Patents

Literature

32results about How to "Continuous entry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

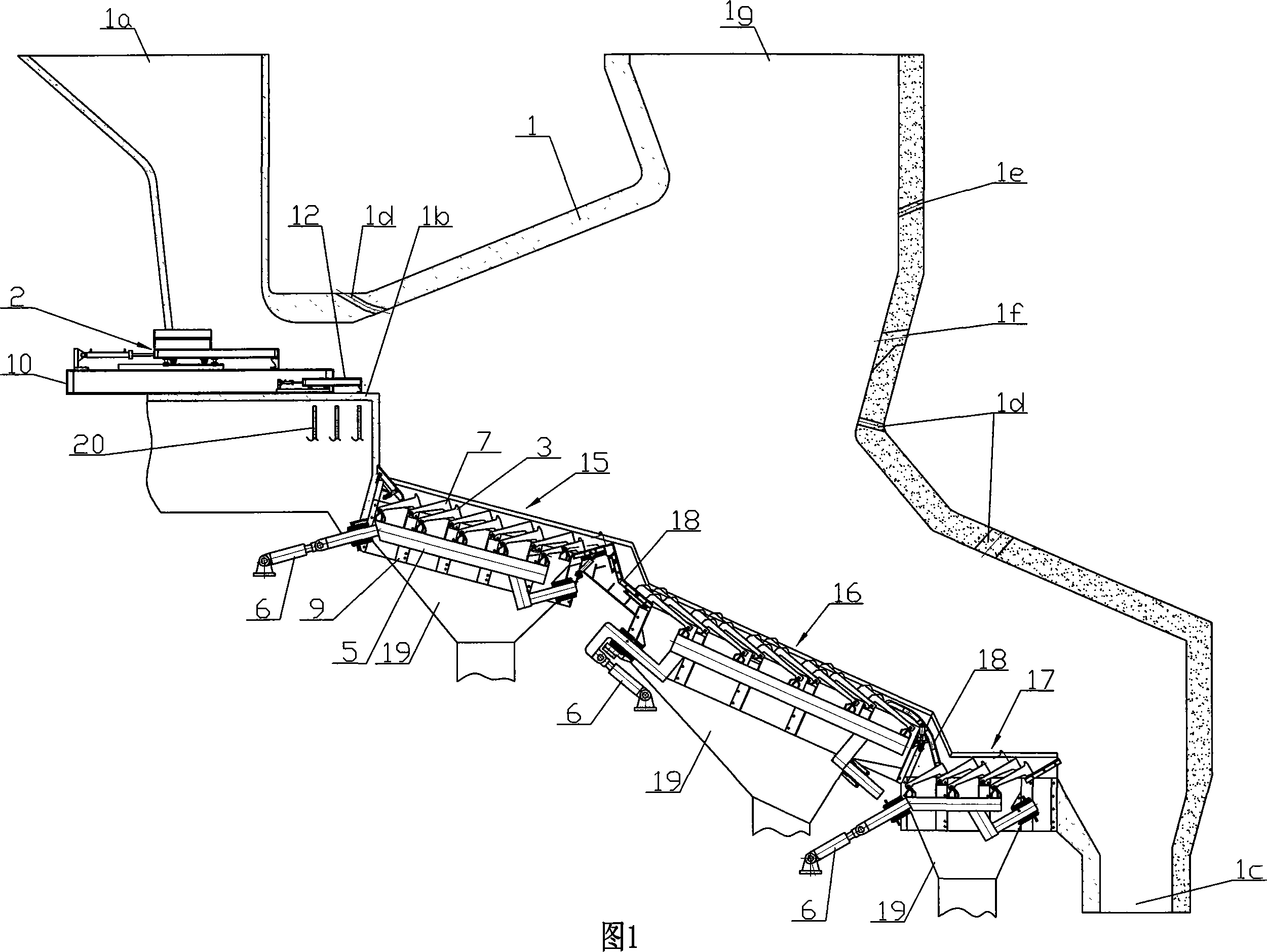

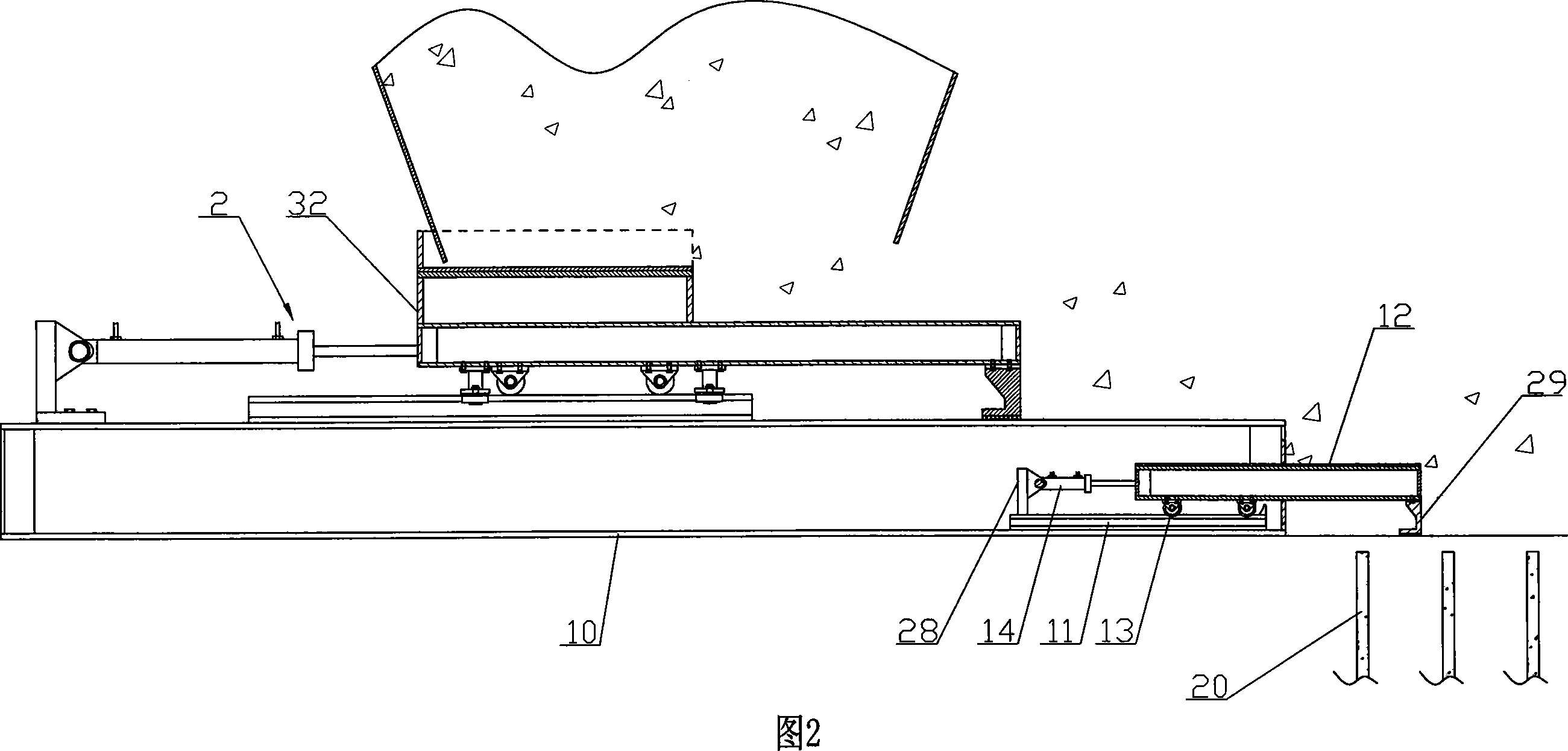

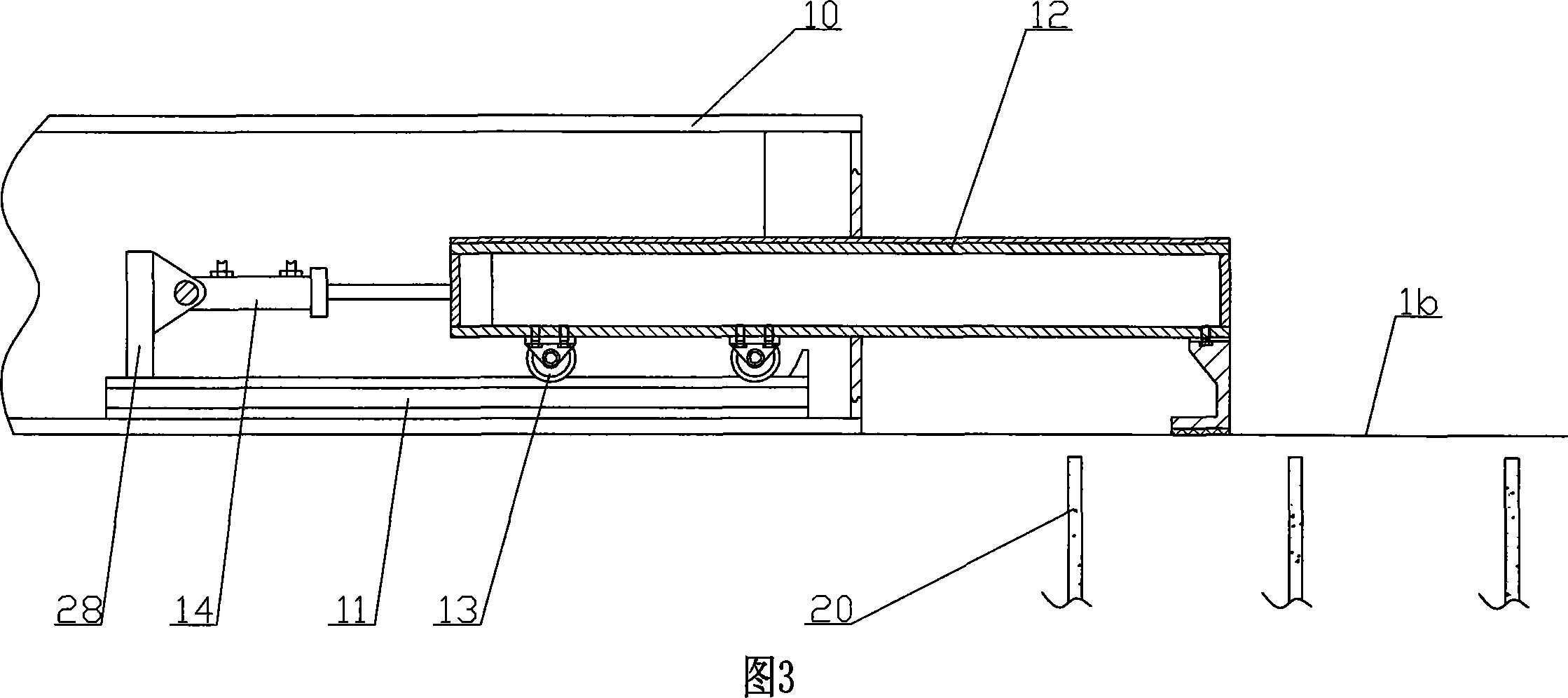

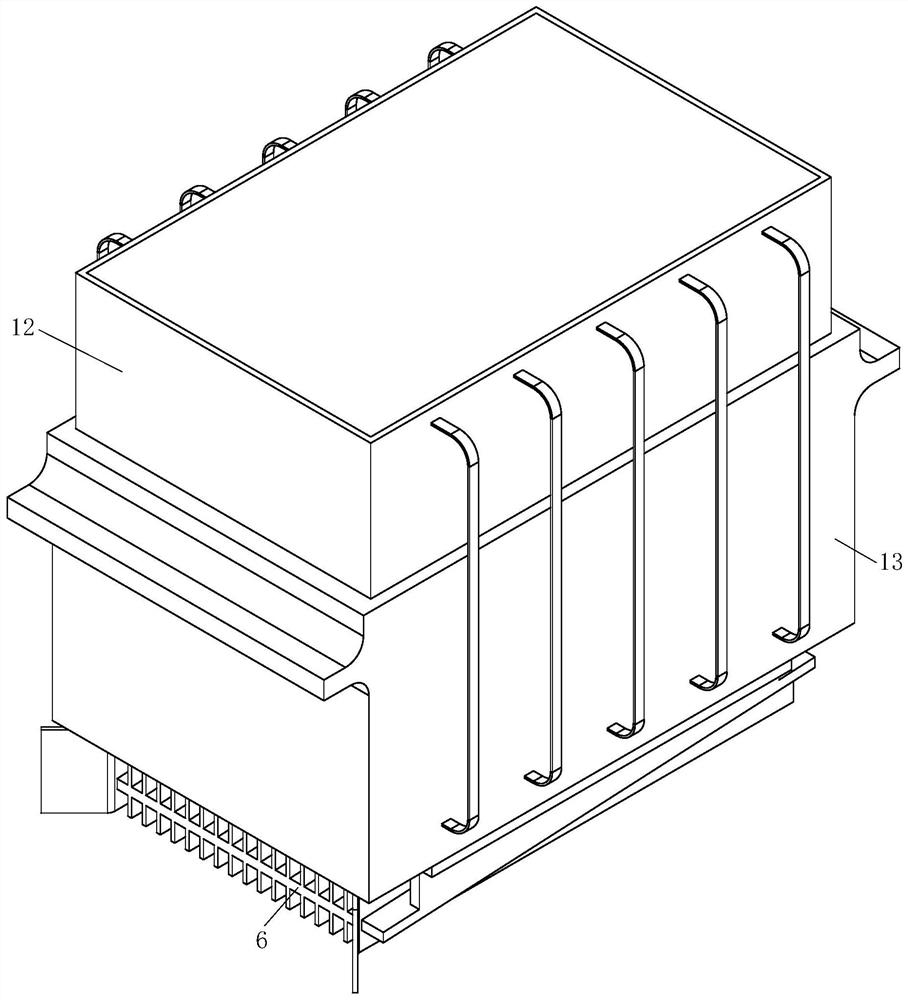

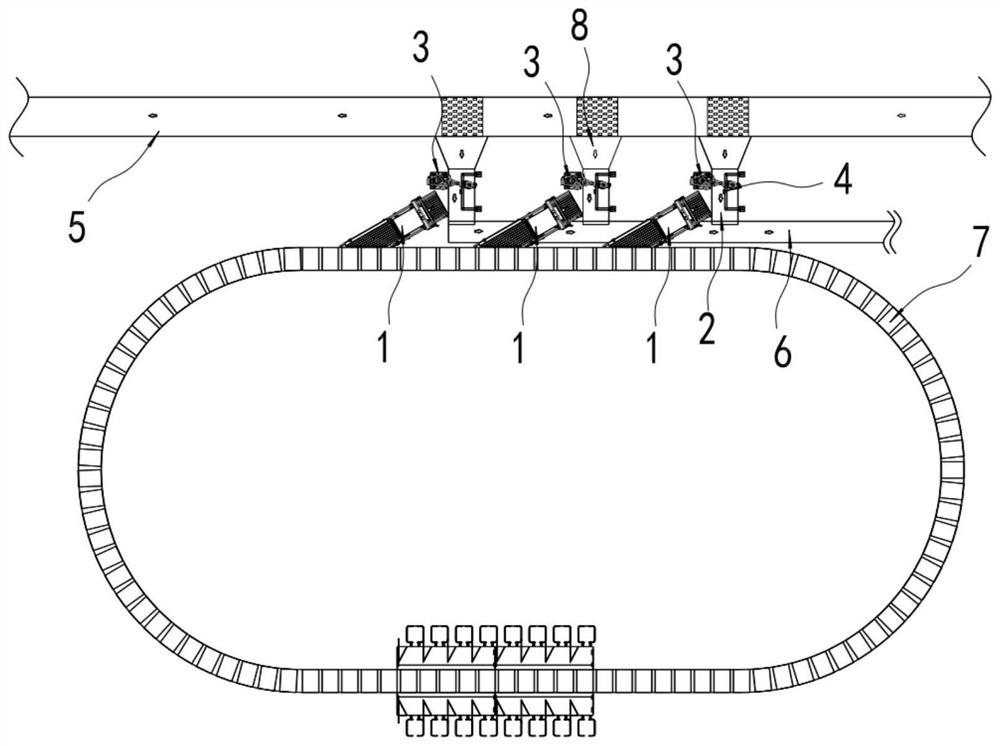

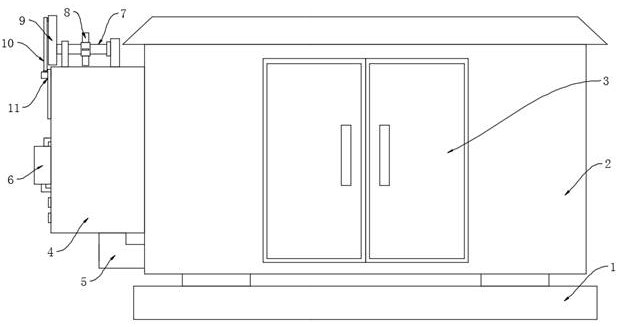

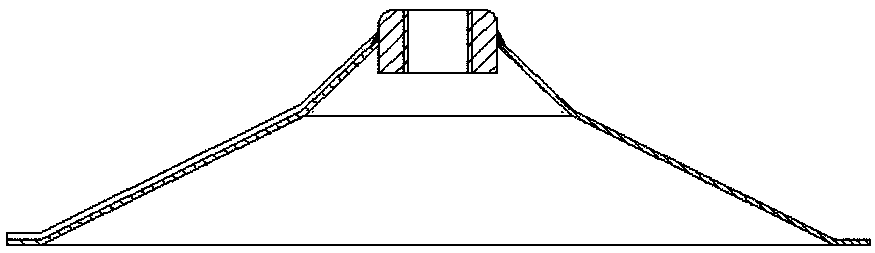

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

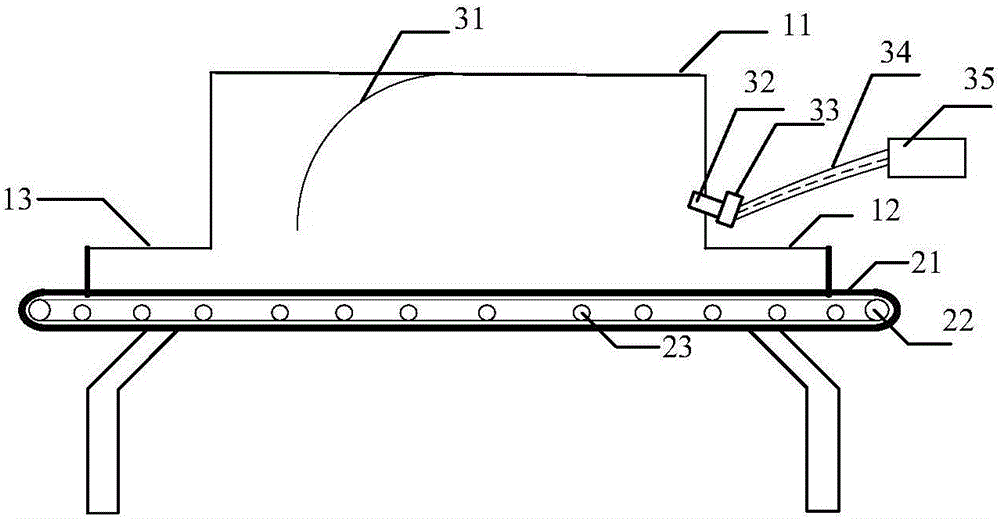

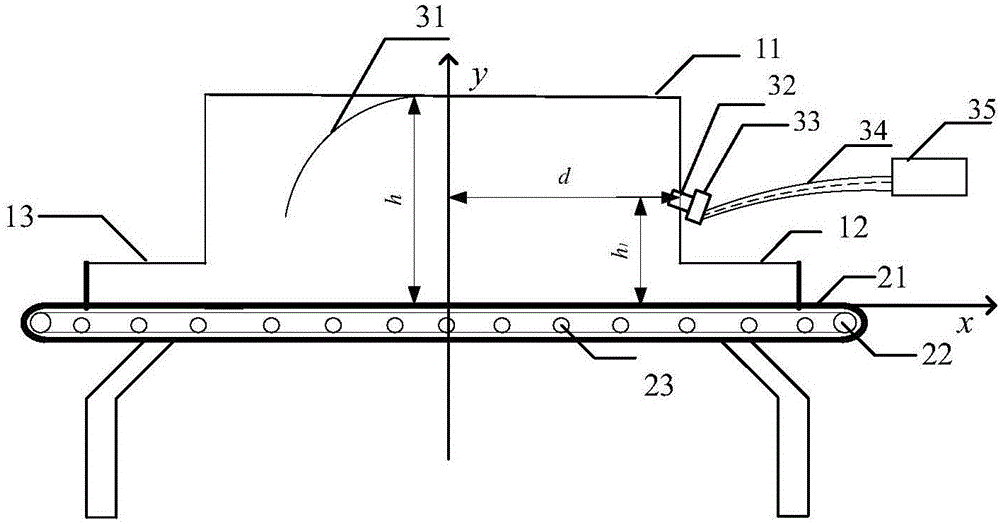

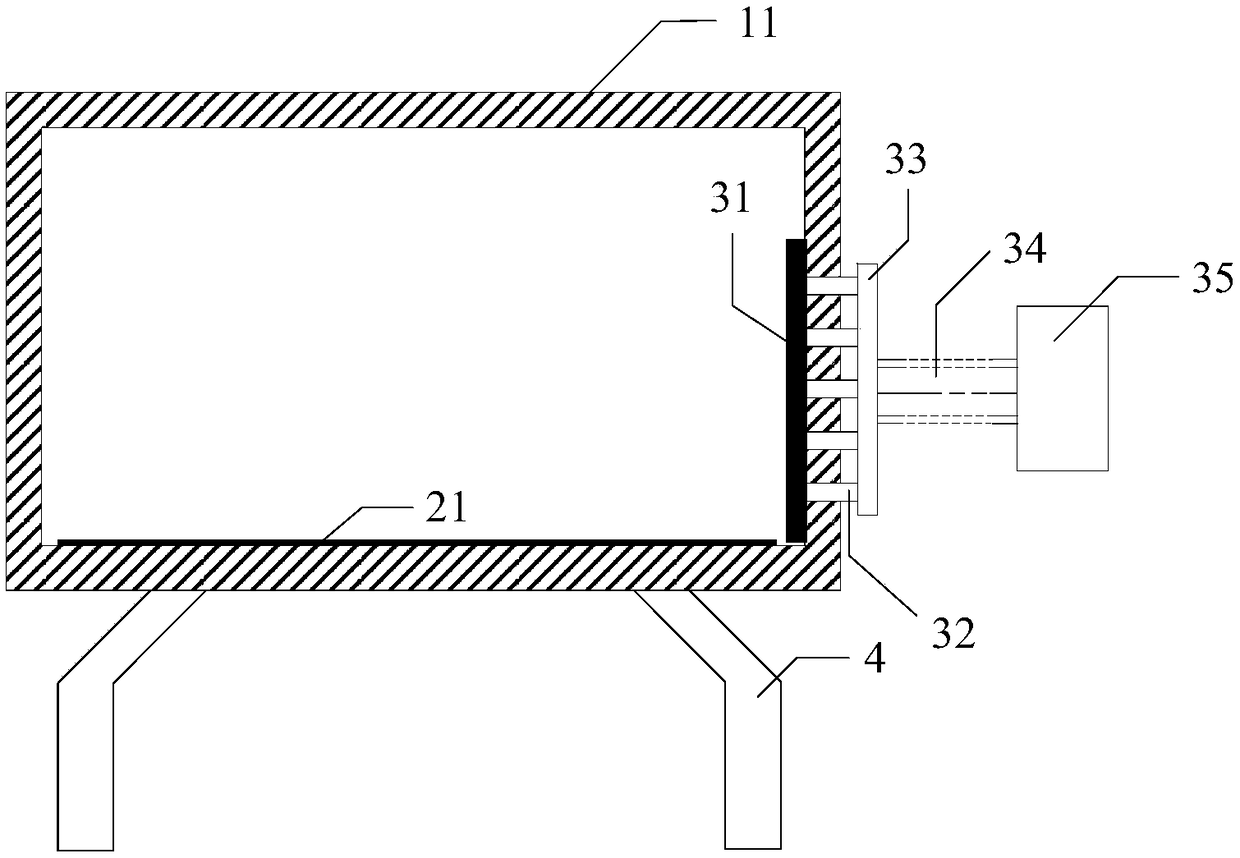

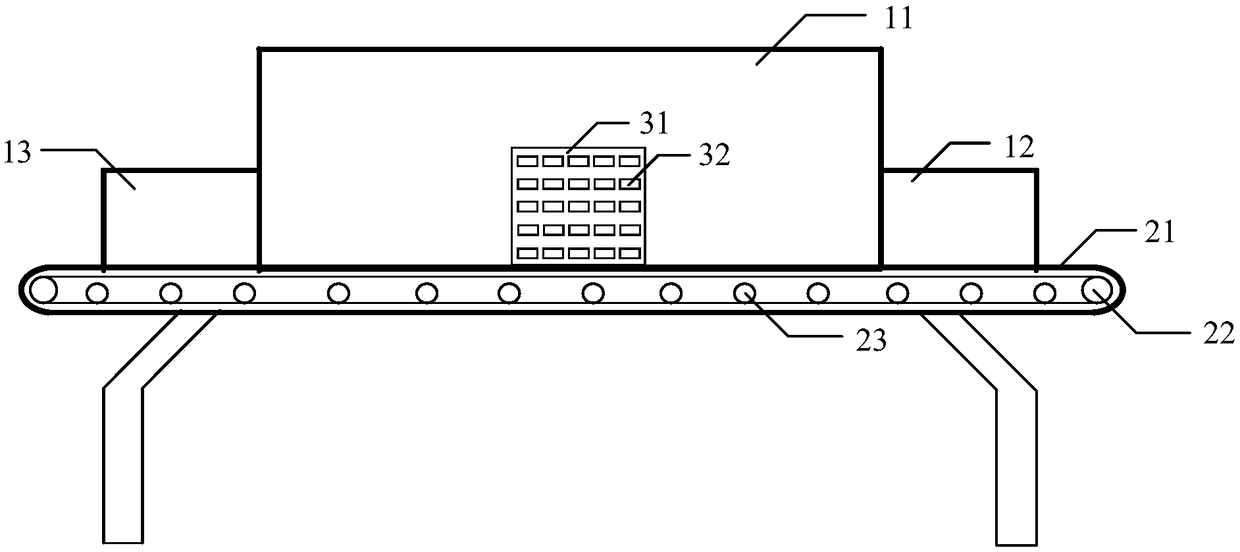

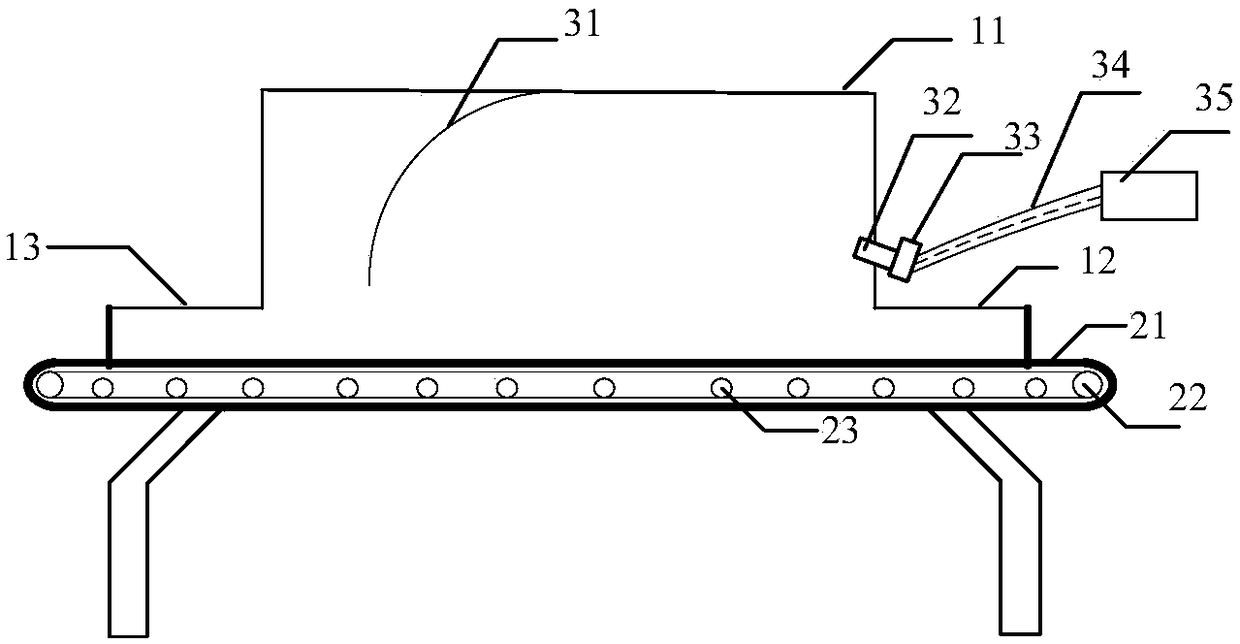

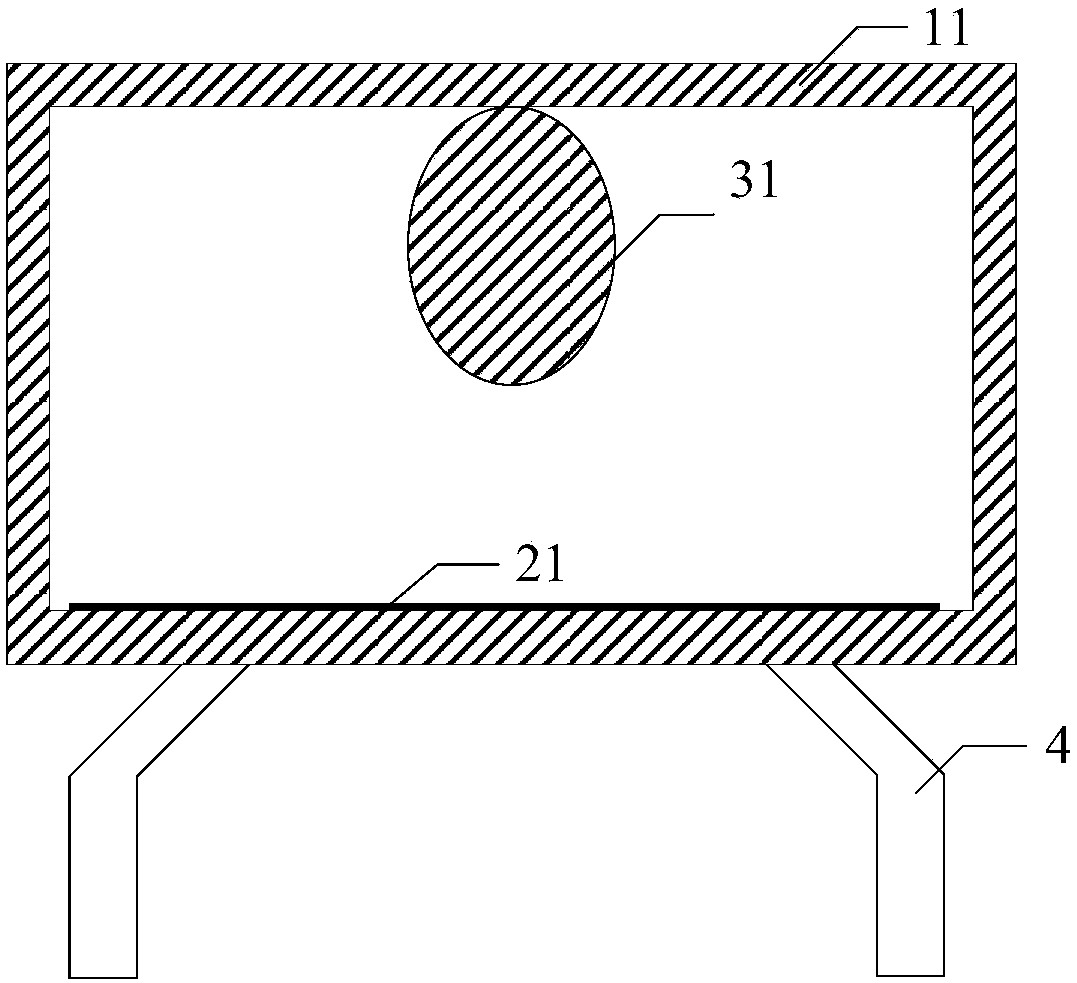

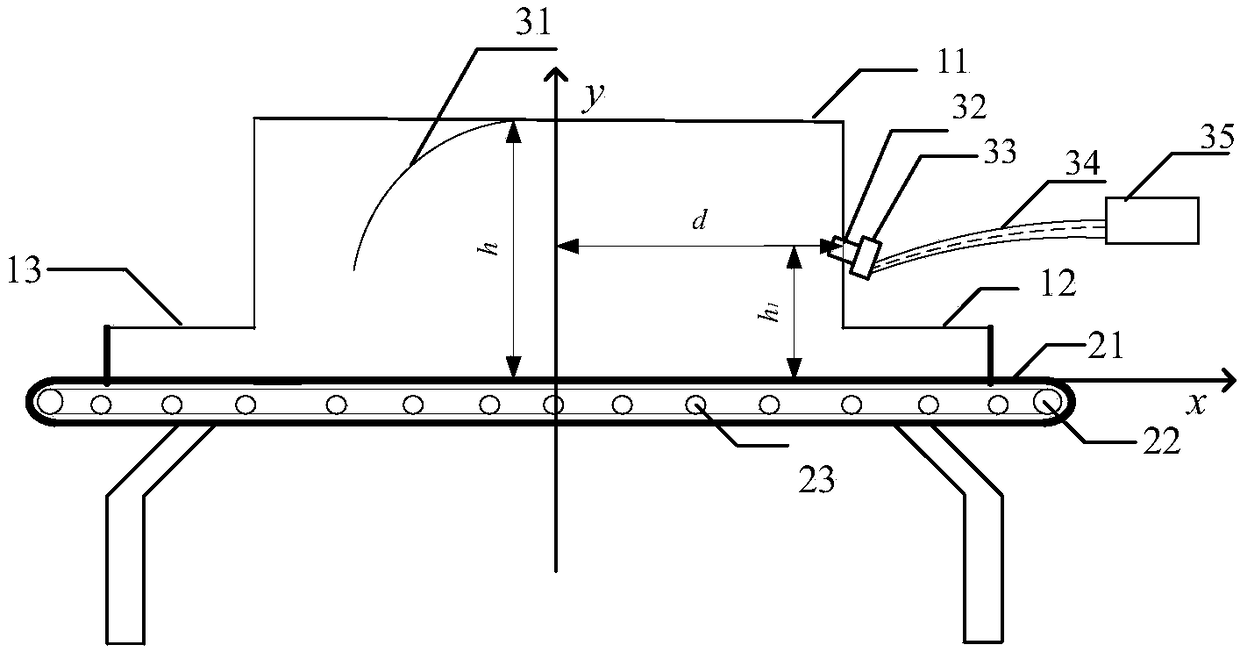

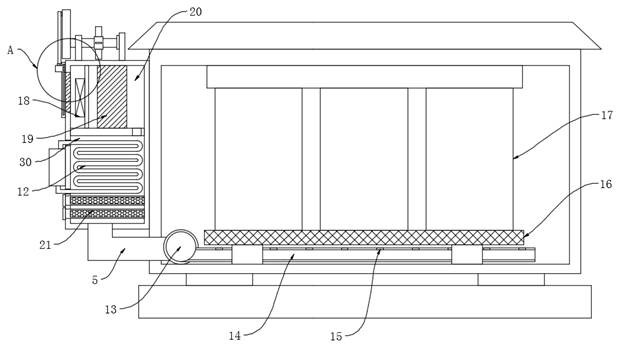

Continuous transmission type focusing microwave reactor

ActiveCN106334508AAvoid the effects of extensionUniform effectMicrowave heatingEnergy based chemical/physical/physico-chemical processesProduction lineMicrowave

The invention belongs to the field of microwave energy utilizing devices, and provides a continuous transmission type focusing microwave reactor. The continuous transmission type focusing microwave reactor comprises a reaction device, a transmission device, a feed device and a supporting device, and is characterized in that the feed device comprises a metal reflecting surface, a radiating trumpet, a coaxial transmission line, a waveguide coaxial converter and a microwave source, wherein the metal reflecting surface is arranged on the inner wall of the top surface of a metal cavity; the microwave source is connected with the radiating trumpet through the coaxial transmission line and the waveguide coaxial converter; the radiating trumpet is fixed to the side wall of the metal cavity, runs through the metal cavity, and irradiates at a certain inclination angle relative to the wall of the metal cavity, so that the focus of the metal reflecting surface is positioned in the direction of a main lobe of the radiating trumpet. In a way of irradiating a detected object at a maximum field strength point by feeding the side end of a waveguide into the metal wall, reflecting and focusing, the continuous transmission type focusing microwave reactor improves the reaction efficiency, speeds up the reaction, improves the reaction uniformity and saves the energy; the continuous transmission type focusing microwave reactor is combined with a continuous transmission type production line, and is applied to large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

