SapC-phosphatide nano vesicle freezed-drying preparation, and preparation method and application thereof

A technology for nanovesicles and freeze-dried preparations, applied in the field of biomedicine, can solve the problems of uneven distribution of the size and number of bilayer membranes, increased differences in the size of lipid vesicles, exposure of active pharmaceutical ingredients, etc., and achieve complete freezing. , rapid drying, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

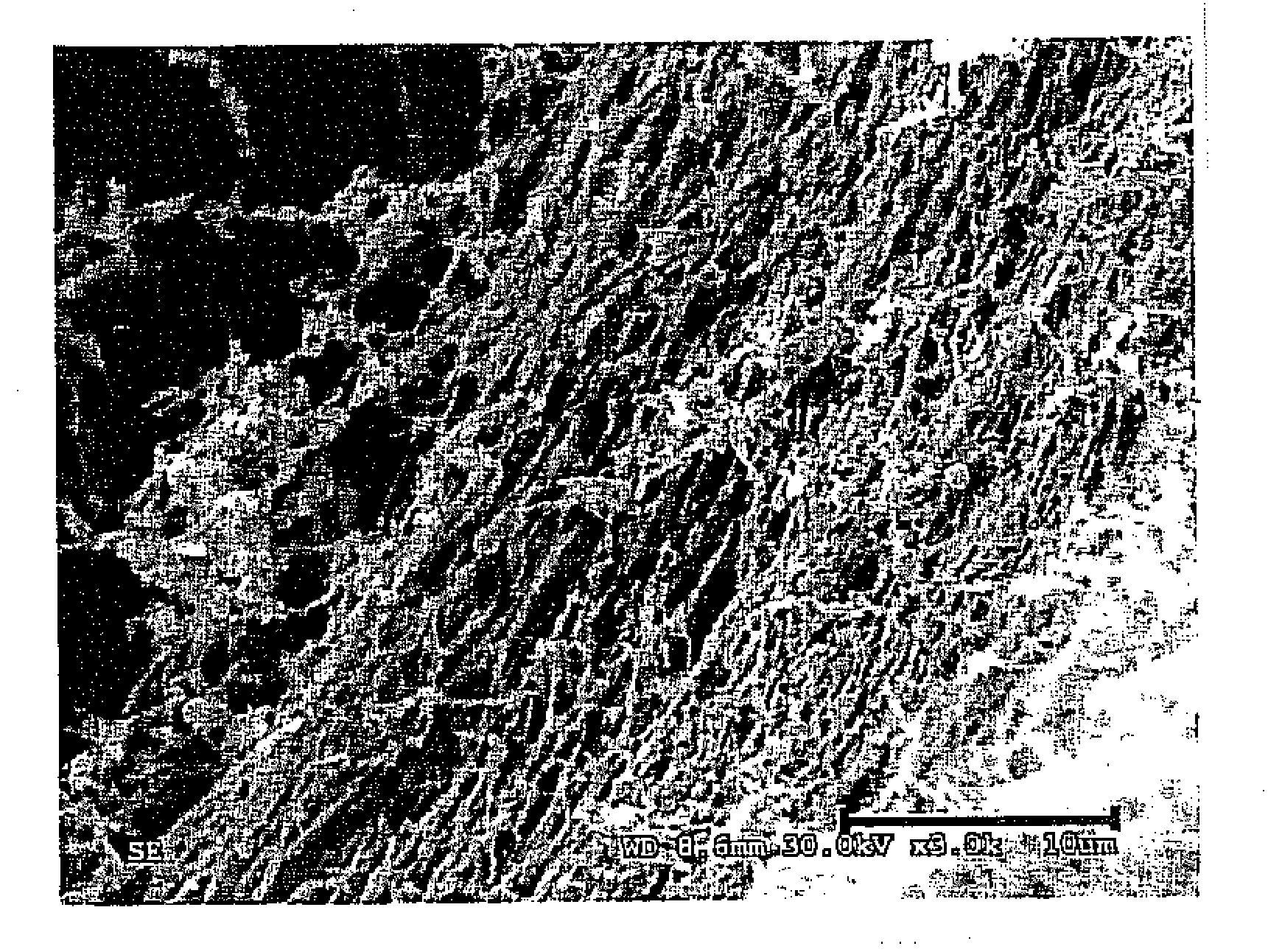

Image

Examples

Embodiment 1

[0060] Example 1: Preparation of SapC-phospholipid nanovesicle freeze-dried preparation sample 1

