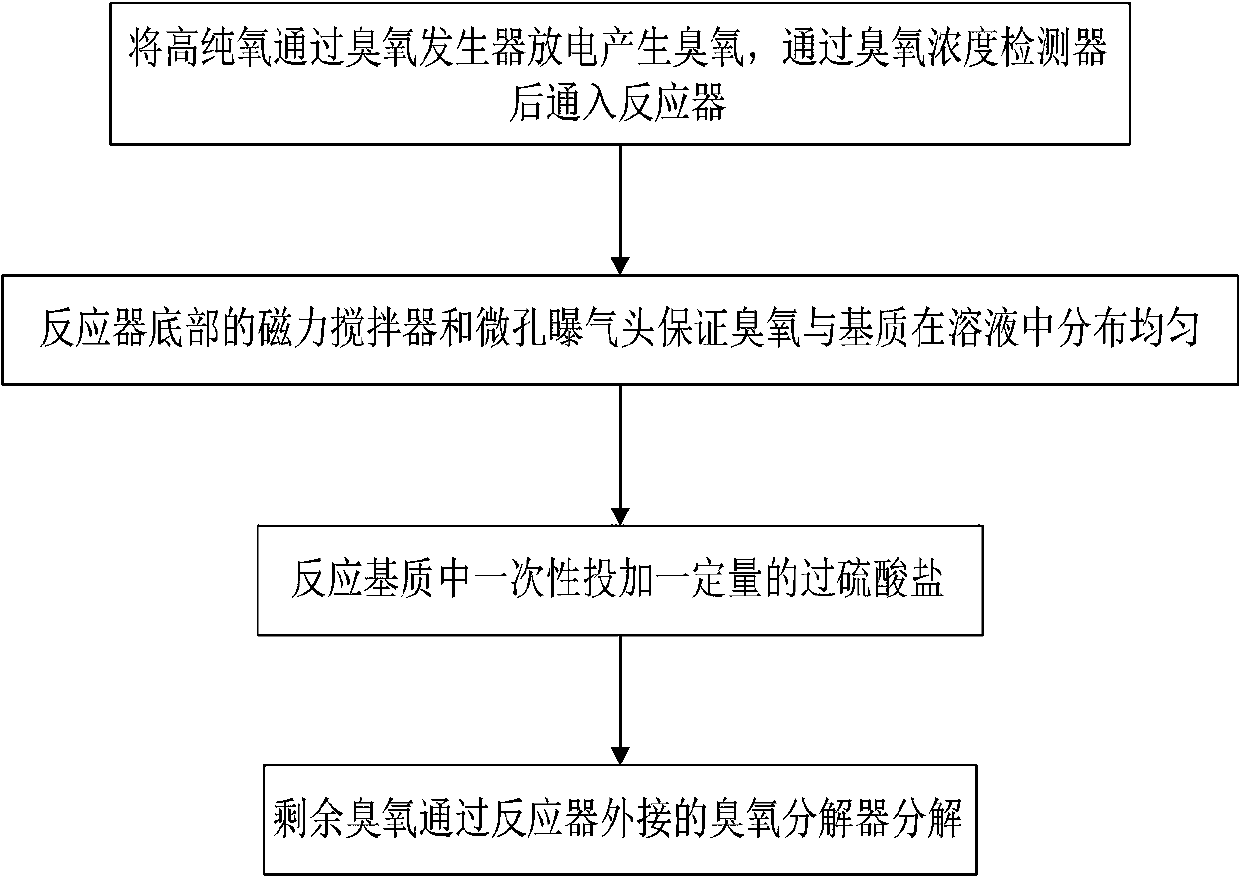

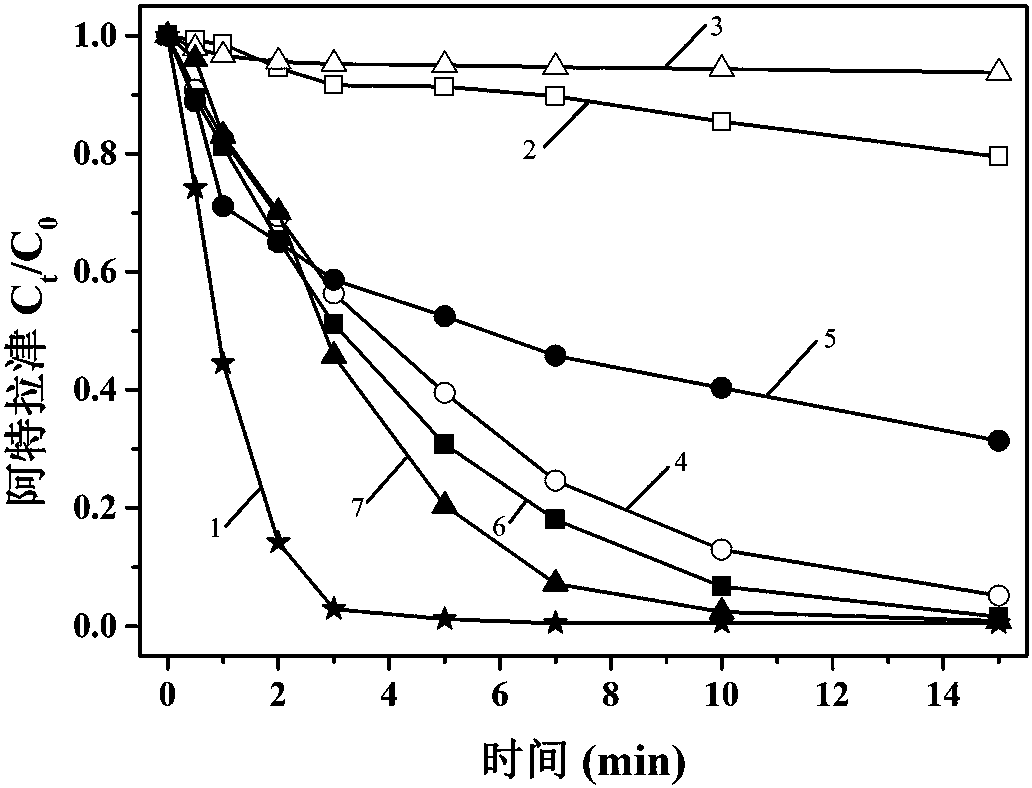

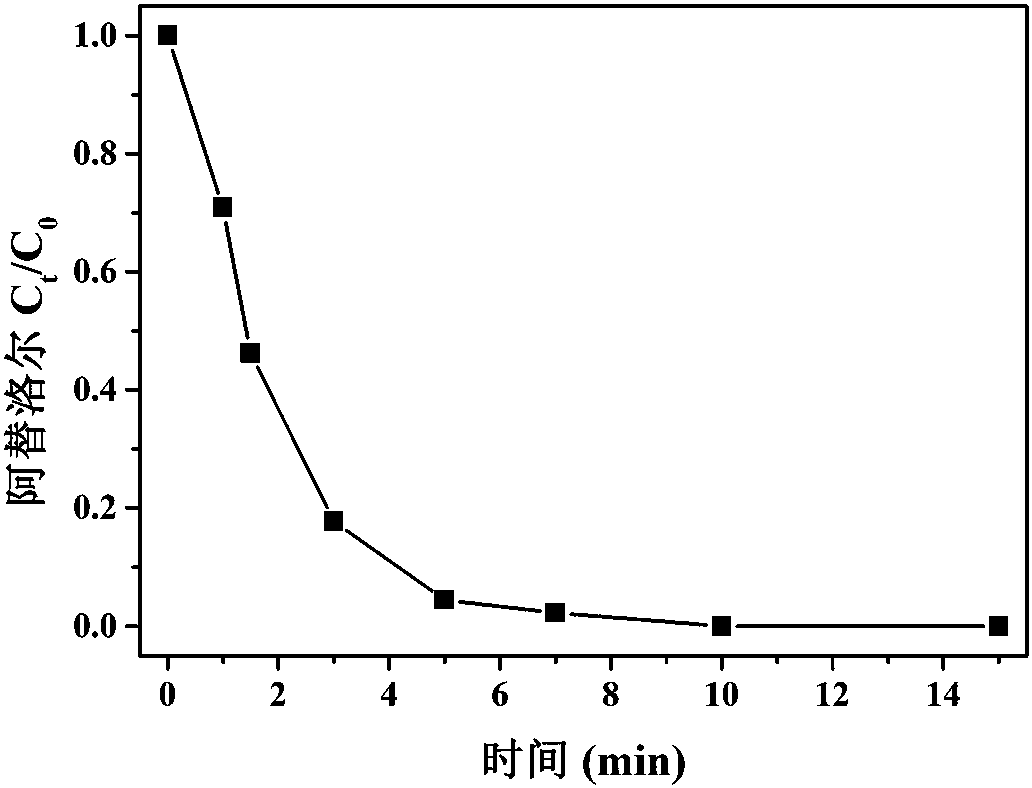

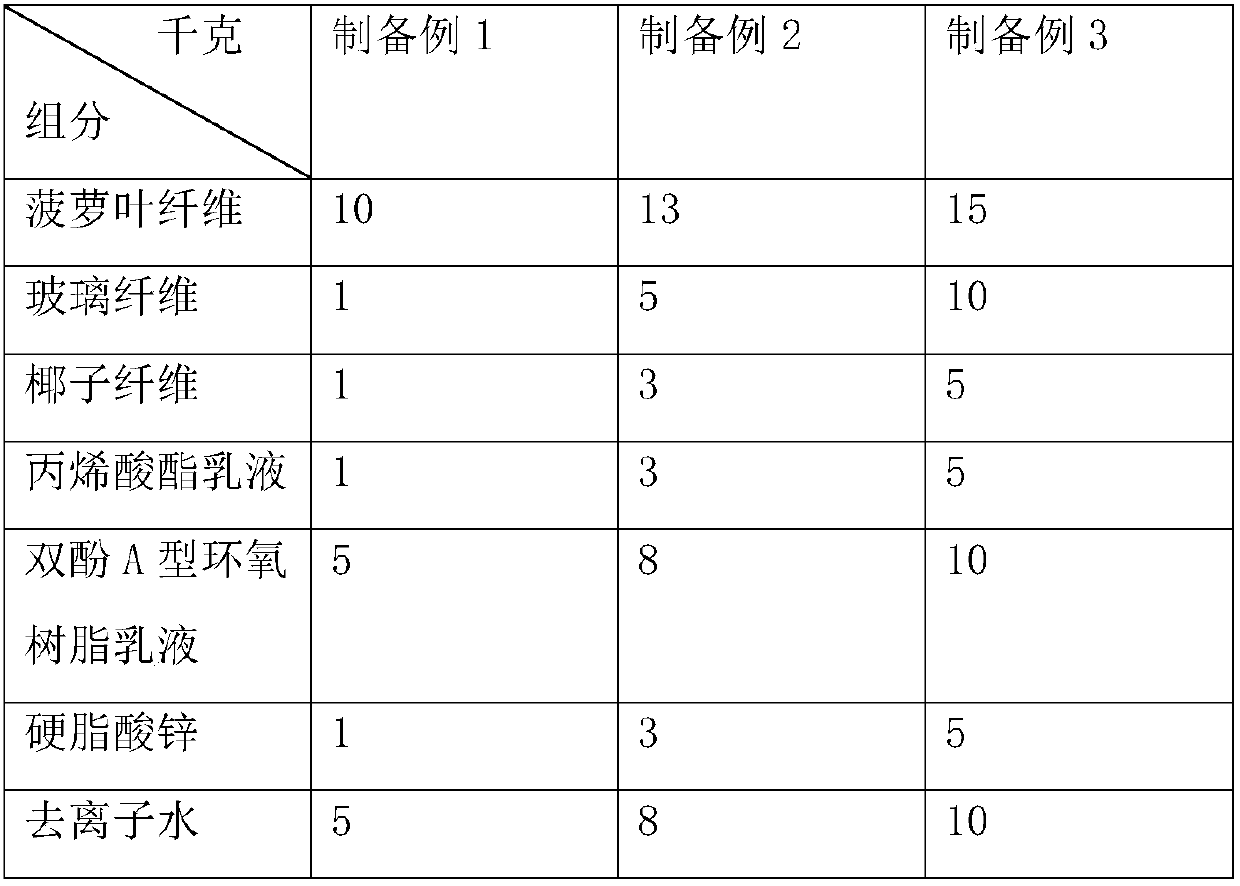

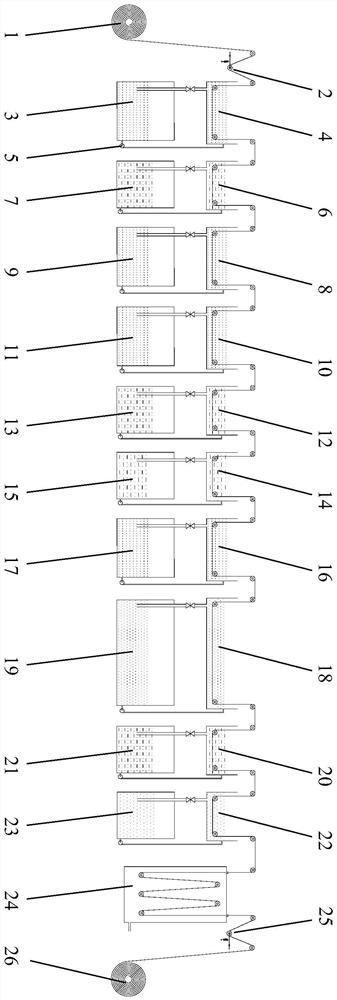