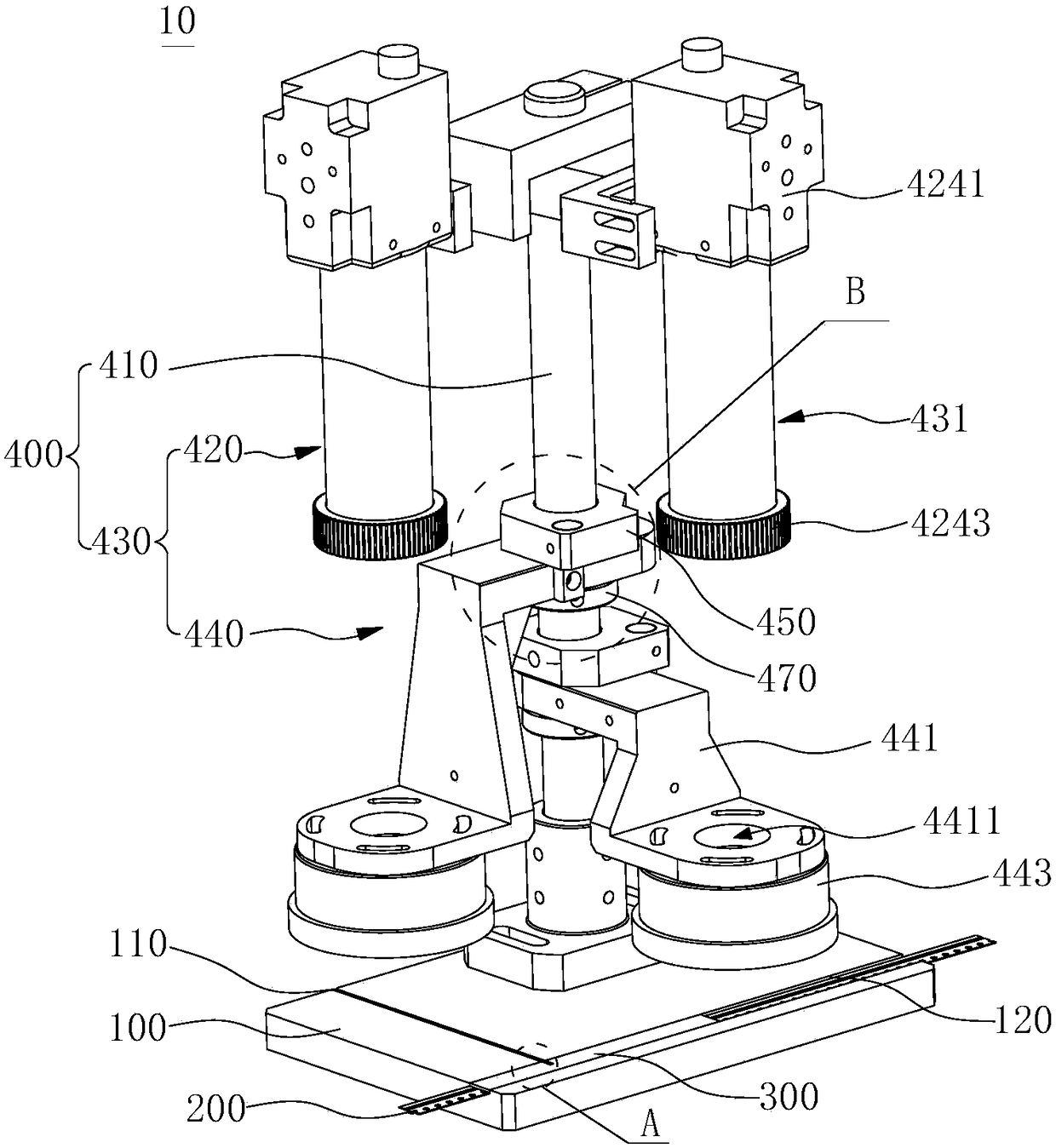

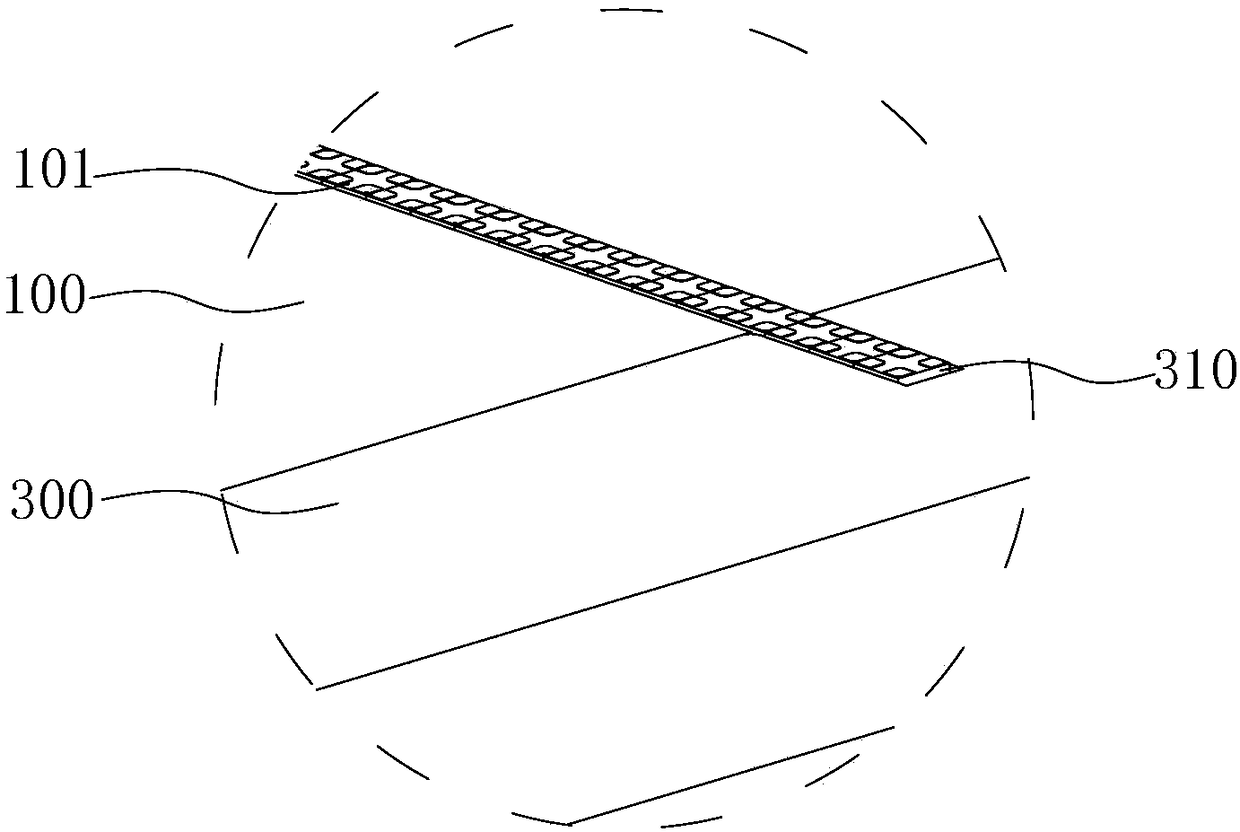

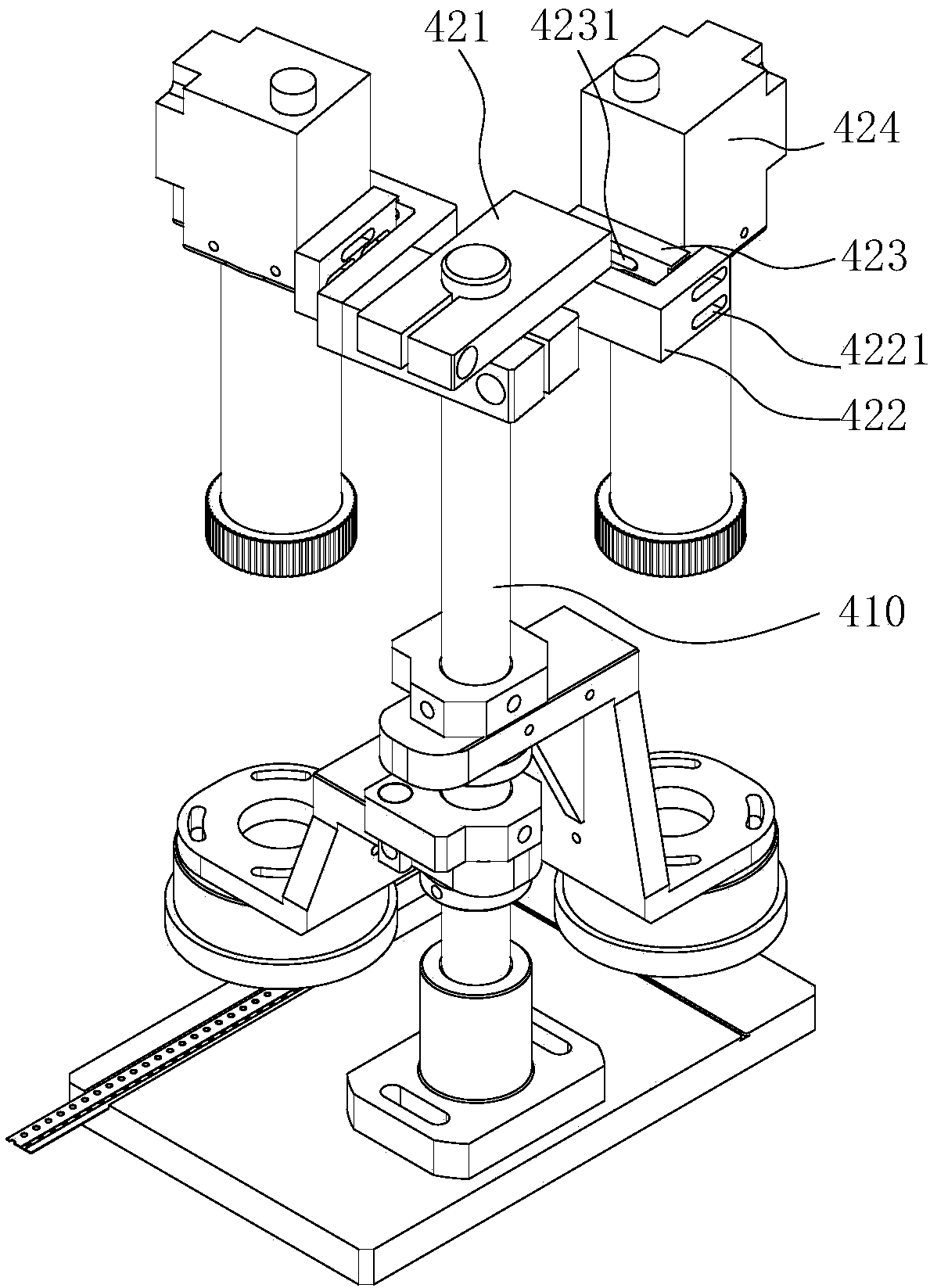

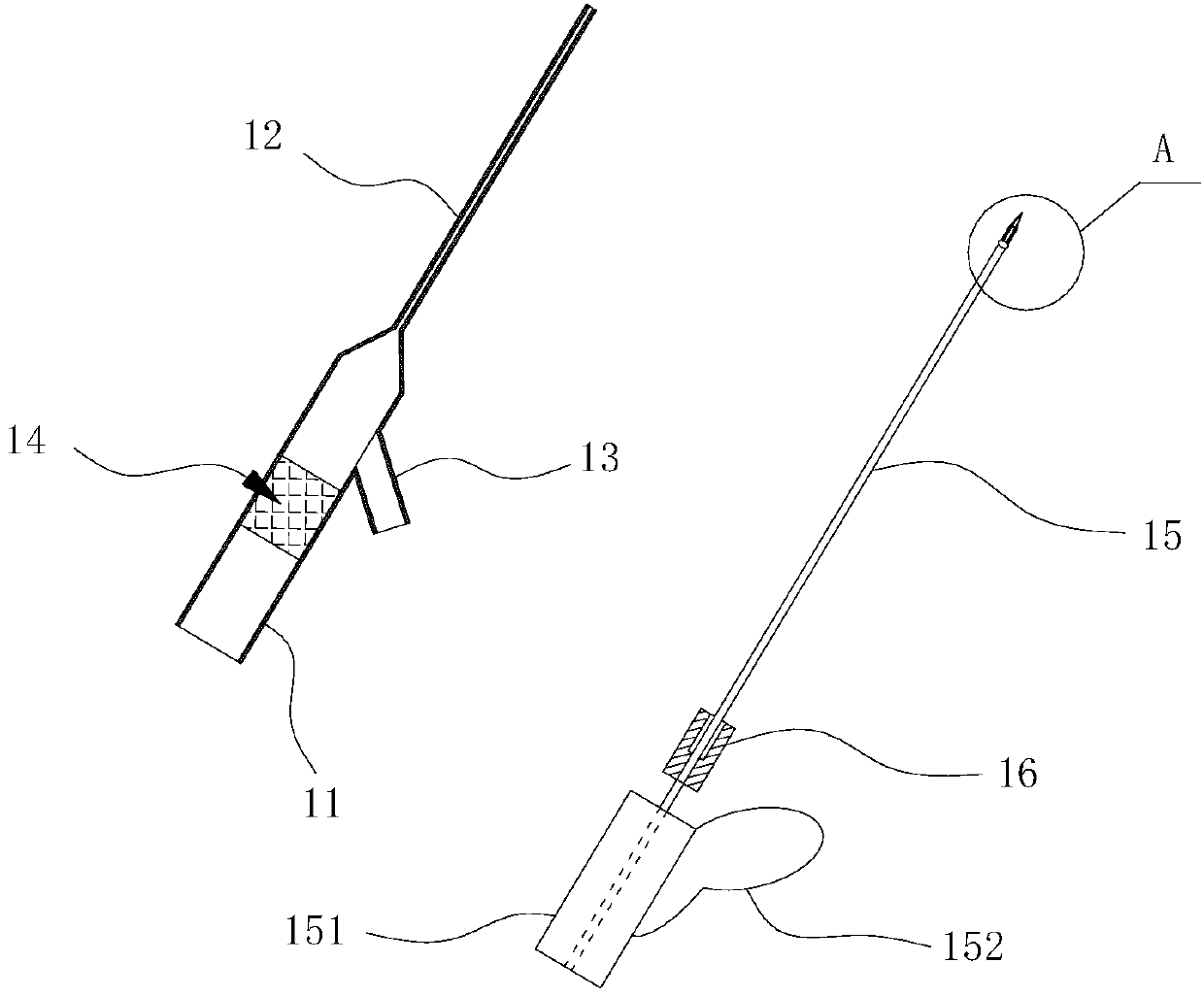

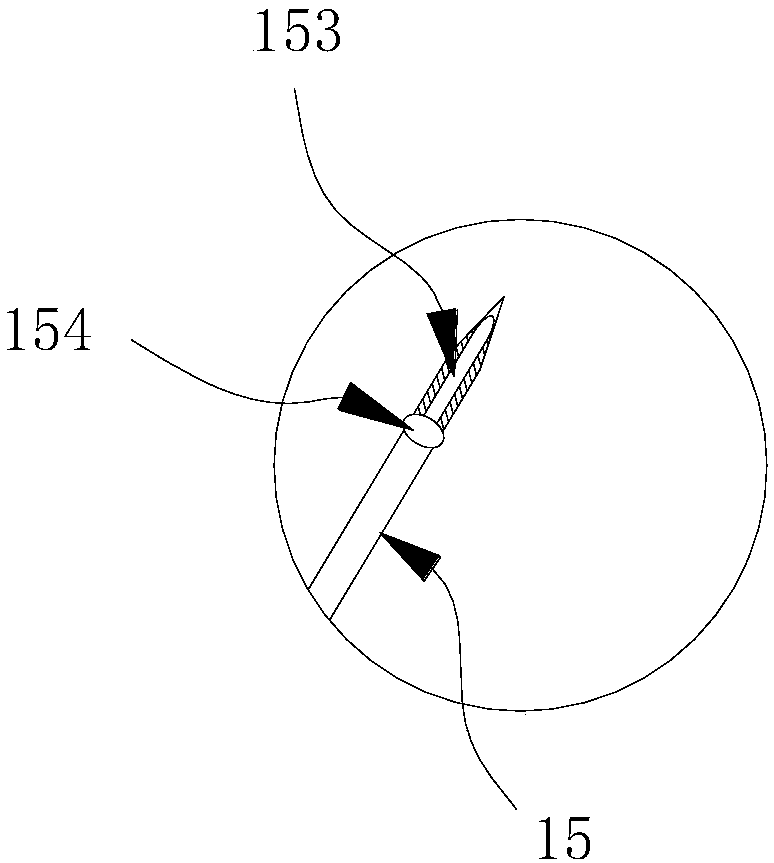

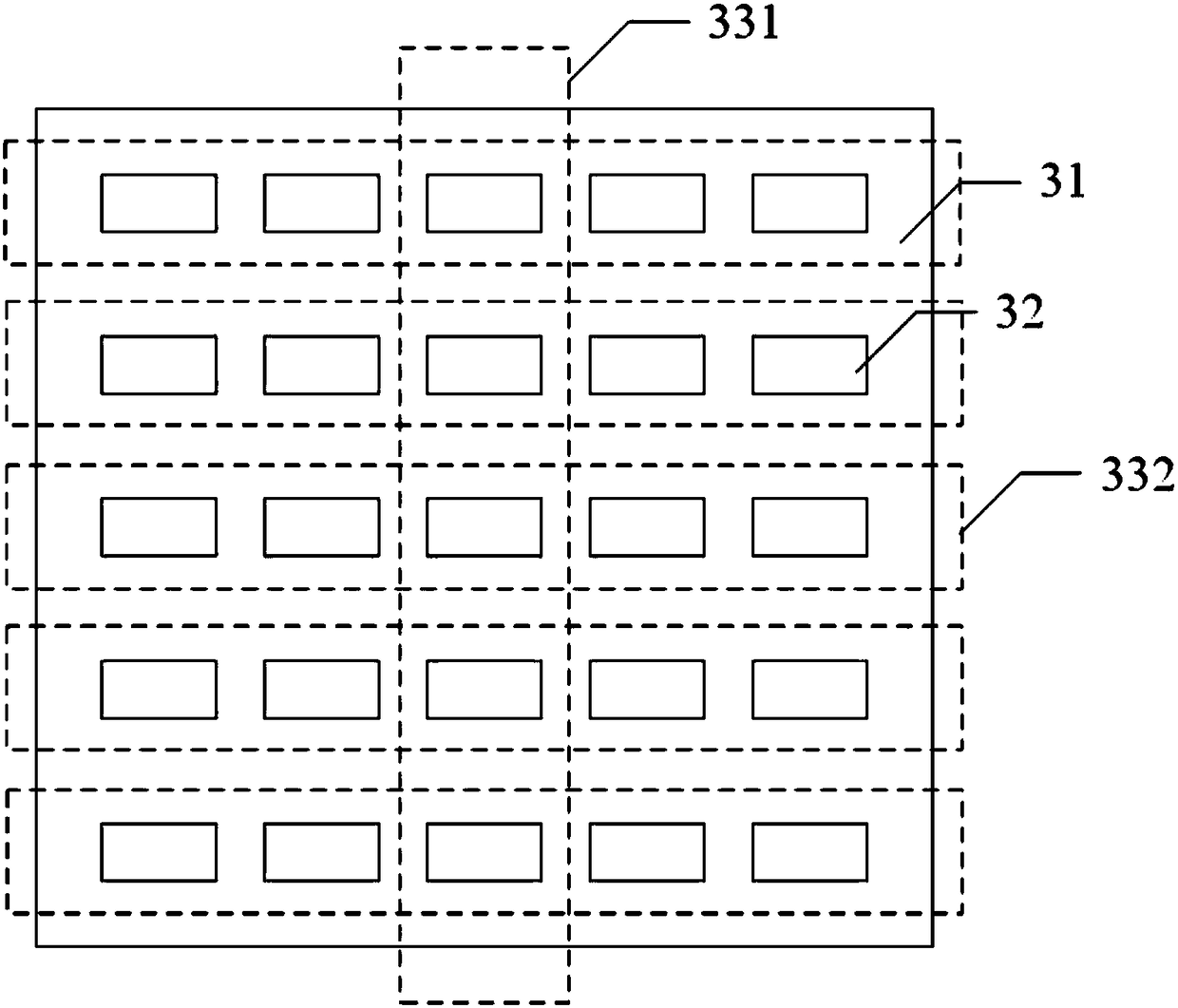

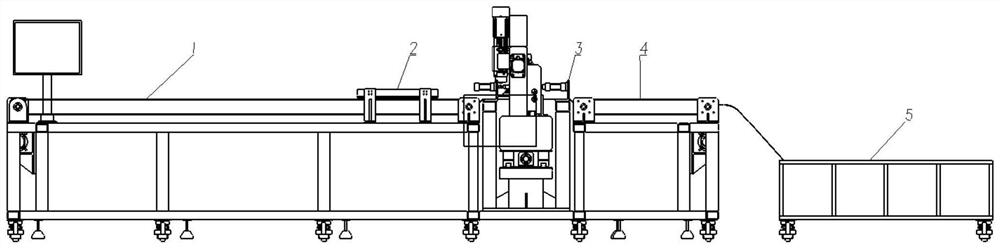

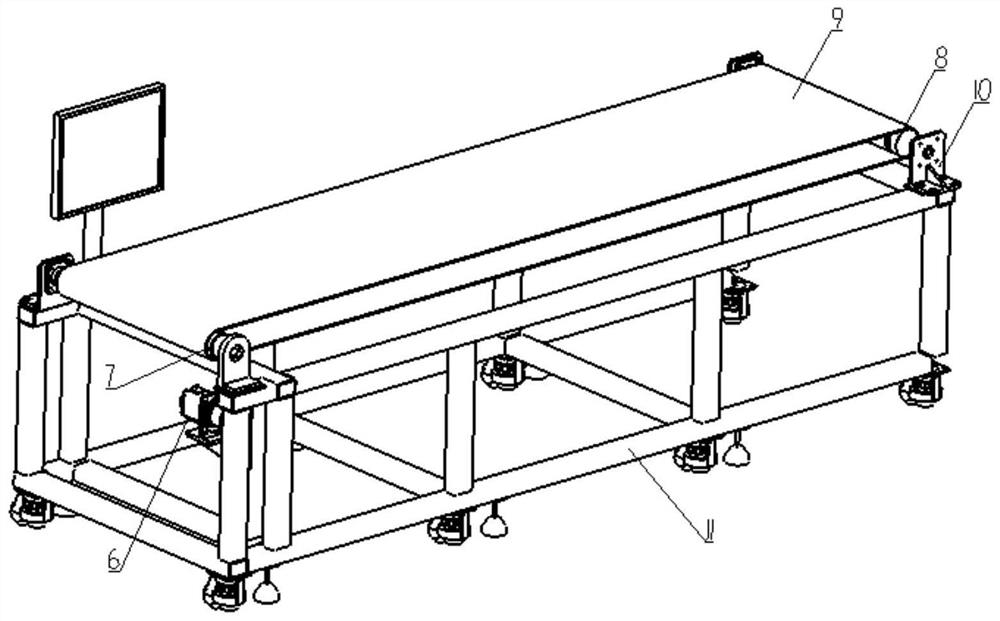

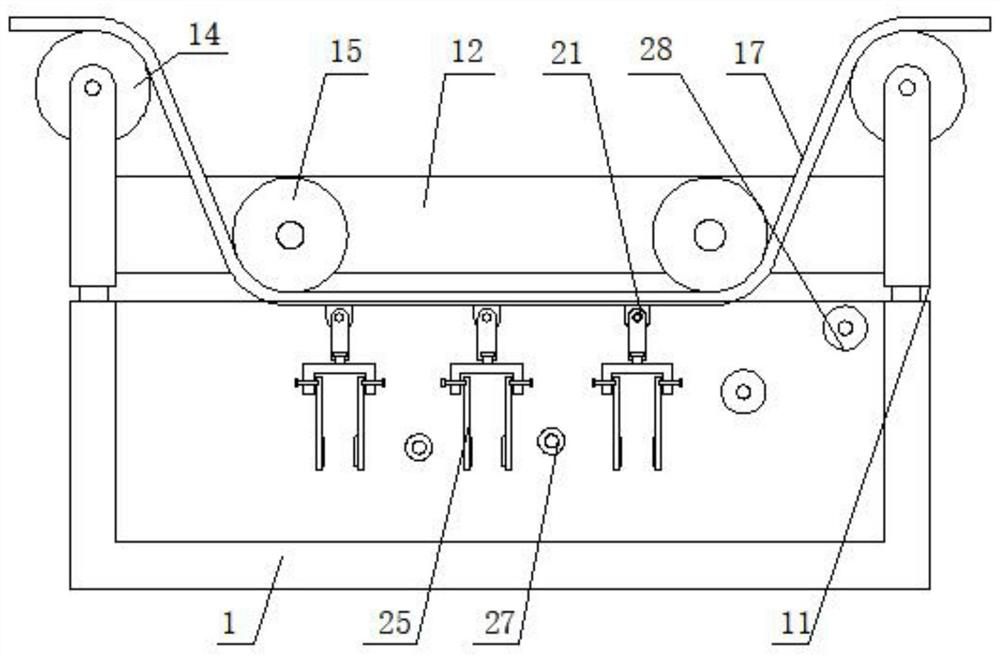

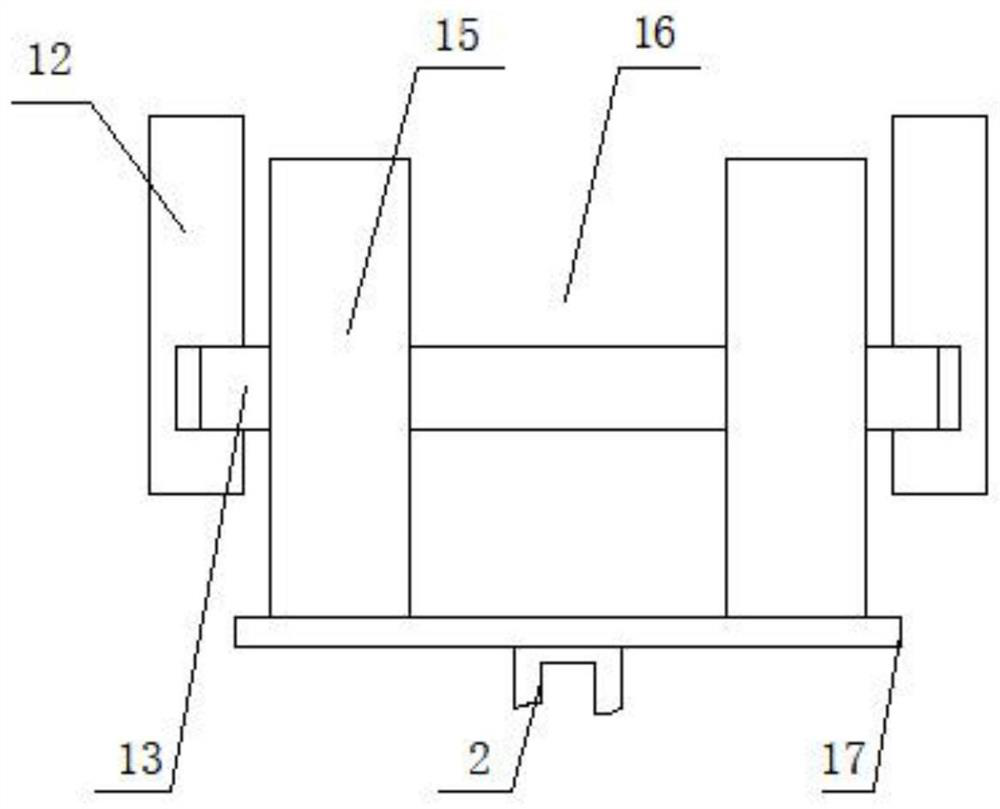

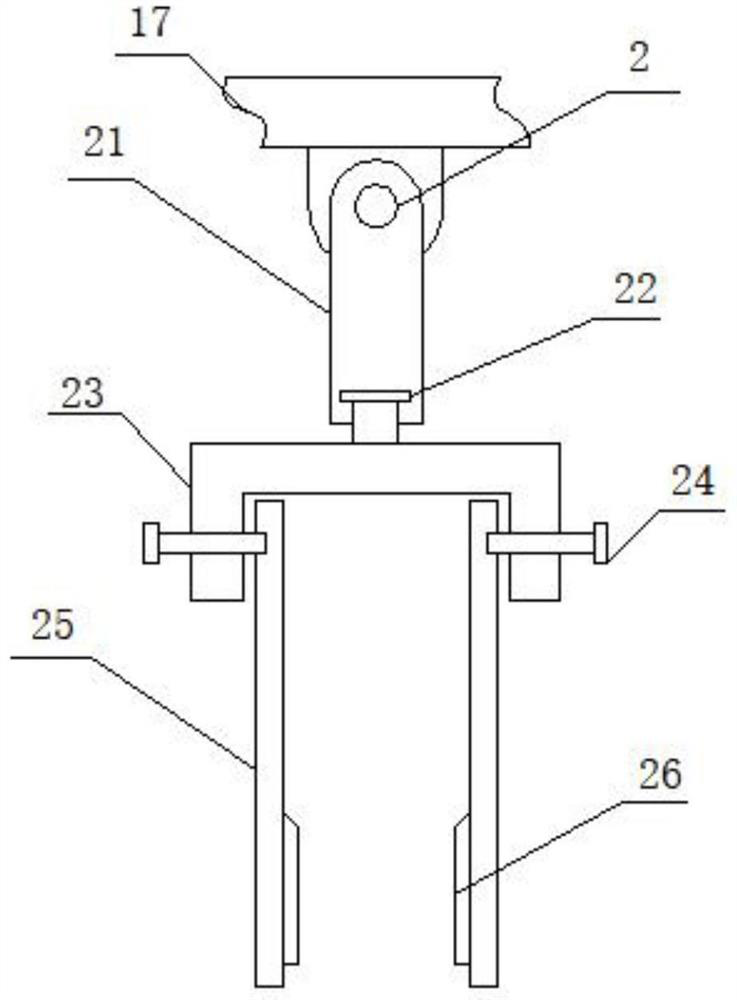

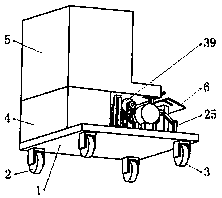

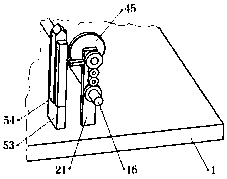

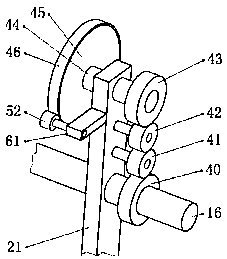

Image detection feeding device and braiding machine

InactiveCN108069085AContinuous entryEasy accessPackaging automatic controlImage detectionEngineering

The invention provides an image detection feeding device and a braiding machine. The image detection feeding device comprises a base, a carrier band and an image detection device. The base is providedwith a storage channel and a feed channel. The carrier band is mounted on the feed channel and used for bearing a material. The carrier band can move along the feed channel relative to the base. Theimage detection device comprises a supporting rod, a first image detection mechanism and a second image detection mechanism. The supporting rod is arranged on the base. Each image detection mechanismcomprises a camera shooting assembly and a light source assembly. The camera shooting assemblies and the light source assemblies are movably mounted on the supporting rod correspondingly. The light source assembly of each image detection mechanism is located between the base and the corresponding camera shooting assembly. The light source assembly and the camera shooting assembly of the first image detection mechanism are aligned with the material on the storage channel and are used for detecting whether the material is insufficient or not. In this way, the image detection feeding device detects whether the material is insufficient or not repeatedly during material feeding to guarantee feeding continuity and then guarantee the operation consistency of the braiding machine so as to improvethe working efficiency.

