High-barrier-property pesticide packing bottle and preparation method thereof

A high-barrier, packaging bottle technology, applied in the direction of adhesives, etc., can solve environmental pollution, accidental poisoning, penetration and other problems, to improve impermeability and mechanical properties, reduce moisture permeability coefficient and air permeability coefficient, and improve impermeability and barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

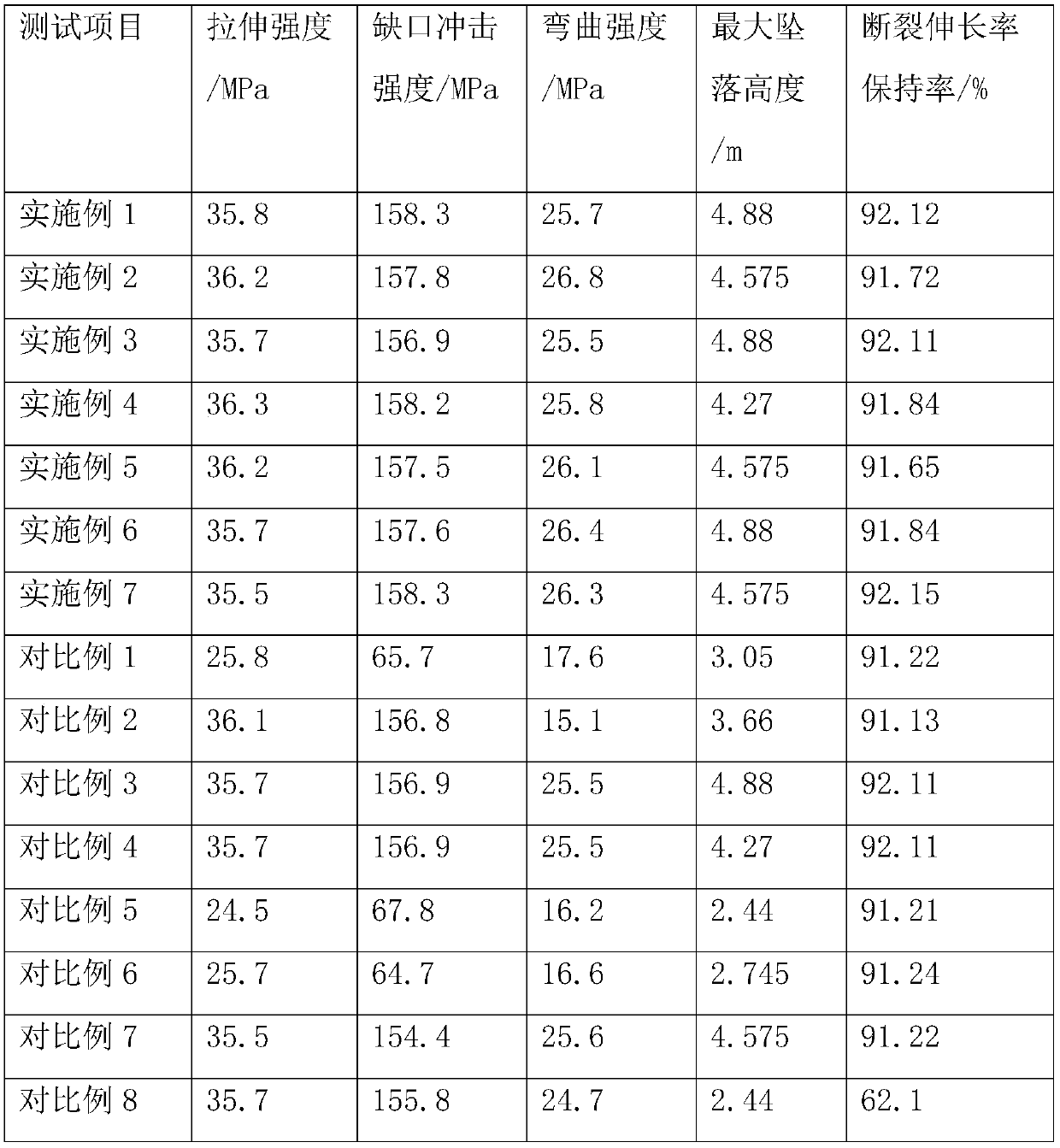

Examples

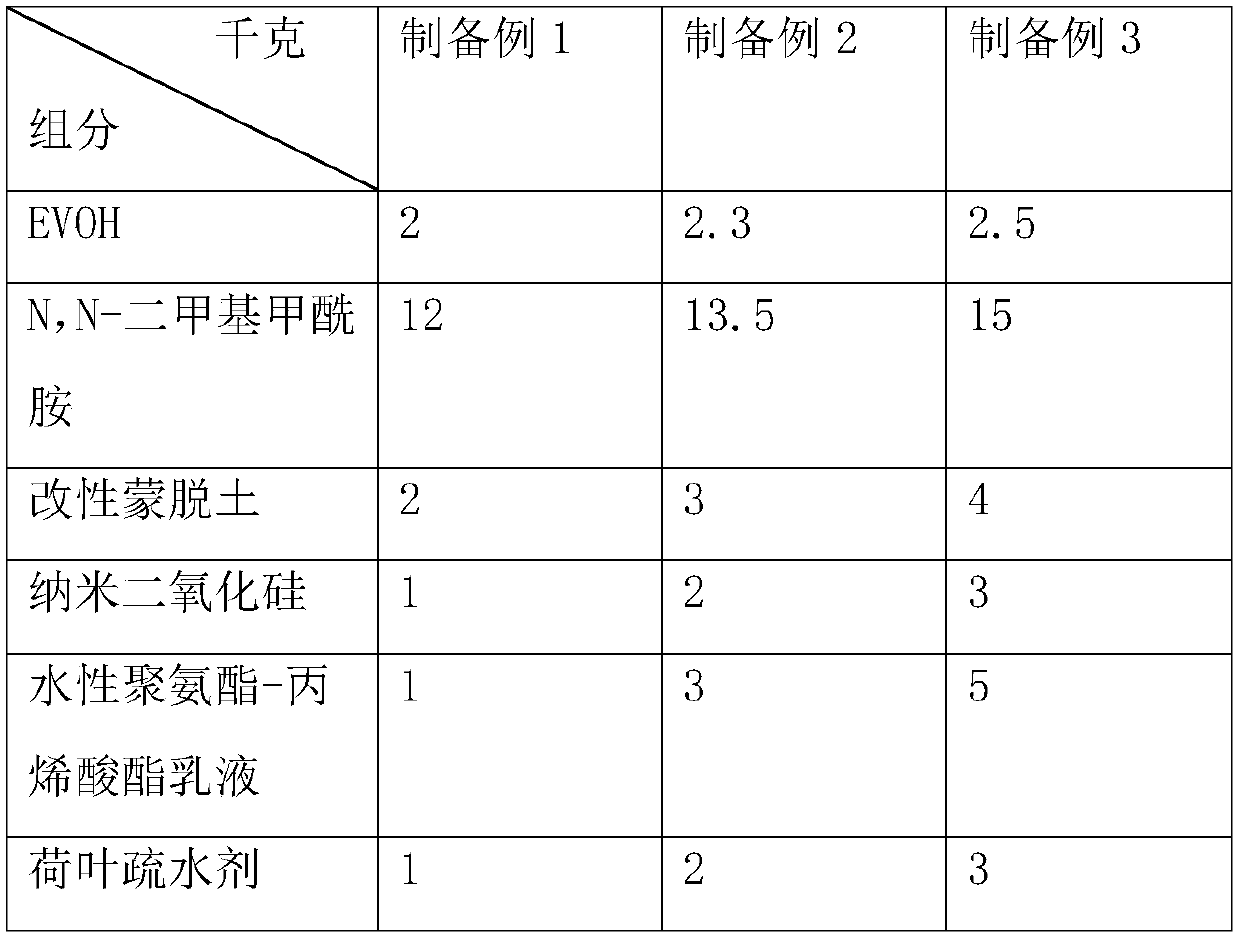

preparation example 1-3

[0044] In the following preparation examples, the water-based polyurethane-acrylate emulsion is selected from the JAZO type water-based polyurethane-acrylate emulsion of Nanjing Jiazhong Chemical Technology Co., Ltd., the lotus leaf hydrophobic agent is purchased from Zhengzhou Yuxiang Chemical Products Co., Ltd., and the sodium-based montmorillonite is selected from For the SM-P Na-based montmorillonite sold by Zhejiang Fenghong New Materials Co., Ltd., each of the above components can also use other types of products of the same type.

preparation example 1

[0045] Preparation example 1: EVOH dissolution: According to the ratio in Table 1, add 2 kg of EVOH and 8 kg of N,N-dimethylformamide into the reactor, heat while stirring, and heat to 180°C to make EVOH fully dissolved, wherein the ethylene content in RVOH is 38%;

[0046] Dissolution of modified montmorillonite: dissolve 2 kg of modified montmorillonite in 4 kg of N,N-dimethylformamide solution, mix well; mix: mix 1 kg of nano-silica and 1 kg of water-based polyurethane-acrylic acid After the ester emulsion is mixed evenly, add the dissolved EVOH and modified montmorillonite, stir at 80°C, add 1 kg of lotus leaf hydrophobic agent while stirring, and mix evenly.