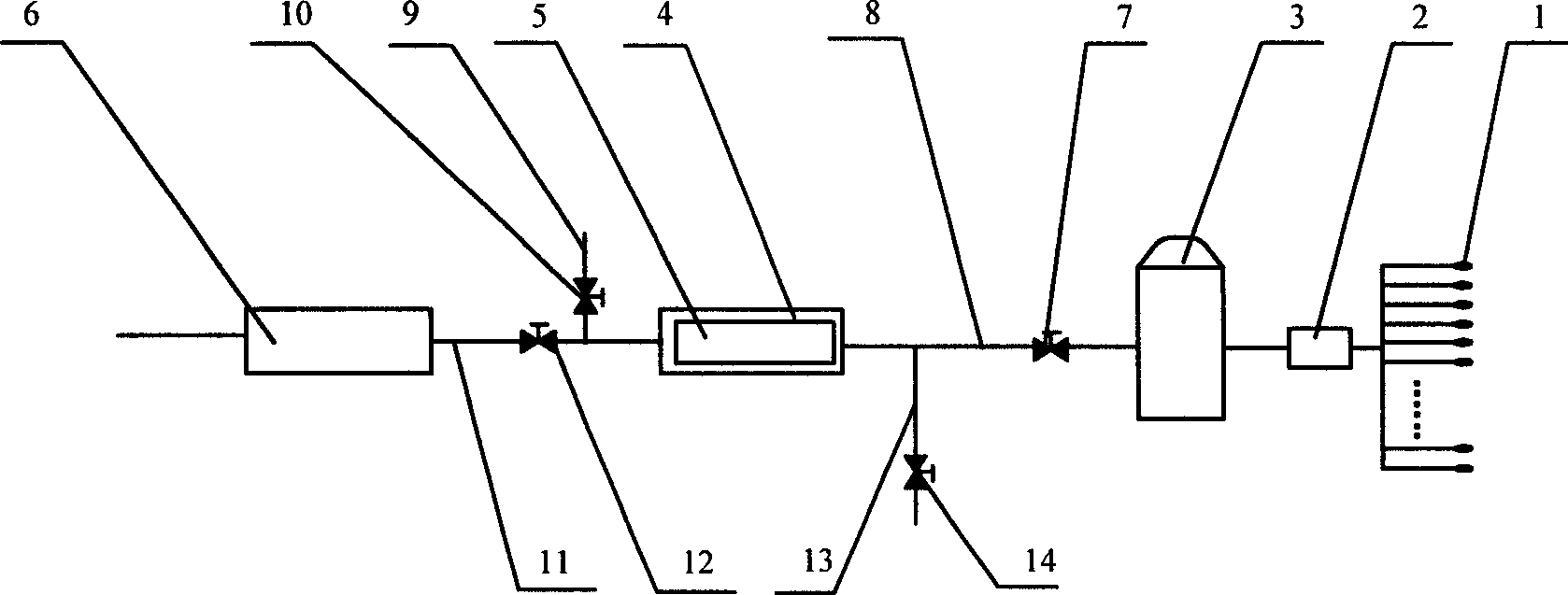

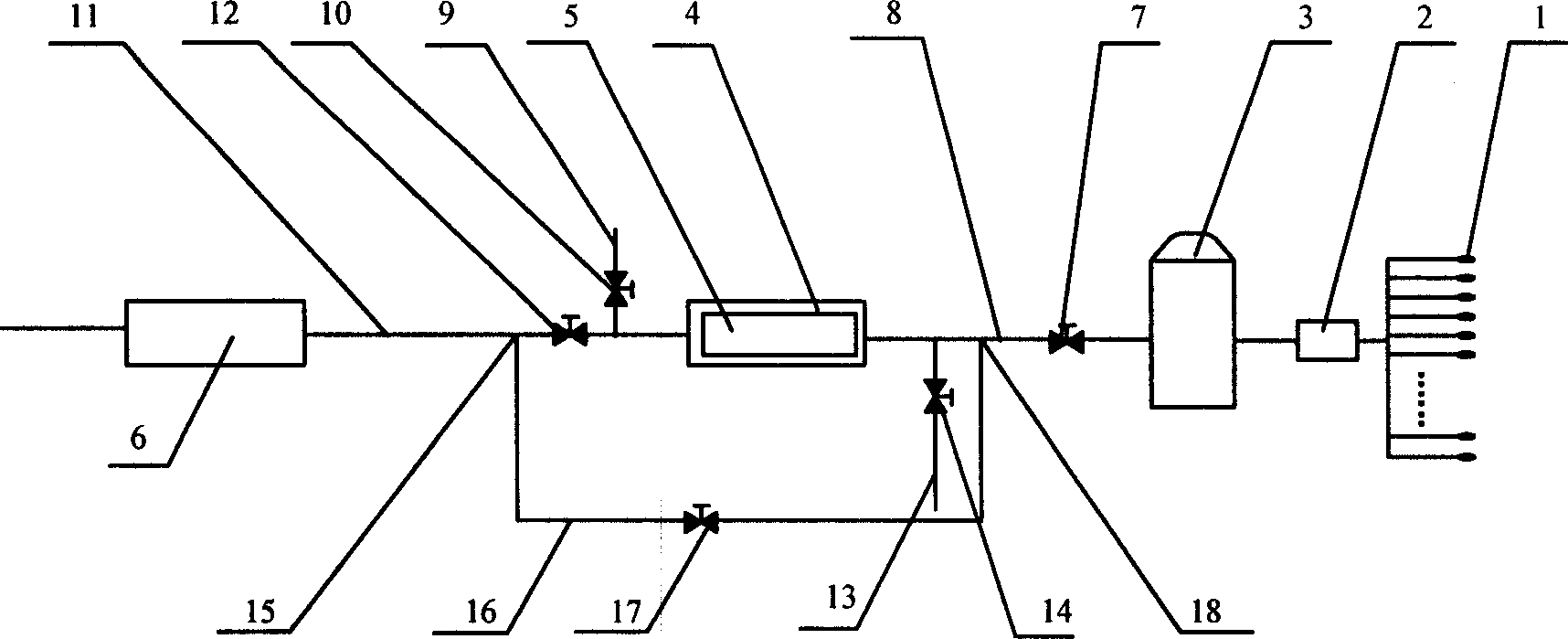

Water treating method utilizing ultraviolet rays to synergize with persulphate in ozone catalysis