Owner:SHENZHEN XUANSHUO INTELLIGENT MANUFACTURING TECHNOLOGY CO LTD

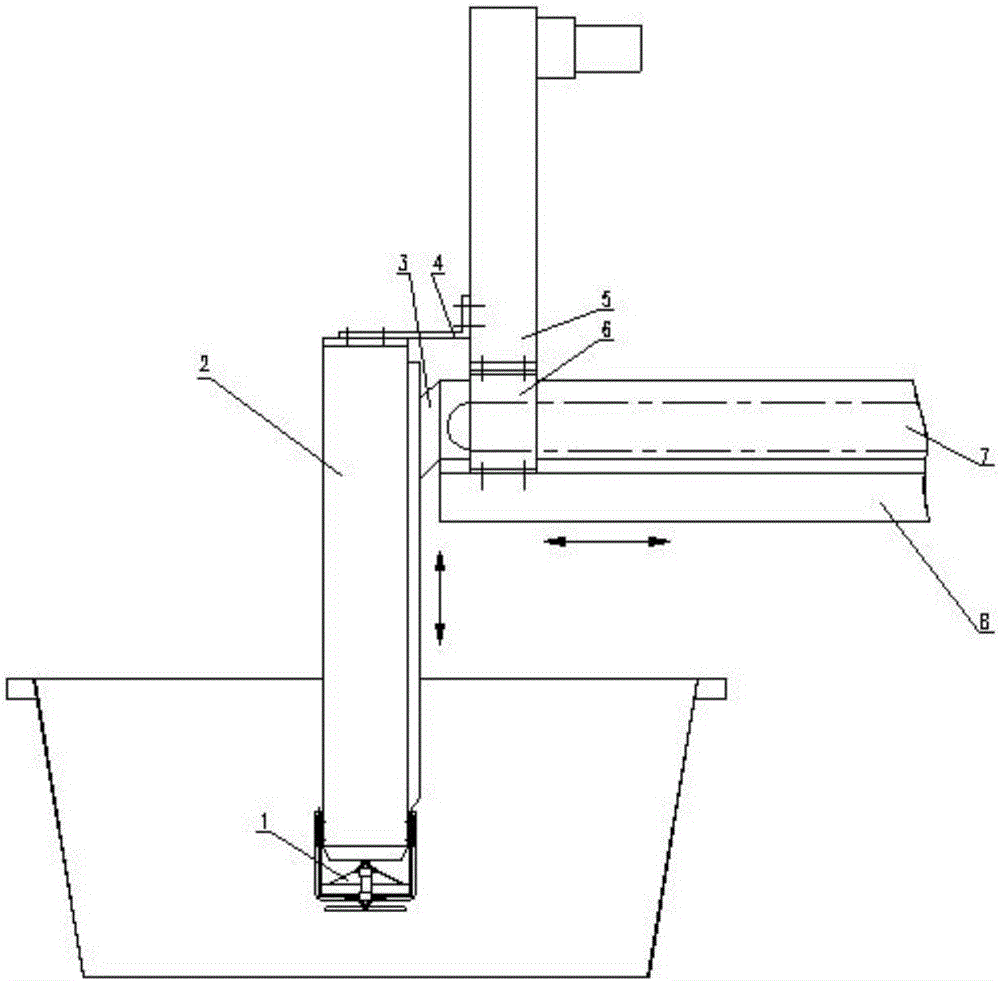

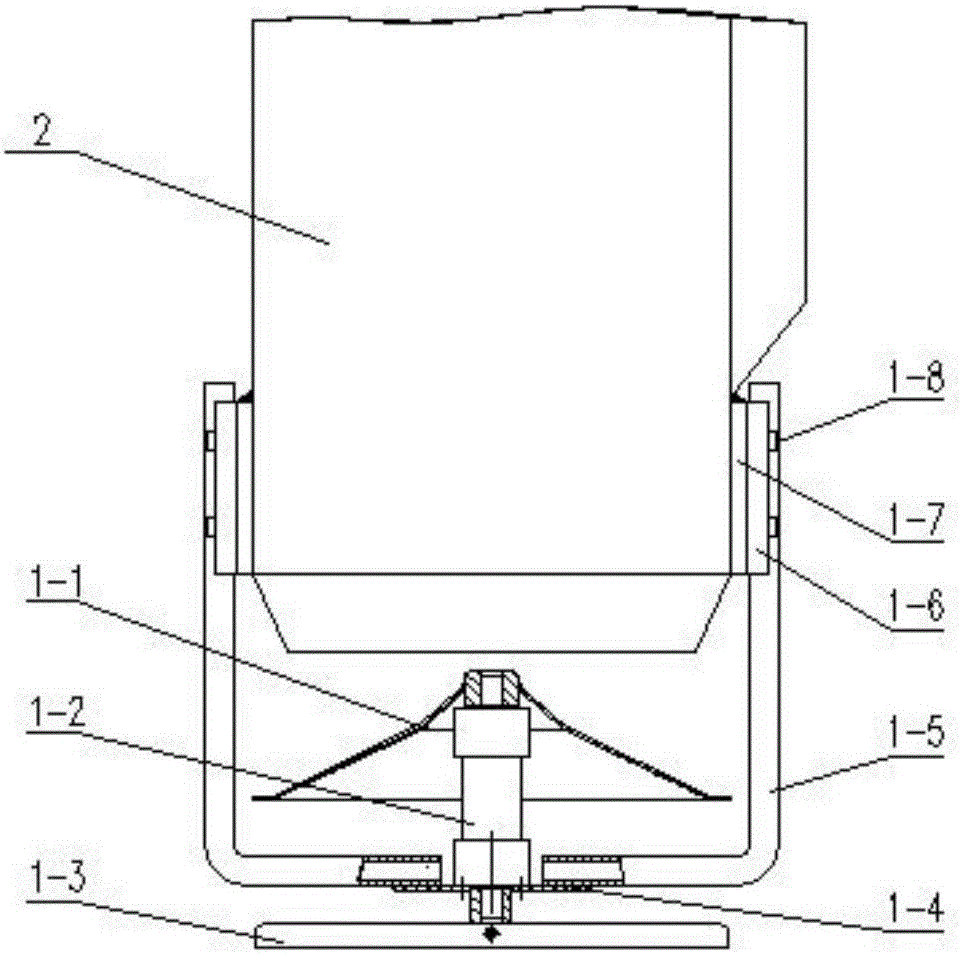

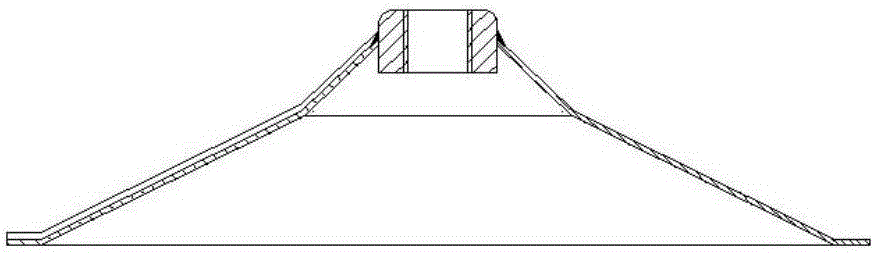

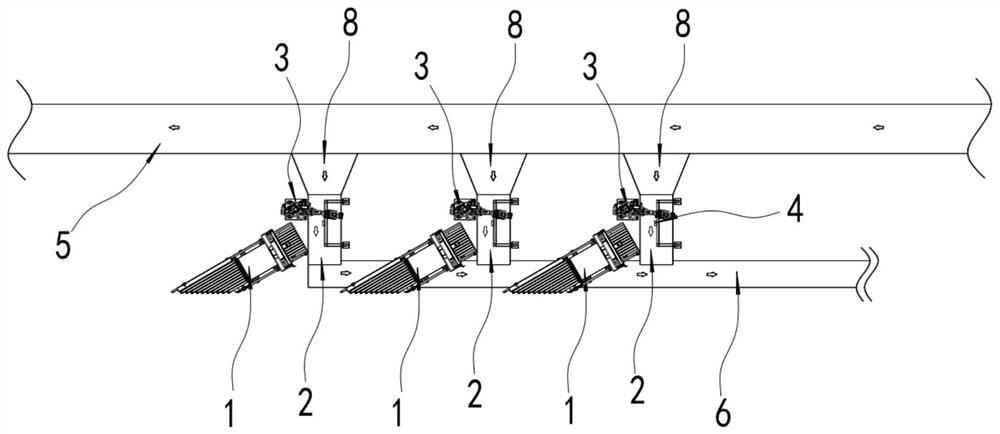

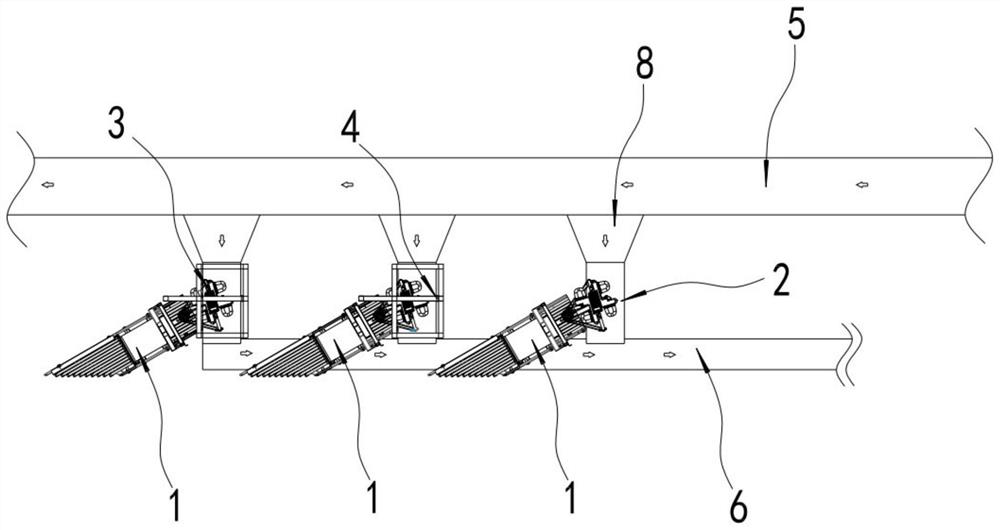

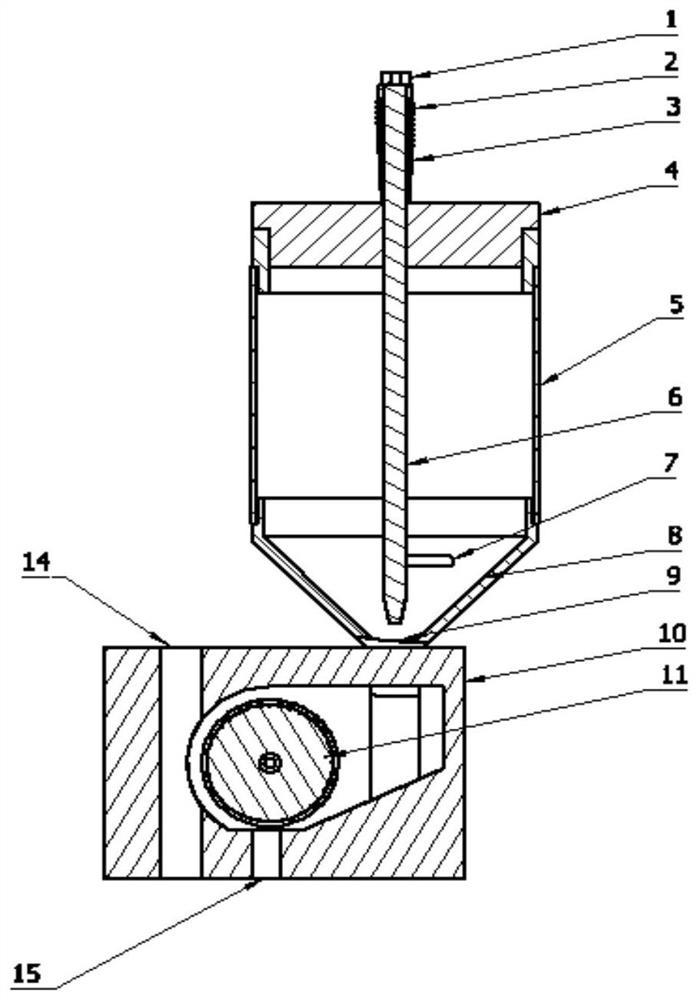

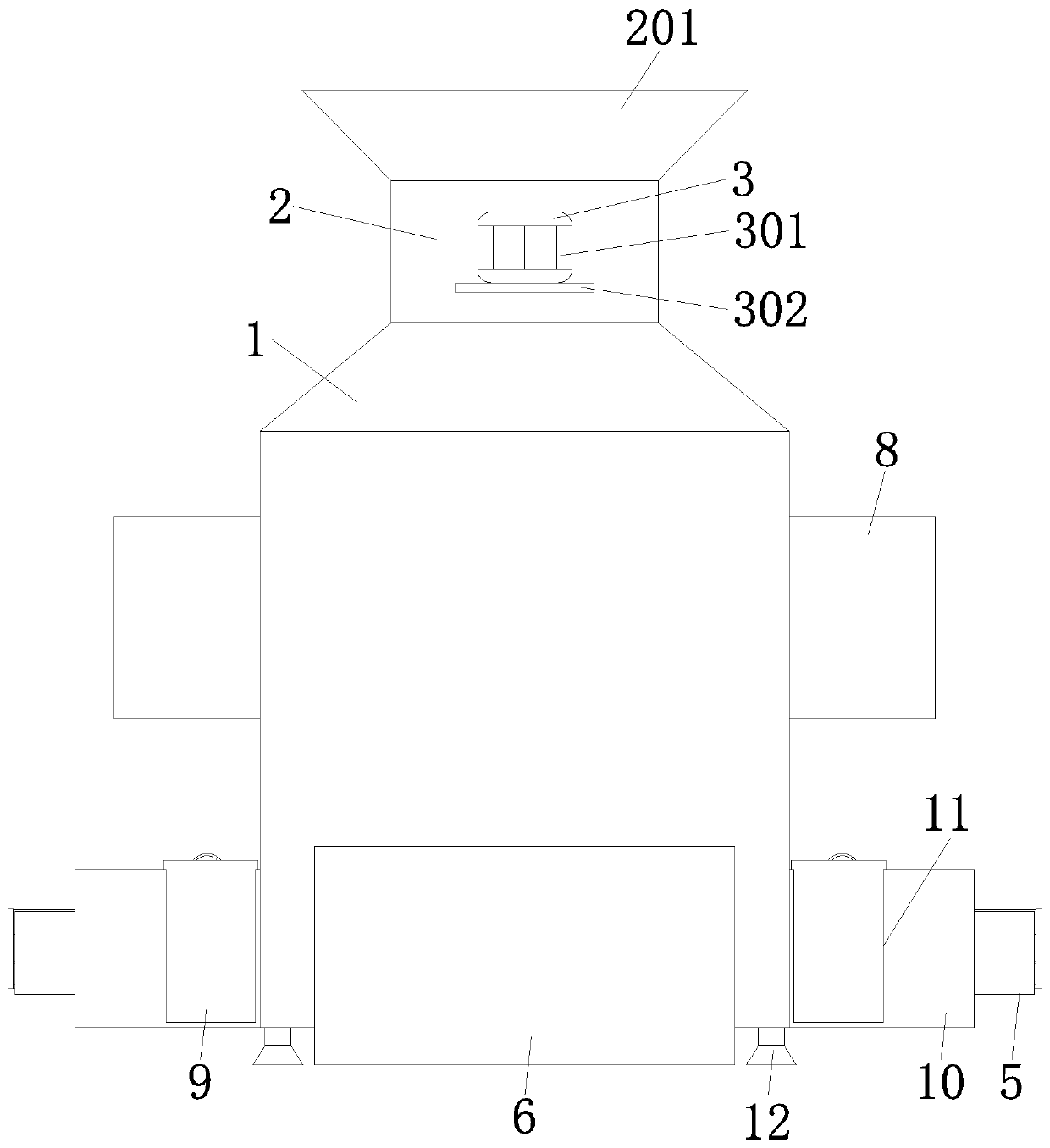

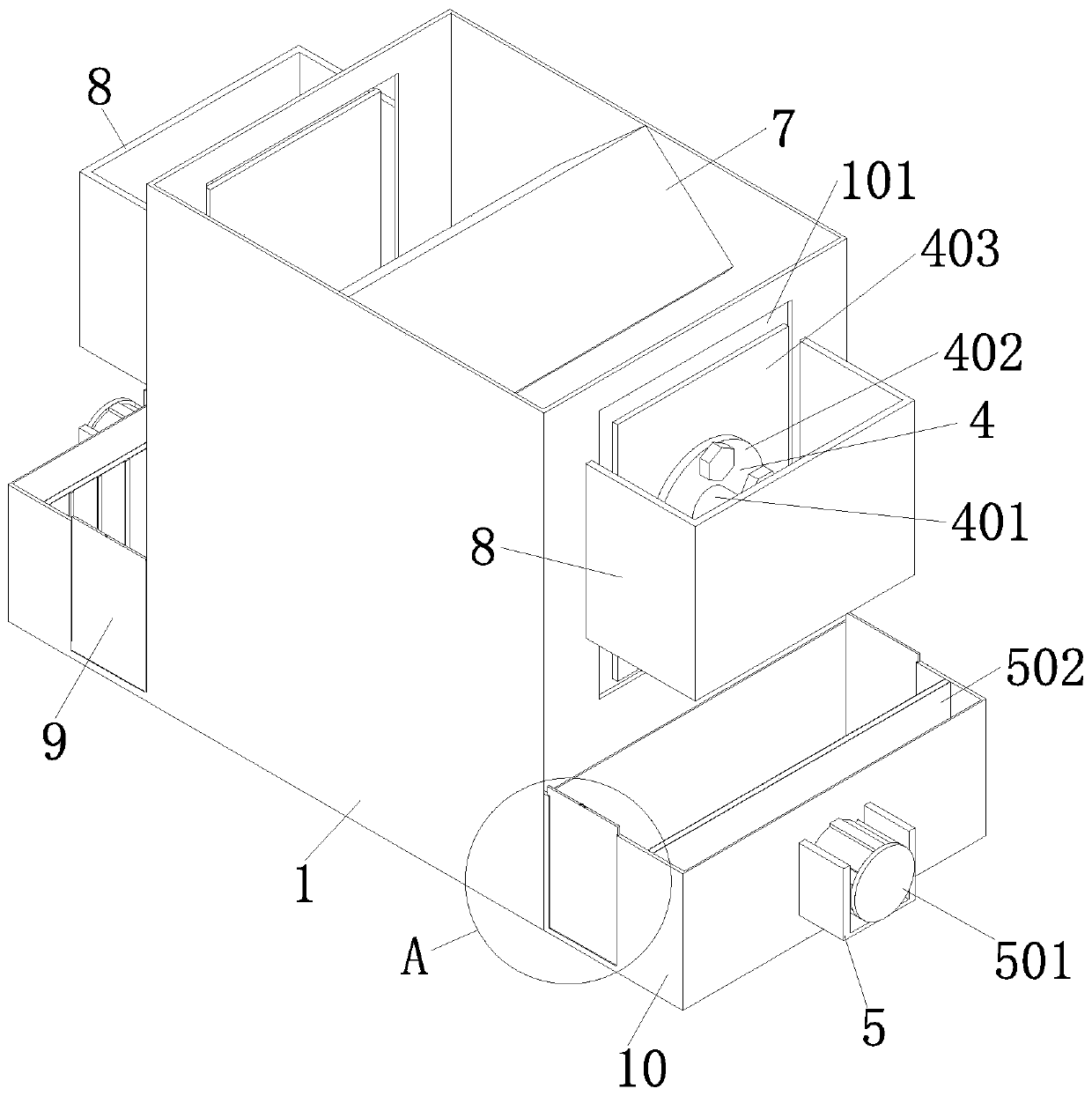

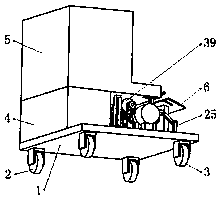

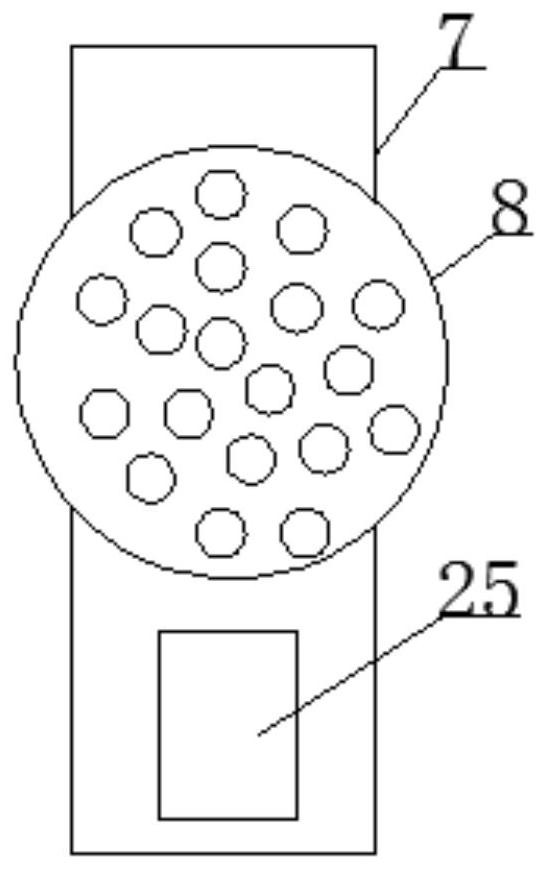

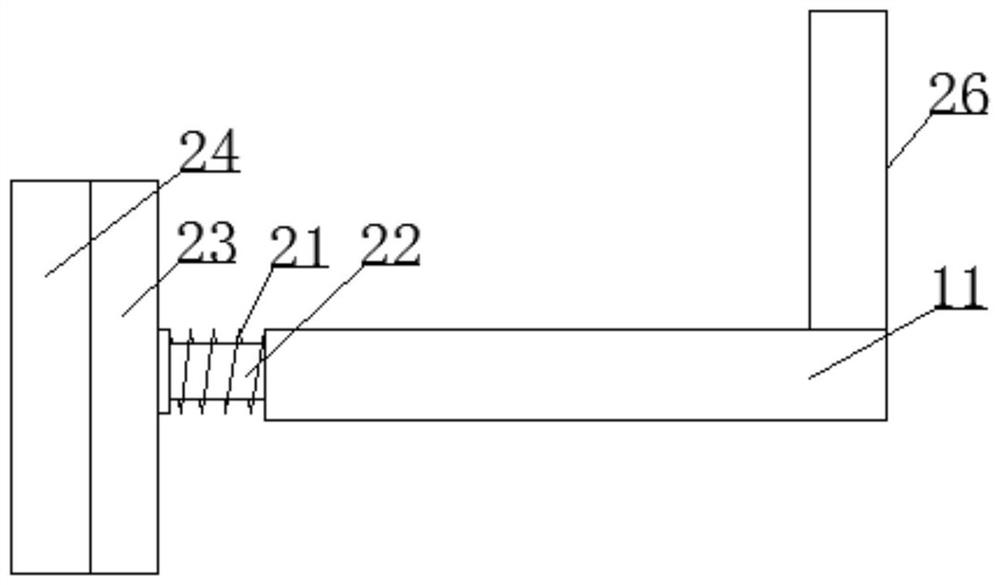

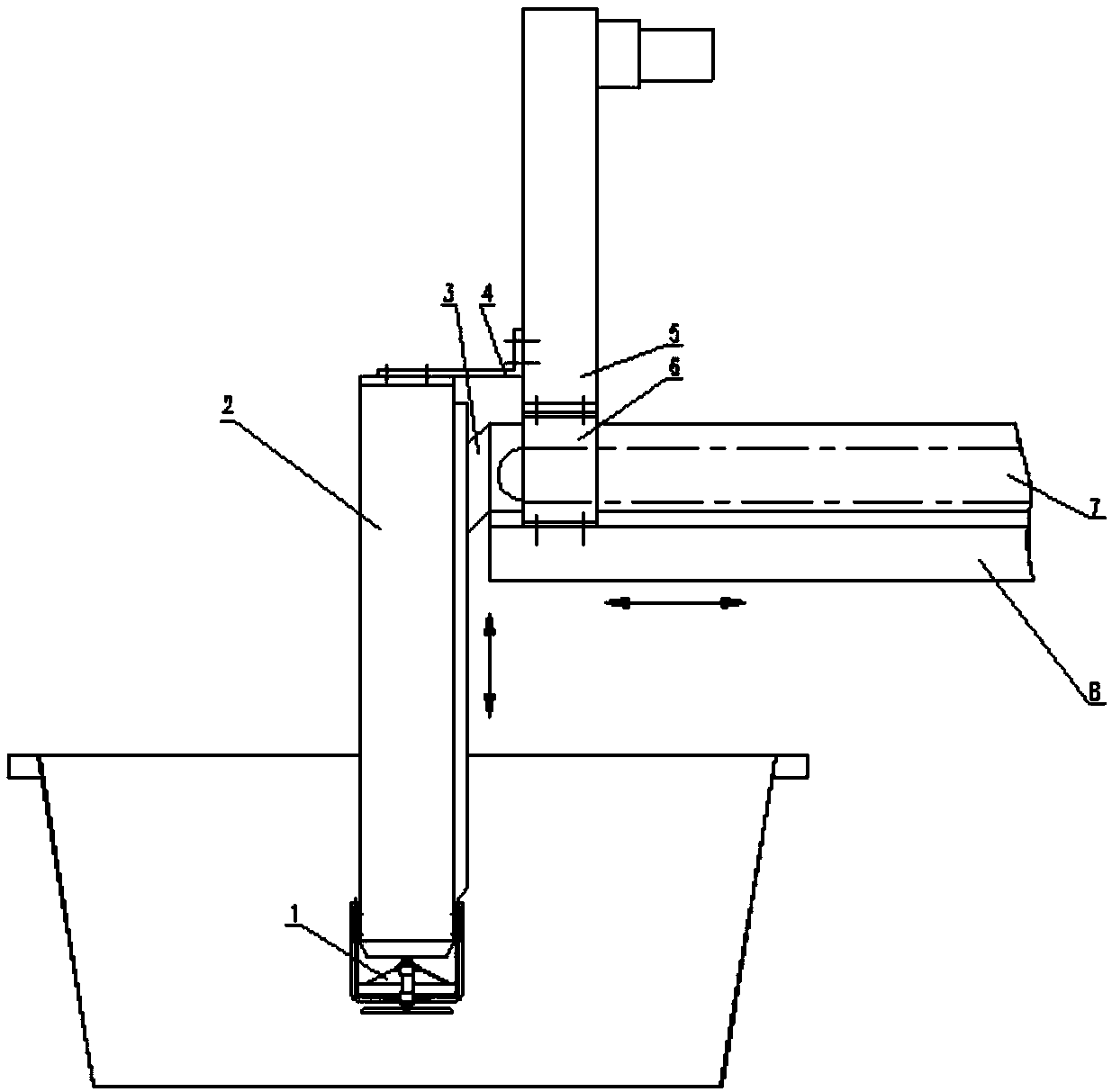

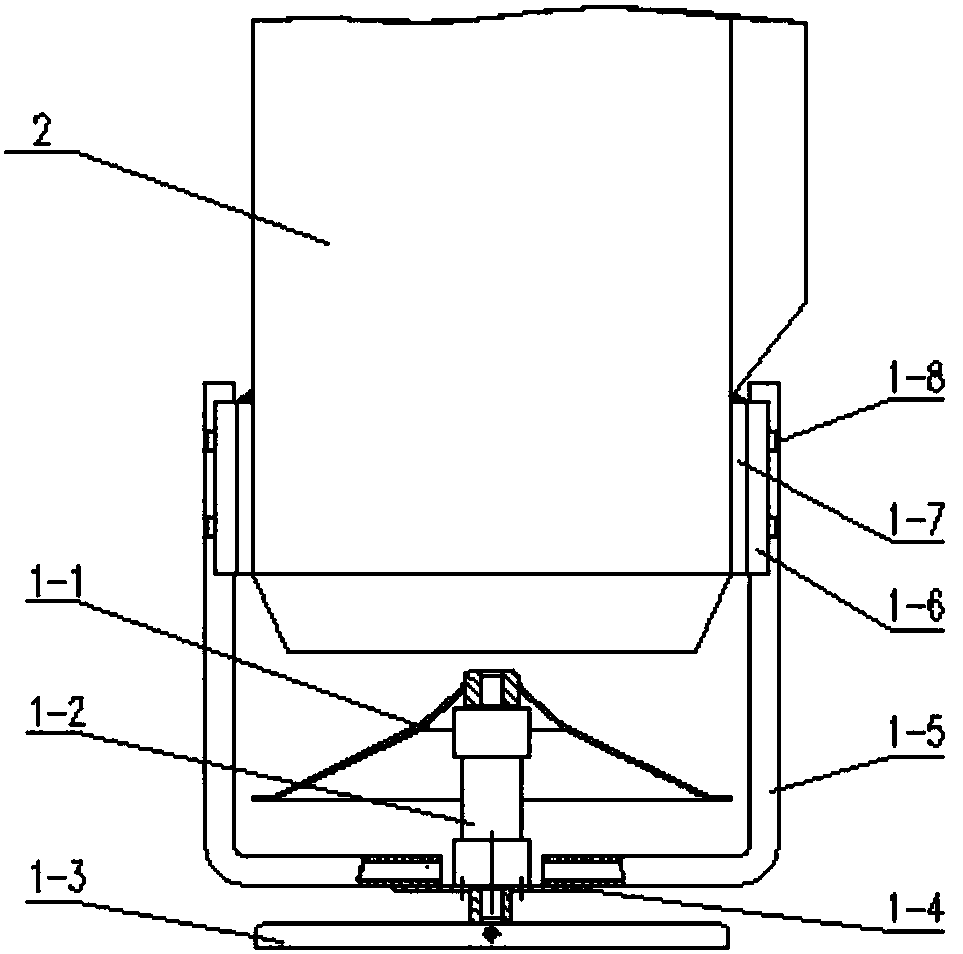

Inverted separating type bucket scattering device

ActiveCN106629105AReduce vibrationContinuous entryConveyorsLoading/unloadingMechanical equipmentMechanical vibration

The invention discloses an inverted separating type bucket scattering device, which belongs to the technical field of automatic steamer-filling system mechanical equipment for a winery. The inverted separating type bucket scattering device comprises an electric scattering device, a liftable scattering bucket, an outlet hopper, a connecting support, a lifting device, a connecting base, a chain scraper conveyor and a telescopic arm. The electric scattering device is arranged on the lower end of the liftable scattering bucket; the liftable scattering bucket is connected with the lifting device through the connecting support on the top end, and is driven by the lifting device to lift up and down vertically; and the lifting device is fixed onto the telescopic arm through the connecting base. According to the inverted separating type bucket scattering device provided by the invention, the whole weight of a device to be lifted is reduced, and the mechanical vibration is reduced; a conical scattering plate is adopted, so that the uniformity in scattering is realized; a transmission long shaft in the bucket is removed, so that wine materials can be continuously and uniformly fed favorably; and the manufacturing and assembling cost is remarkably reduced.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

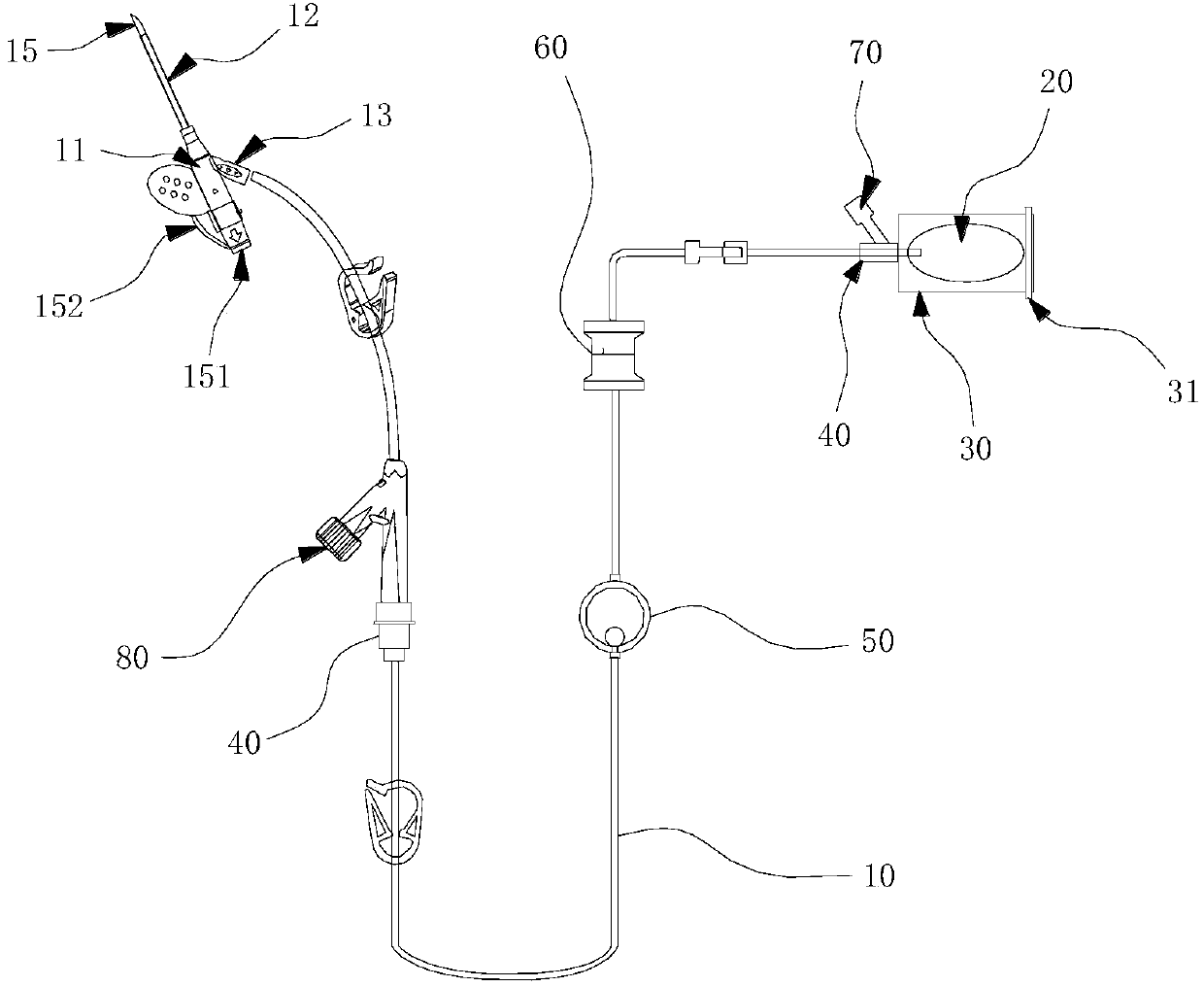

Freestyle needleless precision control indwelling infusion system

PendingCN107929871AIncrease pressureContinuous entryFiltering accessoriesMedical devicesNeedle freeInfusion method

The invention relates to the technical field of medical instrument and specifically relates to a freestyle needleless precision control indwelling infusion system. The system comprises an infusion bagassembly which is composed of infusion long tubes connected in series, an infusion prolongation tube assembly and an indwelling infusion flexible tube assembly; the infusion bag assembly comprises anouter pressure box and an elastic infusion bag; the infusion prolongation tube assembly comprises an infusion prolongation tube and an accessory fine speed control valve, precision medicine tube, a positive pressure connector type needleless drug addition port and a Luer connector; the indwelling infusion flexible tube assembly comprises a positive pressure connector, a side hole steel needle, adirect current tube and an infusion hose connected to one end thereof; a side wall of the direct current tube extends slantly and is provided with an infusion branch tube; the direct current tube chamber is provided with medical silica gel pad; a stab-resistant locking assembly is installed on the side hole steel needle so that the needle tip is wrapped when the stab-resistant locking assembly getoff from the direct current tube. The invention fundamentally eliminates the risks existing in the existing infusion system, and provides the patient with a more reliable and safer infusion method, and at the same time ensures the safety of the medical staff and eliminates the risk of getting stabbed and infected.

