Negative oxygen ion material for air purification

A negative oxygen ion, air purification technology, applied in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of lack of deodorization function, materials easy to breed bacteria, etc., to prevent mold, prevent reproduction, and improve the effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

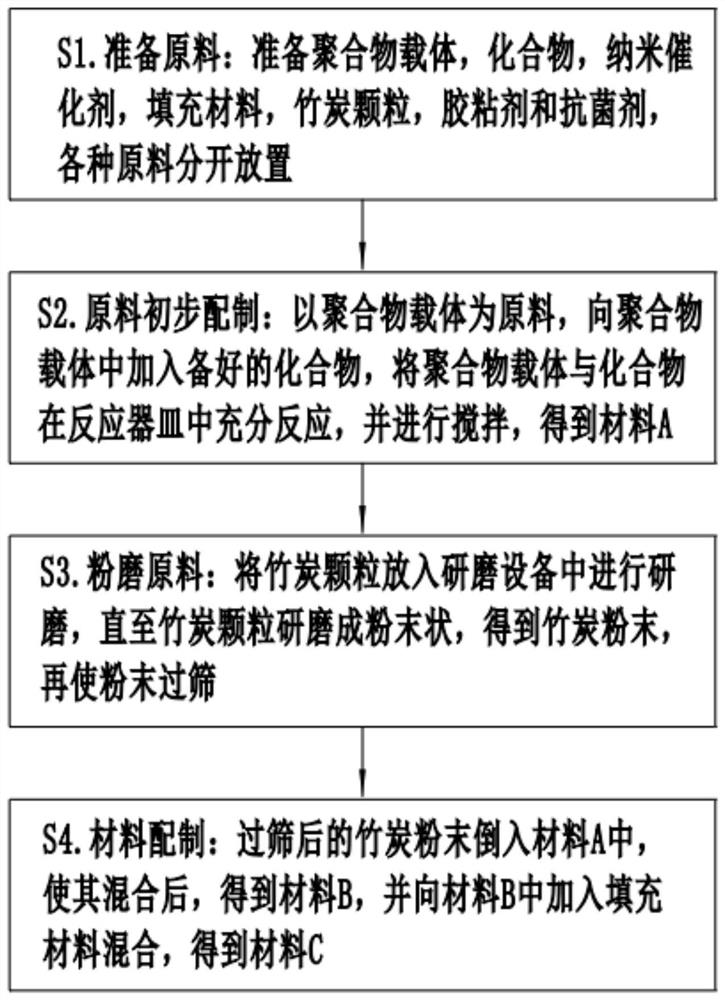

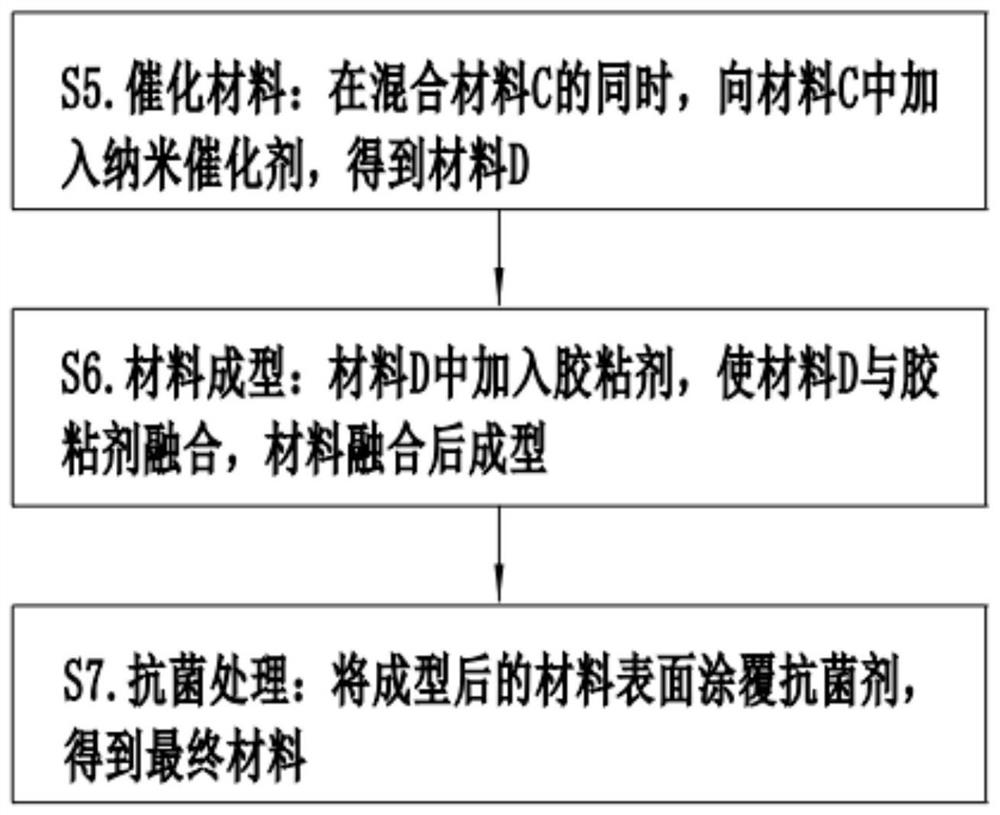

[0033] A negative oxygen ion material for air purification, comprising the following steps,

[0034] S1. Prepare raw materials: prepare polymer carriers, compounds, nano catalysts, filling materials, bamboo charcoal particles, adhesives and antibacterial agents, place various raw materials separately, the polymer carrier is polyethylene, and the compound is hydroxyl;

[0035] S2. Preliminary preparation of raw materials: use the polymer carrier as the raw material, add the prepared compound to the polymer carrier, fully react the polymer carrier and the compound in the reaction vessel, and stir to obtain material A, the polymer carrier and the compound Fully react in the reaction vessel, and stir, the stirring time is 5 minutes, and the ratio of polymer carrier to compound is 2:1;

[0036] S3. Grinding raw materials: Put the bamboo charcoal particles into the grinding equipment for grinding until the bamboo charcoal particles are ground into powder to obtain bamboo charcoal po...

Embodiment 2

[0043] A negative oxygen ion material for air purification, comprising the following steps,

[0044] S1. Prepare raw materials: prepare polymer carriers, compounds, nano catalysts, filling materials, bamboo charcoal particles, adhesives and antibacterial agents, place various raw materials separately, the polymer carrier is polyethylene, and the compound is hydroxyl;