InactiveCN110316807AEasy to store and transportHas bactericidal abilityWater/sewage treatment by irradiationWater treatment compoundsPersulfateUltraviolet

The invention provides a water treating method utilizing ultraviolet rays to synergize with persulphate in ozone catalysis. An embodiment of the water treating method includes: enabling high-purity oxygen to produce ozone by discharging an ozone generator; enabling the ozone to pass through an ozone concentration detector and then enter an ozone contact reactor; ensuring the ozone and a matrix tobe uniformly distributed in a solution through a magnetic stirrer and a microporous aerating head; adding a certain amount of the persulphate into a reaction matrix at one time; and decomposing the rest ozone through an ozone decomposer which is connected with the reactor externally. By the aid of an advanced combined oxidization technology utilizing the ultraviolet rays to synergize with the persulphate in ozone catalysis, atrazine in different water body conditions can be removed efficiently and quickly, and pollutants can be completely mineralized into H2O and CO2 in a short time; by introducing the ultraviolet rays, on one hand, decomposing efficiency and mineralizing efficiency of the ozone are improved, on the other hand, wastewater can be sterilized and disinfected, cost on water treatment is saved, and accordingly the water treating method can be applied to treatment of micro organic pollutants in drinking water, recycled water and even industrial wastewater in the future.

Owner:WUHAN TEXTILE UNIV

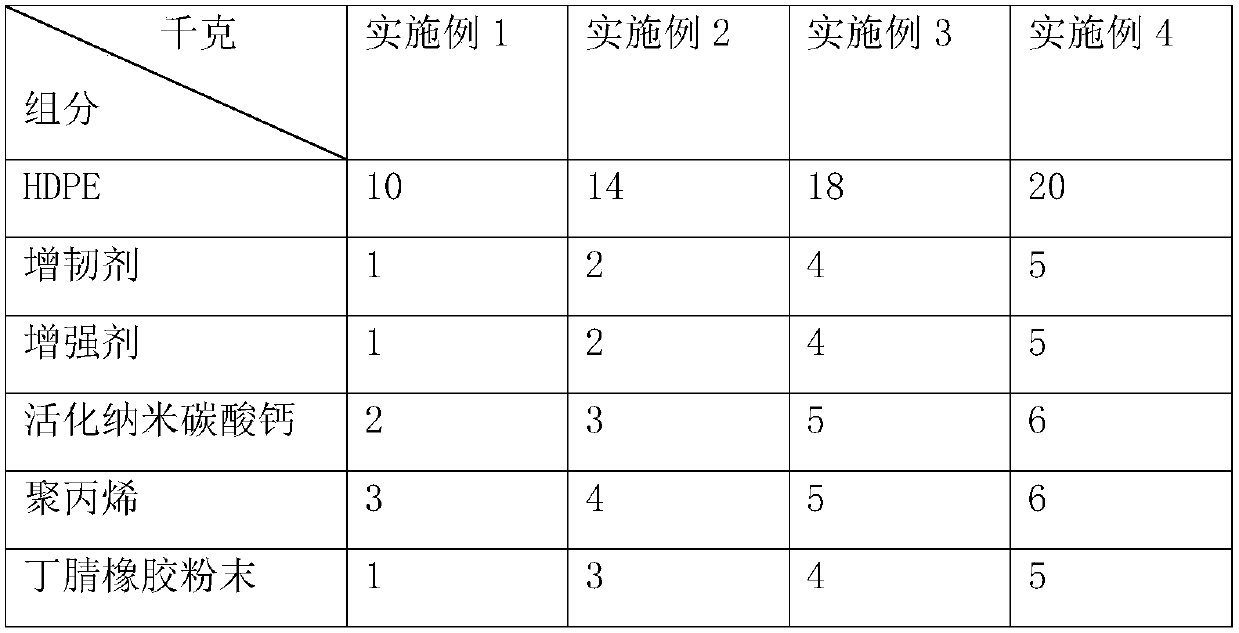

Pesticide storing container and preparation method thereof

ActiveCN109573234AImproves Strength and ToughnessImprove impact resistanceAgricultural articlesBottlesPolypropylenePesticide

The invention discloses a pesticide storing container and a preparation method thereof. The pesticide storing container comprises an inner layer, a bonding layer I, a blocking layer, a bonding layer II and an outer layer which are sequentially bonded from inside to outside; and the inner layer is prepared from the following components in parts by weight: 10-20 parts of HDPE, 1-5 parts of a flexibilizer, 1-5 parts of a reinforcing agent, 2-6 parts of activated nano calcium carbonate, 3-6 parts of polypropylene, and 1-5 parts of butyronitrile rubber powder. The preparation method of the pesticide storing container comprises the steps: S1, melt extrusion is conducted; S2, blow molding is conducted; and S3, trimming treatment is conducted, specifically, a semi-finished blank product is trimmed, and a finished product is prepared. The pesticide storing container has the advantages of being high in strength, good in toughness and high in falling resistance; and additionally, the preparationmethod has the advantages that the prepared pesticide storing container is good in strength, good in toughness and high in falling resistance.

Owner:杭州普信塑料包装有限公司

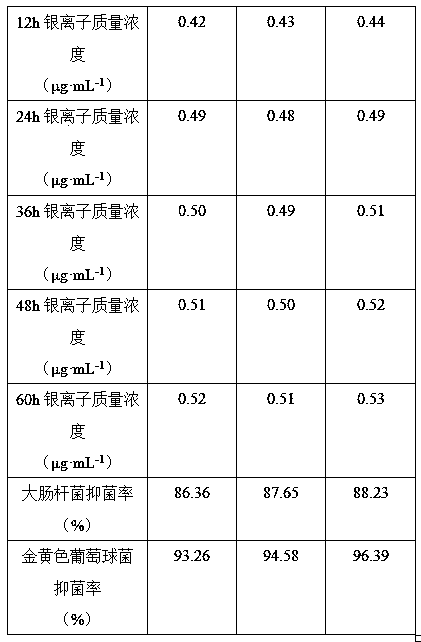

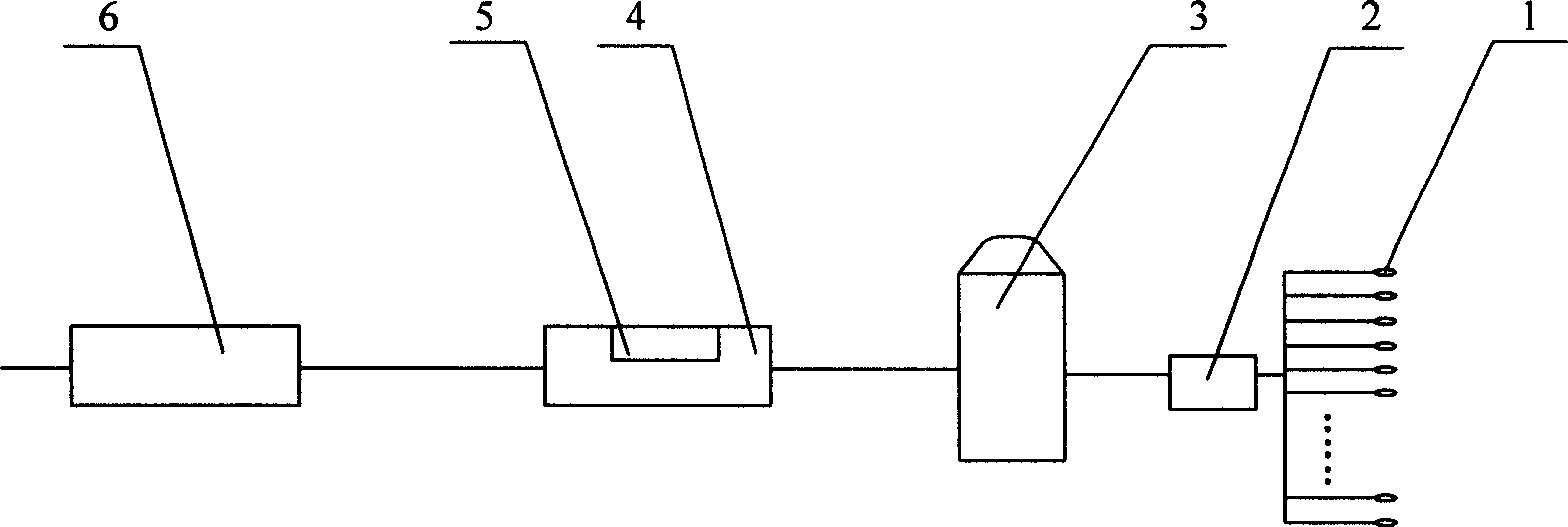

Filter material for self-antibacterial and self-disinfecting mask and manufacturing method thereof

PendingCN111841149ADoes not change filterabilityNo change in physical propertiesBiochemical fibre treatmentMembrane filtersFiberMicroorganism

The invention belongs to the technical field of daily protection products, in particular to a filter cloth material for a mask with self-antibacterial and self-disinfecting functions and a manufacturing method thereof. The specific implementation process comprises the steps of discharging, degreasing, washing, acid pickling, sensitizing, washing, activating, pre-silvering, silvering, washing, surface modifying, drying, collecting and the like, and proper nano-silver particles can be deposited on the fiber surface after a conventional mask filter material is treated by the method, so that the killing effect on microorganisms such as bacteria or viruses is realized. According to the technology, the defect that an existing mask filter material can only filter particulate matter or droplets but cannot exterminate bacteria or viruses can be overcome; meanwhile, the nano-silver particles and the filter material fibers are firmly combined and are only distributed on the surfaces of the filtermaterial fibers, and compared with other silver-containing filter materials, the nano-silver filter material has the advantages of continuous industrial production, high effective utilization rate ofsilver, strong binding force of the silver particles and the filter material fibers, low manufacturing cost and the like.

