Full-automatic thick material straight line sewing machine

A sewing machine, fully automatic technology, used in sewing machines, sewing equipment, textiles and papermaking for sewing quilts, etc., can solve the problems of heavy materials not being pressed tightly, unable to sew straight lines, reducing manpower, etc., to maintain cleanliness, The effect of preventing needle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the content, features and effects of the present invention, the following examples are given and described in detail with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

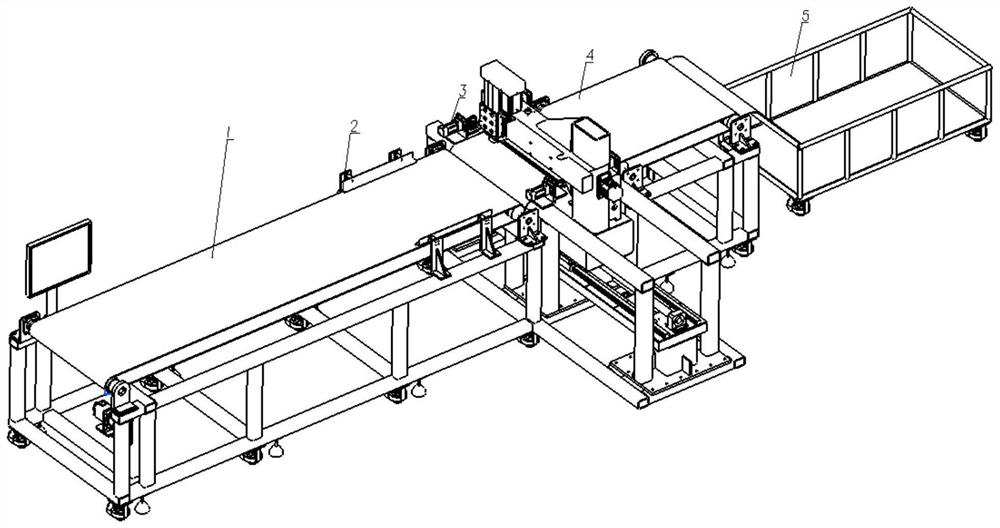

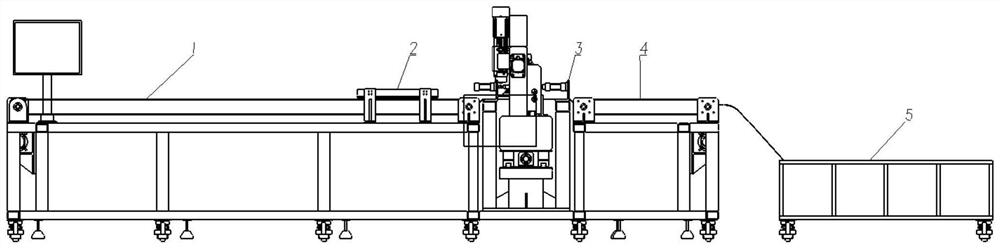

[0048] Fully automatic thick material linear sewing machine, the whole machine includes: feeding device (1), limiting device (2), sewing device (3), discharging device (4), and material receiving frame (5).

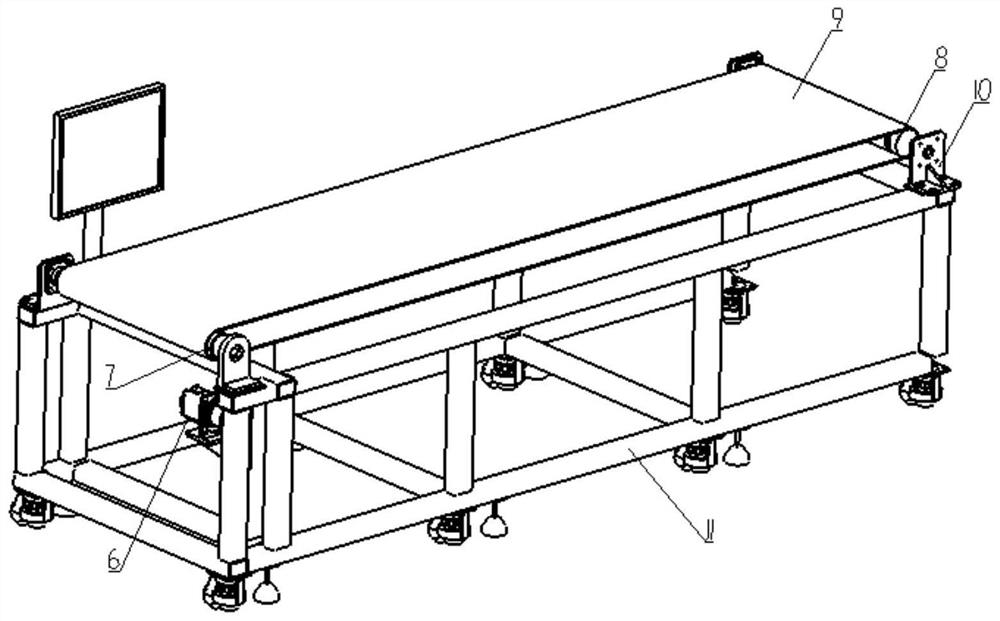

[0049] Moreover, the filled thick material mat is placed on the conveyer belt of the feeding device (1), and the motor drives the rollers to move, thereby driving the conveyer belt to continuously rotate, and the thick material mat moves forward along with the conveyer belt.

[0050] Moreover, when the thick material enters the limit device (2), the limit cylinder (12) stretches out, and the limit plate (13) limits the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com