Soybean oil based silk-screen ink

A soybean oil-based, soybean oil technology, applied in ink, printing, household appliances, etc., can solve problems such as harm to the health of manufacturers and users, harmful pollution of air and printed surfaces, etc., achieve excellent environmental protection, eliminate harmful effects, The effect of low heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

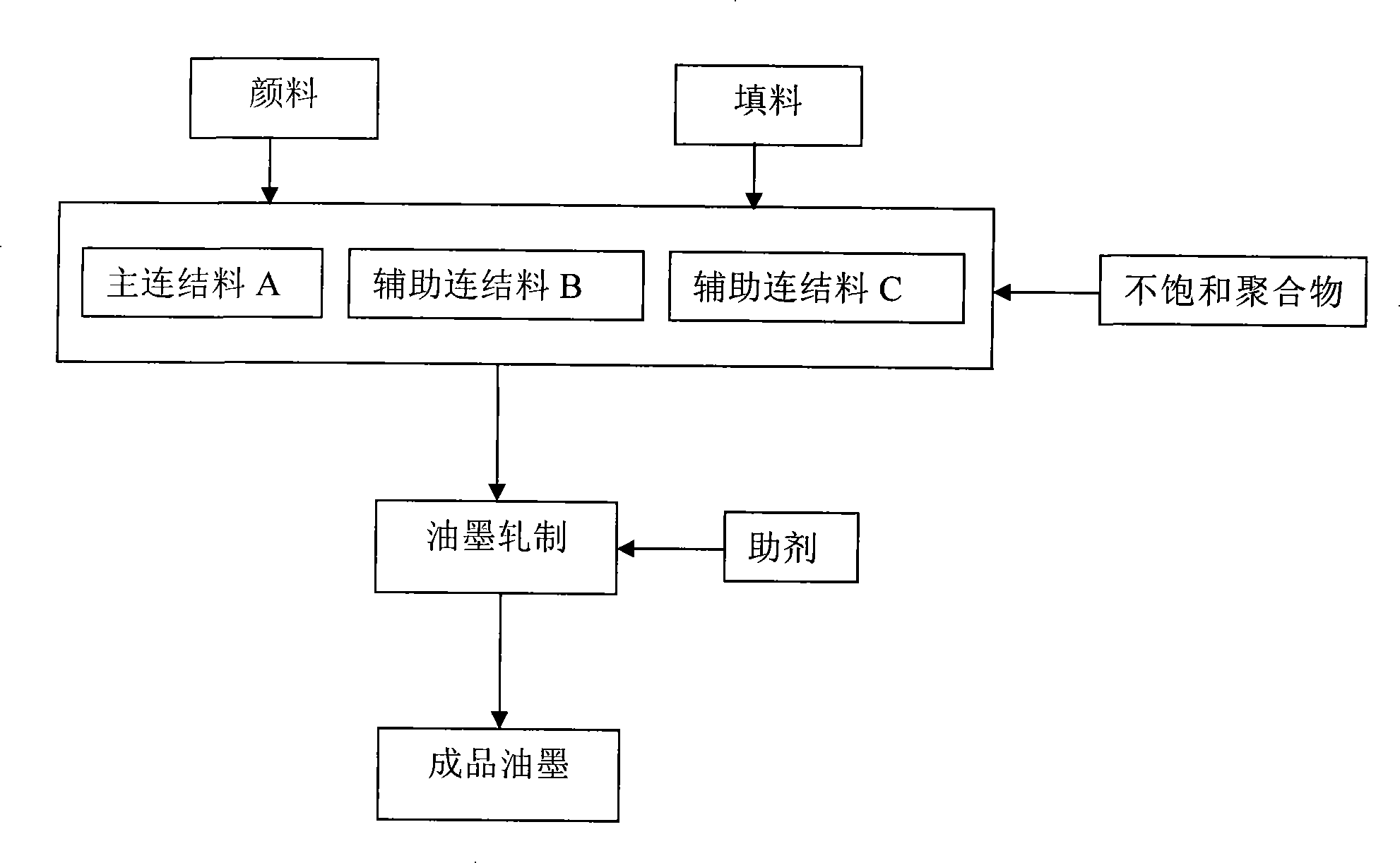

Method used

Image

Examples

Embodiment Construction

[0076] The invention relates to a soybean oil-based anti-counterfeiting screen ink, which is characterized in that soybean oil is used instead of petroleum solvent, and magnetic and / or fluorescent materials can be added, which is suitable for printing on various screen machines. The raw material components of the ink include binders, pigments, fillers, anti-counterfeiting materials, other additives (including unsaturated polymers, debonding agents, desiccants, waxes) and so on. The ink can be made into red ink, yellow ink, blue ink, black ink and other color inks according to the weight percentage of raw material components. The formula is shown in Table 1 to Table 10 (in parts by weight):

[0077] Table 1. Formula of soybean oil-based screen ink

[0078] Raw material name

Red ink

Yellow ink

Blue ink

Black ink

Binding material A

20~80

20~80

20~80

20~80

Binding material B

0~15

0~15

0~15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com