Owner:常州微度化工新材料科技有限公司

Preparation method of medical foam dressing with slow-release antibacterial effect

PendingCN110433321AGood biocompatibilityImprove antibacterial propertiesAbsorbent padsBandagesFiberBiocompatibility Testing

The invention relates to a preparation method of a medical foam dressing with a slow-release antibacterial effect, and belongs to the technical filed of dressings. According to the preparation method,silver ions are loaded on chitosan fibers, nano-zinc oxide is loaded on sodium alginate fibers, toluene diisocynate and polyethylene glycol are taken as raw materials, and the medical foam dressing with the slow-release antibacterial effect is prepared through a foaming technology; the sodium alginate fibers have the moisture absorbing performance and thus are very suitable for the medical dressing; alginic acid is a polysaccharide substance extracted from marine plants and is a random linear segmented copolymer formed by guluronic acid (G) and mannuronic acid (M) which are subjected to bonding through glucosidic bonds; chitosan is also a natural macromolecular compound and has the good biocompatibility and antibacterial property; and after blending, the silver ions and the nano-zinc oxide can be embedded in a three-dimensional mesh molecular structure of the sodium alginate fibers, thus the problems of discoloration, falling-off, burst release, high cytotoxicity and the like of the silver ions are expected to be relieved, and thus the slow-release antibacterial effect is achieved.

Owner:张明

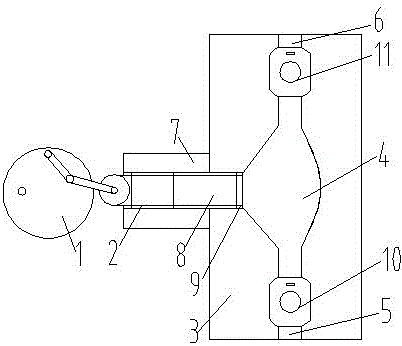

Medical infusion machine

InactiveCN106215277ALow costImprove reliabilityMedical devicesPressure infusionEngineeringMechanical engineering

The invention discloses a medical infusion machine which comprises an intelligent control system, an alarming device, a driving device and a piston reciprocating pump. The alarming device, the driving device and the piston reciprocating pump are connected with the intelligent control system respectively, the piston reciprocating pump comprises a pump body and a piston body mounted on the side face of the pump body, a pump cavity is arranged in the pump body and communicated with a piston cavity of the piston body, a piston rod is arranged in the piston body, and a sealing ring is arranged between the piston body and the piston rod. The medical infusion machine is more accurate in infusion flow control, capable of realizing infusion with different flows for different patients and different medicine liquids, more durable and higher in reliability.

Owner:鲁绍荣

Preparation method of tough non-woven fabric for packaging

ActiveCN109537162AIncreased load-bearing capacityHigh strengthMonocomponent copolyesters artificial filamentMelt spinning methodsPolymer scienceFiber drawing

The invention provides a preparation method of tough non-woven fabric for packaging. The preparation method of the tough non-woven fabric for packaging comprises the following steps: S1, preparing soaking liquid; S2, performing big-screw high-temperature melt extrusion on a mixture of a fine fiber polymer and binder fiber under the heating temperature of 260 to 280 DEG C to obtain a polymer B in amolten state, performing pressurizing and spinning jet on the polymer B through an extruding machine under 4.8 to 5.3 MPa, stretching the jet yarn by a stretcher to form a fiber drawing object C, guiding into a solution A, soaking for 4 to 8 hours and guiding on a lapper; and S3, when three layers or four layers of fiber drawing objects C are stacked on the lapper, guiding the stacked object to irradiate by an ultraviolet irradiating area for 15 minutes, guiding into a hot rolling mill to perform hot rolling to obtain non-woven fabric and winding and forming, wherein during hot rolling, resinpowder is sprayed on the surface of the fiber drawing object uniformly and the hot rolling conditions are 160 to 180 DEG C and 4 MPa. Good bearing effect, high toughness and bactericidal ability areachieved.

Owner:桐城市鸿江包装有限公司

Glassine release paper

InactiveCN108824072AImprove hygiene standardsHas bactericidal abilityNon-macromolecular organic additionPaper/cardboardSolvent freePulp and paper industry

The invention relates to the technical field of release paper, in particular to glassine release paper. The glassine release paper comprises a glassine raw paper layer, one side surface of the glassine raw paper layer is uniformly coated with a release material layer, and the other side surface of the glassine raw paper layer and one side, which is far away from the glassine raw paper layer, of the release material layer are both coated with solvent-free silicone oil layers. According to the glassine release paper, sterilization treatment is carried out on the glassine raw paper, the hygienicstandard of the glassine raw paper is effectively improved, by dipping the glassine raw paper in a sterilizing solution, the sterilizing solution can be blended in the glassine raw paper, the glassineraw paper can have sterilizing ability for a long time, the bacteria and fungi are prevented from breeding in the glassine release paper, by further arranging the release material and the solvent-free silicone oil, the smoothness of the surface of the glassine release paper can be improved, and the anti-sticking ability of the glassine release paper can be improved as well.

Owner:WENZHOU XINYI SPECIAL PAPER

Dispersed type wet toilet paper and manufacturing method thereof

InactiveCN107174154AImprove tensile propertiesGood mechanical propertiesNon-fibrous pulp additionSpecial paperFiberEpoxy

The invention discloses dispersed type wet toilet paper and belongs to the technical field of wet toilet paper. The dispersed type wet toilet paper comprises a wetting solution and wet toilet paper base paper which is soaked in the wetting solution; the wet toilet paper base paper is prepared from, by weight, 60-80 parts of wood pulp, 20-40 parts of coconut fiber, 5-8 parts of linen fiber, 10-14 parts of epoxy resin and 3-5 parts of water-absorbent resin; the wetting solution is prepared from, by weight, 1-2 parts of aloe, 3-4 parts of tea leaves, 5-6 parts of folium artemisiae argyi, 0.5-1 part of bitter herb, 0.8-1.5 parts of fresh ginger, 0.2-0.6 part of radix sophorae flavescentis, 2-3 parts of mint, 1-2 parts of Chinese Pulsatilla Root, 0.3-0.7 part of brucea javanica, 0.5-0.8 part of radix angelicae, 0.8-1 part of essence, 7-10 parts of alcohol, 6-14 parts of propolis and 120-140 parts of deionized water. The invention further discloses a manufacturing method of the dispersed type wet toilet paper. According to the dispersed type wet toilet paper and the manufacturing method thereof, undesirable odor can be effectively removed, bacteria can also be effectively killed, and therefore it is ensured that the anus large intestine is kept clean.

Owner:山东励仙电力工程有限公司

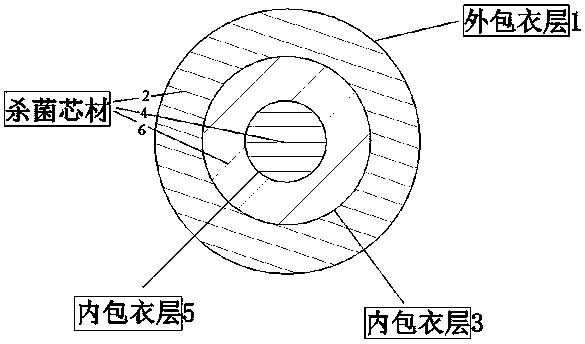

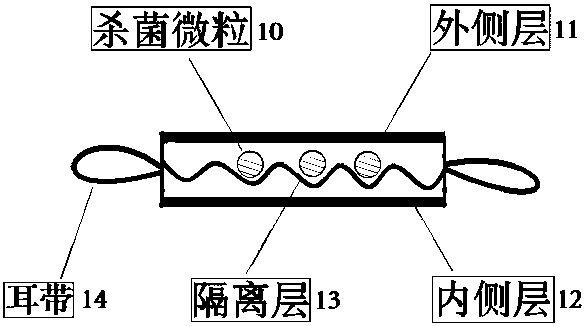

Reusable sterilizing and antiviral comfortable mask

InactiveCN111227352AHas bactericidal abilityAntiviralProtective garmentSpecial outerwear garmentsActivated carbonSoluble Film

The invention discloses a reusable sterilizing antiviral comfortable mask which is formed by overlapping two or more layers of materials, and sterilizing particles are embedded between the layers. Themask frame is molded by memory metal, the sterilization particles are provided with outer coating layers and sterilization core materials, and the outer coating layers are made of water-soluble filmmaterials. An inner coating layer is arranged inside the outer coating layer or inside the outer coating layer, a sterilization core material is filled among the coating layers, and the inner coatinglayer is made of an alcohol-soluble film material. The mask has the sterilization and antiviral capacity of silver ions or / and iodine elementary substances, the activated carbon fibers adsorb peculiarsmells, water washing resistance and alcohol spraying resistance are achieved, and the mask can be repeatedly used for multiple times.