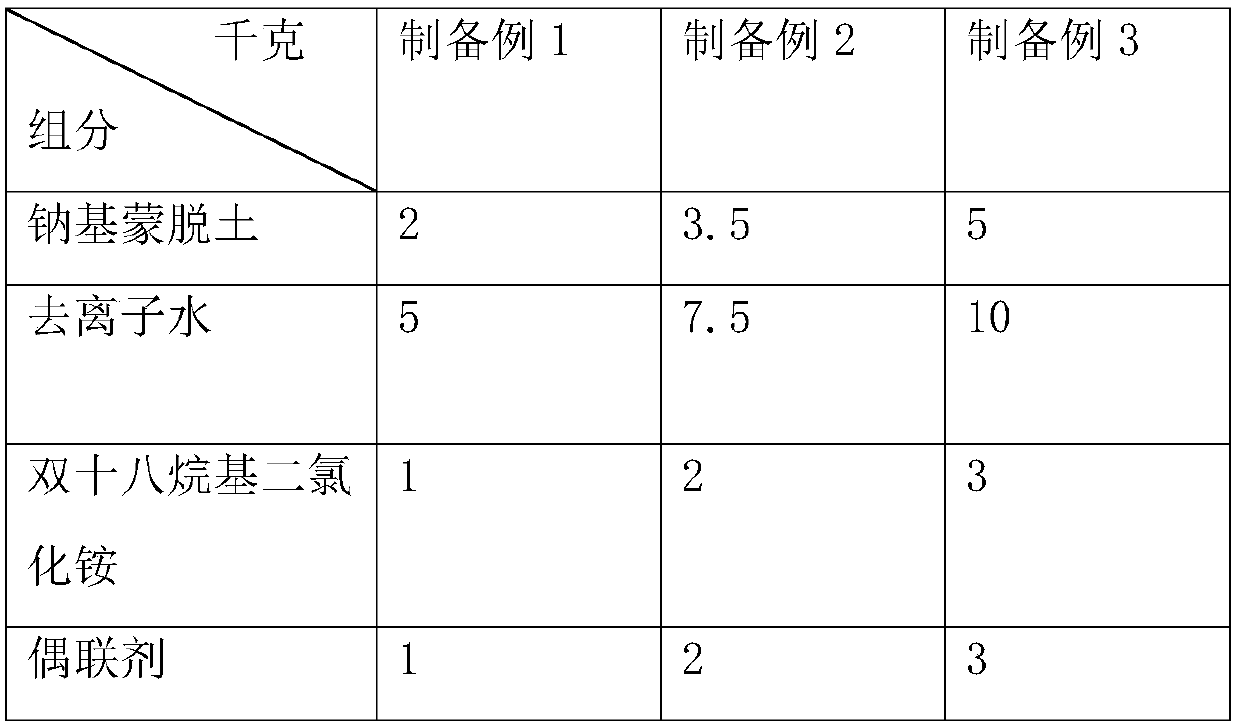

[0047] Wherein the preparation method of modified montmorillonite is as follows: (1) according to the proportioning in table 2, get 2 parts of sodium-based montmorillonite and 5 parts of deionized water and mix, be mixed with montmorillonite suspension, adjust with HCl solution pH to 1, stirred at 80°C for 2h;

[...

preparation example 2

[0054] Preparation Example 2: EVOH Dissolution: According to the ratio in Table 1, add 2.3 kg of EVOH and 9 kg of N,N-dimethylformamide into the reactor, heat while stirring, and heat to 1850°C to make EVOH fully dissolved, wherein the ethylene content in RVOH is 38%;

[0055] Dissolution of modified montmorillonite: dissolve 3 kg of modified montmorillonite in 4.5 kg of N, N-dimethylformamide solution, and mix well;

[0056] Mixing: After mixing 2 kg of nano-silica and 3 kg of water-based polyurethane-acrylate emulsion evenly, add dissolved EVOH and modified montmorillonite, stir at 90°C, and add 2 kg of lotus leaf hydrophobic agent while stirring ,well mixed.

[0057] Wherein the preparation method of modified montmorillonite is as follows: (1) according to the proportioning in table 2, get 3.5 parts of sodium-based montmorillonite and 7.5 parts of deionized water and mix, be mixed with montmorillonite suspension, adjust with HCl solution pH to 1, stirred at 83°C for 2.5h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com