Preparation method of tough non-woven fabric for packaging

A technology for non-woven fabrics and packaging, applied in the field of preparation of strong and tough non-woven fabrics for packaging, can solve problems such as hidden safety hazards, limited load bearing, and poor non-woven packaging strength and toughness, so as to improve the toughness, Improve the effect of antibacterial type and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

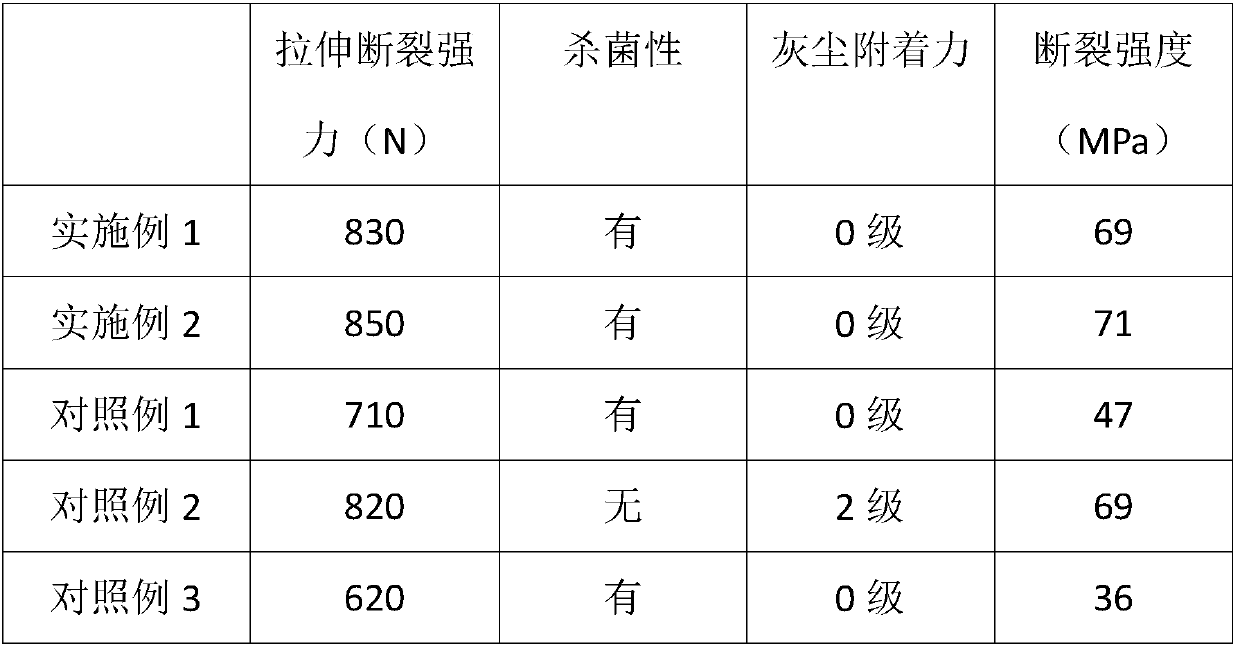

Examples

Embodiment 1

[0018] Described mica powder is modified mica powder, and specific modification method is as follows: 1) take raw material mica powder by following mass ratio: acetone: lauroyl peroxide: acrylic acid=2:3:1.5:4, and described mica Add the powder into acetone, add the lauroyl peroxide and the acrylic acid under stirring, ultrasonically disperse for 15 minutes, react at 65°C for 1 hour, filter the reaction product, and dry it in an oven at 90°C for 4 hours to obtain acrylic acid Surface-modified mica powder A; 3) adding mica powder A and polyethylene wax into an extruder according to the mass ratio of mica powder A: polyethylene = 12:7, extruding and granulating to obtain a modified mica powder.

[0019] S1: Add 4 parts of nano-silica, 2 parts of mica powder, 0.4 parts of nano-silver, and 20 parts of benzophenone to the methacrylate copolymer solution, and ultrasonically disperse and stir evenly to obtain solution A;

[0020] S2: The fine fiber polymer includes low melting point ...

Embodiment 2

[0024] Described mica powder is modified mica powder, and specific modification method is as follows: 1) take raw material mica powder by following mass ratio: acetone: lauroyl peroxide: acrylic acid=2:3:1.5:4, and described mica Add the powder into acetone, add the lauroyl peroxide and the acrylic acid under stirring, ultrasonically disperse for 15 minutes, react at 65°C for 1 hour, filter the reaction product, and dry it in an oven at 90°C for 4 hours to obtain acrylic acid Surface-modified mica powder A; 3) adding mica powder A and polyethylene wax into an extruder according to the mass ratio of mica powder A: polyethylene = 12:7, extruding and granulating to obtain a modified mica powder.

[0025] S1: Add 6 parts of nano-silica, 4 parts of mica powder, 0.6 parts of nano-silver, and 30 parts of benzophenone to the methacrylate copolymer solution, and ultrasonically disperse and stir evenly to obtain solution A;

[0026] S2: The fine fiber polymer includes low melting point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com