Owner:仇一斐

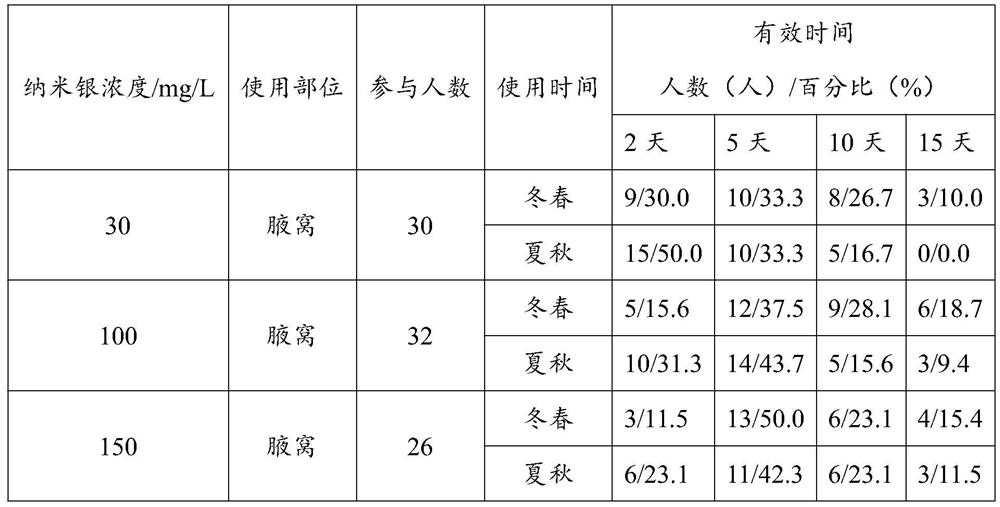

Application of nano-silver in preparing cosmetics or medicines for preventing and removing bromhidrosis, liquid and preparation method of liquid

PendingCN112137954AGood effectImprove securityCosmetic preparationsInorganic active ingredientsSolventCutis

The invention relates to the technical field of deodorization cosmetics and provides application of nano-silver in preparing cosmetics or medicines for preventing and removing bromhidrosis, liquid anda preparation method of the liquid. The nano-silver is used to prepare cosmetics or medicines for preventing and removing bromhidrosis, the new use of the nano-silver is provided, besides, the nano-silver is high in safety, good in environmental protection property, outstanding in sterilization performance and remarkable in preventing and removing the bromhidrosis. The provided liquid comprises nano-silver, polydopamine coating a surface of the nano-silver, and a solvent. The polydopamine is coated on the surface of the nano-silver, stability of the product can be remarkably improved, and theproduct can be stored under conventional conditions, the polydopamine has strong adhesion force, can be firmly adhered to surfaces of hair and skin, prevents the nano-silver from losing due to sweatand friction effects, and achieves effects of long-term sterilization and deodorization. Furthermore, concentration of the nano-silver in the provided liquid is relatively low, so that cost of the liquid can be further reduced.

Owner:成都志俊时代科技有限公司

Secondary-cleaned atomized water treatment device

ActiveCN1569666AEliminate hazardsHas bactericidal abilityWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsWater sourceWater quality

The invention discloses a secondary-cleaned atomized water treatment device, which comprises pipeline-connected high pressure pump and atomization injector, wherein the high pressure pump is provided with a reaction chamber connected through circuit, the cleaner is connected with the reaction chamber. The atomized water treatment device can be provided with cleaners of different functions so as to remove the imperfect substance in the water according to the different water quality for the water source.

Owner:马钟炜

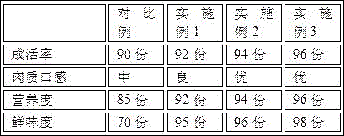

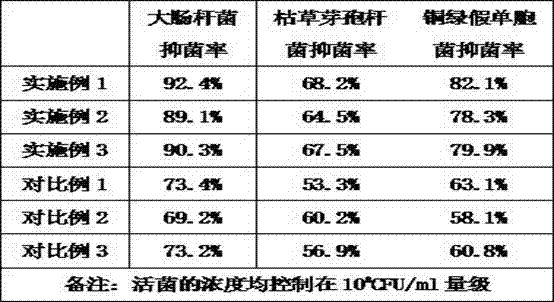

Broiler feed

InactiveCN106509474AHistoricalEnhance immune functionAnimal feeding stuffAccessory food factorsBiotechnologyGrape seed

The invention discloses a broiler feed. The broiler feed is prepared from the following raw materials in percentage by weight: 8-10 parts of a product made of tender shoots of fiveleaf gynostemma herbs, 50-60 parts of corn flour, 4-6 parts of oat, 4-6 parts of wheat, 20-30 parts of bean meal, 5-7 parts of silkworm chrysalis meal, 4-6 parts of peach kernel powder, 4-6 parts of shiitake mushrooms, 3-5 parts of dried juncus effusus, 3-5 parts of grape seeds, 0.6-0.8 part of table salt, and 1-3 parts of Weixianwu, wherein the Weixianwu is prepared by uniformly mixing fresh ginger with garlic, a green feed and rotted leaves in the mass ratio of the fresh ginger to the garlic, to the green feed and to the rotted leaves being 1 to 1 to 3 to 2. The broiler feed prepared by the formula can improve the immunity of broilers, and is delicious in meat quality and mouth feel.

Owner:CHONGQING CHANGSHOU DISTRICT BIAOGAN CHICKEN RAISING COOP

Surface grafting modified polyurethane medical catheter and preparation method thereof

ActiveCN101711894BGood effectGood biocompatibilityCatheterCoatingsBiocompatibility TestingVolumetric Mass Density

Owner:珠海福尼亚医疗设备有限公司

Manufacturing process of household daily anti-microbial non-woven fabric

InactiveCN107090666AHas bactericidal abilityImprove the bactericidal effectFibre typesNon-woven fabricsDiameter ratioWoven fabric

The invention relates to a manufacturing process of household daily anti-microbial non-woven fabric. The manufacturing process is characterized by including the following steps of S1, raw material preparation, wherein a Vistamaxx VM6202 POE elastomer is selected as a main material, a PP material accounting for 4% of the total quantity and nano-silver powder accounting for 0.1% of the total quantity are doped, high polymer slices are manufactured, and the water content of the slices is controlled to be smaller than 4%; S2, feeding and melting, wherein the slices are fed into a screw extruder for melt extrusion, a slipping agent is additionally added into the screw extruder, the length-diameter ratio of the screw extruder is (15-30):1, the temperature of the feeding section is controlled to be 190+ / -10 DEG C, the temperature of the compression section is controlled to be 230+ / -10 DEG C, and the screw speed is 40+ / -10 r / min; S3, filtering and spinning; S4, cooling and drafting; S5, wet formation and prepressing; 6, hot rolling and solidifying; S7, after-finishing, wherein a hot-rolled web is soaked in sol containing nano-silver, each time of soaking is not shorter than 20 min, the web is ultrasonically dispersed for 15 min, and then ultraviolet irradiation is carried out for 10 min; S8, drying; S9, winding.

