Filtering and drying device for calcium carbonate preparation

A filter drying, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, heating device, filter screen, etc., to achieve the effect of complete drying, uniform dispersion, and enlarged movement path

Pending Publication Date: 2021-03-02

耒阳市百汇粉体有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a kind of filter drying device for calcium carbonate preparation, to solve the current market problem that the above background technology proposes, because calcium carbonate contains larger lumps, it cannot be dried by simply relying on drying. Problem with filtering it out and crushing it again to get it completely dry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

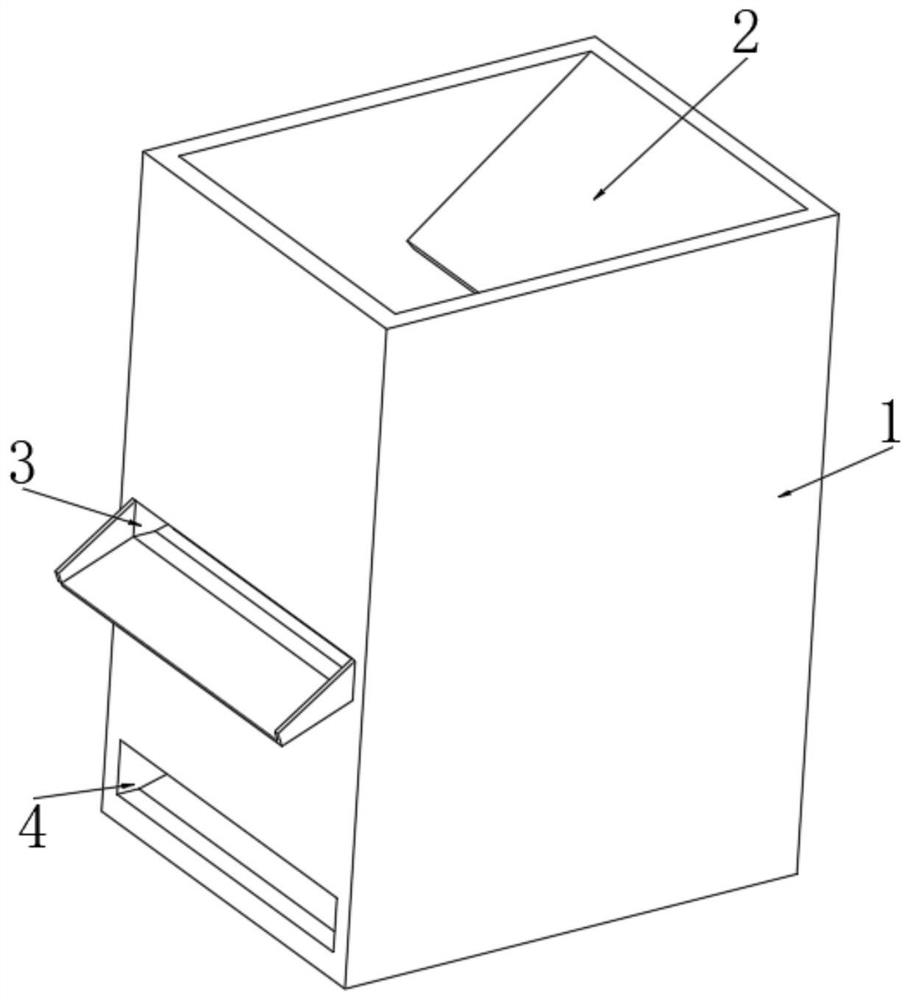

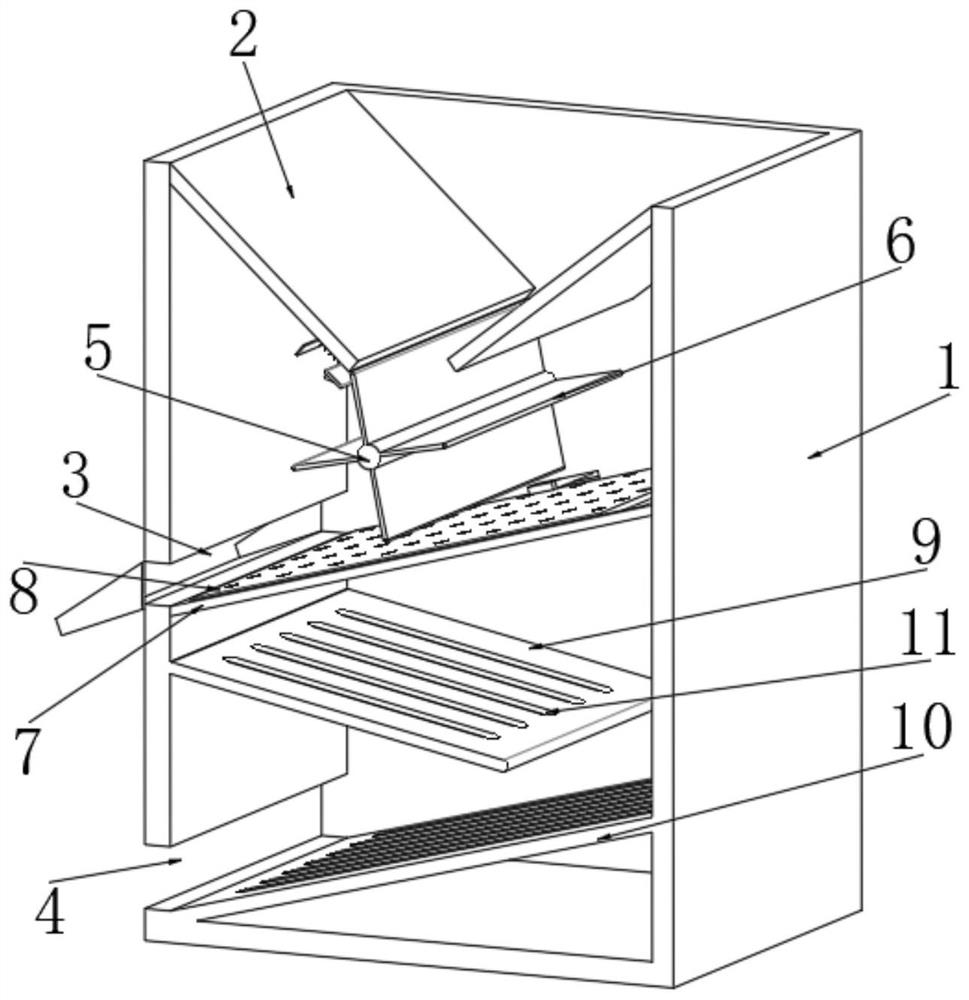

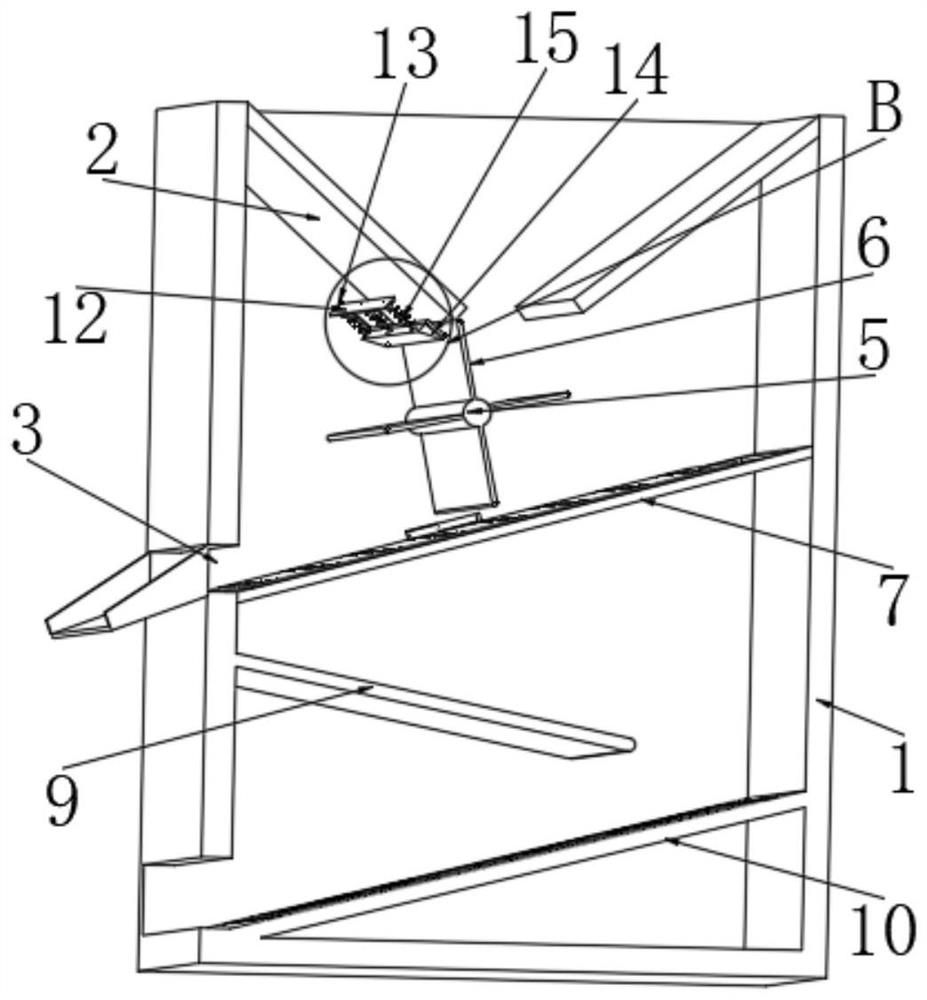

The invention discloses a filtering and drying device for calcium carbonate preparation. The filtering and drying device comprises a machine body, wherein two baffles are symmetrically arranged on theinner side wall, close to the top, of the machine body, and the two baffles are obliquely arranged; a rotating