Owner:程基才

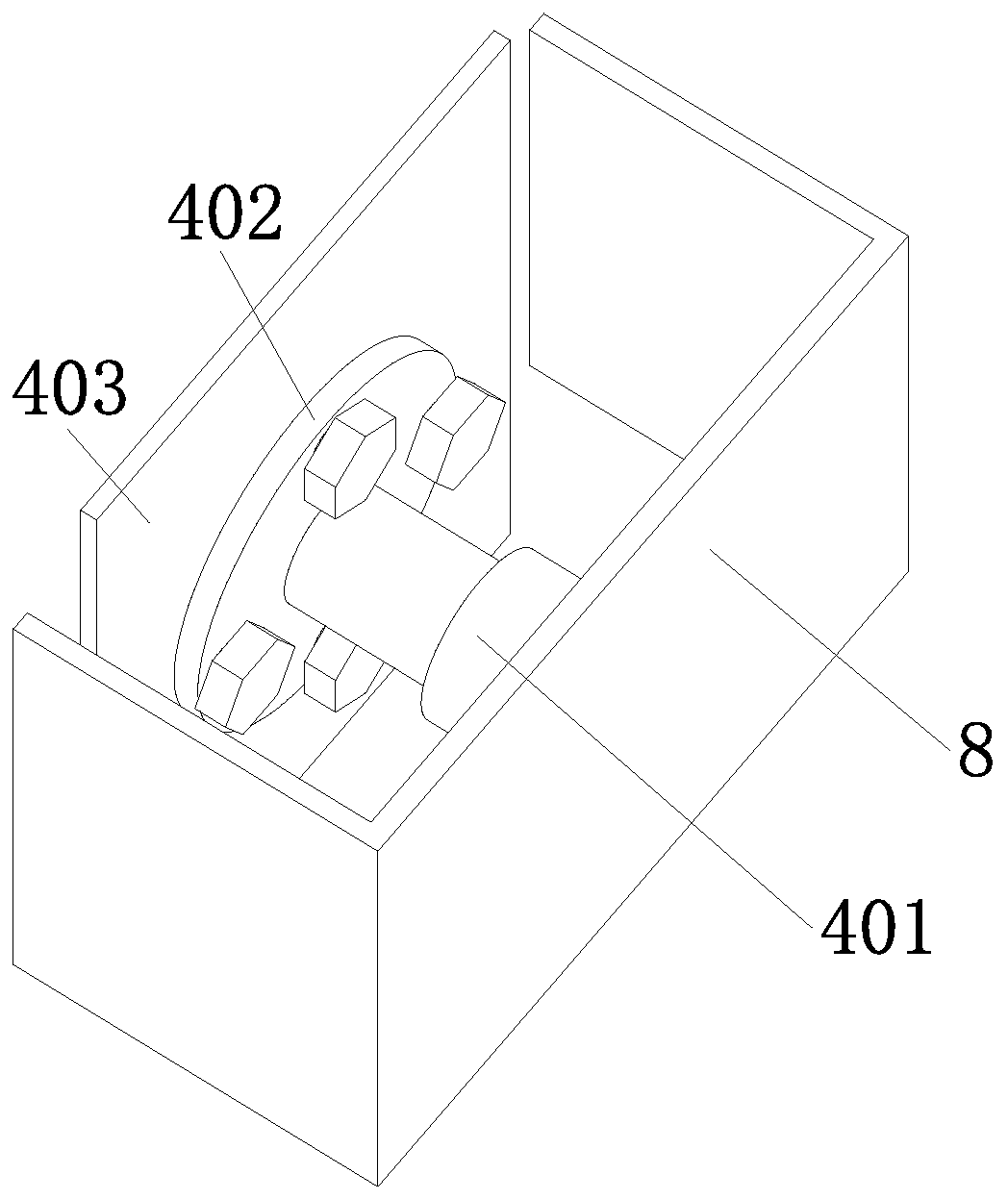

Conveniently installed agricultural automobile cleaning device

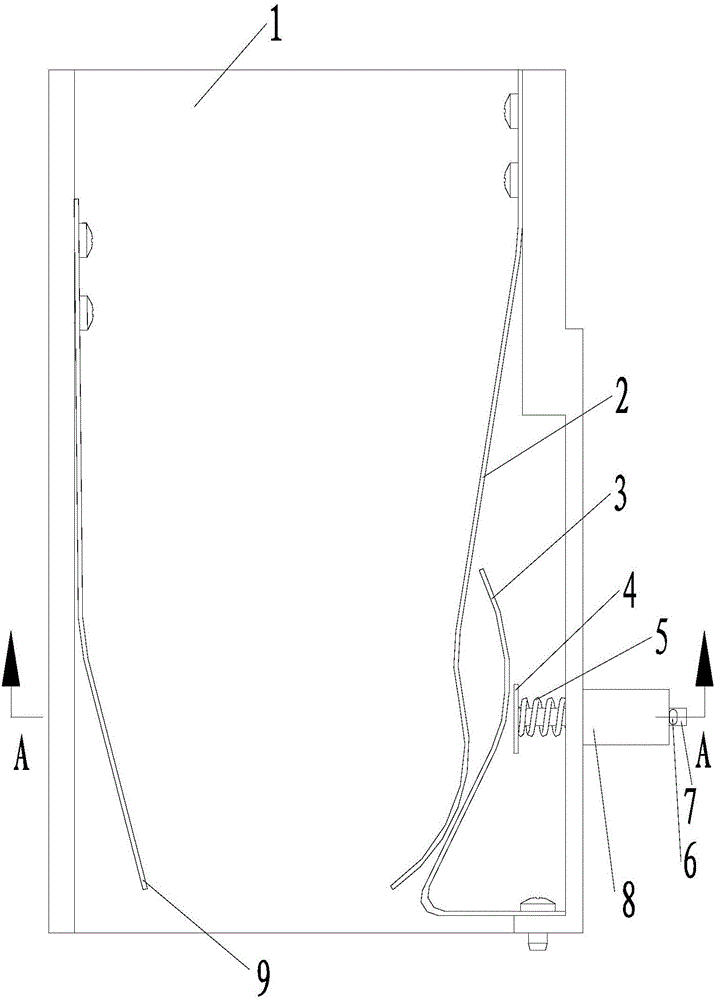

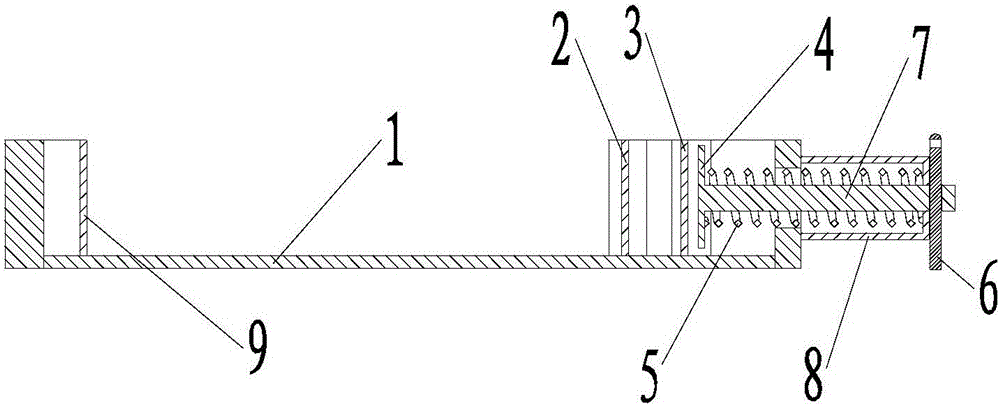

ActiveCN108891385AEasy to installContinuous entryVehicle cleaningAgricultural engineeringCoil spring

The invention aims to solve the problem that a body of an existing agricultural automobile is not conveniently cleaned, and discloses a conveniently installed agricultural automobile cleaning device which comprises a water tank, a first connecting rod, a positioning plate, a second connecting rod, a telescopic air bag, a through hole, a guide tank, a water spraying disk, a sliding plate, a baffleplate, a sleeve pipe, a rotating shaft, a sleeve, a sleeve ring, a pushing rod, a first screw spring, a positioning block, a sliding rod, a supporting block, a rotating disk, a second screw spring, aguide rod, a connecting plate, an adsorption plate, a guide groove and a positioning rod. The cleaning device is convenient to install, the sleeve ring rotates through rotation of wheels, so that thepush plate can repeatedly push the sliding plate, the telescopic air bag is repeatedly extruded, so that water is conveniently sprayed onto a body, mud on the body is rapidly cleaned, cleanliness of the body is kept, and the cleaning device is worthy of popularization in the field of agricultural machinery.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

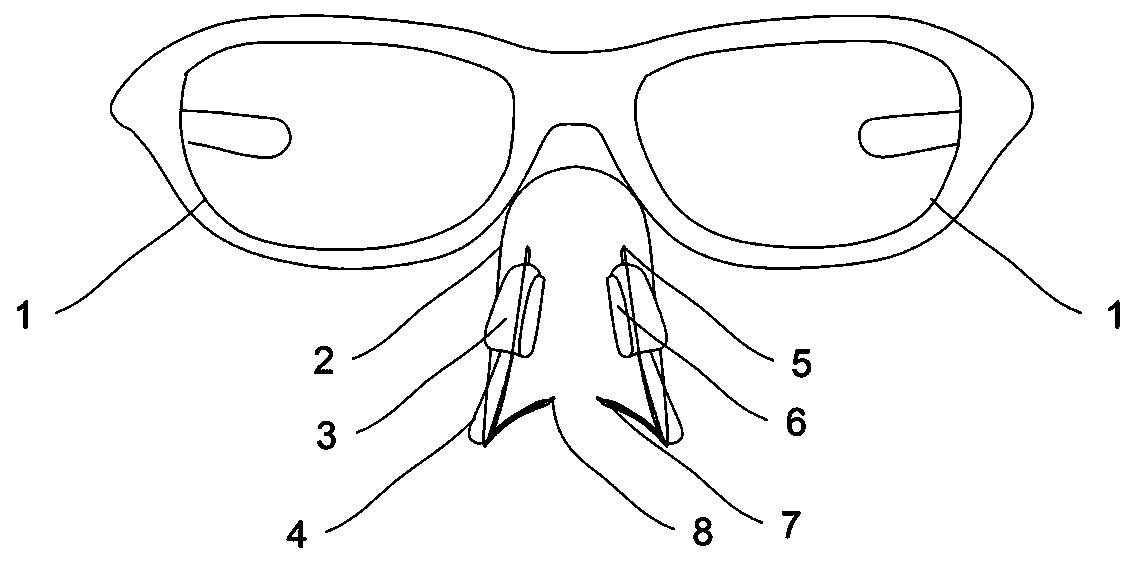

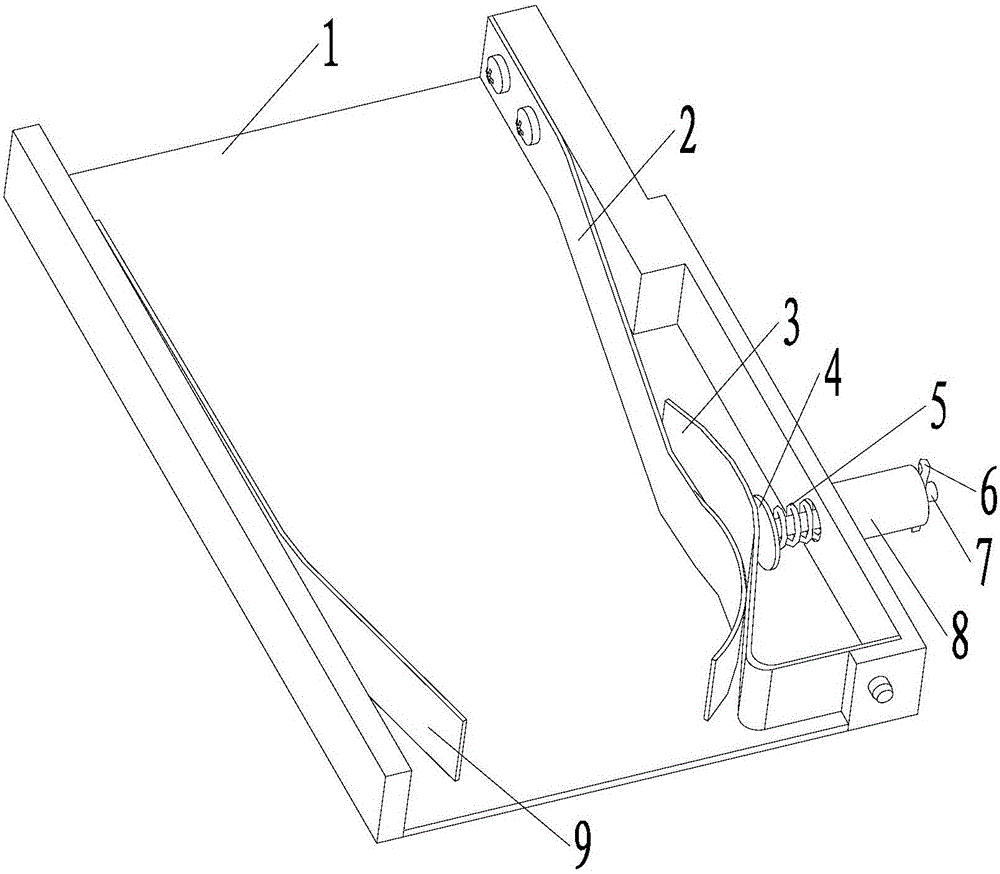

Nasal cavity sustained release drug dosing device

PendingCN109621172AEasy to fixConsistent temperatureMedical devicesNasal cavitySustained release drug

The invention belongs to the field of nasal cavity drug dosing and therapeutic equipment, and particularly relates to a nasal cavity sustained release drug dosing device comprising an eyeglass frame,a spring clip, a liquid storage bag, a capillary tube, a curved support frame, a clip piece and a contact. The spring clip is movably arranged under the eyeglass frame, and the spring clip is n-shaped. The lower end of the spring clip is provided with the curved support frame, and the curved support frame is tilted upward. The connection between the spring clip and the curved support frame is provided with the clip piece, and the clip piece is tilted upward. The upper end of the curved support frame is provided with the liquid storage bag, and the contact is disposed under the liquid storage bag through the capillary tube and disposed at the top end of the clip piece. The dosing device is attractive in appearance, can preheat a drug during dosing to the nasal cavity, and allows the drug tobe slowly released into the nasal cavity continuously, and the therapeutic effect is achieved through the nasal cavity, so that the drug is more acceptable to a patient, and the therapeutic effect isgood.

Owner:YUNNAN UNIV OF TRADITIONAL CHINESE MEDICINE

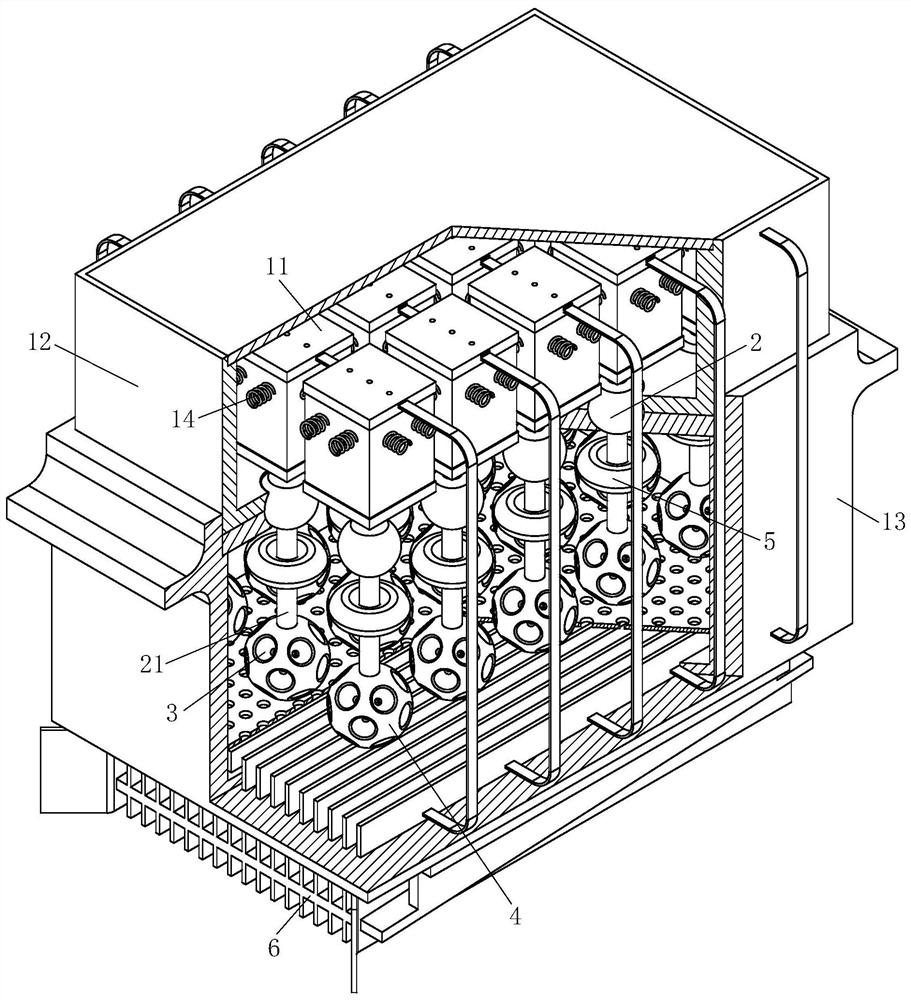

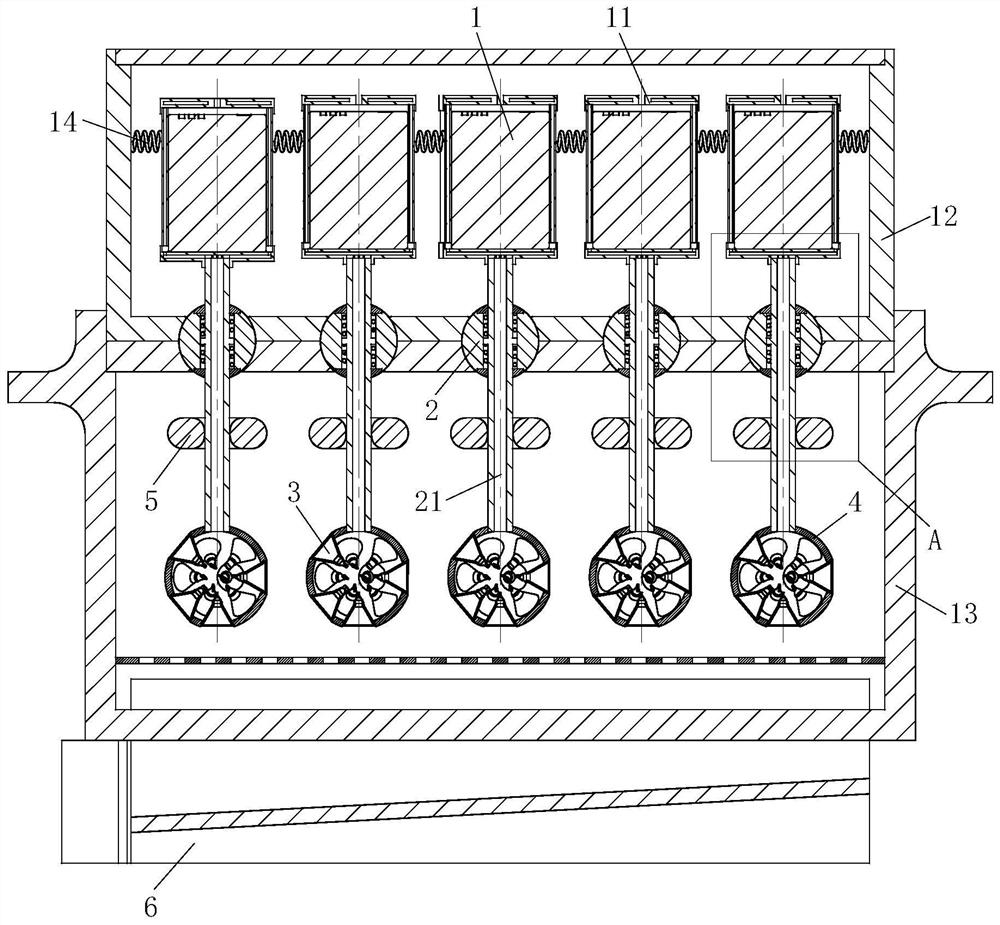

New energy automobile battery pack capable of dissipating heat through vibration

InactiveCN113650489AReduced service lifeReduce the temperatureElectric propulsion mountingSecondary cellsNew energyEngineering

The invention belongs to the technical field of new energy automobile batteries, and particularly relates to a new energy automobile battery pack utilizing vibration to dissipate heat. The battery pack comprises a battery block, a box body, an upper shell, a lower shell, a first spring, a ball body, a hollow rod, a second spring, a baffle ring and a water suction head. The vibrating box body drives the hollow rod to slide back and forth on the ball body, so that in the process that the box body drives the hollow rod to move, the water suction head at the end of the hollow rod moves in liquid in the lower shell, and then the liquid in the lower shell enters the hollow rod and then enters a water passing groove of the box body; and heat generated in the battery block is transmitted to the liquid through the box body, so that the temperature of the box body is reduced, the heat generated by the battery can be transmitted to the box body, the battery block in the water box body is cooled, and then the liquid absorbing the heat in the box body enters the bottom of the lower shell through the water pipe. Therefore, the circulation of the liquid is realized, and the continuous heat dissipation of the battery block is further realized.

Owner:邢金凤

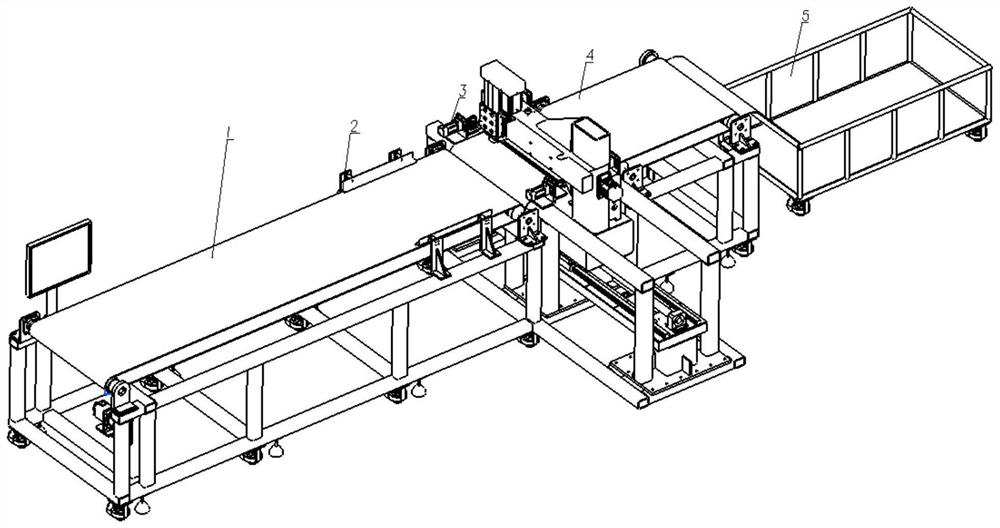

Article sorting system package loading method, article sorting package loading system and sorting system

PendingCN113578759ARealize automatic uploadingAchieve cullingSortingProcess engineeringVisual recognition

The invention discloses an article sorting system package loading method, an article sorting package loading system and a sorting system. According to the article sorting system package loading method, batch articles can continuously enter a sorting conveying line through a sliding groove; different types of batch articles on the sorting conveying line are recognized through a 3D visual recognition device; a sorting robot is controlled to load the articles meeting the package loading condition to a package supply conveying line; and abnormal articles not meeting the package loading condition are conveyed to the outside through the sorting conveying line to be not loaded. According to the invention, the abnormal articles are effectively removed, the articles meeting the package loading condition are automatically packaged, manual sorting is not needed, the step of pre-sorting is omitted, and the automation degree is high.

