Preparation method for lithium iron phosphate positive electrode of lithium ion battery

A lithium-ion battery and lithium iron phosphate technology, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of the positive electrode being difficult to completely dry and the solid components being difficult to disperse, and achieve good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

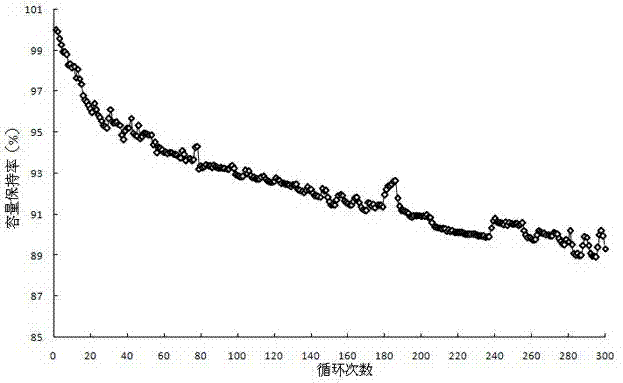

Image

Examples

Embodiment 1

[0027] (1) Weighing: Based on the total mass of the positive electrode slurry, weigh each component according to the following mass percentages: 45% lithium iron phosphate, 2% conductive agent, 2% water-based binder, 3% ethanol, 48% ionized water, the conductive agent is conductive carbon black, and the water-based binder is made by mixing sodium alginate and acrylonitrile multi-polymer copolymer LA133 at a mass ratio of 3:5.

[0028] (2) Preparation of premix: After mixing ethanol and conductive agent evenly, add water-based binder and part of deionized water, and ball mill until the material fineness is 5 μm to obtain a premix, in which the mass of part of deionized water is 40% of the total mass of deionized water.

[0029] (3) Primary dispersion: add lithium iron phosphate to the premix and then ball mill until the material fineness is 5 μm.

[0030] (4) Secondary dispersion: add the materials in step (3) to the planetary slurry mixer, add the remaining amount of deionize...

Embodiment 2

[0037] (1) Weighing: Based on the total mass of the positive electrode slurry, weigh each component according to the following mass percentages: 47% lithium iron phosphate, 2.7% conductive agent, 2.6% water-based binder, 4% ethanol, Ionized water 43.7%, the conductive agent is conductive carbon black and carbon nanotubes (mass ratio 1:2), and the water-based binder is made of sodium alginate and acrylonitrile multi-polymer copolymer LA133 in a mass ratio of 3:6.

[0038] (2) Preparation of premix: After mixing ethanol and conductive agent evenly, add water-based binder and part of deionized water, and ball mill until the fineness of the material is 7 μm to obtain a premix, in which the mass of part of deionized water is 35% of the total mass of deionized water.

[0039] (3) Primary dispersion: Add lithium iron phosphate to the premix and then ball mill until the material fineness is 6 μm.

[0040] (4) Secondary dispersion: Add the materials in step (3) into the planetary slurry...

Embodiment 3

[0046] (1) Weighing: Based on the total mass of the positive electrode slurry, weigh each component according to the following mass percentages: 50% lithium iron phosphate, 3% conductive agent, 3% water-based binder, 5% ethanol, Ionized water 39%, of which the conductive agent is conductive carbon black, carbon nanotubes and flake graphite (mass ratio 1:2:1), and the water-based binder is composed of sodium alginate and acrylonitrile multi-polymer LA133 in a mass ratio of 3:2 Mixed,.

[0047] (2) Preparation of premix: After mixing ethanol and conductive agent evenly, add water-based binder and part of deionized water, and ball mill until the material fineness is 10 μm to obtain premix, in which the mass of part of deionized water is 30% of the total mass of deionized water.

[0048] (3) Primary dispersion: Add lithium iron phosphate to the premix and then ball mill until the material fineness is 10 μm.

[0049] (4) Secondary dispersion: add the materials in step (3) into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com