[0045] S2. Preliminary preparation of raw materials: use the polymer carrier as the raw material, add the prepared compound to the polymer carrier, fully react the polymer carrier and the compound in the reaction vessel, and stir to obtain material A, the polymer carrier and the compound Fully react and stir in the reaction vessel, the stirring time is 12 minutes, and the ratio of polymer carrier to compound is 3:1;

[0046] S3. Grinding raw materials: Put the bamboo charcoal particles into the grinding equipment for grinding until the bamboo charcoal particles are ground into powder to obtain bamboo charcoal po...

Embodiment 3

[0053] A negative oxygen ion material for air purification, comprising the following steps,

[0054] S1. Prepare raw materials: prepare polymer carriers, compounds, nano catalysts, filling materials, bamboo charcoal particles, adhesives and antibacterial agents, place various raw materials separately, the polymer carrier is polystyrene, and the compound is hydroxyl;

[0055] S2. Preliminary preparation of raw materials: use the polymer carrier as the raw material, add the prepared compound to the polymer carrier, fully react the polymer carrier and the compound in the reaction vessel, and stir to obtain material A, the polymer carrier and the compound Fully react and stir in the reaction vessel, the stirring time is 15 minutes, and the ratio of polymer carrier to compound is 3:2;

[0056] S3. Grinding raw materials: Put the bamboo charcoal particles into the grinding equipment for grinding until the bamboo charcoal particles are ground into powder to obtain bamboo charcoal pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com