Owner:SUZHOU GP LOGISTICS SYST

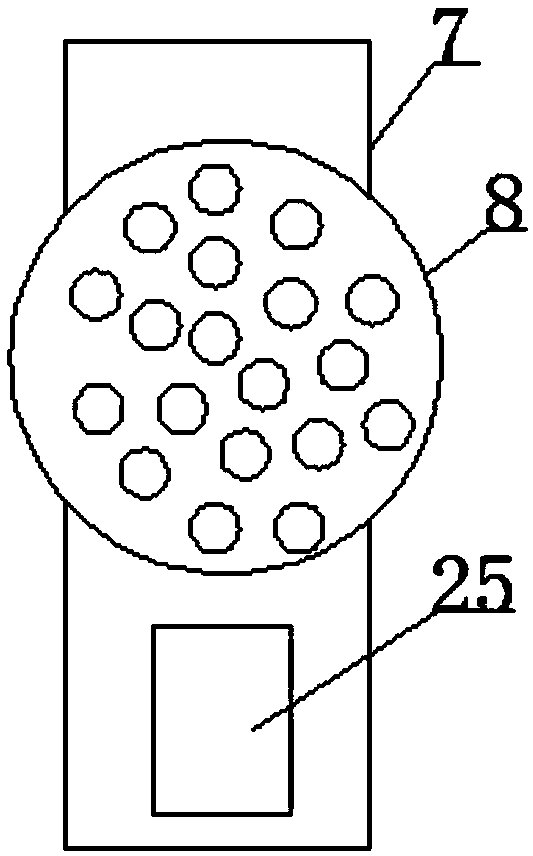

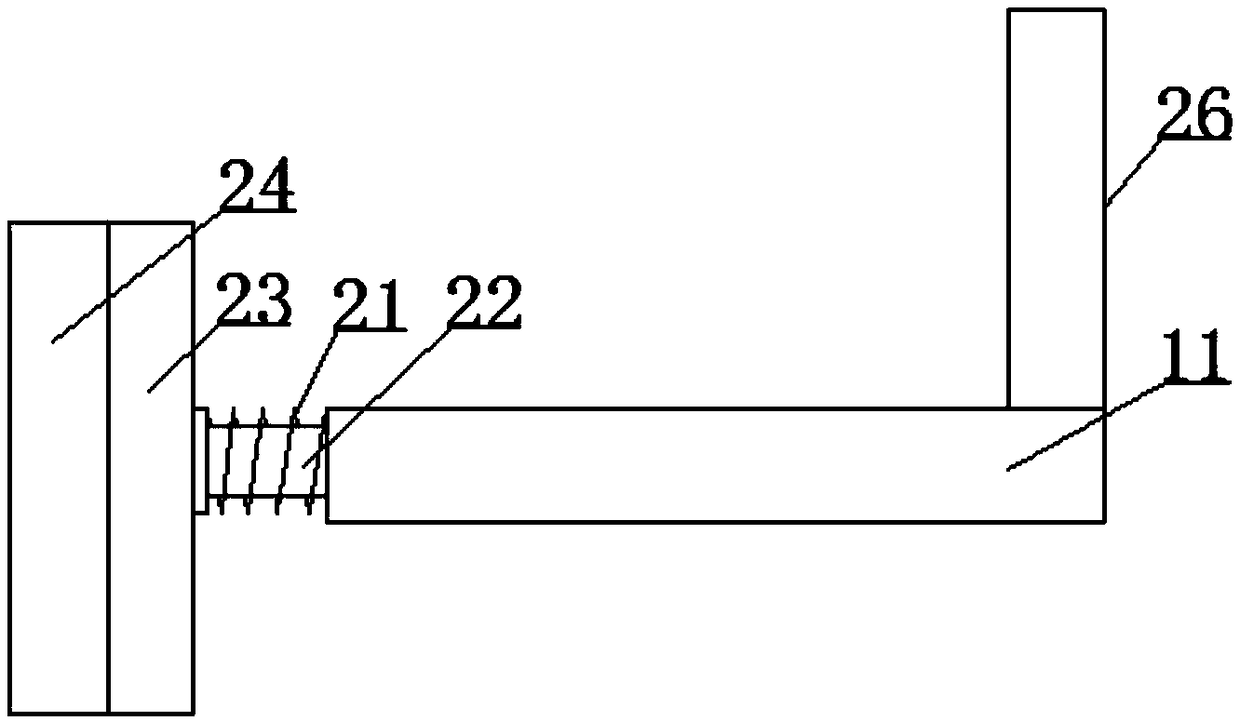

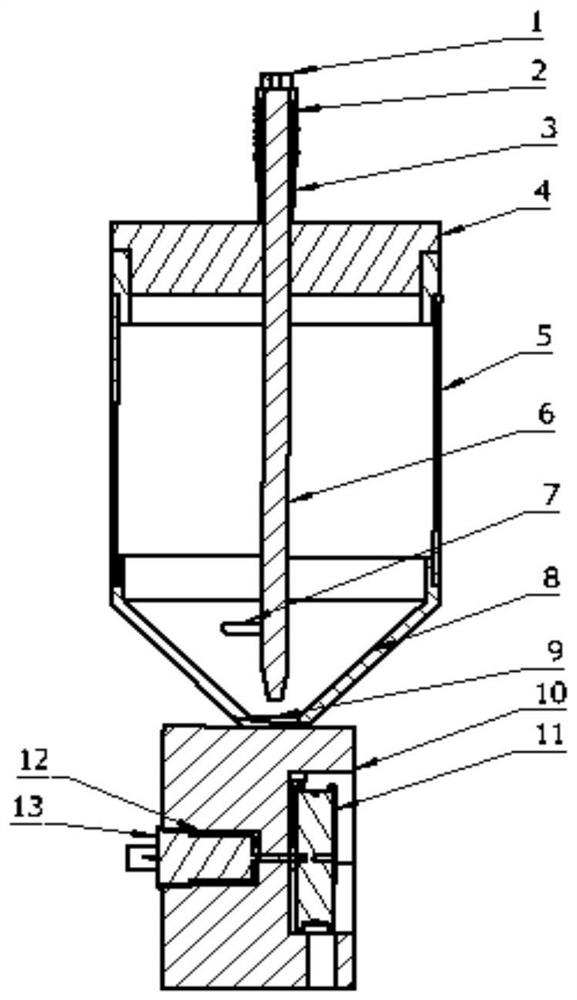

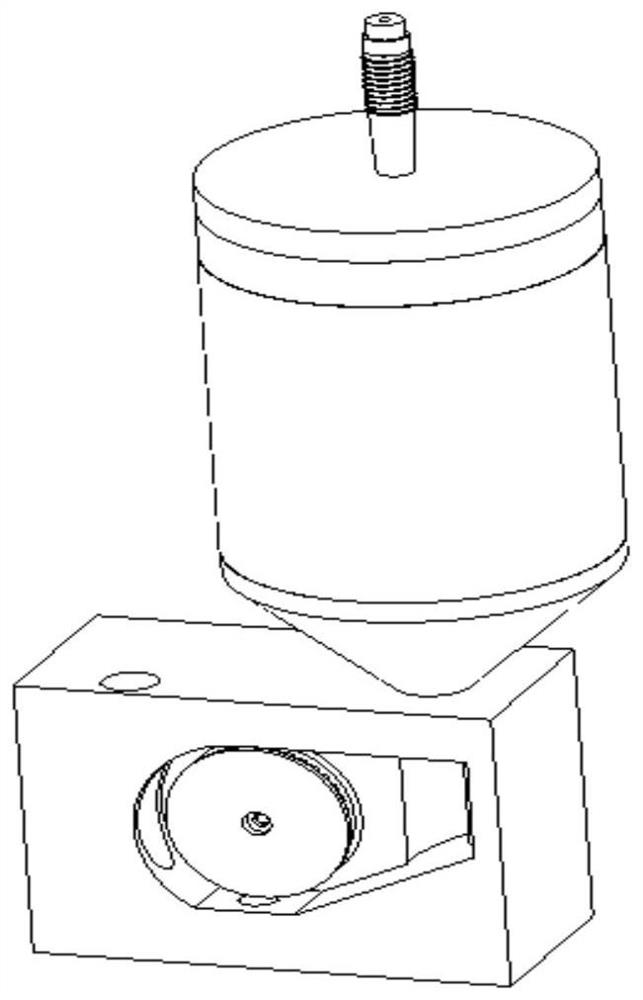

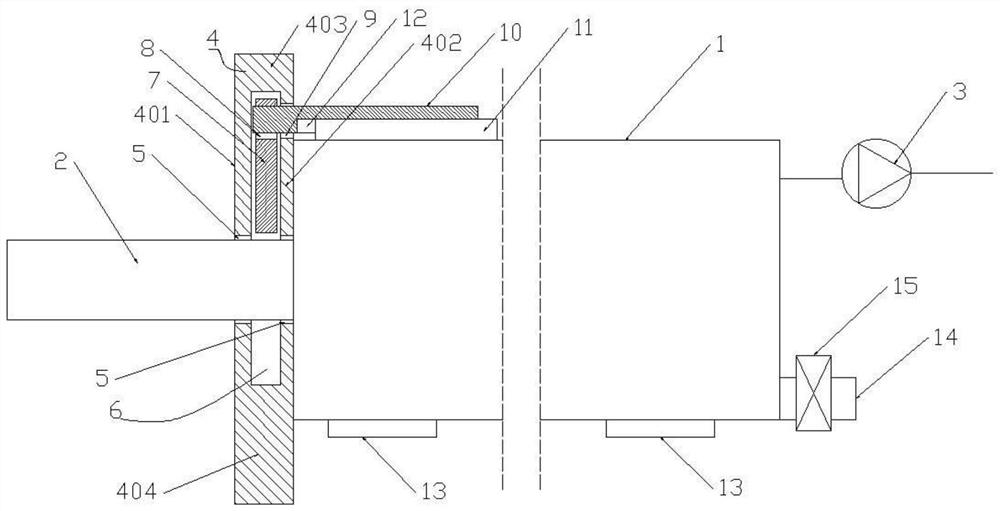

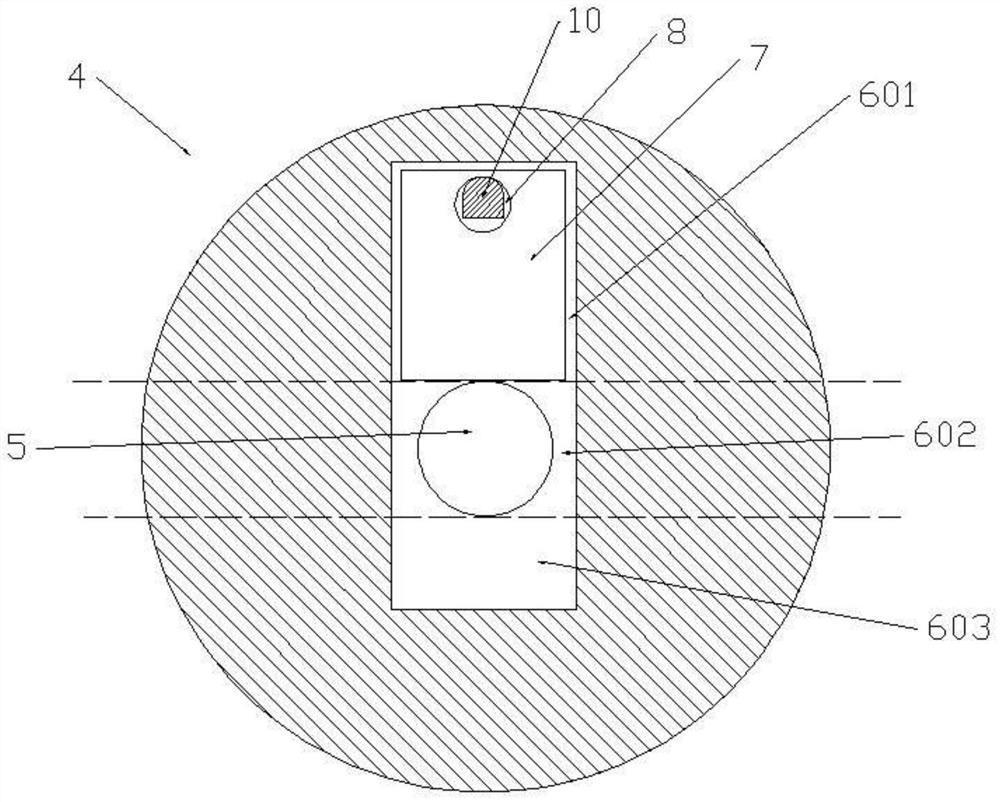

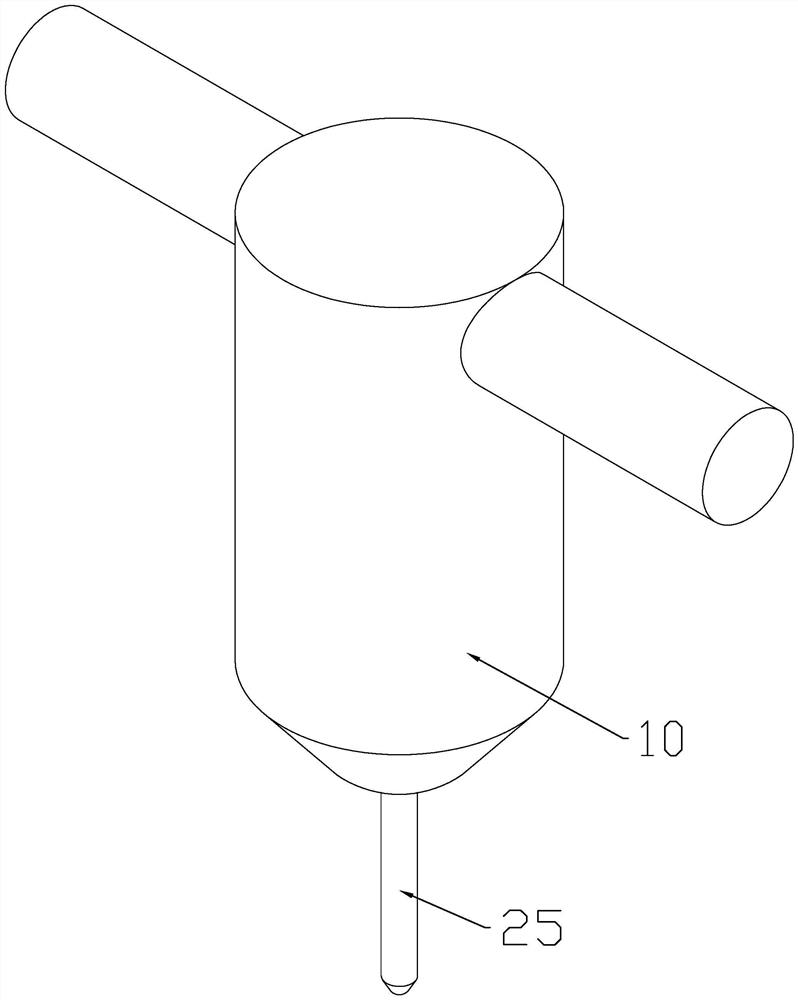

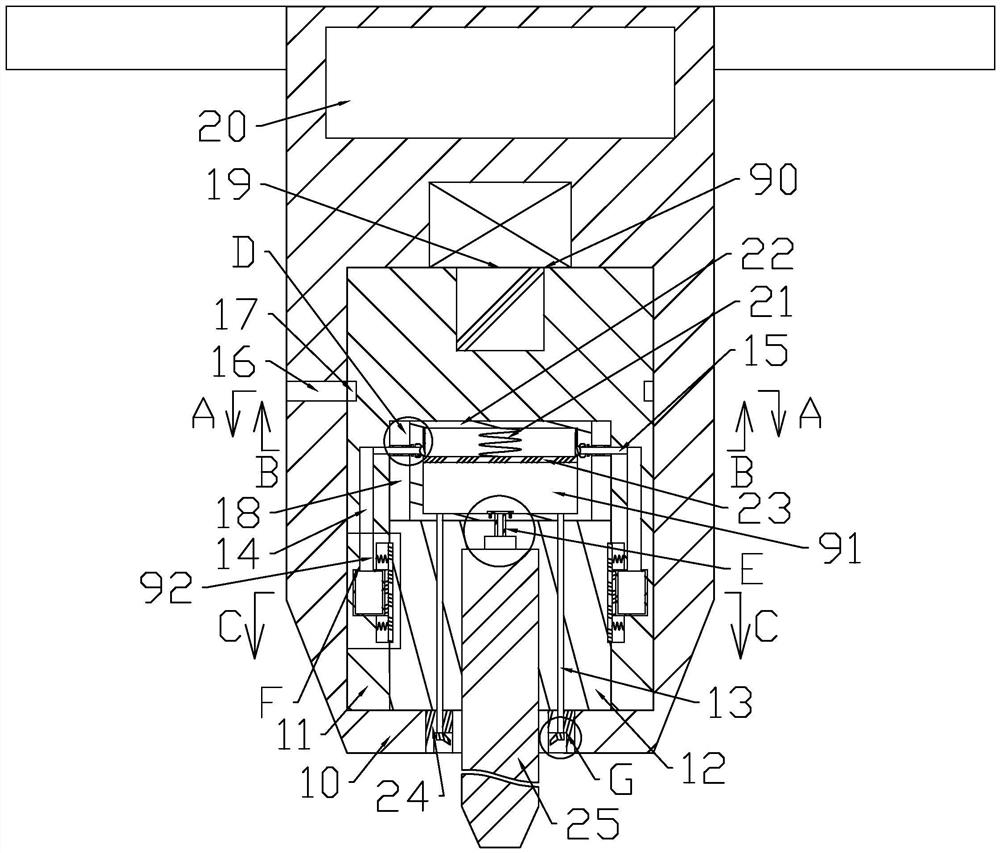

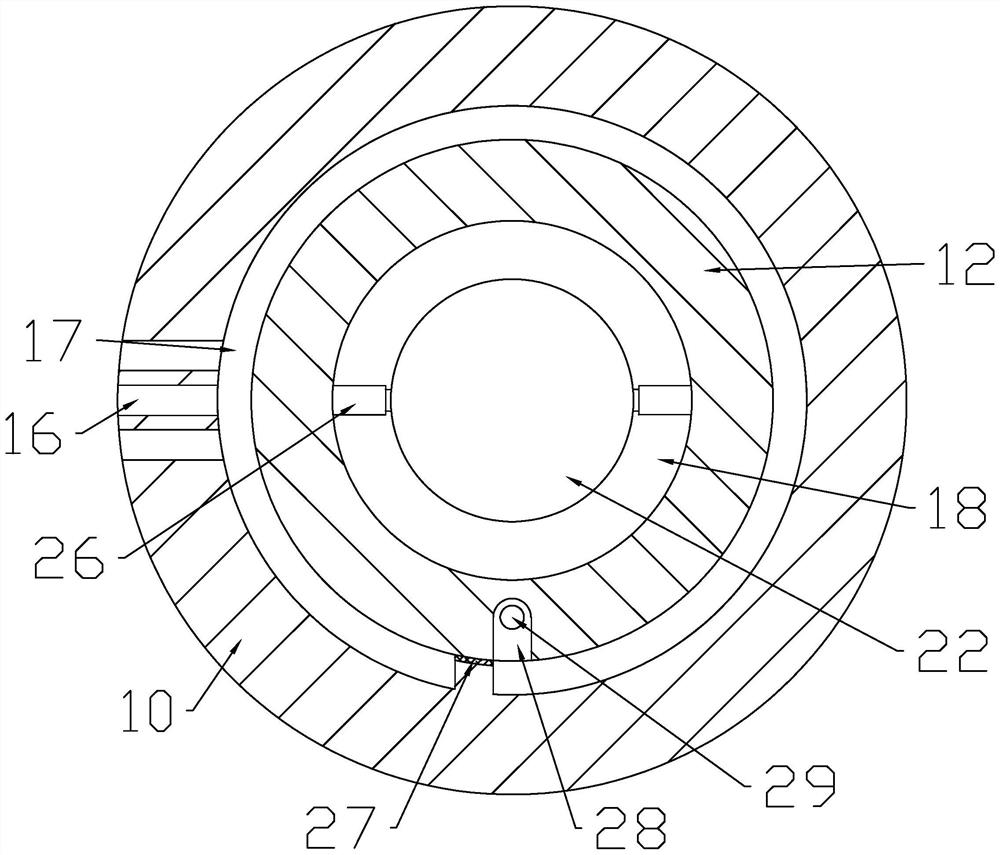

Rotary ultrasonic vibration gas current-carrying powder feeder and electric arc additive system

PendingCN113333916AContinuous entrySolve the problem of powder feeding volume controlAdditive manufacturing apparatusShaking/oscillating/vibrating mixersGas cylinderMetallic materials

The invention belongs to the field of metal materials, and particularly relates to a rotary ultrasonic vibration gas current-carrying powder feeder and an electric arc additive system. A powder cylinder and a transfer chamber arranged below the powder cylinder are included. A rotatable ultrasonic vibration stirring rod is arranged in the powder cylinder, and powder in the powder cylinder uniformly falls into the transfer chamber through powder cylinder through holes in the bottom end of the powder cylinder through ultrasonic vibration and stirring. A hub and a transfer chamber through hole are formed in the transfer chamber, a plurality of hole grooves are evenly distributed in the circumferential face of the hub, the upper portion of the transfer chamber through hole is connected with a gas cylinder, and after powder in the powder cylinder falls into the transfer chamber, the hub rotates, so that the powder in the hole grooves of the hub is driven to enter the transfer chamber through hole, the powder transferred by the hub is uniformly and stably conveyed into deposited metal in the manner that gas passes through the bottom of the through hole. The problem that powder is poor in flowability and cannot fall off from the powder cylinder can be solved through the rotatable ultrasonic vibration rod, and the applicability of the powder feeder to powder with different flowability is improved.

Owner:NANJING UNIV OF SCI & TECH

Rubber additive production sampling device

PendingCN114593954AImprove sampling accuracyGuaranteed accuracyWithdrawing sample devicesCleaning using toolsProcess engineeringElectrical and Electronics engineering

The invention provides a rubber additive production sampling device. The rubber additive production sampling device comprises a sampling barrel and a pushing block, a sampling head is fixed at one end of the sampling barrel; a through hole A is formed in the material pushing block; when the sampling head is inserted into the through hole A, the material pushing block can be hermetically connected with the sampling head, and the material pushing block can move along the axis direction of the sampling head; a long-strip-shaped groove A is formed in the material pushing block and comprises an M part, an N part and an E part, and the M part, the N part and the E part are sequentially arranged from top to bottom. The N part is communicated with the through hole A. A baffle is arranged in the groove A and can move up and down along the groove A. The sampling device has the advantages of being reasonable in design, high in practicability and convenient to use. By using the sampling device, accurate sampling can be realized, the consistency of the sampling amount of each working procedure is ensured, and the detection accuracy and accuracy are improved.

Owner:山东元禾新材料科技股份有限公司

Building decoration material crushing, sorting and recycling device

InactiveCN111437954AReduce volumeEasy to recycle and transportGrain treatmentsPressesMagnetic separatorStructural engineering

The invention discloses a building decoration material crushing, sorting and recycling device. A crushing box is fixedly connected with the top of a box body of the building decoration material crushing, sorting and recycling device. A crushing mechanism is arranged in the crushing box. A double pitch roof type material guide plate is fixedly connected with an inlet end of an inner cavity of the box body. Protection frames are fixed to the left side and the right side of the box body. The side, close to the box body, in each protection frame is open, and the side wall of the side, away from the box body, in each protection frame is fixedly connected with a horizontal reciprocating type magnetic separation mechanism. Openings matched with the horizontal reciprocating type magnetic separation mechanisms are formed in the two sides of the box body correspondingly. The lower ends of the material guide plate are higher than the horizontal reciprocating type magnetic separation mechanisms, and a gap is reserved between each lower end of the material guide plate and the corresponding inner side wall of the box body. A compression box which is fixedly connected with the bottom side wall ofthe box body and provided with an opening in the upper end is arranged under each protection frame. The side, away from the box body, in each compression box is provided with a horizontal reciprocating type compression mechanism. The front side and the rear side of each compression box are each provided with a material taking port. A port sealing mechanism is arranged at each material taking port. A collecting box is arranged at the bottom of the front side of the box body. The building decoration material crushing, sorting and recycling device is high in sorting efficiency and saves labor.

Owner:上海子轩建筑科技集团有限公司

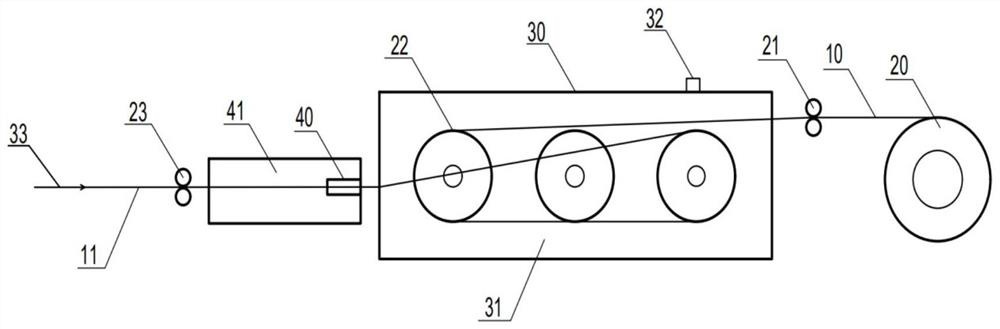

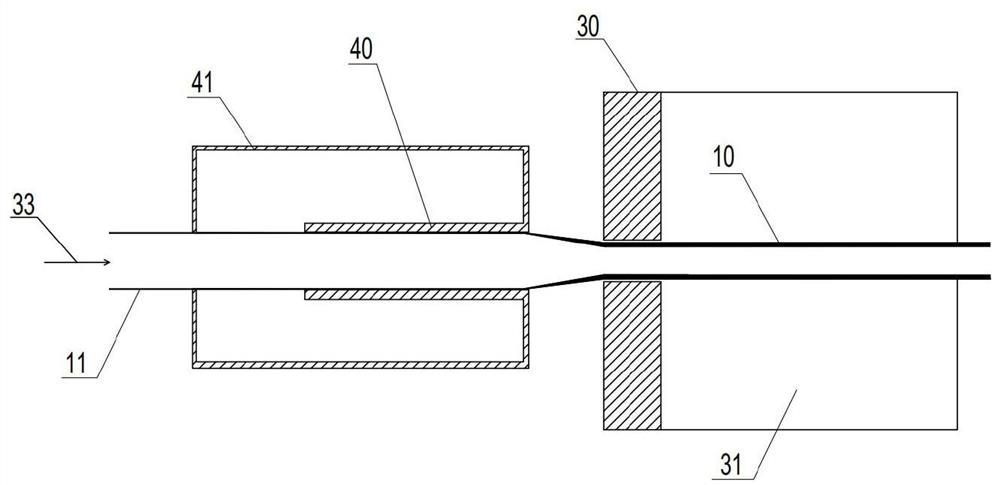

Shaping and forming equipment for cavity material pipe

PendingCN112172099AControl shaping forceAdjustable heating stateShaping toolsMetal-working feeding devicesInternal pressureControl system

The invention discloses shaping and forming equipment for a cavity material pipe. The shaping and forming equipment comprises a heating system, a shaping system, a pressure control system and a conveying system. The heating system comprises a heating cavity and a heating medium, and the heating medium is located in the heating cavity and used for heating the shaped material to the softening or deformable temperature; the shaping system is positioned at the rear end of the heating cavity, comprises a shaping cavity and a cooling system, and is used for shaping, cooling and shaping the material;the pressure control system comprises a material internal pressure control system for controlling the shaping force of the shaping material and a heating cavity pressure control system; and the conveying system comprises a material conveying mechanism and a material separating machine and is used for conveying materials to pass through the heating system and a cooling and shaping system, so thatthe material can be continuously shaped.

Owner:朱辉

Medicine bottle pouring preventing device used for vertical type ultrasonic bottle washing machine

InactiveCN106238405AContinuous entryIntensive smooth entryHollow article cleaningCleaning using liquidsEngineeringElastic cylinder

The invention discloses a medicine bottle pouring preventing device used for a vertical type ultrasonic bottle washing machine. The medicine bottle pouring preventing device comprises a bottle conveying mesh belt, a left elastic baffle strip, a right elastic baffle strip, a right rebound strip, an elastic cylinder and a cylindrical sleeve, and further comprises a cylindrical sleeve arranged at the outer side of the right wall; the two side walls of the tail end of the bottle conveying mesh belt are separately equipped with the left elastic baffle strip and the right elastic baffle strip; the right rebound strip is arranged between the right elastic baffle strip and the right wall; the elastic cylinder is arranged between the right rebound strip and the right wall; the elastic cylinder comprises a cylinder body, a cylindrical surface and a compression spring; the compression spring abuts against the cylindrical surface and applies elastic force; the cylinder body is sleeved by the cylindrical sleeve; and the cylinder body gets out of the end part of the cylindrical sleeve, and is positioned through an open pin. The medicine bottle pouring preventing device guarantees that bottles continuously and densely enter a packing auger, and the follow-up bottles are prevented from being loosened and poured after bottles at the top end flow out, so that normal production and operation is kept.

