Glassine release paper

A glassine base paper, Xin release technology, applied in the field of release paper, can solve the problems of insufficient bonding, low quality, skin damage, etc., and achieve the effect of improving anti-sticking ability, improving smoothness, and improving hygiene standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

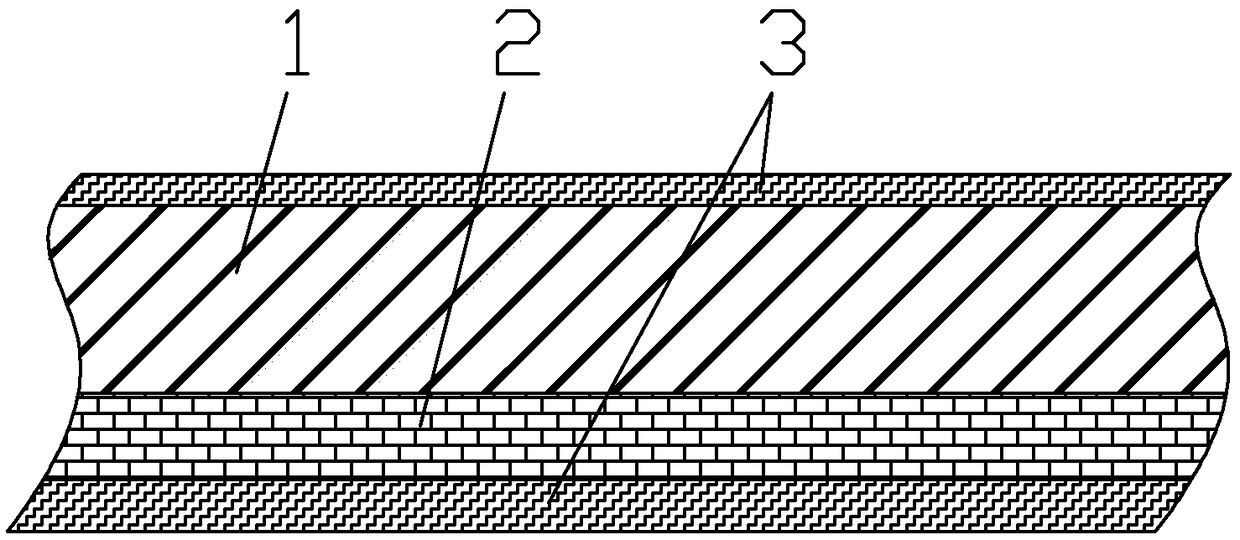

[0021] refer to figure 1 , a glassine release paper, comprising a glassine base paper layer 1, the glassine base paper layer 1 is specifically glassine base paper, one side of the glassine base paper layer 1 is evenly coated with a release material layer 2, The thickness of the release material layer 2 is 1 / 3 of the thickness of the glassine base paper layer 1, and the release material layer 2 is specifically made of a release material.

[0022] The surface of the other side of the glassine base paper layer 1 and the side of the release material layer 2 away from the glassine base paper layer 1 are also coated with a solvent-free silicone oil layer 3, and the thickness of the solvent-free silicone oil layer 3 is the thickness of the release material layer 2. 1 / 3 of the thickness, and the solvent-free silicone oil layer 3 is specifically made of solvent-free silicone oil, spraying the solvent-free silicone oil can improve the smoothness of the surface of the glassine release pa...

Embodiment 2

[0024] The present invention also provides a release material, its formula by weight is as follows: 35 parts of emulsion type silicone release agent, 8 parts of alkyd resin, 8 parts of octadecyl carbamate, 5 parts of p-toluenesulfonic acid, 5 parts of ethyl acetate, 3 parts of stabilizer, 3 parts of initiator.

[0025] The present invention also provides a solvent-free silicone oil, whose formula by weight is as follows: 40 parts of solvent-free silicone oil, 5 parts of metal powder, 3 parts of fluoride additive, 3 parts of flame retardant, and 1 part of catalyst.

[0026] The metal powder is specifically a mixture of aluminum powder, copper powder, zinc powder and silicon powder, and the molar mass ratio of aluminum powder, copper powder, zinc powder and silicon powder is 1:1:2:4.

[0027] The present invention also provides a method for processing glassine base paper, the specific steps are as follows:

[0028] S1. Select the glassine base paper, cut the glassine base paper...

Embodiment 3

[0031] The present invention also provides a release material, and its formula by weight is as follows: 38 parts of emulsion type silicone release agent, 9 parts of alkyd resin, 9 parts of octadecyl carbamate, 5.5 parts of p-toluenesulfonic acid, 5.5 parts of ethyl acetate, 3.5 parts of stabilizer, and 3.5 parts of initiator.

[0032] The present invention also provides a solvent-free silicone oil, whose formula by weight is as follows: 45 parts of solvent-free silicone oil, 6 parts of metal powder, 3.5 parts of fluoride additive, 3.5 parts of flame retardant, and 1.5 parts of catalyst.

[0033] The metal powder is specifically a mixture of aluminum powder, copper powder, zinc powder and silicon powder, and the molar mass ratio of aluminum powder, copper powder, zinc powder and silicon powder is 1:1:2:4.

[0034] The present invention also provides a method for processing glassine base paper, the specific steps are as follows:

[0035] S1. Select the glassine base paper, cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com