Nano waterproof breathable film and preparation method thereof

A waterproof and breathable film, nanotechnology, applied in the field of waterproof and breathable materials for sanitary products, can solve the problem of stuffy sanitary products and other problems, and achieve the effect of low price of experimental raw materials, high tensile strength and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

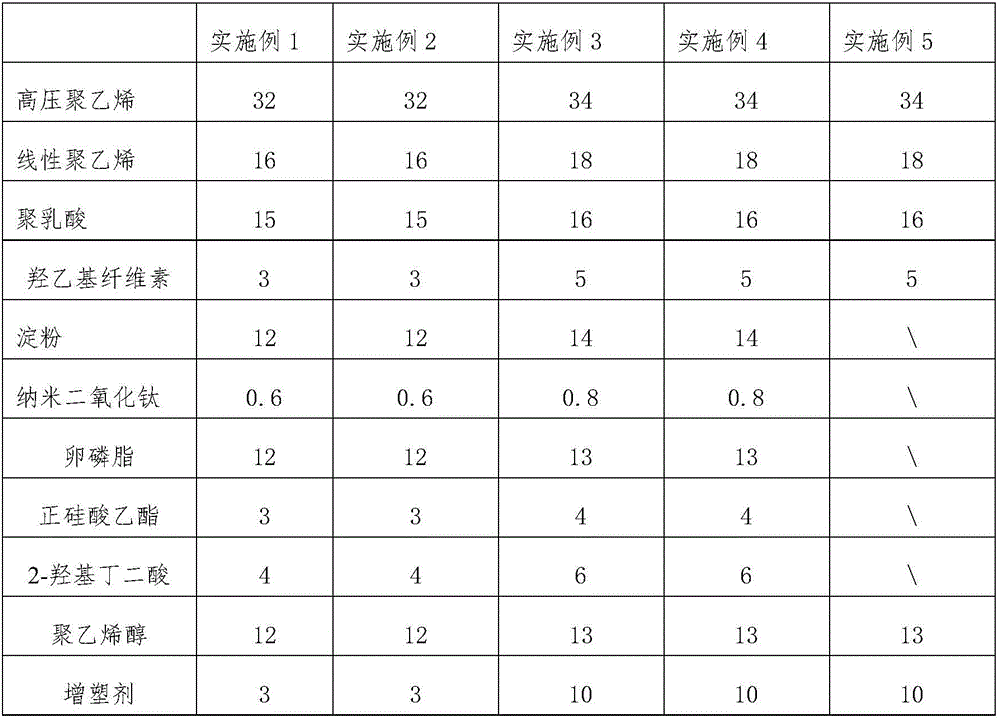

[0024] The preferred embodiment 1 of the present invention provides a nano waterproof and breathable membrane, the raw material components of which are shown in Table 1, wherein the plasticizer is thermoplastic elastomer, and the lubricant is chlorinated polyethylene.

[0025] The preparation method of above-mentioned nano waterproof gas-permeable film, comprises the steps:

[0026] Step [1] Add corresponding parts by weight of nano-titanium dioxide particles into absolute ethanol, and disperse them with ultrasonic waves at room temperature for 20 to 30 minutes to fully disperse nano-titanium dioxide to form an ethanol dispersion system; lecithin, ethyl orthosilicate, Add 2-hydroxysuccinic acid to 8-12mL of chloroform / ethanol mixed solvent, add it to the ethanol dispersion system after fully dissolving and mixing, then continue ultrasonication for 0.5-1.5 hours at about 30°C, at 35°C The product A obtained by evaporating the solvent to dryness, then adding the starch into deio...

Embodiment 2

[0035] The preferred embodiment 2 of the present invention provides a nano waterproof and breathable membrane, the raw material components of which are shown in Table 1, wherein the plasticizer is thermoplastic elastomer, and the lubricant is chlorinated polyethylene.

[0036] The preparation method of the above-mentioned nano waterproof and breathable membrane, step [1] to step [3] are the same as in Example 1, and the step [4] is: combine all the prepared nanofibers with half of the prepared core / shell structure The particles are evenly mixed and spread into a film layer with a certain thickness, and then hot-pressed at 40-50°C, after hot pressing, the other half of the core / shell structure particles are evenly spread on the hot-pressed film layer, and then The film layer is dried by infrared drying equipment at 80° C. to finally obtain the nanometer waterproof and breathable film.

Embodiment 3

[0038] The preferred embodiment 3 of the present invention provides a nano waterproof and breathable membrane, the raw material components of which are shown in Table 1, and the preparation method is the same as that of the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com