Owner:ANHUI ZHONGHE PHARMA CO LTD

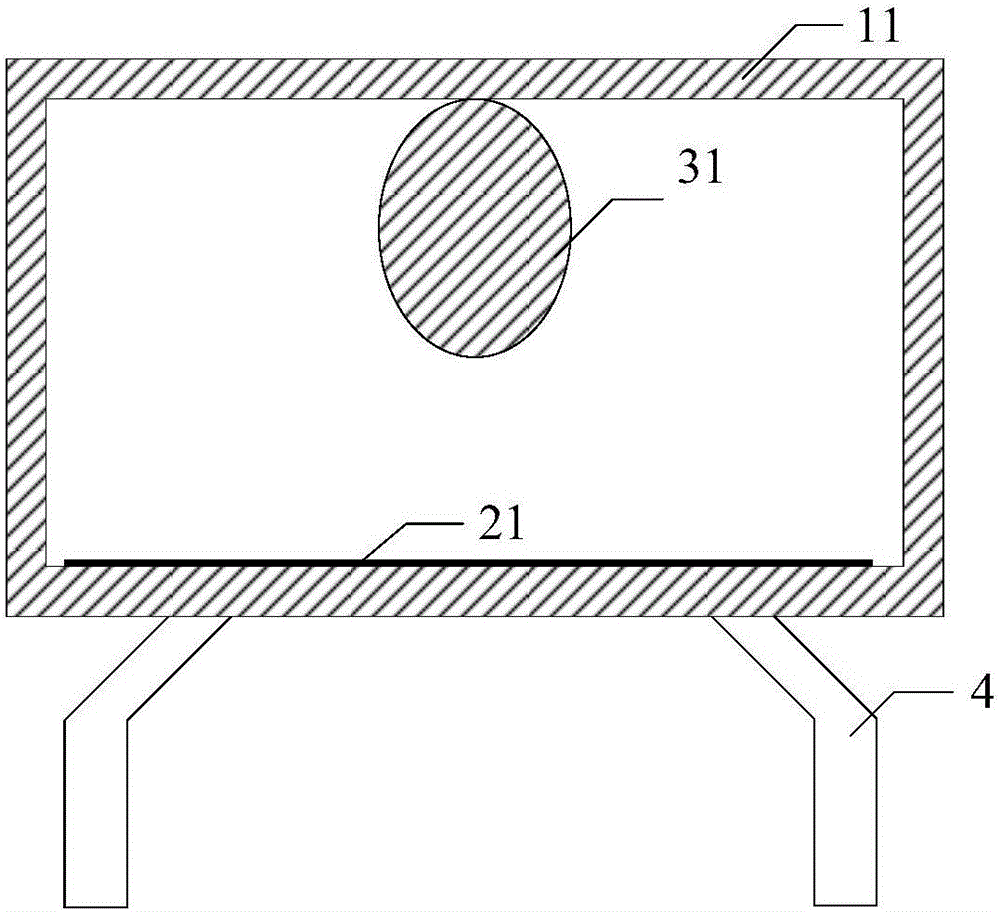

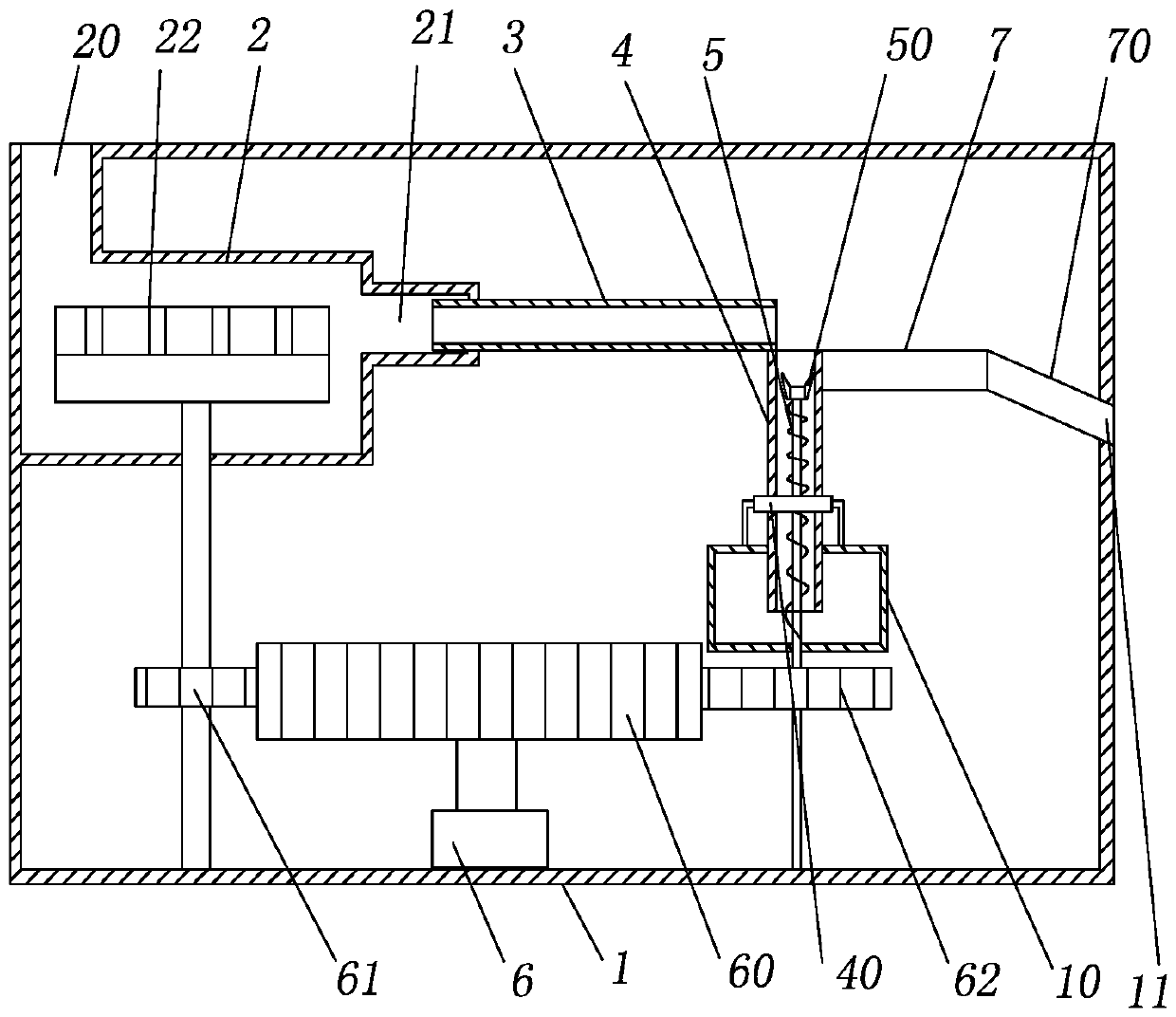

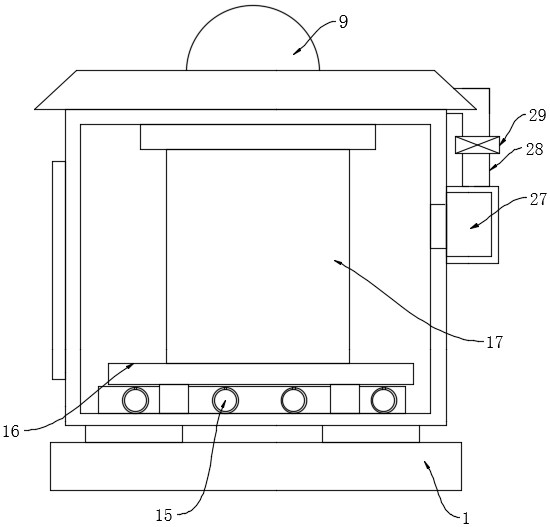

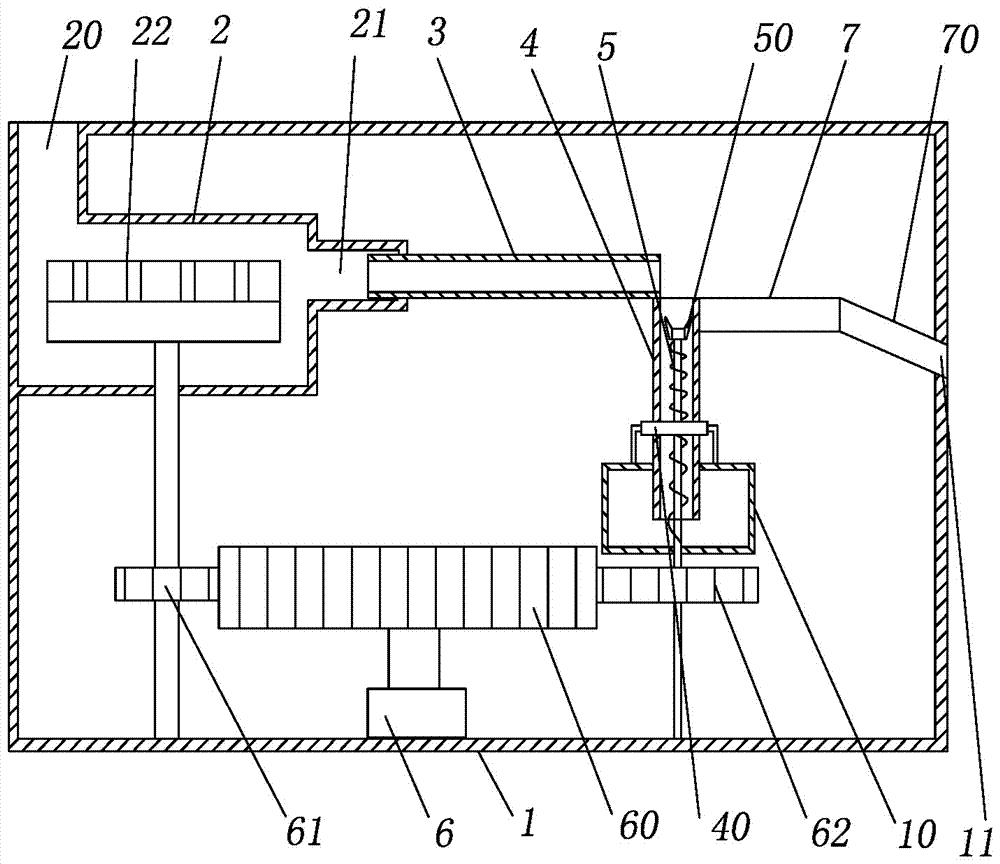

A continuous transmission quasi-non-diffracting wave microwave reactor

ActiveCN106237957BAvoid the Effects of Diffractive SpreadUniform effectMicrowave heatingEnergy based chemical/physical/physico-chemical processesProduction lineMicrowave

The invention belongs to the field of microwave energy application devices, and provides a continuous transmission type quasi-non-diffraction wave microwave reactor, including a reaction device, a transmission device, a feeding device and a supporting device; the feeding device includes a radiator, a feeding waveguide, and a power distribution device. and phase shifter, coaxial transmission line and microwave source; the microwave source is connected to the input end of the power distribution and phase shifter through the coaxial transmission line, and the output end of the power distribution and phase shifter is connected to several feeder waveguides, and the feeder waveguide passes through The radiator is connected to the radiator through the metal cavity. The radiator is located at the middle and lower part of the back of the metal cavity. The radiator is provided with a rectangular radiation port of the same size as the feed waveguide. The present invention adopts the way of multi-feeder feed-in to generate non-diffraction wave to irradiate the reactant, so as to improve the reaction efficiency, speed up the reaction speed, improve the uniformity of the reaction and save energy, and combine it with the continuous transmission production line, and apply it on a large scale In industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

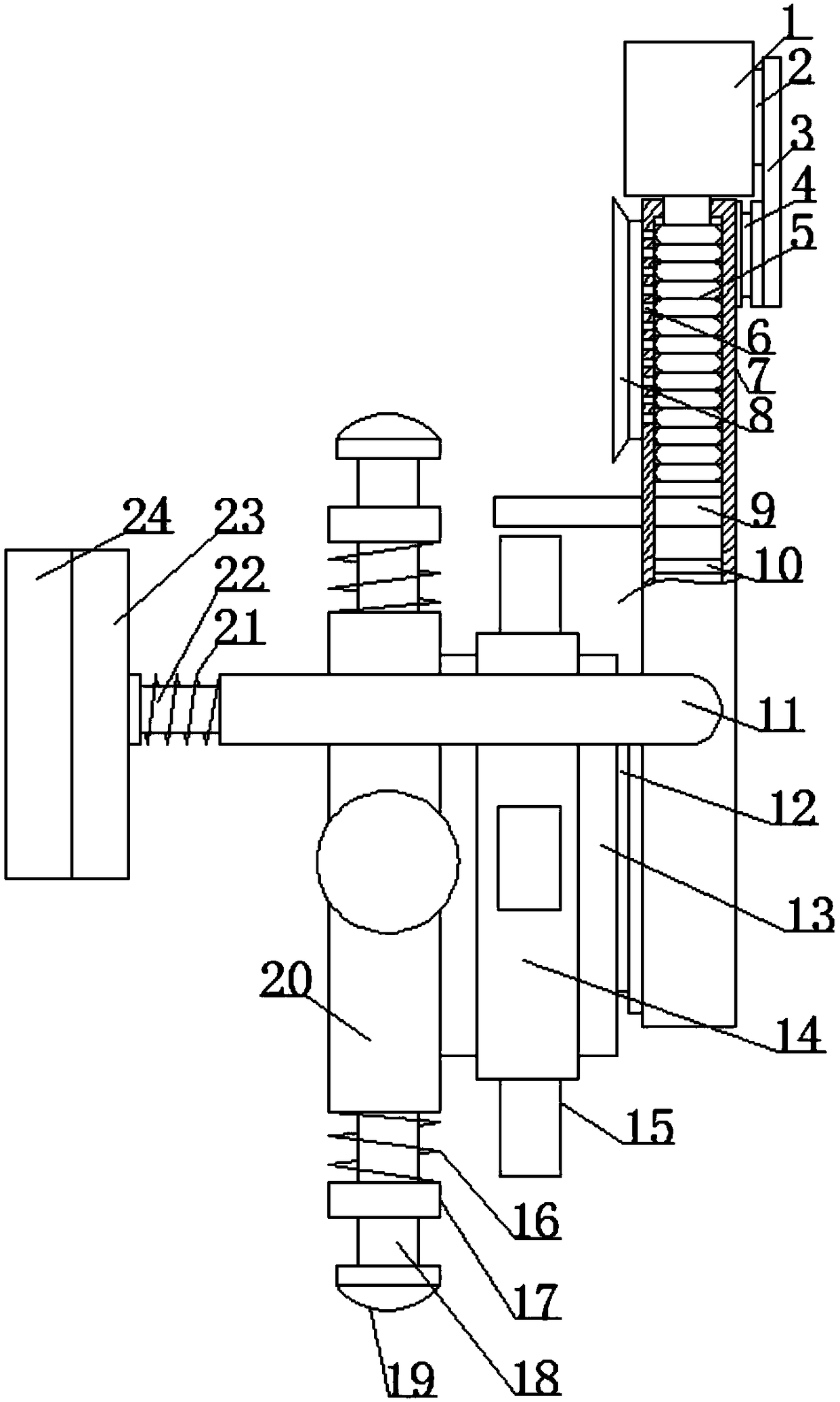

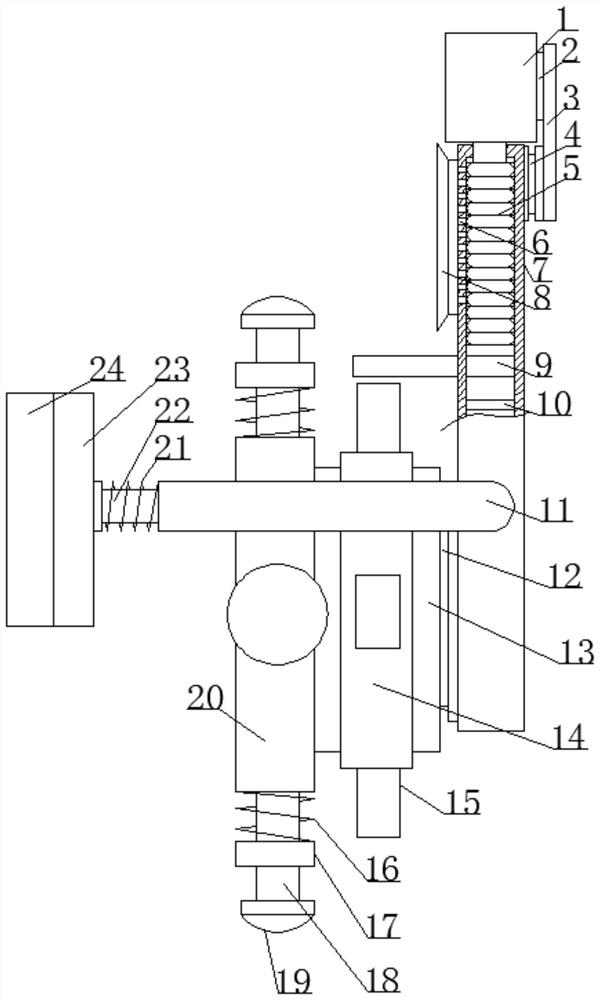

Portable screw tap anti-breaking electric tapping machine

PendingCN114029565AReduce frictionPrevent air pressure leaksThread cutting machinesMaintainance and safety accessoriesInjector nozzleEngineering

The invention belongs to the field of hardware tools, and particularly relates to a portable screw tap anti-breaking electric tapping machine which comprises a shell, a grip is arranged at one end of the shell, a battery is arranged in the side, close to the grip, of the shell, a tapping mechanism is arranged in the shell, a lubricating mechanism is arranged in the tapping mechanism, and the tapping mechanism comprises a rotating block rotationally arranged in the shell; a connecting cavity with an opening deviating from the battery is formed in the rotating block, a section breaking block is rotationally arranged in the connecting cavity, an anti-breaking mechanism for controlling connection of the tapping mechanism and the lubricating mechanism is arranged in the rotating block, and meanwhile, the anti-breaking mechanism further controls spraying of lubricating liquid in the lubricating mechanism; and a sealing cover can enable a small amount of air to enter a lubricating oil tank cavity, and a piston plate is slowly pressed to slide, so that a small amount of lubricating oil in the piston plate is sprayed onto the screw tap through a pressure oil nozzle along a lubricating pipe, lubrication is carried out when the screw tap is used for tapping, and the friction force between the screw tap and a preformed hole is reduced.

Owner:宁波鄞州鑫天机械制造有限公司

A continuously conveying focused microwave reactor

ActiveCN106334508BAvoid the effects of extensionUniform effectMicrowave heatingEnergy based chemical/physical/physico-chemical processesProduction lineMicrowave

The invention belongs to the field of microwave energy application devices, and provides a continuous transmission focused microwave reactor, including a reaction device, a transmission device, a feeding device and a supporting device; it is characterized in that the feeding device includes a metal reflecting surface, a radiation horn, a Axial transmission line, waveguide coaxial conversion and microwave source, the metal reflection surface is set on the inner wall of the top surface of the metal cavity, the microwave source is connected to the radiation horn through the coaxial transmission line and the coaxial conversion of the waveguide, the radiation horn is fixed on the side wall of the metal cavity, and passes through the The radiation passes through the metal cavity and is inclined at a certain angle with the cavity wall, so that the focus of the metal reflection surface is located in the direction of the main lobe of the radiation horn. The invention adopts the mode of feeding the side end of the waveguide into the reflection focusing of the metal wall to realize the point of maximum field strength to irradiate the detection object, so as to improve the reaction efficiency, speed up the reaction speed, improve the uniformity of the reaction and save energy, and combine it with the continuous transmission production line , used in large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

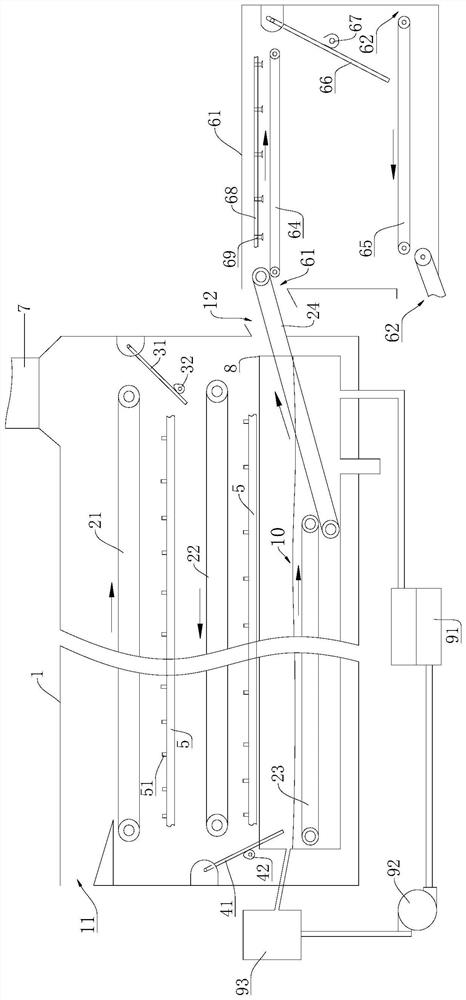

Full-automatic thick material straight line sewing machine

PendingCN113957616AOvercome the problem of straight line sewing not straightOvercome manpower wasteMattress sewingElectric machineryEngineering

The invention discloses a full-automatic thick material straight line sewing machine. The whole machine comprises a feeding device, a limiting device, a sewing device, a discharging device and a material receiving frame; the feeding device comprises a front rack, a feeding conveyor belt motor and a roller bearing bracket; the limiting device comprises a limiting air cylinder and a limiting plate; the sewing device comprises a U-shaped supporting arm, a machine head, a rotating shuttle, a machine head lifting device and a main shaft motor; the material receiving frame comprises a material guide plate and a material receiving framework; a feeding conveyor belt is mounted on a conveyor belt driving roller and a conveyor belt driven roller; a rotating mechanism and a pressing air cylinder are connected with a fixing base and mounted on a middle rack; the machine head lifting device is mounted on the U-shaped supporting arm; the main shaft motor drives the machine head and the rotating shuttle to perform sewing work; and the material guide plate is fixed on the material receiving frame. Through the design, a cushion can automatically and continuously enter a sewing area; and the thick material cushion can be pressed and compacted, so that needle and thread breaking is prevented.

Owner:上工富怡智能制造(天津)有限公司

Circulating heated shrimp cooking equipment

ActiveCN109077216BCook thoroughlyReduce contact areaSteam cooking vesselsFood sciencePrawnProcess engineering

The invention discloses a circulating heating shrimp cooking equipment, which comprises a frame, a cooking device and a heating device. The cooking device includes a cooking chamber, a conveying device, a sliding material board, a shrimp cooking pond, a steam delivery pipe and a steam nozzle. The bottom of the cooking chamber is provided with a boiled shrimp pond, and the conveying device includes a first conveyor belt, a second conveyor belt, a third conveyor belt and a first driving device, and the third conveyor belt is arranged in the shrimp boiled pond , the first drive device drives the first conveyor belt and the third conveyor belt to rotate clockwise, the first drive device drives the second conveyor belt to rotate counterclockwise, and the cooking chamber is inside the first The steam delivery pipe is provided between the conveyor belt and the second conveyor belt and between the second conveyor belt and the third conveyor belt, and several steam nozzles are arranged on the steam delivery pipe. The device can solve the technical problems of low energy utilization rate and insufficient cooking of prawns.

Owner:北海市海庆兄弟水产有限公司

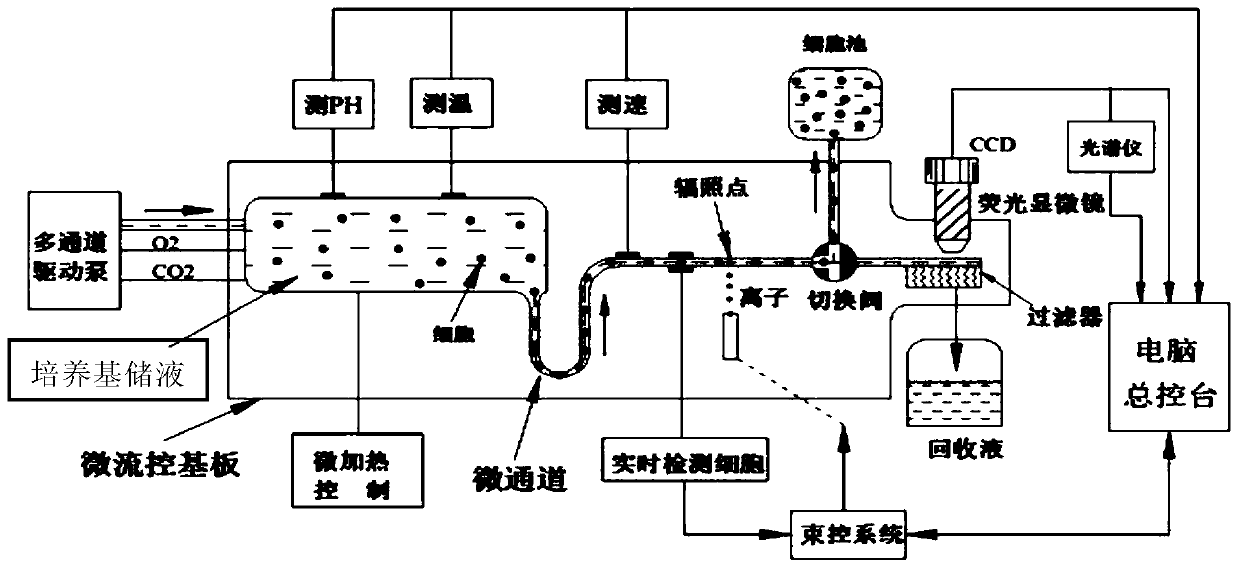

A Microfluidic Chip System for Improving the Irradiation Flux of a Single Ion Beam

ActiveCN105203468BMeet the needs of large quantitiesIrradiation parameters consistentColor/spectral properties measurementsFluorescence/phosphorescenceDifferential signalingMicrofluidic channel

The invention discloses a microfluidic chip system for improving the irradiation flux of a single ion beam, which includes a culture medium storage tank and a microchannel. The microchannel only allows a single cell to move forward in a queue, and real-time detection is installed on both sides of the microchannel. Cell electrode, real-time detection There is a radiation point in front of the cell electrode, and the thickness of the radiation point does not exceed 5 μm; real-time detection of the differential signal generated by the cell electrode pair, and the change of microfluidic impedance in the channel is detected by signal processing technology to quickly identify whether the cell passes or not, the cell The identification signal is connected to the beam control system of the single ion beam device, so that when the cells pass through the irradiation point, the beam control system can control the ions to irradiate the cells in a timely and accurate manner. For the first time in the invention, microfluidics is used in a single ion beam irradiation device, and the irradiation flux is increased by several tens of times, which meets the needs of a large amount of cells in biological experiments, and provides a new high-throughput technology platform for radiation biology. It has potential commercial application prospects.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Rubber shoe lining rubber dipping equipment and method for automatically dipping rubber into rubber shoe lining by adopting same

ActiveCN111920144AContinuous entryAvoid Interfering with WasteShoe gluingIndustrial engineeringSupport plane

The invention discloses rubber shoe lining rubber dipping equipment and a method for automatically dipping rubber into a rubber shoe lining by adopting the same. The rubber shoe lining rubber dippingequipment comprises an open box body, and supporting frames are fixedly mounted at the two ends of the open box body correspondingly. Side plates are fixedly connected to the surfaces of the two sidesof the supporting frame; a guide wheel is rotationally mounted at the other end of each support frame through a rotating shaft; a conveying wheel is rotationally mounted on the side surface of each side plate through a rotating shaft; avoiding grooves are formed in the middle positions of the surfaces of the guide wheels and the conveying wheels; a conveying belt is mounted on the surfaces of theguide wheels and the conveying wheels in a sliding manner. The guide wheels and the conveying wheels are mounted at the upper end of the open box body; the conveying belt rotationally mounted is combined with a clamping plate structure mounted at the bottom, so that rubber bodies can be clamped and positioned respectively, and the continuous conveying stability is guaranteed; meanwhile, the rubber shoes can be independently impregnated, interference waste of the conveying belt is avoided, rubber removal and airing are facilitated, the use convenience and stability can be greatly improved, theimpregnation effect is guaranteed, and the use cost is reduced.

Owner:瑞安市兴旺鞋业有限公司

Stone remover for biomass briquette production system

Owner:遵义双河生物燃料科技有限公司

Anti-oxidation container type photovoltaic transformer

InactiveCN113314304AExtended service lifeAvoid enteringTransformers/inductances coolingDispersed particle filtrationAir filterAir treatment

The invention discloses an anti-oxidation container type photovoltaic transformer which comprises a base, a container body, a box door, an air treatment box, a photovoltaic transformer body, an air treatment mechanism and a cleaning mechanism, the container body is located at the upper end of the base, the box door is installed on the surface of one side of the container body, the air treatment box is installed on one side wall of the container body, a hollowed-out support is arranged at the bottom end in the container body, and the photovoltaic transformer body is located on the hollowed-out support. By arranging the air treatment mechanism, airflow can be subjected to primary filtration and dust removal through a filter screen, meanwhile, airflow is subjected to secondary filtration and dust removal through an air filter part, and then the filtered airflow is cooled through a condensing coil, dried through a honeycomb drying plate and then fed into the container body; and moisture in the gas in contact with the photovoltaic transformer main body is reduced, and the influence of moisture on the transformer main body can be reduced, so that the oxidation phenomenon is avoided.

Owner:JIANG SU ZHONGRONG TECH

Steel tube storage vehicle

InactiveCN109262561APrevent rolling outUnblocking the situationWork tools storageOther workshop equipmentEngineeringSteel tube

The invention belongs to the technical field of steel tube stacking or taking, and particularly relates to a steel tube storage vehicle which comprises a base, a stacking shell, an input shaft, a motor, an actuating mechanism and an anti-blocking mechanism. After the motor is started, an output shaft slowly rotates and transfers power, so that the actuating mechanism acts, steel tubes in a discharging shell can be lifted out one by one by action of the actuating mechanism, the anti-blocking mechanism acts after the output shaft transfers power, and blocking of the steel tubes can be relieved by action of the anti-blocking mechanism. The steel tubes can be orderly discharged from the discharging shell, and a large number of steel tubes can be prevented from rolling out of the discharging shell at a stroke and further causing potential hazards to workers. The steel tube storage vehicle is simple in structure, a large number of building steel tubes can be conveniently stacked, or the required building steel tubes can be orderly taken, and good use effects are achieved.

