Blowing drying device after underwater pressure test of welded pipe

A drying device and welded pipe technology, applied in the direction of progressive dryers, drying solid materials, and drying solid materials without heating, etc., can solve the problems of non-drying, rubbing off the surface of metal pipes, corrosion spots of stainless steel, etc., and save manpower and material resources , avoid water stains and rust, and dry completely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

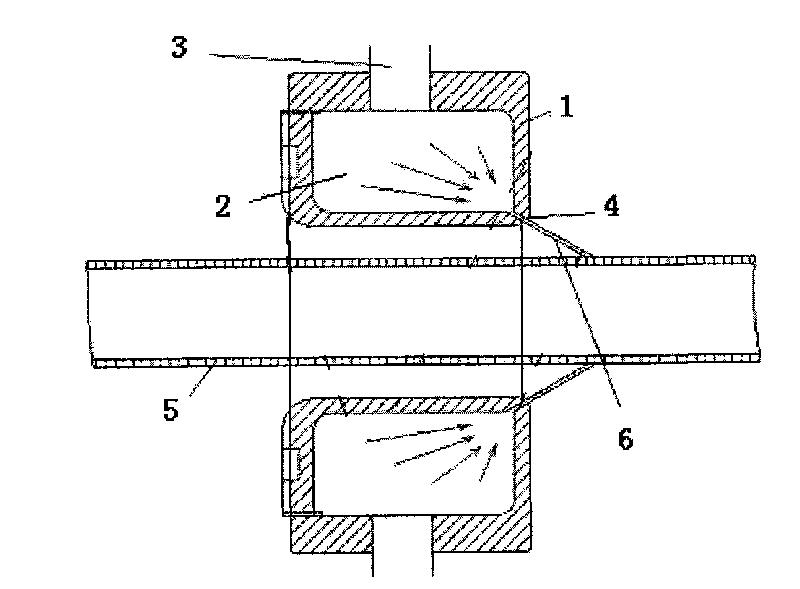

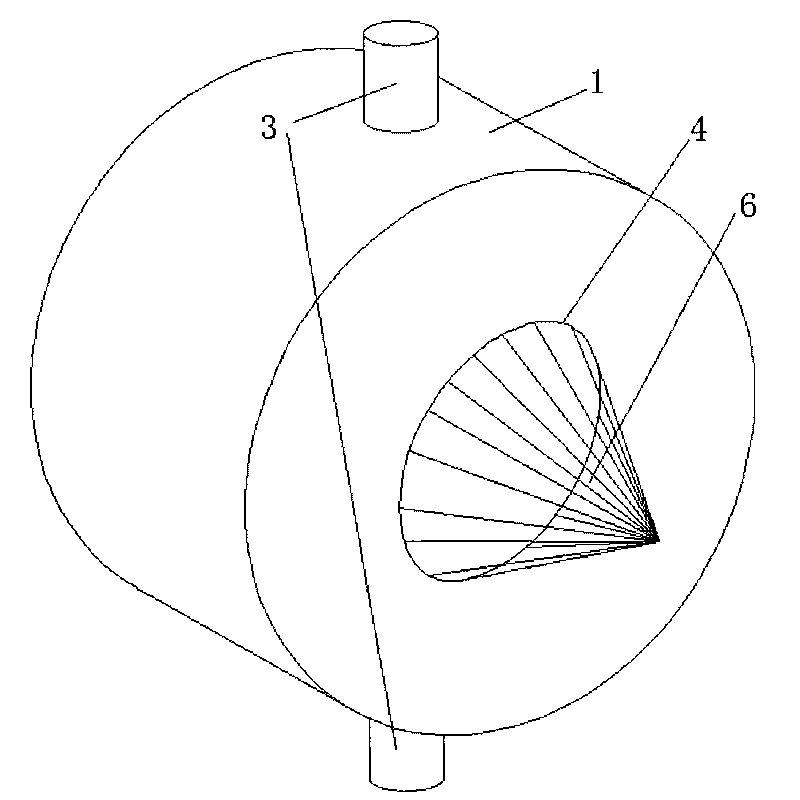

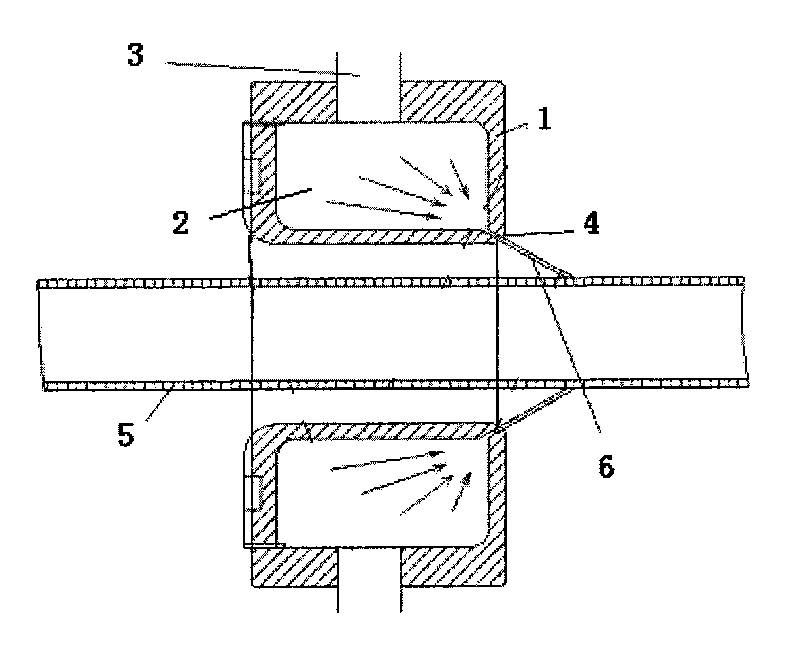

[0012] Depend on figure 1 , figure 2 It can be seen that the present invention includes: a cylindrical passage 1 through which the stainless steel welded pipe 5 can pass; at least one air inlet 3 is arranged outside the cylindrical passage 1, and there is an annular air cavity 2 inside the cylindrical passage 1; The annular air chamber 2 is connected to the air inlet 3; there is a blowing gap 4 at a corner of the annular air chamber 2, near the axis of the cylindrical channel 1;

[0013] The blowing slit 4 is at an angle of 45° to the axial direction of the annular cavity.

[0014] In the present invention, when the stainless steel welded pipe after the hydrostatic test passes through the conical air curtain 6 ejected from the annular gap of the cylindrical channel, the moisture on the surface of the steel pipe can be quickly blown away, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com