Method and device for drying sludge by utilizing thermal power plant waste heat

A technology for sludge drying and thermal power plants, applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc., which can solve problems such as unfavorable sludge transportation, storage and further treatment, high-grade electric energy, energy waste, etc. , to achieve the effects of easy large-scale scale, energy saving, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

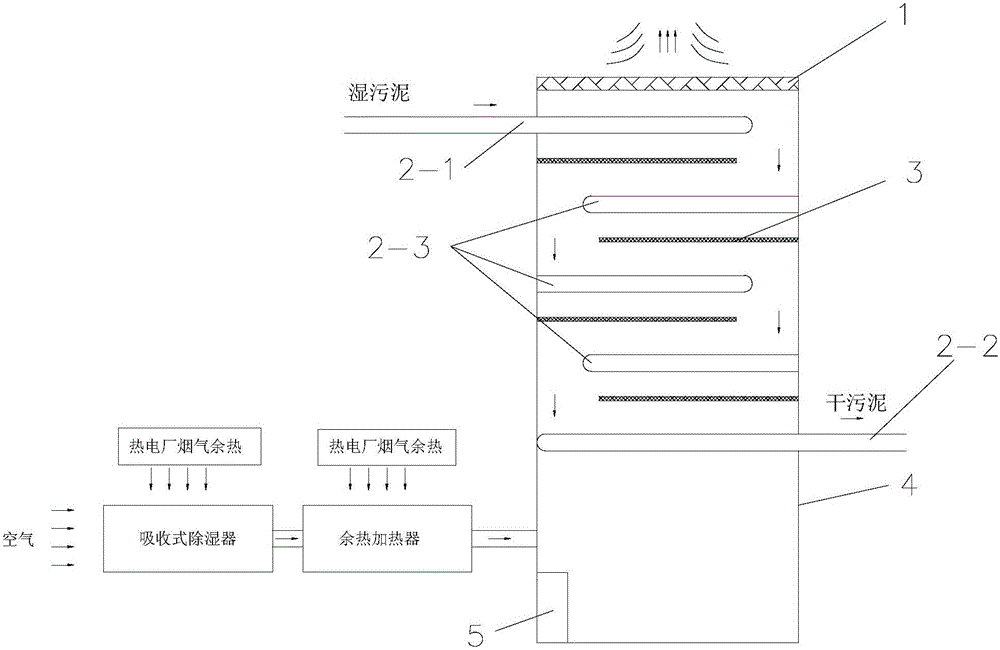

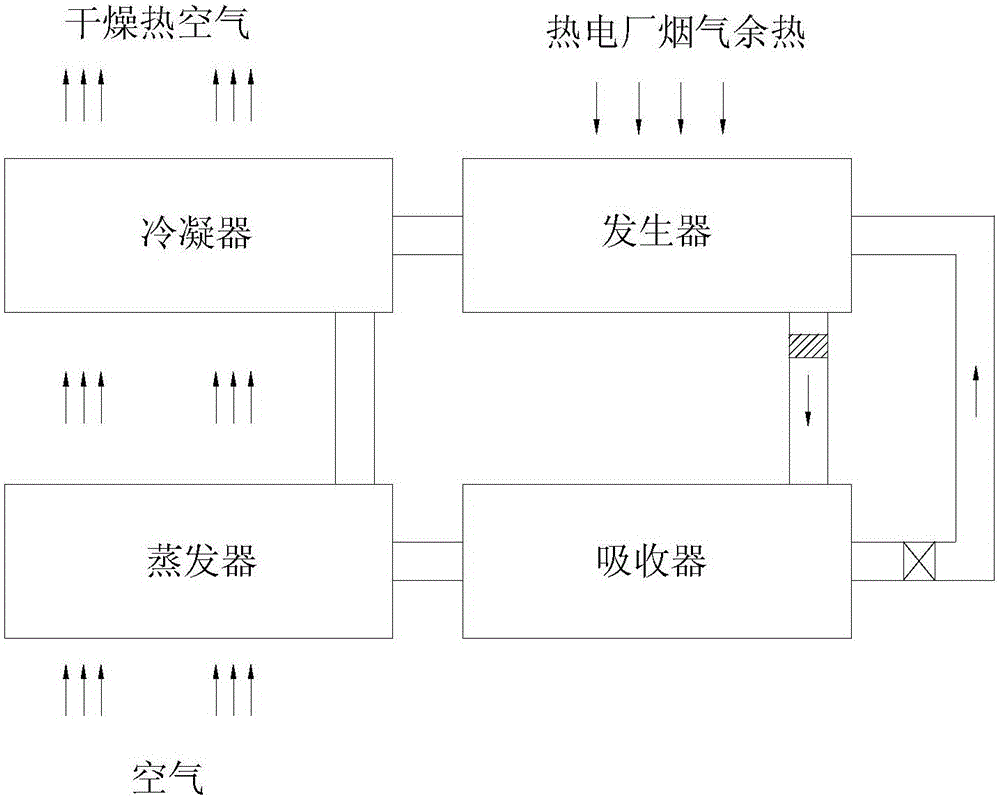

[0035] As shown in Figures 1 and 2. The invention discloses a sludge drying device combined with waste heat utilization of a thermal power plant, comprising a furnace 4, a plate-type feeding conveyor belt 2-1 arranged on the inner upper part of the furnace 4, and a plate-type discharge conveying belt 2-2 arranged on the inner lower part of the furnace 4 ;

[0036] Between the plate feed conveyer belt 2-1 and the plate discharge conveyer belt 2-2, there are multi-layer middle plate conveyer belts 2-3 staggeredly distributed from top to bottom; The internal airflow channels are spaced into S-shaped airflow channels;

[0037] The lower side wall of the furnace 4 is provided with a drying air supply device; the drying air passes through the plate type discharge conveyor belt 2-2, the middle layer plate type conveyor belt 2-3 and the plate type feed conveyor belt 2-1 sequentially from bottom to top, drying Under the action of their diversion, the wind circulates in the furnace 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com