shaft is rotationally connected to the inner side wall, close to the baffles, of the machine body, and a plurality of material blocking plates are uniformly and fixedly connected to the outer side wall of the rotating shaft; a supporting frame is obliquely and fixedly connected to the inner side wall, located below the material blocking plates, of the machine body, and a sieve plate is slidably connected to the upper side wall of the supporting frame; an L-shaped inclined block is fixedly connected to the side wall of one side of the sieve plate, and a rectangular opening is formed in the side wall of the side, close to the L-shaped inclined block, of the machine body; and the side wall of one end of the rotating shaft penetrates through the side wall of the machine body and is fixedly connected with a cam. The invention relates to the technical field of calcium carbonate production and processing. The rotating shaft is driven to rotate through the material blocking plates, so that the cam pushes a push plate to move, then the sieve plate can be driven to shake, and calcium carbonate particles can be conveniently screened.

Description

technical field [0001] The invention relates to the technical field of calcium carbonate production and processing, in particular to a filtering and drying device for preparing calcium carbonate. Background technique [0002] Calcium carbonate is an important class of functional inorganic fillers. It has the advantages of low price, abundant reserves, stable performance, easy processing, and non-toxicity. It can significantly improve the processing performance and physical properties of materials and reduce production costs. It is widely used In the fields of plastics, rubber, paint, paper, etc.; in the production and preparation of calcium carbonate, it is necessary to filter out the calcium carbonate mixed with water. Since the calcium carbonate contains relatively large lumps, it is impossible to simply rely on drying to remove It is dry and needs to be filtered out and crushed again to make it completely dry. Contents of the invention [0003] The purpose of the prese...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F26B23/04B07B1/32C01F11/18

CPCB07B1/30C01F11/185F26B23/04

Inventor 龚尚文曹玉林

Owner 耒阳市百汇粉体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com