Owner:何召焓

Stone remover for biomass molding fuel production system

The invention relates to the field of solid fuel preparation and in particular relates to a stone remover for a biomass molding fuel production system. The stone remover comprises a stone removing tank, wherein the stone removing tank is internally provided with a feeding box, an ejection removal mechanism, a power mechanism and a splitting plate; an outlet is formed in the stone removing tank; the ejection removal mechanism comprises an air blowing part and an ejection removal part; the air blowing part comprises an air box and blades; an air inlet and an air outlet are formed in the air box;the blades are arranged inside the air box; the ejection removal part comprises a long straight tube and a short straight tube with same cross sections; and the power mechanism comprises a spiral rod, a motor, a central gear, blade gears and a spiral rod gear. By adopting the technical scheme, stone in crushed straw articles can be effectively removed.

Owner:遵义双河生物燃料科技有限公司

An easy-to-install agricultural vehicle cleaning device

ActiveCN108891385BEasy to installContinuous entryVehicle cleaningAgricultural scienceAgricultural engineering

The invention aims to solve the problem that a body of an existing agricultural automobile is not conveniently cleaned, and discloses a conveniently installed agricultural automobile cleaning device which comprises a water tank, a first connecting rod, a positioning plate, a second connecting rod, a telescopic air bag, a through hole, a guide tank, a water spraying disk, a sliding plate, a baffleplate, a sleeve pipe, a rotating shaft, a sleeve, a sleeve ring, a pushing rod, a first screw spring, a positioning block, a sliding rod, a supporting block, a rotating disk, a second screw spring, aguide rod, a connecting plate, an adsorption plate, a guide groove and a positioning rod. The cleaning device is convenient to install, the sleeve ring rotates through rotation of wheels, so that thepush plate can repeatedly push the sliding plate, the telescopic air bag is repeatedly extruded, so that water is conveniently sprayed onto a body, mud on the body is rapidly cleaned, cleanliness of the body is kept, and the cleaning device is worthy of popularization in the field of agricultural machinery.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

A kind of inverted separation bucket type material spreading device

ActiveCN106629105BReduce vibrationContinuous entryConveyorsLoading/unloadingMechanical equipmentMechanical vibration

The invention discloses an inverted separating type bucket scattering device, which belongs to the technical field of automatic steamer-filling system mechanical equipment for a winery. The inverted separating type bucket scattering device comprises an electric scattering device, a liftable scattering bucket, an outlet hopper, a connecting support, a lifting device, a connecting base, a chain scraper conveyor and a telescopic arm. The electric scattering device is arranged on the lower end of the liftable scattering bucket; the liftable scattering bucket is connected with the lifting device through the connecting support on the top end, and is driven by the lifting device to lift up and down vertically; and the lifting device is fixed onto the telescopic arm through the connecting base. According to the inverted separating type bucket scattering device provided by the invention, the whole weight of a device to be lifted is reduced, and the mechanical vibration is reduced; a conical scattering plate is adopted, so that the uniformity in scattering is realized; a transmission long shaft in the bucket is removed, so that wine materials can be continuously and uniformly fed favorably; and the manufacturing and assembling cost is remarkably reduced.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Storage steel pipe vehicle used in building field

InactiveCN109434791APrevent rolling outUnblocking the situationOther workshop equipmentLow speedArchitectural engineering

The invention belongs to the technical field of steel pipe stacking or taking, in particular to a storage steel pipe vehicle used in the building field. The vehicle comprises a base, a stacking shell,an input shaft, a motor, an executing mechanism and an anti-blocking mechanism, wherein after the motor is started, an output shaft is enabled to rotate at a low speed, the output shaft enables the executing mechanism to act through power transmission, and the action of the executing mechanism can lift one all steel pipes in a discharging shell one by one; the output shaft enables the anti-blocking mechanism to act through power transmission, and the action of the anti-blocking mechanism can solve the blocking condition of the steel pipes; and the steel pipes can be orderly discharged from the discharging shell so as to prevent a large number of steel pipes from being rolled out from the discharging shell wholly, and further avoid the potential damage to workers due to the fact that a large number of steel pipes are rolled out. The vehicle is simple in structure, and can be used for conveniently stacking a large number of building steel pipes or orderly taking the required amount of the building steel pipes, so that the good use effect is achieved.

Owner:吴建康

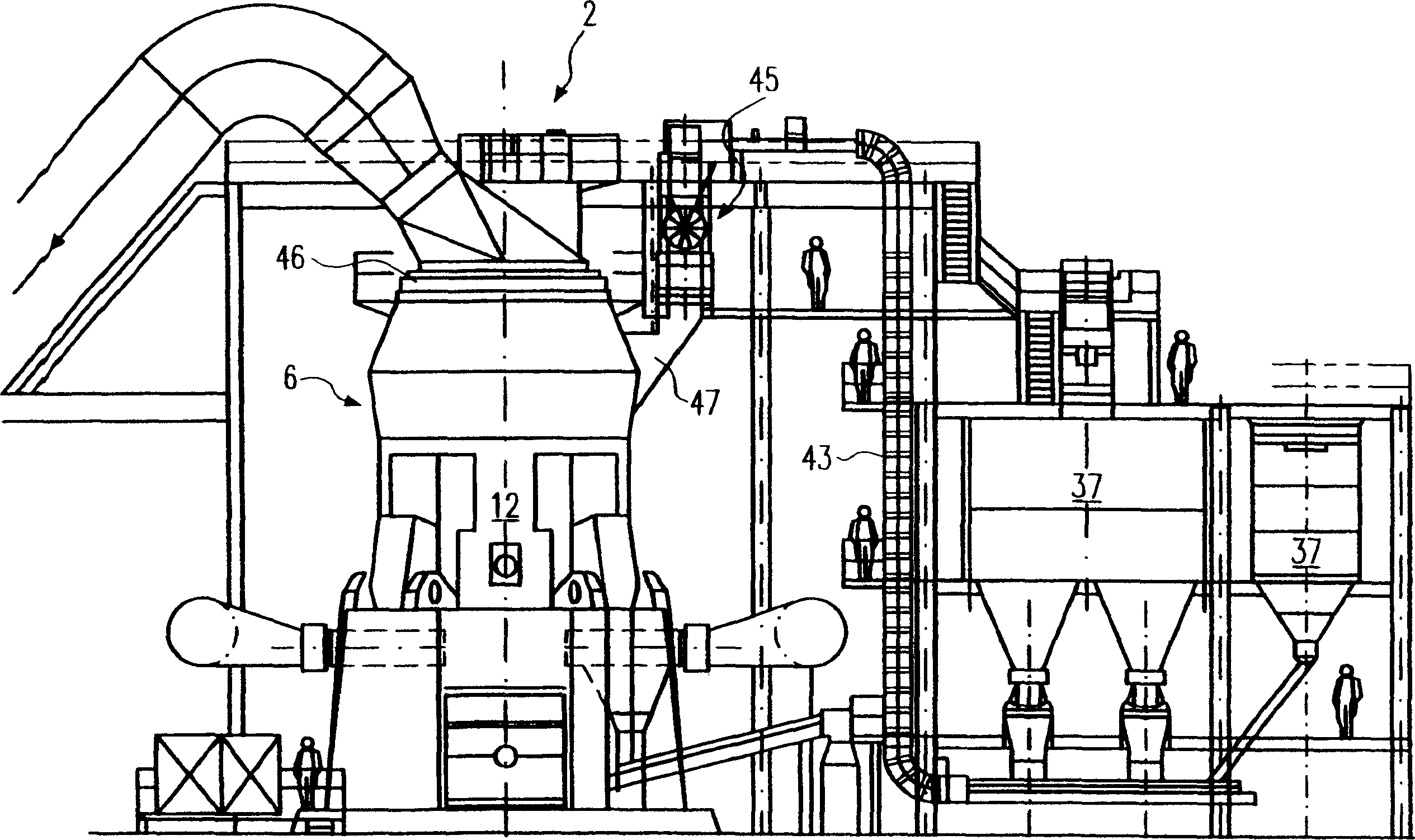

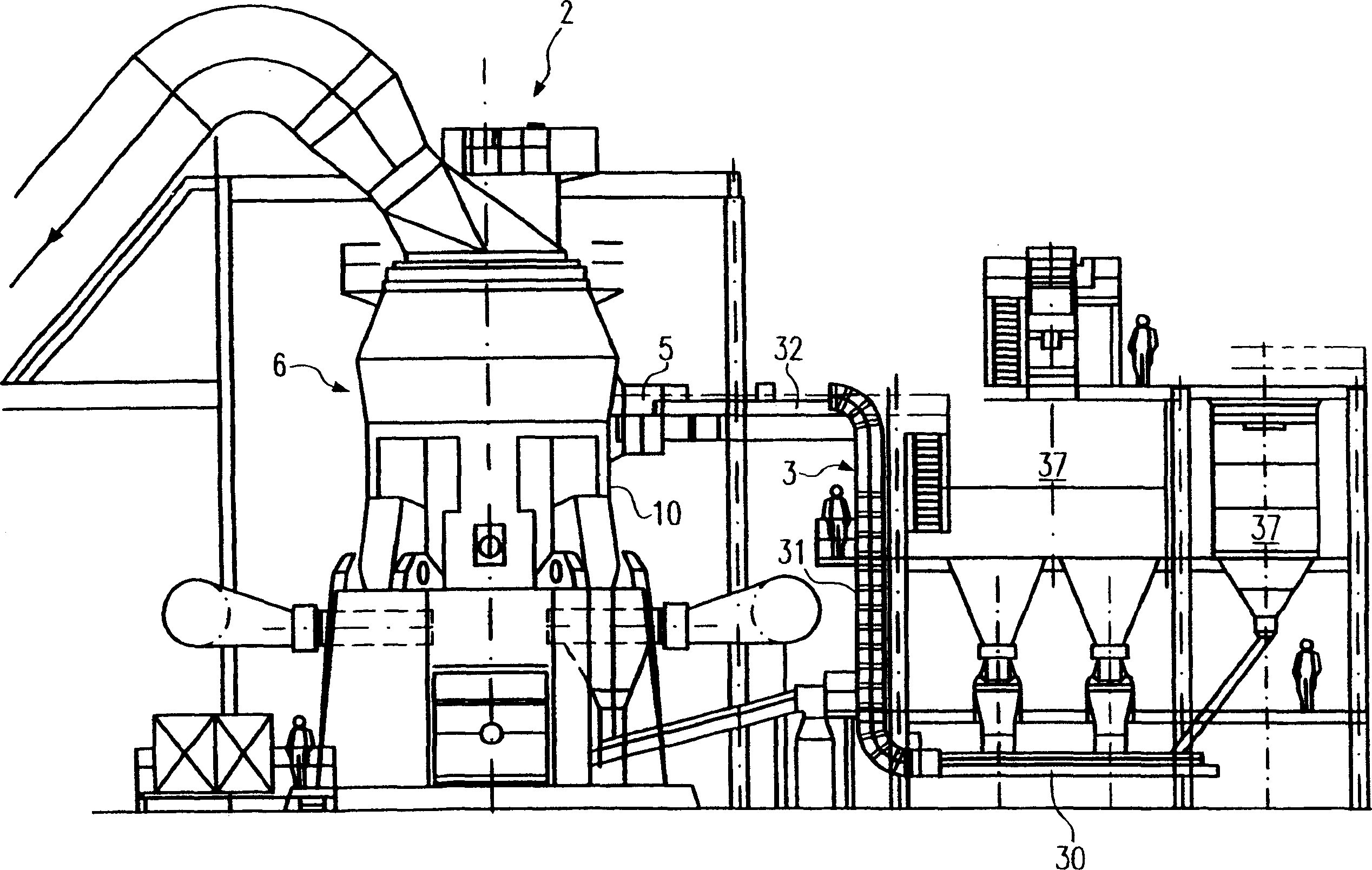

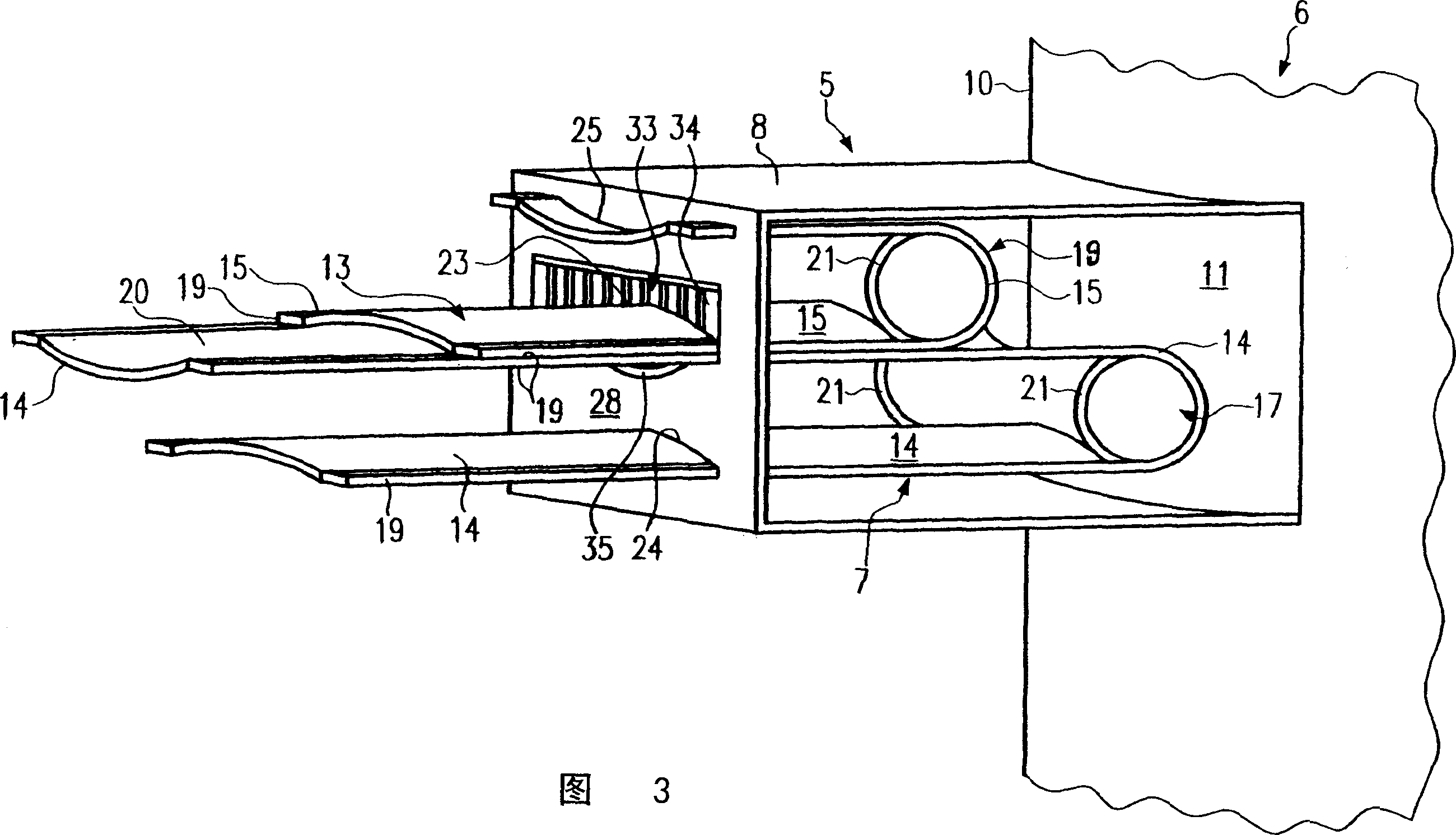

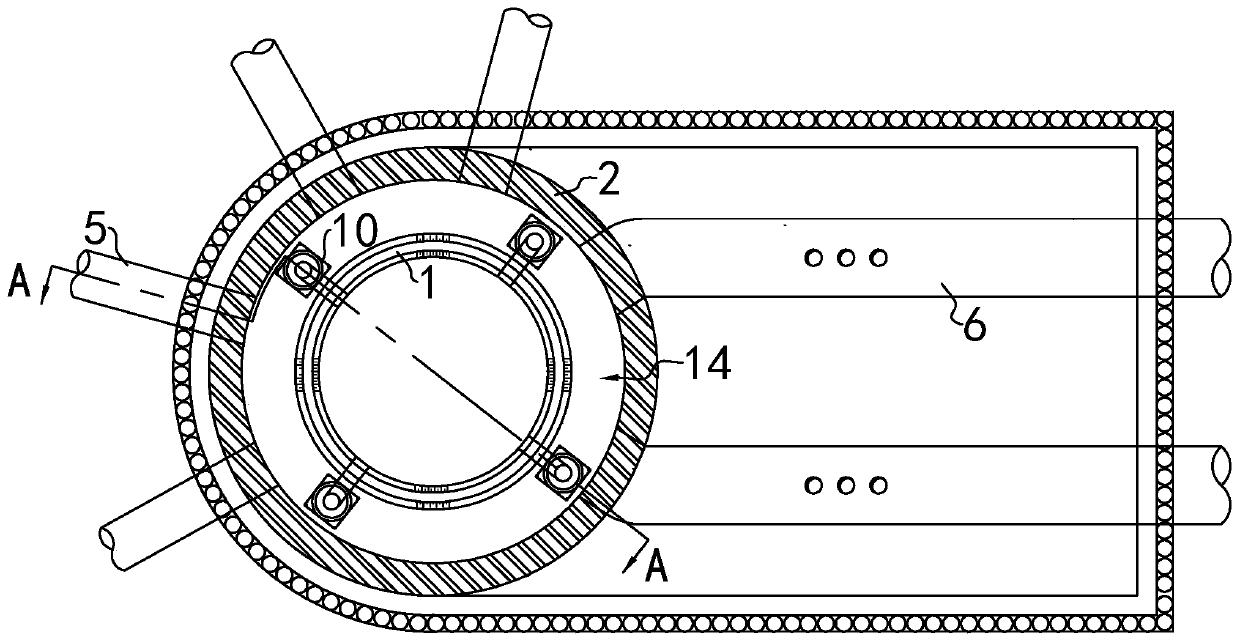

Device for supplying material

A device for supplying material to a container, particularly for supplying raw material to a vertical mill with air flow conveying in a milling plant. A conveyor is provided for the material, whereof an end region is located in a feed device. The feed device and the end region of the conveyor located therein are incorporated into the pressure system of the container or the vertical mill. The feed device can be constructed as a sandwich lock and the conveyor as a double strap belt conveyor for the material to be supplied.

Owner:LOESCHE GMBH

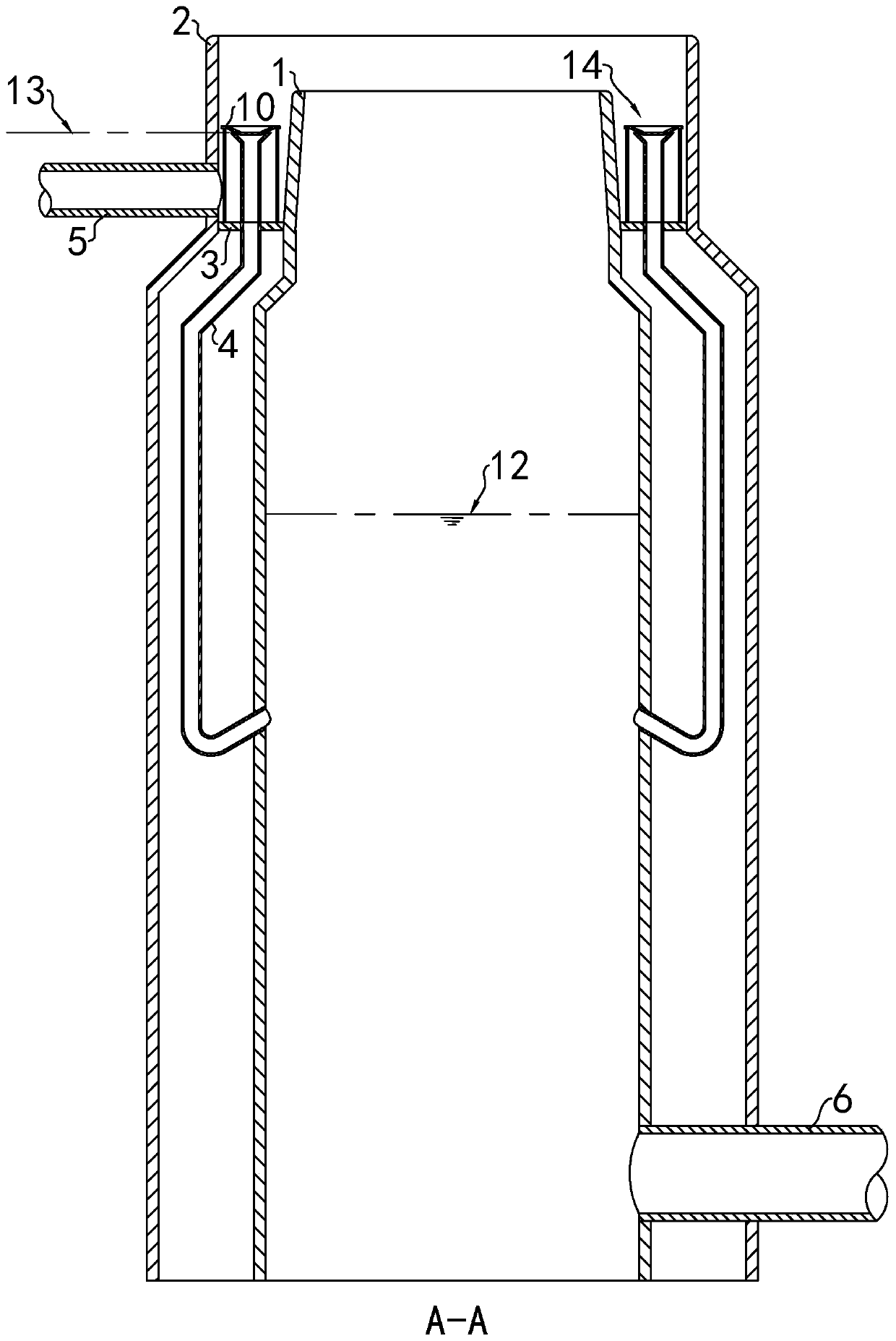

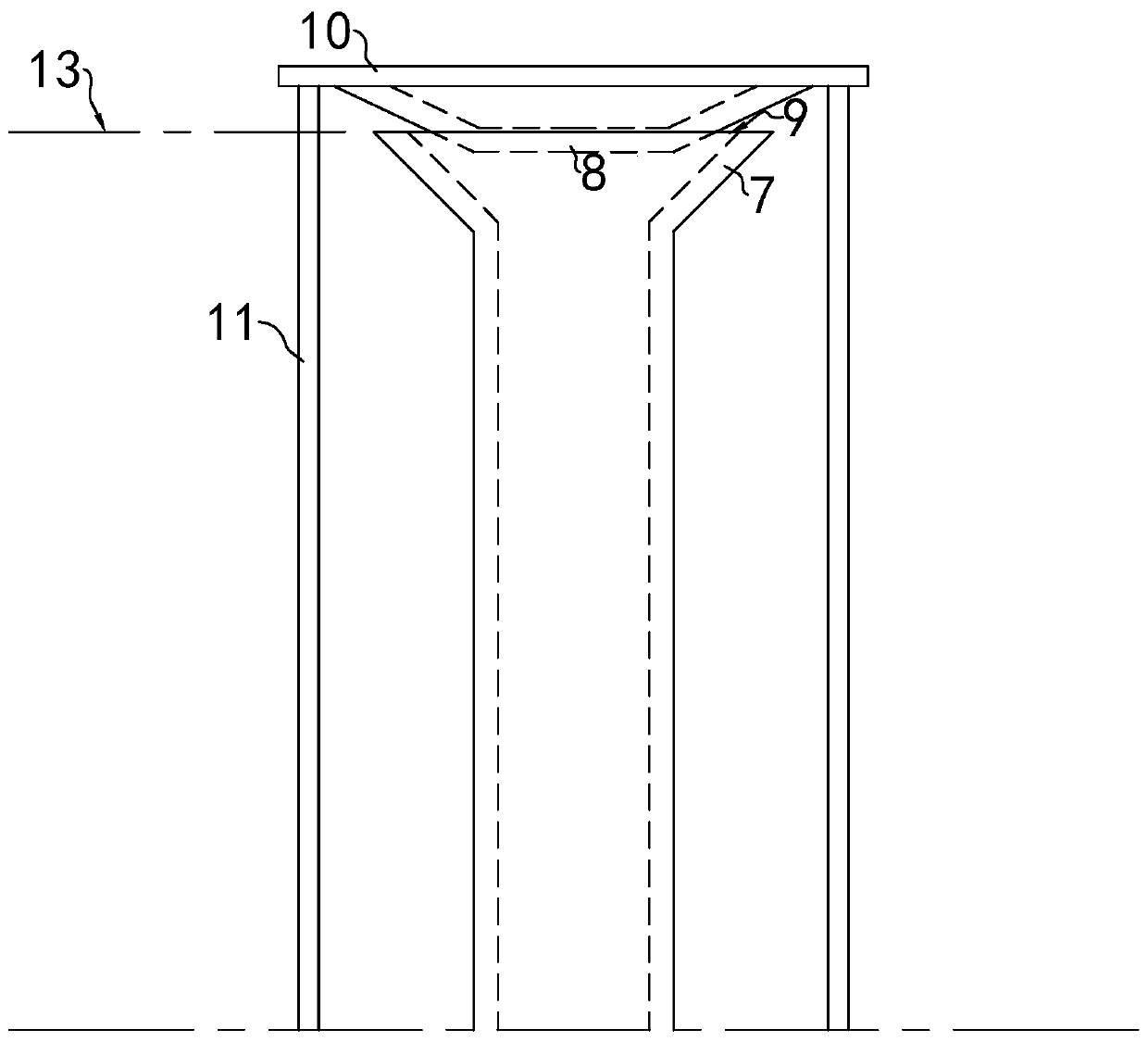

Distributing pipe inlet device for high water tank

PendingCN110029703AReduce the degree of aerationContinuous entryWater supply tanksInsertion stentWater velocity

The invention discloses a distributing pipe inlet device for a high water tank, and relates to the field of hydraulic structures. The distributing pipe inlet device includes a pipe body and a support,one end of the pipe body communicates with a distributing pipe, a pipe mouth is formed in the other end of the pipe body, and the pipe mouth is arranged in an overflow groove; the support includes araised part fixed outside the pipe mouth, the radial dimension of the pipe mouth gradually expands outwards from the pipe body, the raised part protrudes into the pipe mouth, and a flow passing gap isarranged between the raised part and the inner side of the pipe mouth. The distributing pipe inlet device has the beneficial effects that the raised part is matched with the pipe mouth with the gradually expanded radial dimension to form the annular flow passing gap, the raised part is at the center of the pipe mouth, the flow passing gap can decrease the water velocity and disperse water inflow,the conditions for formation of an aspirating vortex can be destroyed, formation of a penetrating aspirating zone can be inhibited, the degree of water aeration can be decreased, water continuously and stably flows into the distributing pipe advantageously, and the distributing pipe inlet device can adapt to operational states of different water levels and flow rates. According to the technical scheme, the structure is simple, the manufacturing cost is low, and maintenance is easy.

Owner:GUANGDONG RES INST OF WATER RESOURCES & HYDROPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com