[0061] Specific steps are as follows:

[0062] 1) Prepare SapC aqueous solution. Add 3.34 g / L SapC protein (manufactured by GMP, Changji Company) and 16.67 g / L disaccharide auxiliary material, and filter sterilize.

[0063] 2) Prepare phospholipid (DOPS) organic solution (organic aqueous solution). Phospholipid dry powder (1 g / L) was dissolved in 80% tert-butanol (filter sterilized).

[0064] 3) Add SapC aqueous solution (0.6 ml / cart) to phospholipid organic solution (1.0 ml / cart), and mix. Phospholipid organic solution: SapC aqueous solution = 1:1 (v / v).

[0065] 4) Freezing: 1.6 ml / cartridge, -40°C, 6 hours.

[0066] 5) Vacuum drying: heating up to 25°C for 6 hours, drying time for 24 hours.

[0067] A polypeptide protein-phospholipid nanovesicle freeze-dried preparation, namely sample 1, with SapC:DOPS:adjuvant ratio of 2:1:10 (weight ratio) was obtained. The product...

Embodiment 2

[0068] Example 2: Preparation of SapC-phospholipid nanovesicle freeze-dried preparation sample 2

[0069] Specific steps are as follows:

[0070] 1) Prepare SapC aqueous solution. Add 3 g / L SapC protein (manufactured by GMP, Changji Company) and 20 g / L disaccharide auxiliary material, and filter sterilize.

[0071] 2) Prepare phospholipid (DOPS) organic solution (organic aqueous solution). Phospholipid dry powder (1 g / L) was dissolved in 80% tert-butanol (filter sterilized).

[0072] 3) Add SapC aqueous solution (1.0 ml / tube) to phospholipid organic solution (1.0 ml / tube) and mix. Phospholipid organic solution:SapC aqueous solution=0.8:1 (v / v).

[0073] 4) Freezing: 2.0 ml / cartridge, -40°C, 12 hours.

[0074] 5) Vacuum drying: heating up to 25°C for 6 hours, drying time for 24 hours.

[0075] A polypeptide protein-phospholipid nanovesicle freeze-dried preparation, namely sample 2, with SapC:DOPS:adjuvant ratio of 3:1:20 (weight ratio) was obtained.

Embodiment 3

[0076] Example 3: Preparation of SapC-phospholipid nanovesicle freeze-dried preparation sample 3

[0077] Specific steps are as follows:

[0078] 1) Prepare SapC aqueous solution. Add 4 g / L SapC protein (manufactured by GMP, Changji Company) and 20 g / L disaccharide auxiliary material, and filter sterilize.

[0079] 2) Prepare phospholipid (DOPS) organic solution (organic aqueous solution). Phospholipid dry powder (1 g / L) was dissolved in 80% tert-butanol (filter sterilized).

[0080] 3) Add SapC aqueous solution (1.0 ml / tube) to phospholipid organic solution (1.0 ml / tube) and mix. Phospholipid organic solution:SapC aqueous solution=0.8:1 (v / v).

[0081] 4) Freezing: 2.0 ml / cartridge, -40°C, 12 hours.

[0082] 5) Vacuum drying: heating up to 25°C for 6 hours, drying time for 24 hours.

[0083] A polypeptide protein-phospholipid nanovesicle freeze-dried preparation, namely sample 3, with a SapC:DOPS:adjuvant ratio of 6:1:30 (weight ratio) was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com