Owner:浙江华晨非织造布有限公司

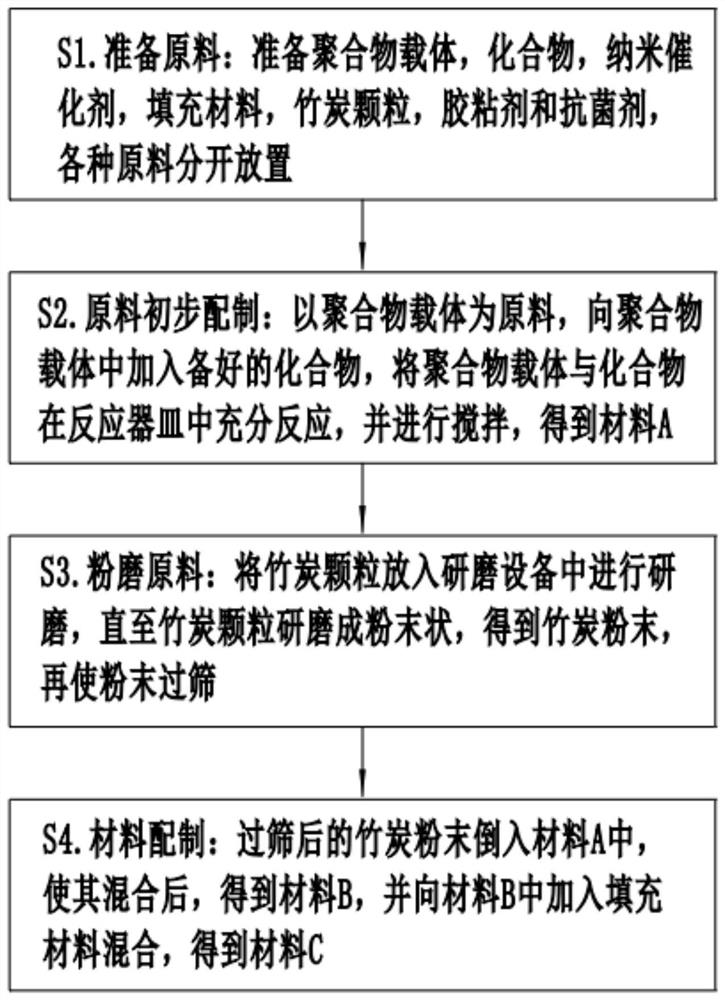

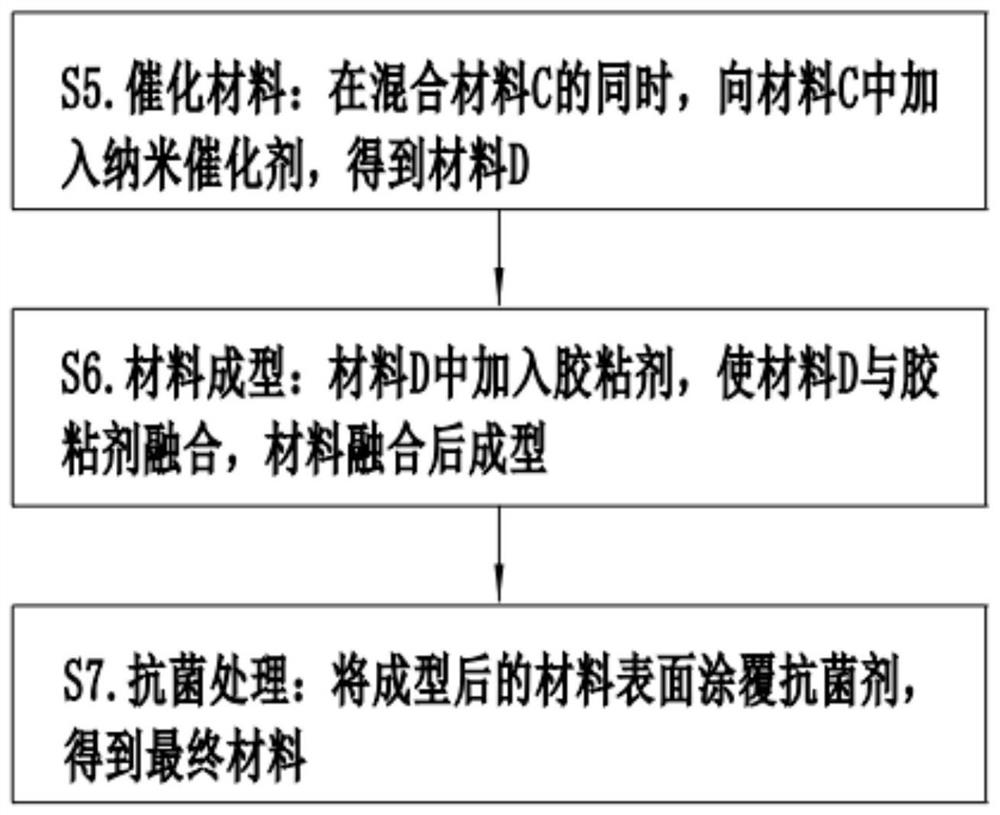

Negative oxygen ion material for air purification

InactiveCN112076619AReduce impurityEliminate odorGas treatmentDispersed particle separationNano catalystPtru catalyst

The invention relates to the field of negative oxygen ion materials, in particular to an air purification negative oxygen ion material which is prepared by the following steps: S1, preparing raw materials: preparing a polymer carrier, a compound, a nano catalyst, a filling material, bamboo charcoal particles, an adhesive and an antibacterial agent, and separately placing various raw materials; S2,primary preparation of raw materials: taking a polymer carrier as a raw material, adding the prepared compound into the polymer carrier, fully reacting the polymer carrier with the compound in a reaction vessel, and stirring to obtain a material A; S3, grinding the raw materials: putting the bamboo charcoal particles into grinding equipment for grinding until the bamboo charcoal particles are ground into powder to obtain bamboo charcoal powder, and then sieving the powder. According to the invention, the nano-catalyst is added into the material, is a nano-photocatalyst, has oxidation capacityafter reacting with surrounding oxygen, and can decompose pollutants such as formaldehyde in air into harmless and odorless substances, so that the purpose of purifying air is achieved.

Owner:上海多礼新材料研究中心

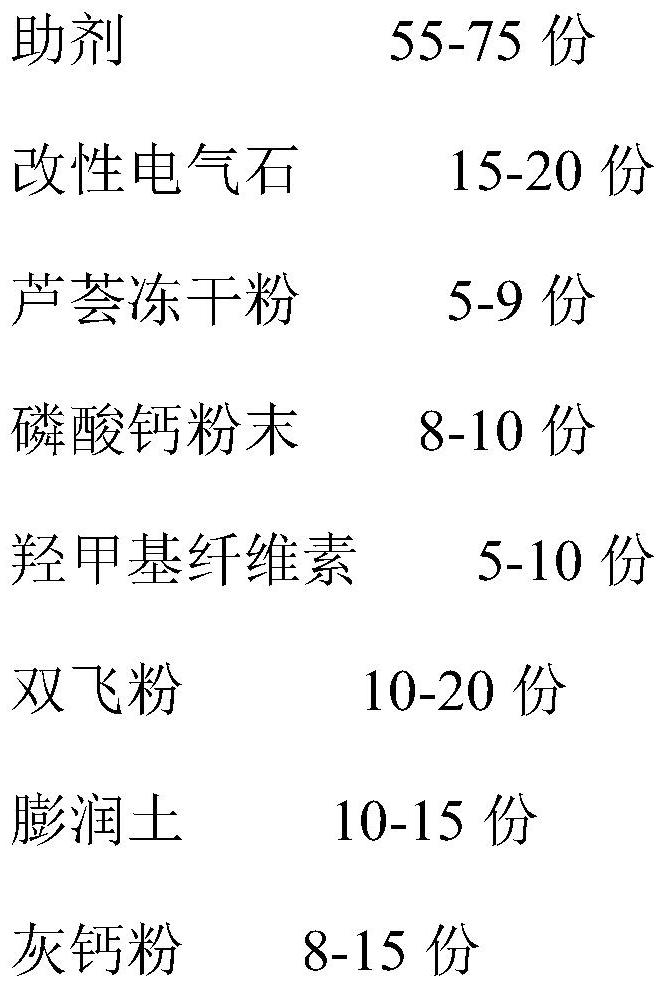

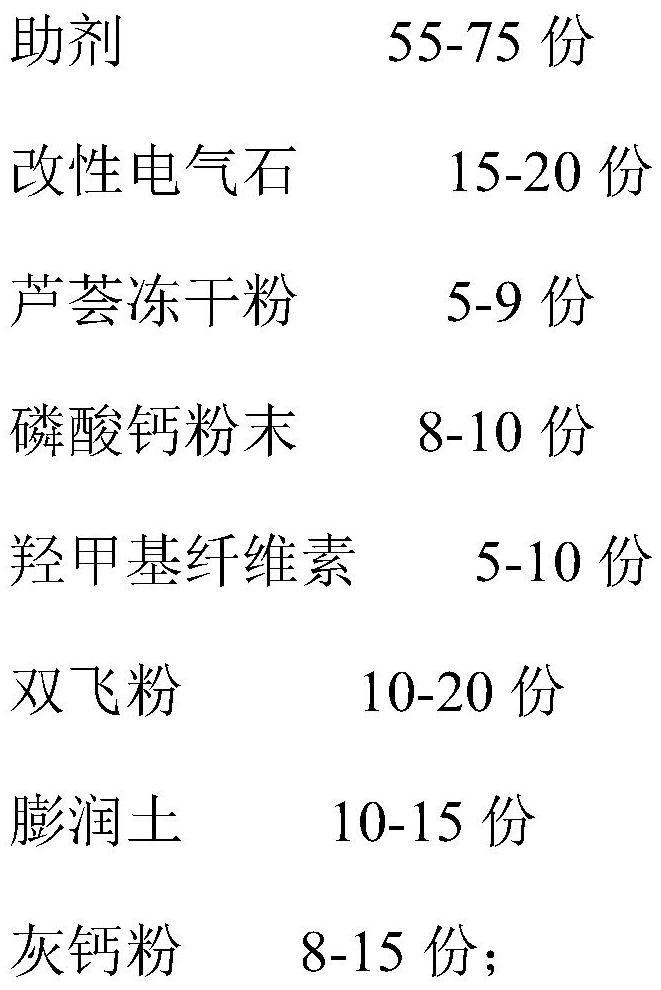

A decorative coating that decomposes formaldehyde and releases high-concentration negative oxygen ions

ActiveCN111808531BPurification effectMitigate indoor pollutionAntifouling/underwater paintsPaints with biocidesAir decontaminationOxygen ions

The invention relates to the technical field of interior decorative coatings, in particular to a decorative coating that absorbs and decomposes formaldehyde and releases negative oxygen ions. In order to further improve the purpose of the decorative paint releasing high-concentration negative oxygen ions to decompose indoor formaldehyde, the present invention provides a decorative paint that absorbs and decomposes formaldehyde and releases negative oxygen ions. In parts by weight, the decorative paint of the present invention includes the following components: 200-300 parts of paint additives, 80-100 parts of water. The components of the decorative paint prepared by the present invention have a synergistic effect, and can release high-concentration negative oxygen ions. The concentration of negative oxygen ions is as high as 80,000 per cubic centimeter. It can be decomposed into non-toxic and tasteless carbon dioxide and water, alleviate indoor pollution, has a significant impact on air purification, and has a good application prospect.

