Storage steel pipe vehicle used in building field

A field, steel pipe technology, applied in the field of steel pipe stacking or access, can solve the problems of hurting others, easy rolling and falling of construction steel pipes, rolling and collapse, etc., to achieve the effect of convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

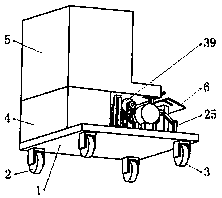

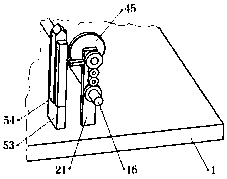

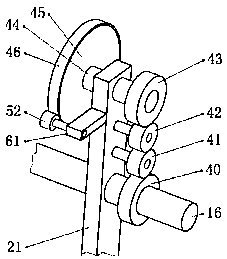

[0044] Such as figure 1 As shown, it includes a base 1, a directional wheel 2, a steering wheel 3, a stacking shell 5 installed on the base 1 through a total support block 4, such as figure 2 As shown, the inclined plate 6, the baffle plate 14, the output shaft 16 installed on the base 1 through two symmetrically distributed first support plates 7, such as Figure 10 As shown, the motor 17 installed on the base 1 by the first support block 18, such as Figure 10 As shown, the reducer 19, the input shaft 22, the second support plate 21, the actuator 25, and the anti-blocking mechanism 39 installed on the base 1 through the second support block 20, such as figure 1 As shown, two directional wheels 2 are symmetrically installed at one end of the lower surface of the base 1, and two steering wheels 3 are symmetrically installed at the other end; as figure 2 , 4 As shown, there is a discharge case 8 on the stacking case 5, a stacking groove 9 is arranged in the stacking case 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com