Straw building material brick and machining method thereof

A processing method and technology of building materials bricks, applied in the field of building materials, can solve the problems of invisible straw value, environmental pollution, waste of resources, etc., and achieve the effects of protecting human health, overcoming deterioration and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

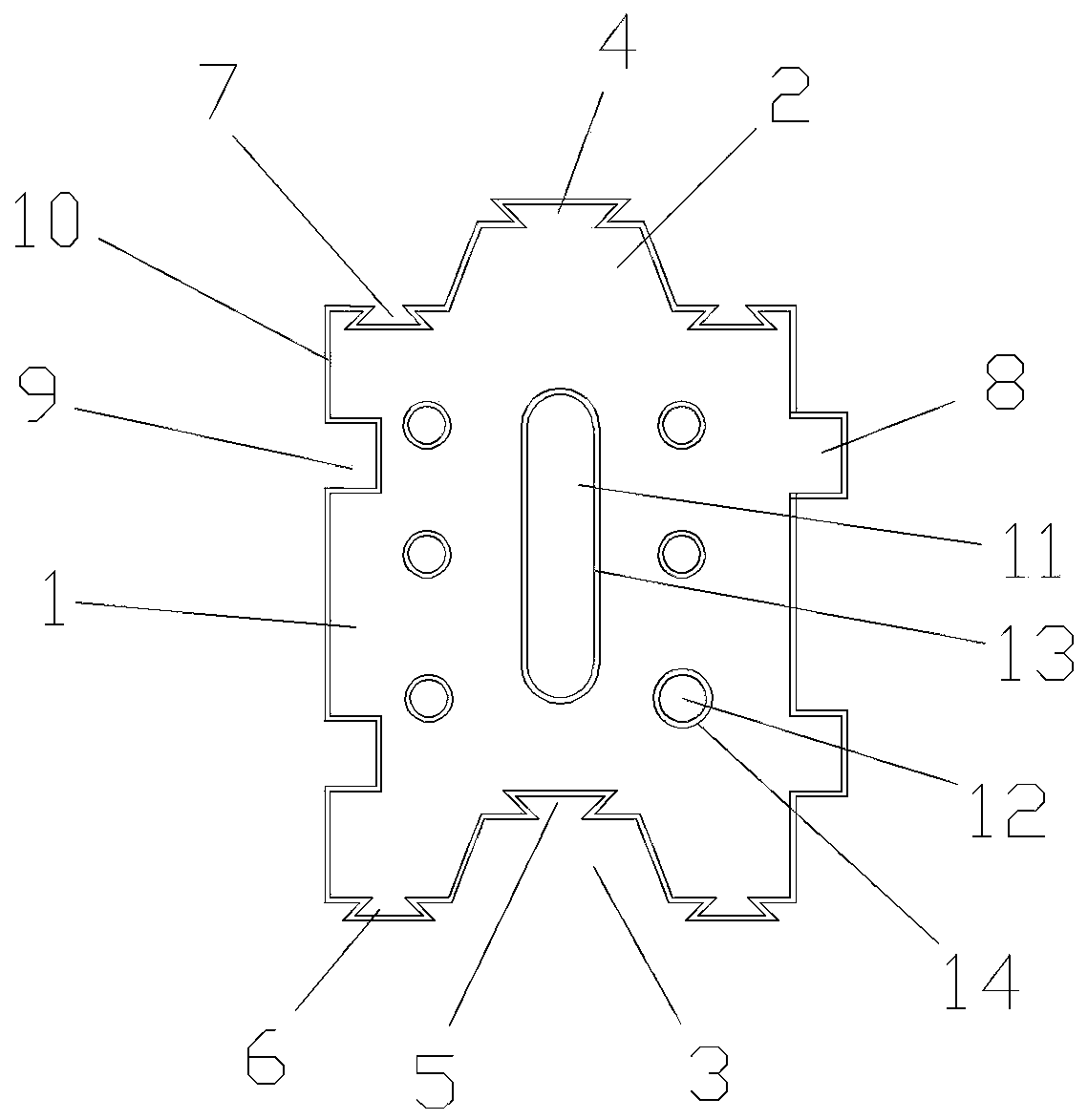

[0032] Embodiment one, such as figure 1 As shown, the present invention relates to a straw building material brick, comprising a square body 1, two first protrusions 2 and two first card slots 3 are respectively provided on opposite sides of the body 1, the first protrusions 2 are The cross section is a trapezoidal elongated plate, and the side length of the top of the first bump 2 is smaller than the side length of the bottom, and the first locking groove 3 is a trapezoidal groove with the same shape as the first bump 2 . A third bump 4 is arranged on the top of the first bump 2 . The third bump 4 is also a long plate with a trapezoidal cross section. The third bump 4 is placed upside down on the first bump 2 . A third locking groove 5 is provided at the bottom of the first locking groove 3 , and the third locking groove 5 is a trapezoidal groove having the same shape as the third protrusion 4 . A fourth protruding block 6 is respectively arranged on both sides of the first ...

Embodiment 2

[0045] Embodiment 2. On the basis of Embodiment 1, wormwood can also be substituted for dried citrus peel, peppermint, Hedyotis diffusa, Jiguxiang, trigeminus, aescin, peppermint or camphor as needed. The straw in the first embodiment can also be cut into 0.5cm, 1cm, 2.5cm, 3cm, 4cm and 5cm. When drying, the hot air of the dryer is set to 25 0 C, drying for 20 minutes, the moisture content of the straw is 8%.

[0046] Before mixing the herbs with the straw, the glue needs to be configured into a liquid state and pre-wrapped on the straw, which not only effectively bonds the straw and herbs together, but also preserves the efficacy of the herbs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com