Owner:佛山市邦韵建材有限公司

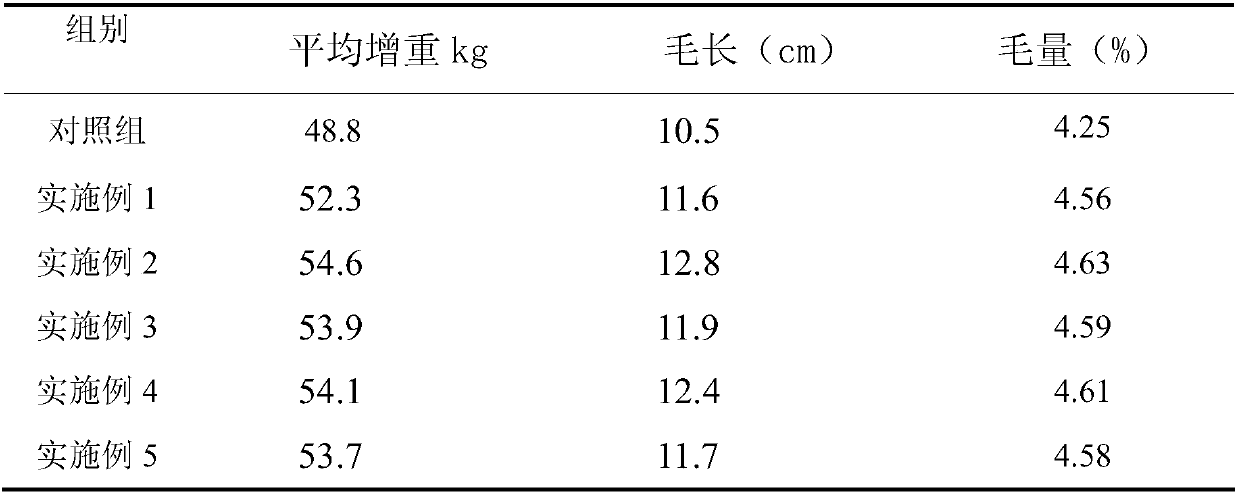

Feed for promoting growth of wool and preparation method thereof

InactiveCN107889940APromote growthPromote growth and developmentAnimal feeding stuffAccessory food factorsWeight gainingAnimal science

The invention relates to feed for promoting the growth of wool. The feed comprises 35 to 65 parts of nutrients, 0.5 to 2 parts of aminoethanethiol hydrochloride, 0.5 to 2 parts of sulfaguanidine, 1 to10 parts of calcium tablets, 1 to 10 parts of cellulase, 1 to 10 parts of urea, 1 to 10 parts of olive oil and 1 to 20 parts of methyl cellulose. Compared with the breed ewe in a control group, the breed ewe eating the feed has larger average weight gain, wool length and wool amount.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

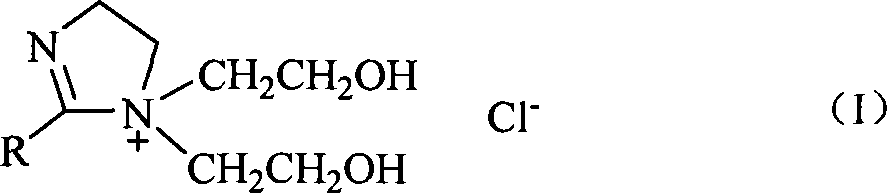

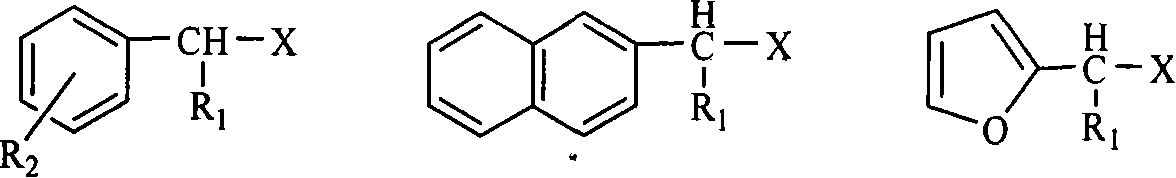

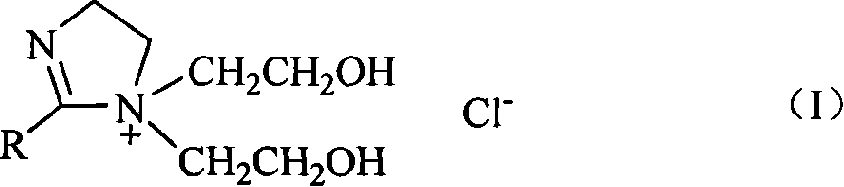

Halogen compound oxo reaction method

ActiveCN101139275AGood water solubilityGood biodegradabilityOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reactionHalogenProtein carbonyl

The present invention discloses a method of the halide carbonylation reaction. The key point of the technology is that the reaction uses a novel phase transfer catalyst 2-alkyl-1- 2 (2- hydroxyethyl)-2-chlorine imidazoline; the catalyst has the good catalytic performance for the carbonylation of the benzyl halogen, alpha-alkyl benzyl halogen and so on through the NaCo(CO)4; the phase transfer catalyst has the advantages of the good water-soluble performance, the good biodegradable performance, the low toxicity, the high efficiency of being recycled and reused, and so on.

Owner:陕西高安绿能生物化工有限公司

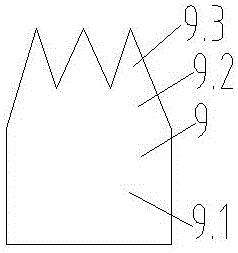

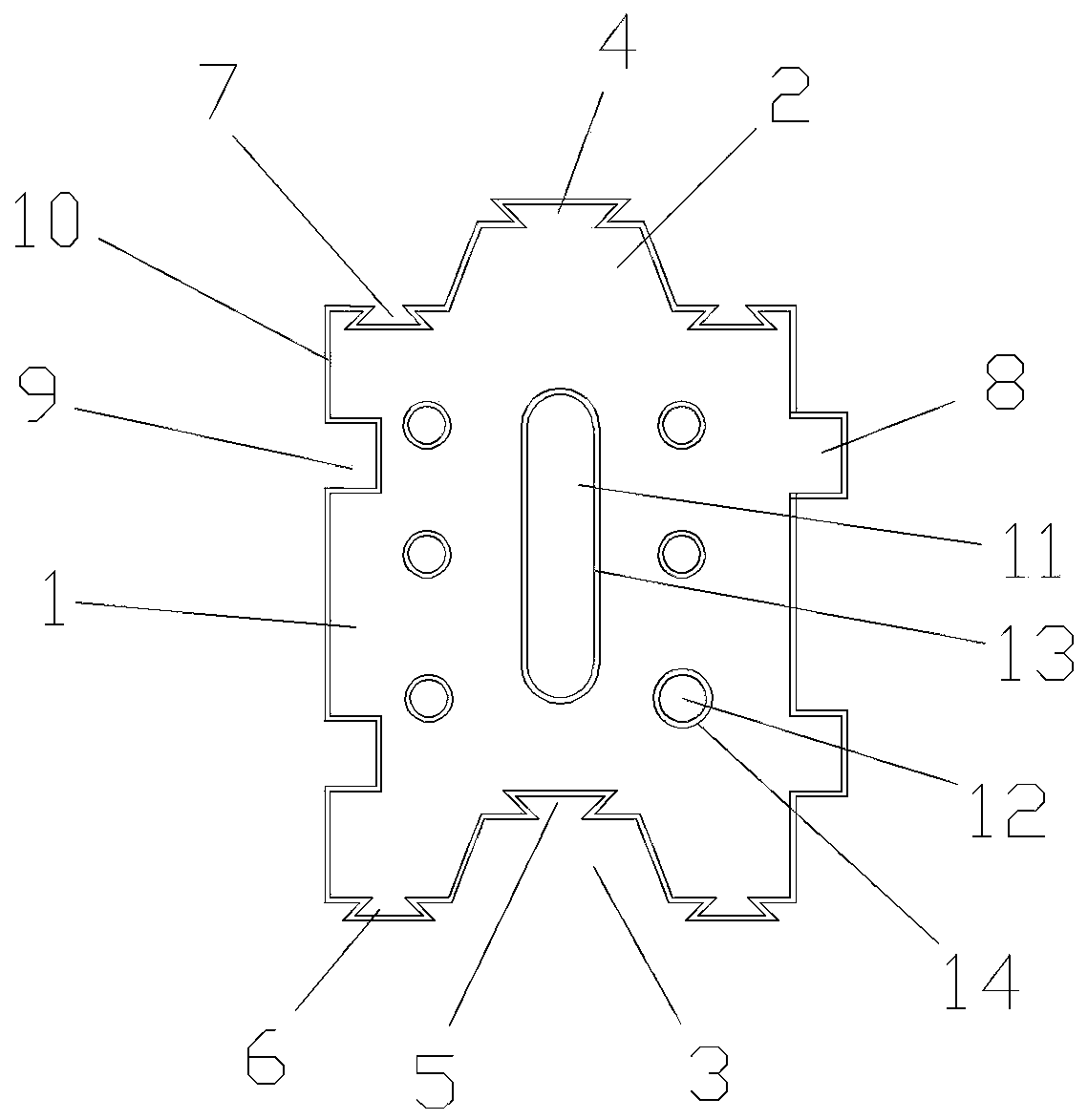

Straw building material brick and machining method thereof

InactiveCN111546456AReduce intensityHigh strengthConstruction materialWallsHuman bodyIsolation effect

The invention relates to a straw building material brick. A body is included. First protruding blocks and first clamping grooves are formed in the two opposite sides of the body correspondingly, and second protruding blocks and second clamping grooves are formed in the other two opposite side walls of the body correspondingly. A kidney-shaped through hole is formed in the body. An outer carbonization layer is arranged on the outer side of the body, and a first inner carbonization layer is arranged in the kidney-shaped through hole. The building material brick comprises following components including, by weight, 60-85 parts of plant straw, 20-38 parts of herbs and 3-10 parts of bonding glue. The straw building material brick has the advantages that the straw building material brick is formed through extrusion of the straw, the weight is small, the strength is high, impact performance is good, and good heat preservation and sound isolation effects are achieved. In the straw building material brick machining process, no pollution is caused to the environment, the purpose of repelling mosquitoes is achieved by adding different herbs in the straw, meanwhile, a corrosion remover and a bacteriostatic agent are added in a plate, a certain sterilization capability is achieved, bacterium breeding is reduced, the technical problem about plate deterioration is solved, and the purpose of protecting the health of human bodies is achieved.

