Device for supplying material

The technology of a feeding device and a locking device is applied in the directions of transportation and packaging, conveyors, grain processing, etc., which can solve the problem of high overall height of the feeding device, and achieve the effects of simple structure, low overall height, and reduced manufacturing and installation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

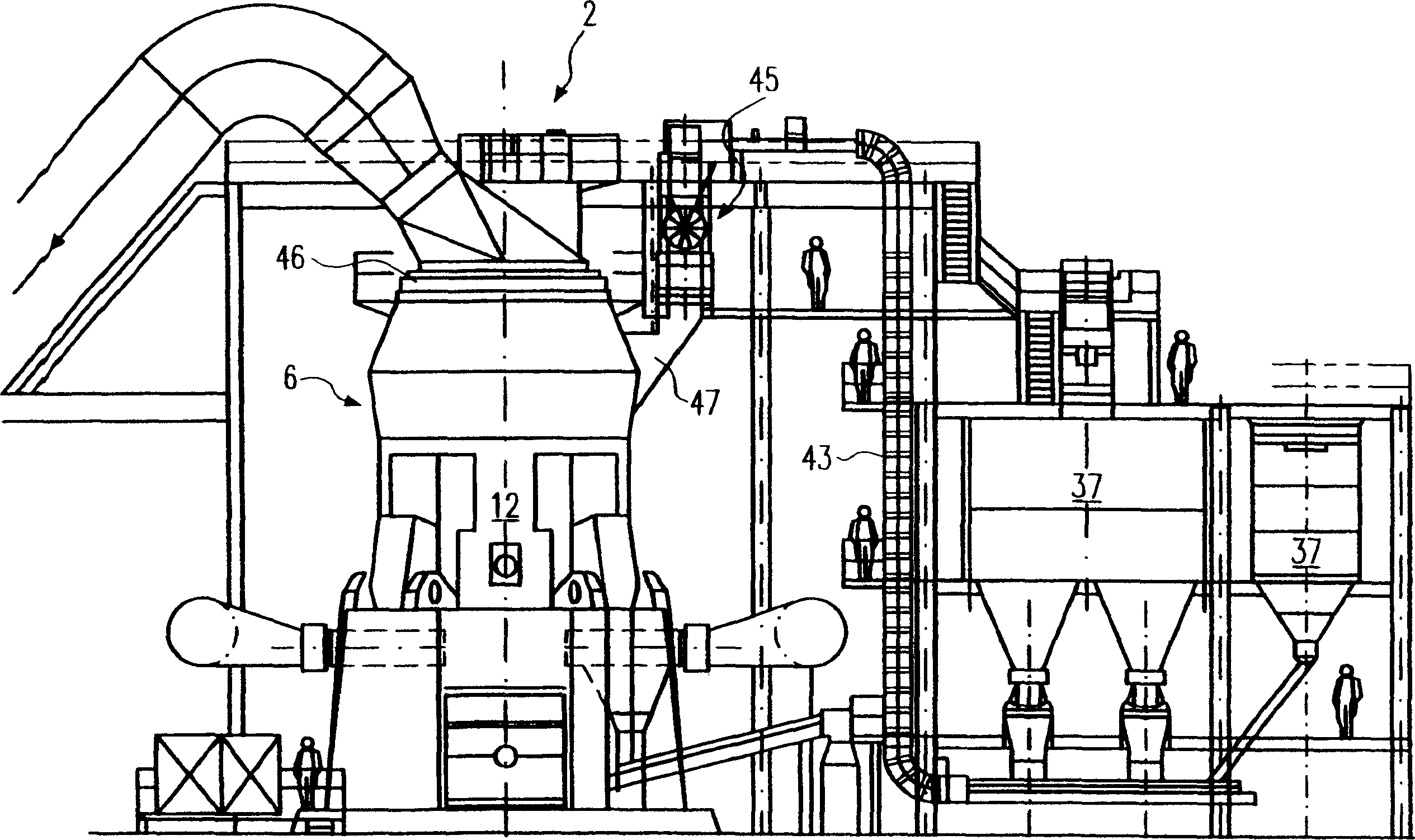

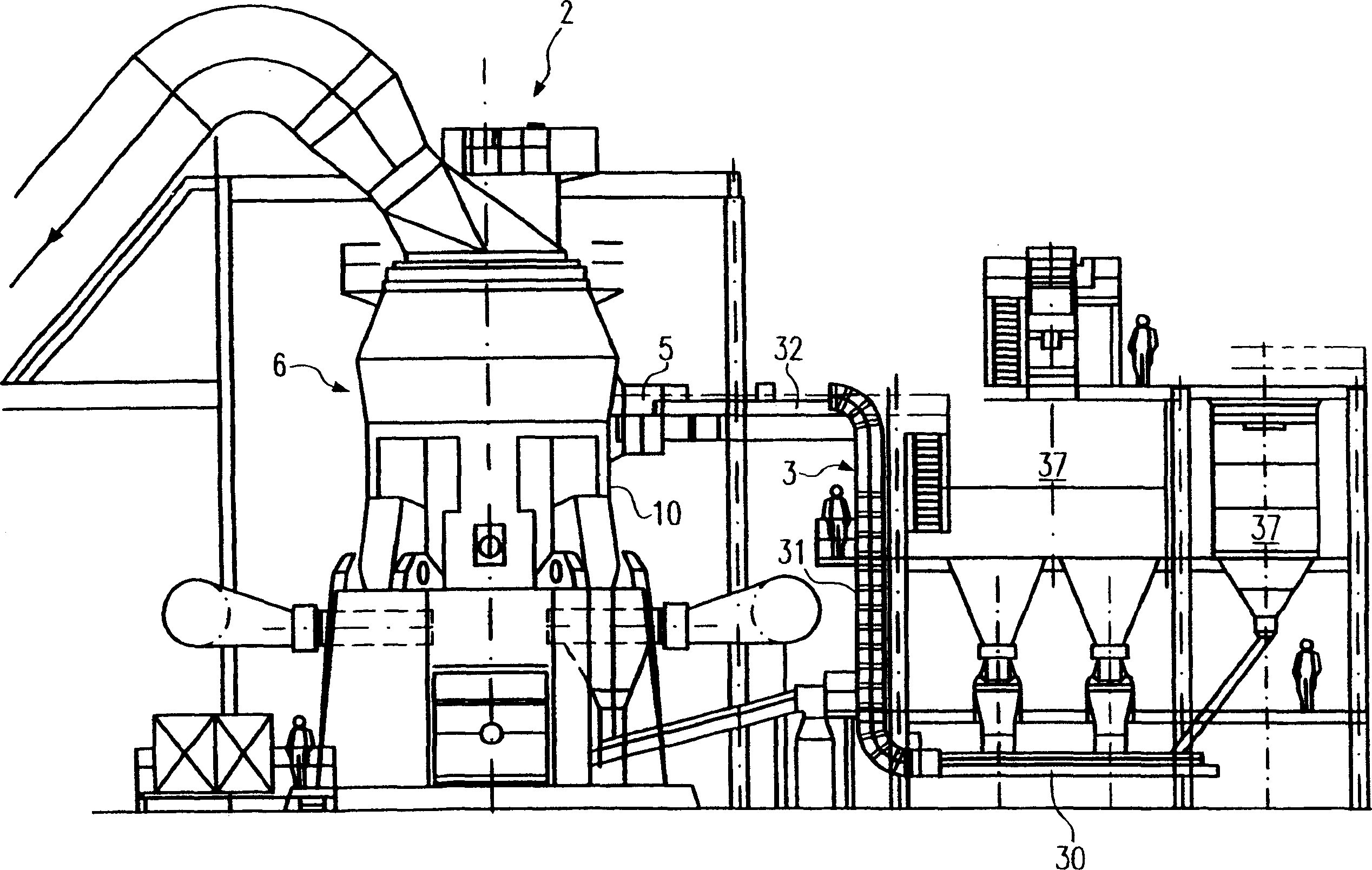

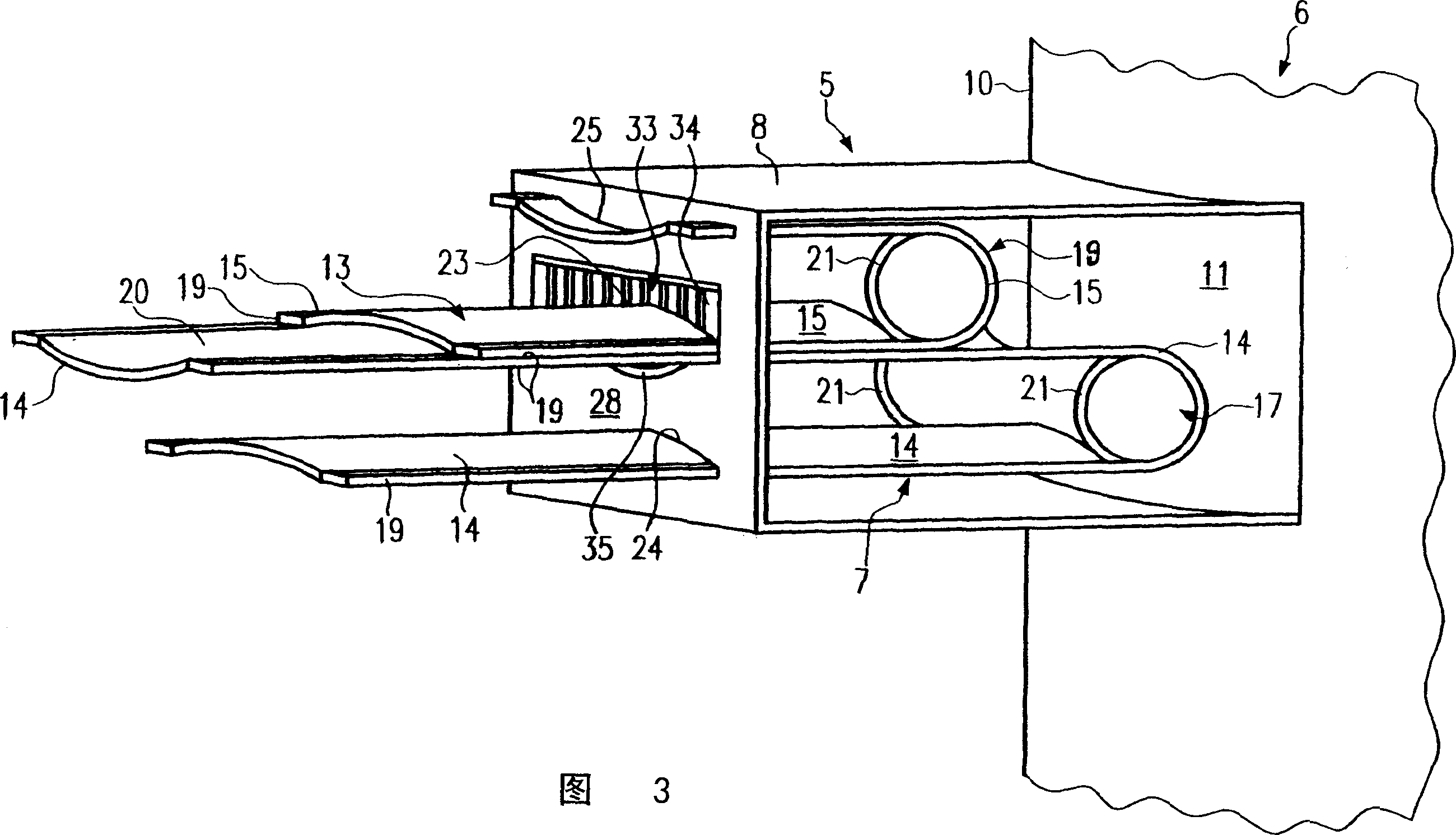

[0028] shown in figure 2 A partial view of the milling plant 2 is somewhat similar to that shown in figure 1 are the same as in the prior art, such as the pneumatic discharge roller mill as the vertical mill 6 with air flow conveying and the silo 37 in which the material to be crushed in the vertical mill 6 is stored. The feeding device according to the invention has a double belt conveyor 3 as a conveyor and a feeding device for the material, not shown, which is fed by the double belt conveyor 3 , a blocking device adapted to this feeding device , hereinafter referred to as the sandwich locking device 5 .

[0029] The above-mentioned sandwich locking device 5 is fastened to the casing 10 of the vertical mill 6 in a gas-tight and / or pressure-tight manner in the vicinity of the feed hole 11 (see FIG. 3 ).

[0030] Compare figure 1 The prior art milling equipment in the figure 2 A grinding plant with a feeding device according to the invention, which has a sandwich-type lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com