Printing ink composition containing starch

A technology of printing ink and composition, which is applied in the field of printing ink, can solve the problems that the ink cannot be dried immediately, affects the quality of the printed product, and the printing quality is difficult to guarantee, and achieves good gloss of the product, solves the adhesion of the printed matter, and completely dries the product Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

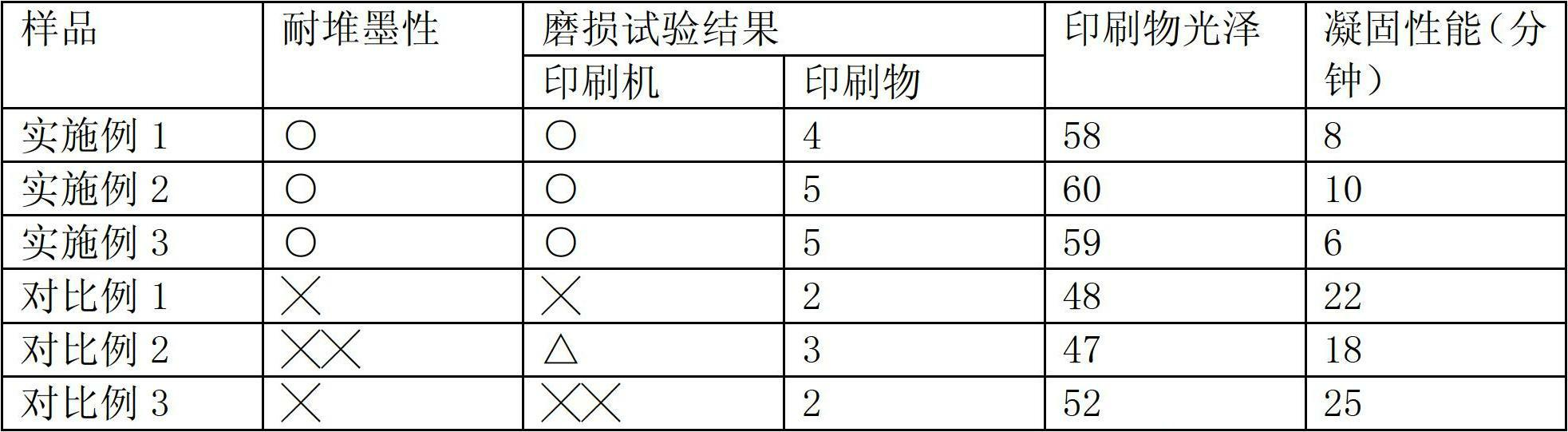

Examples

Embodiment 1

[0033] A printing ink composition containing starch, in parts by weight, 2 parts of starch are added to 100 parts of printing ink;

[0034] The fineness of the starch is 8 microns;

[0035] Described printing ink contains by weight percentage:

[0036] 10% titanium dioxide;

[0037] 40% Glycerin Rosin Ester;

[0038] 6% acrylic resin;

[0039] 20% linseed oil;

[0040] 20% isopropanol and ethyl acetate mixture; the weight ratio of isopropanol and ethyl acetate is 1:3;

[0041] 4% auxiliary agent; in the described auxiliary agent, manganese isooctanoate: dibutyl phthalate: the weight ratio of BYK2000 dispersant is 1: 2: 7;

[0042] The printing ink composition is prepared by the following method:

[0043] Mix the titanium dioxide, glycerin rosin ester, acrylic resin, linseed oil, isopropanol and ethyl acetate mixture and additives in the above ratio evenly with a high-speed shear mixer to obtain a shear dispersion, and then in the shear dispersion Add starch, put it into...

Embodiment 2

[0045] A printing ink composition containing starch, in parts by weight, 2.5 parts of starch are added to 100 parts of printing ink;

[0046] The fineness of the starch is 12 microns;

[0047] Described printing ink contains by weight percentage:

[0048] 11% titanium dioxide;

[0049] 40% Glycerin Rosin Ester;

[0050] 6% acrylic resin;

[0051] 18% linseed oil;

[0052] 20% isopropanol and ethyl acetate mixture, the weight ratio of isopropanol and ethyl acetate is 1:3;

[0053] 5% auxiliary agent; in the auxiliary agent, manganese isooctanoate: dibutyl phthalate: the weight ratio of BYK2000 dispersant is 1: 2: 7; the printing ink composition is prepared by the following method:

[0054] Mix the titanium dioxide, glycerin rosin ester, acrylic resin, linseed oil, isopropanol and ethyl acetate mixture and additives in the above ratio evenly with a high-speed shear mixer to obtain a shear dispersion, and then in the shear dispersion Add starch, put it into a grinder and gr...

Embodiment 3

[0056] A printing ink composition containing starch, in parts by weight, 2 parts of starch are added to 100 parts of printing ink;

[0057] The fineness of the starch is 10 microns;

[0058] Described printing ink contains by weight percentage:

[0059] 10% titanium dioxide;

[0060] 40% Glycerin Rosin Ester;

[0061] 6% acrylic resin;

[0062] 20% soybean oil;

[0063] 20% isopropanol and ethyl acetate mixture; the weight ratio of isopropanol and ethyl acetate is 1:3;

[0064] 4% auxiliary agent; in the described auxiliary agent, manganese isooctanoate: dibutyl phthalate: the weight ratio of BYK2000 dispersant is 1: 2: 7;

[0065] The printing ink composition is prepared by the following method:

[0066] Mix the titanium dioxide, glycerin rosin ester, acrylic resin, soybean oil, isopropanol and ethyl acetate mixture and additives in the above ratio evenly with a high-speed shear mixer to obtain a shear dispersion, and then add it to the shear dispersion The starch is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com