Owner:阜阳市宏桥秸秆科技有限公司

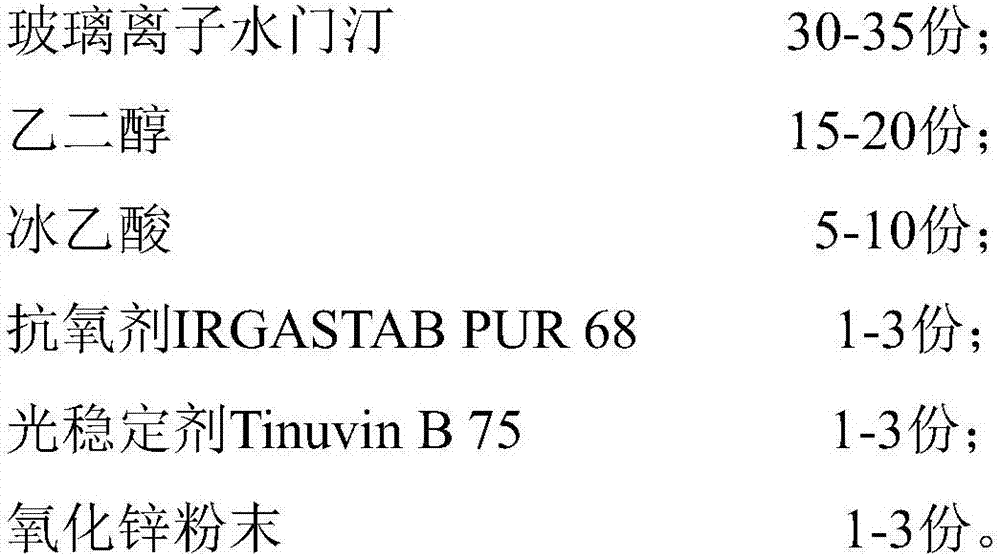

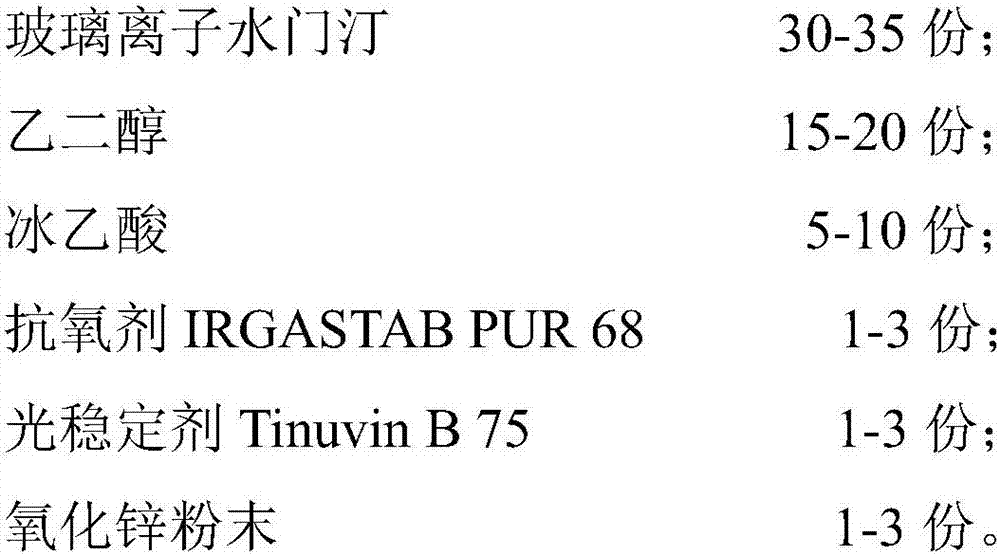

Anti-yellowing and ultraviolet-proof coating

InactiveCN108003668AImprove anti-yellowing abilityImprove wear resistanceAntifouling/underwater paintsPaints with biocidesWear resistantOxide

The invention relates to an anti-yellowing and ultraviolet-proof coating. The anti-yellowing and ultraviolet-proof coating is prepared from, by weight, 30-35 parts of glass ionomer cement, 15-20 partsof ethylene glycol, 5-10 parts of glacial acetic acid, 1-3 parts of antioxidant IRGASTAB PUR 68, 1-3 parts of light stabilizer Tinuvin B 75 and 1-3 parts of zinc oxide powder. According to the anti-yellowing and ultraviolet-proof coating, the glass ionomer cement is added in the formula, so that the coating has a super-strong wear resistant property; the added antioxidant IRGASTAB PUR 68 belongsto an amine-free formula, and the anti-yellowing capacity can be improved; the added light stabilizer Tinuvin B 75 has an anti-yellowing capacity.

Owner:江苏黄金屋光学眼镜有限公司

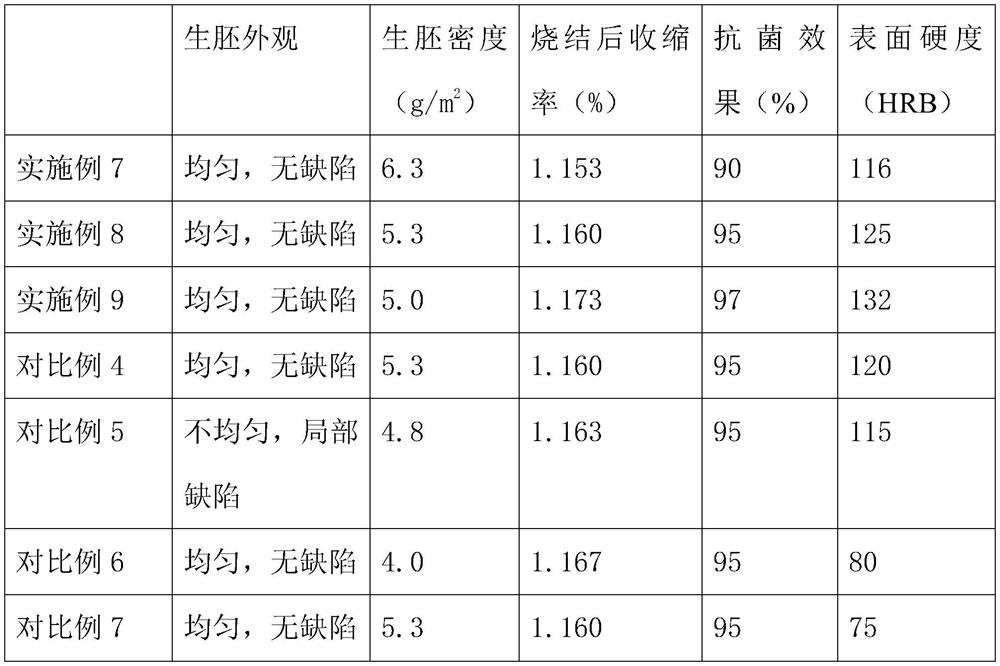

Feed for preparing antibacterial stainless steel cutting tool, cutting tool and preparation method of cutting tool

PendingCN114226716ADiffusion is easy to achieveEvenly distributedTransportation and packagingMetal-working apparatusCarbide siliconSS - Stainless steel

The invention discloses a preparation method of an antibacterial stainless steel feed. The preparation method comprises the following steps: S1, uniformly mixing nanoscale silicon carbide spherical powder and powder with an antibacterial function into 10-15% of a binder, and mixing to obtain a premix A; s2, uniformly mixing the water-gas combined atomized stainless steel powder and tungsten carbide into 85-90% of a binder, and mixing to obtain a premix B; and S3, compounding the premix A and the premix B, banburying, crushing and granulating to obtain the feed. The invention further discloses a preparation method of the antibacterial stainless steel cutting tool. The preparation method comprises the following steps of preorder preparation, injection, degreasing, sintering, heat treatment and edging. The metal injection molding method is adopted for preparing the antibacterial stainless steel cutting tool, the feeding fluidity is good, antibacterial elements are evenly distributed, the sintering density is high, the size stability is good, the product size precision is high, the mechanical property is excellent, batch production can be achieved, machining is little or not needed later, and the cost is low.

Owner:TIANJIAO HOUSEHOLD MFG LTD GUANGDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com